Abstract

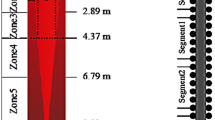

The triangular zone cracks in 2101 duplex stainless steel produced by the vertical continuous caster have troubled company A for a long time. To simulate the temperature and thermal stress distributions in the solidification process of 2101 duplex stainless steel produced by the vertical continuous caster, a two-dimensional viscoelastic–plastic thermomechanically coupled finite element model was established by the secondary development of the commercial nonlinear finite element analysis software MSC Marc. The results show that the thermal stress on the surface reaches a maximum at the exit of the mould, and the highest thermal stresses at the centre of the wide face and the narrow face are 75 and 115 MPa, respectively. Meanwhile, the internal temperature of slab is still higher than the solidus temperature, resulting in no thermal stress. The slab shows different high-temperature strengths and suffers from different stresses at different positions; thus, the risk of cracking also varies. At a location of 6–8 m from the meniscus, the temperature of the triangular zone is 1270–1360 °C and the corresponding permissible high-temperature strength is about 10–30 MPa, while the thermal stress at this time is 60 MPa, which is higher than the high-temperature strength. As a result, triangular zone cracks form easily.

Similar content being viewed by others

References

S. Hintikka, J. Konttinen, K. Leiviska, M. Tolvanen, in: Steelmaking Conference Proceedings Vol. 75, Toronto, 1992, pp. 887-891.

Q. Liu, L.Z. Wang, L.G. Cao, L.Q. Zhang, M. Liang, J. Iron Steel Res. 17 (2005) No. 6, 6-9.

D. Constales, J. Kacur, R.V. Keer, Int. J. Numer. Methods Eng. 53 (2002) 539-565.

P. Han, X.Z. Zhang, J. Iron Steel Res. 14 (2002) No. 73-76.

T.K. He, Continuous Casting (2012) No.4, 43-46.

F.Q. Zhang, C. Li, Z.S. Jiang, X.H. Wang, J.M. Zhang, G.S. Zhu, Iron and Steel 39 (2004) No. 10, 20-23.

J.K. Park, B.G. Thomas, I.V. Samarasekera, Ironmak. Steelmak. 29 (2002) 359-375.

K.K. Cai, L. Shao, X.H. Liu, J. Iron Steel Res. 5 (1993) No. 2, 1-8.

J.X. Fu, J.S. Li, H. Zhang. Acta Metall. Sin. 46 (2010) 91-96.

J.X. Fu, J.S. Li, H. Zhang, Int. J. Miner. Metal. Mater. 17 (2010) 723-728.

J.X. Fu, J.S. Li, H. Zhang, X.Z. Zhang, J. Iron Steel Res. Int. 17 (2010) No. 8, 20-24.

J.X. Fu, J.S. Li, H. Zhang, J. Iron Steel Res. 22 (2010) No.2, 9-11.

J.X. Fu, J.S. Li, H. Zhang, X.Z. Zhang, Steelmaking 26 (2010) 62-65.

J.X. Fu, J.S. Li, H. Zhang, Sci. China Technol. Sci. 54 (2011) 1228-1233.

J.X. Fu, W.S. Hwang, J.S. Li, S.F. Yang, Z. Hui, Steel Res. Int. 82 (2011) 1266-1272.

B. Barber, B.A. Lewis, B.M. Leckenby, Ironmak. Steelmak. 12 (1985) 171-175.

K. Sorimachi, J.K. Brimacombe, Ironmak. Steelmak. 4 (1977) 240-245.

T. Nozaki, J.I. Matsuno, K. Murata, H. Ooi, M. Kodama, Trans. Iron Steel Inst. Jpn. 18 (1978) 330-338.

K.H. Kim, T.J. Yeo, K.H. Oh, D.N. Lee, ISIJ Int. 36 (1996) 284-289.

T.W. Clyne, M. Wolf, W. Kurz, Metall. Mater. Trans. B 13 (1982) 259-266.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51474142, 51671124).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, J., Wu, Yx., Wang, Y. et al. Thermomechanical analysis of triangular zone cracks in vertical continuous casting slabs based on viscoelastic–plastic model. J. Iron Steel Res. Int. 25, 813–820 (2018). https://doi.org/10.1007/s42243-018-0118-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0118-z