Abstract

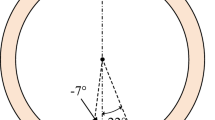

The velocity distribution of sinter and gas in vertical cooling furnace (VCF) has an important influence on gas–solid heat transfer. Based on the slot model of single hopper in the VCF of Meishan Iron and Steel Co., Ltd., the velocity and particle size distribution of sinter and the velocity and pressure distribution of gas were studied using a computational fluid dynamics–discrete element method model to obtain the gas–solid flow rule in the VCF. The results showed that the velocity of sinter near the wall and the edge of vent cowl was lower than that in the rest of the same plane. Therefore, the rectangular section of the vertical cooling furnace can be divided into a quasi-static zone, a plug flow zone and a convergent flow zone according to the flow velocity of the sinter. The average particle size and the void fraction of sinter bed were distributed in "W" and "V" shape along the width direction, respectively. The distribution of gas velocity in the furnace cavity was uneven, and the high-velocity area gradually changed from the center to the edge of the furnace cavity with the rise of gas. Reducing the ratio of edge to center gas flow from 2.7:1 to 0.7:1 could improve the gas velocity, but could not change the gas velocity distribution. The gas velocity distribution was more affected by the average particle size distribution of the sinter bed. It was suggested that measures need be taken to adjust it to improve the gas velocity distribution in the VCF.

Similar content being viewed by others

References

Z.C. Guo, Z.X. Fu, Energy 35 (2010) 4356–4360.

X.H. Zhang, Z. Chen, J.Y. Zhang, P.X. Ding, J.M. Zhou, Appl. Therm. Eng. 54 (2013) 7–15.

F.Y. Tian, L.F. Huang, L.W. Fan, H.L. Qian, Z.T. Yu, Powder Technol. 301 (2016) 1284–1293.

K. Sun, C.T. Tseng, D.S.H. Wong, S.S. Shieh, S.S. Jang, J.L. Kang, W.D. Hsieh, Energy 80 (2015) 275–283.

J.J. Cai, H. Dong, The method and device of sintering waste heat recovery and utilization with vertical tank, CN 101655320B, China, 2011.

H. Dong, L. Li, W.J. Liu, B. Wang, Y.S. Suo, J.J. Cai, Chin Metallurgy 22 (2012) No. 1, 6–11.

J.S. Feng, H. Dong, A.H. Wang, Q. Zhang, J.J. Cai, J. Iron Steel Res. 27 (2015) No. 6, 7–11.

F.Y. Tian, L.F. Huang, L.W. Fan, H.L. Qian, J.X. Gu, Z.T. Yu, Y.C. Hu, J. Ge, K.F. Cen, J. Zhejiang Univ. Sci. A (Appl. Phys. Eng.) 17 (2016) 89–100.

H.Z. Li, J.Y. Gao, J.S. Feng, H. Dong, Y.W. Yang, J. Iron Steel Res. 30 (2018) 8–13.

Y. Peng, W.S. Wang, X.B. Shi, C.H. Guo, P. Xu, Sinter. Pelletiz. 44 (2019) No. 1, 6–8+27.

J.S. Feng, S. Zhang, H. Dong, G. Pei, Powder Technol. 344 (2019) 177–182.

S. Zhang, L. Zhao, J.S. Feng, X.F. Luo, H. Dong, Appl. Therm. Eng. 157 (2019) 113708.

Z. Cui, W. Shao, Z.Y. Chen, L. Cheng, Appl. Energy 206 (2017) 1297–1308.

Y. Zheng, H. Dong, J.J. Cai, J.S. Feng, L. Zhao, J.Y. Liu, S. Zhang, Appl. Therm. Eng. 151 (2019) 335–343.

Z.D. Cheng, H.T. Wang, J.S. Feng, Y.F. Xia, H. Dong, Energies 14 (2021) 4522.

L.S. Pan, X.L. Wei, Y. Peng, Y.J. Ma, B. Li, Appl. Therm. Eng. 127 (2017) 592–601.

C.Y. Xu, Z.C. Liu, S.C. Wang, W. Liu, Energies 12 (2019) 385.

J.P. Fu, J.J. Cai, J. Iron Steel Res. Int. 27 (2020) 898–912.

W.Y. Wu, X.J. Liu, X. Liang, D.H. Xia, Int. J. Therm. Sci. 172 (2022) 107283.

S. Zhang, L. Zhao, J.S. Feng, H. Dong, Int. J. Heat Mass Transfer 182 (2022) 122036.

T.F. Qi, H.F. Li, Y.J. Zhang, L. Shao, Metals 12 (2022) 1187.

Q.F. Hou, M. Samman, J. Li, A.B. Yu, ISIJ Int. 54 (2014) 1772–1780.

H. Zhou, S.Y. Wang, B.B. Du, M.Y. Kou, Z.Y. Tang, J.H. Yang, S.L. Wu, D.Y. E, Int. J. Chem. React. Eng. 18 (2020) 20200012.

M.H. Bai, S.F. Han, W.Y. Zhang, K. Xu, H. Long, Ironmak. Steelmak. 44 (2017) 685–691.

H. Zhou, X. Tian, M.Y. Kou, S.L. Wu, Y.B. Shen, Y.T. Li, Y.S. Shen, Powder Technol. 376 (2020) 537–548.

H. Zhou, K. Xu, X. Tian, M.Y. Kou, S.L. Wu, Y.S. Shen, Powder Technol. 392 (2021) 672–679.

Z.S. Dong, Q.G. Xue, H.B. Zuo, X.F. She, J. Li, J.S. Wang, ISIJ Int. 56 (2016) 1588–1597.

M.Y. Kou, S.L. Wu, G. Wang, B.J. Zhao, Q.W. Cai, Steel Res. Int. 86 (2015) 686–694.

J.N.M. Batista, D.A. Santos, R. Béttega, Particuology 54 (2021) 91–101.

T.F. Qi, J. Huang, J.J. Sun, Y.J. Zhang, J. Iron Steel Res. 34 (2022) 239–247.

X.K. Zhang, J. Xu, J.J. Sun, Y.J. Zhang, Z.H. Zhang, W. Ge, Chin. J. Theoret. Appl. Mech. 51 (2019) 64–73.

Acknowledgements

Financial support provided by the Fundamental Research Funds for the Central Universities of China (N2225022) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qi, Tf., Li, Hf., Sun, Jj. et al. Simulation of gas–solid flow in sinter vertical cooling furnace. J. Iron Steel Res. Int. 30, 2133–2142 (2023). https://doi.org/10.1007/s42243-023-00983-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00983-9