Abstract

How to fabricate durable superhydrophobic materials for cyclic oil/water separation to solve oil-induced pollutions is still a problem. Herein, we fabricated a durable Superhydrophobic Stainless Steel Mesh (SH-SSM) with nano/micro flower-like sheets by self-assembly of zinc stearate for the cyclic separation of various oil/water mixtures. The SH-SSM exhibits durable superhydrophobicity against static or dynamic treatments. In virtue of durable superhydrophobicity of the SH-SSM, the dusts on surface of SH-SSM can be removed completely by running water immediately showing excellent self-cleaning performance. Moreover, the SH-SSM can be used to perform gravity-driven separation of heavy oil/water and light oil/water mixtures by utilizing its superhydrophobicity that oil phase penetrates the mesh and water phase is restricted. Separation efficiencies of the SH-SSM can reach 99.99%. After 20 cycles of separation, the separation efficiencies for are > 97.00% and > 98.25% for heavy oil/water and light oil/water mixtures, respectively. Flux values of dichloromethane, hexane and petroleum ether are 2.5 × 105 L m−2 h−1, 1.7 × 105 L m−2 h−1, and 1.8 × 105 L m−2 h−1, respectively. This study proposes a facial approach to prepare durable superhydrophobic and self-cleaning material for cyclic and fast separation of oil/water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

During the past decades, a large amount of oils have been released into the ocean, rivers and lakes, etc., due to oil spills, natural disasters, or offshore petroleum exploration and production industries [1,2,3]. These oils lead to heavy environment pollutions and risks to human beings [4]. In terms of on-demanding elimination of oil-induced pollutions, varieties of treatments have been developed to solve this problem; however, traditional treatments such as combustion [5], air flotation [6], hydrocarbon degrading [7], chemical coagulation [8], and absorption [9] are not promising methods for large-scale oil/water separation anymore because of their low efficiency, energy consumption, hardness of recycle. Therefore, a more cost-effective and easy processing strategy is required to be developed for practical oil/water separations. Stainless Steel Mesh (SSM) based physical separation technology is recognized as a promising candidate to perform oil/water separation due to its low energy requirement, easily scaled-up ability, and low cost [10]. For better separation of oil/water and inspired from nature, the SSM-based materials were typically surface-modified to exist superwetting property that has superiority in oil/water separation because of the unique interfacial wettability [11, 12].

In general, superwetting SSMs can be divided into superhydrophilic SSMs and superhydrophobic SSMs [13, 14]. The former SSMs are used to separate oil/water by processing water removal and oil phase is restricted [15], while the latter SSMs possess oil removal ability and water phase is restricted [16]. The former superhydrophilic SSMs need to be pre-wetted by water to realize oil/water separation. On the contrary, if the superhydrophilic SSMs are first contacted by oil phase, the oil/water separation is failed because underoil superhydrophobicity is hard to be realized. For superhydrophobic SSMs, no matter the superhydrophobic SSMs are first contacted by oil or water, the SSMs are still water-repellent whereas the SSMs are oil affinitive. Thus, the superhydrophobic SSMs can always keep oil/water separation ability without prewetting process. SSMs performing superhydrophobicity need extra construction hierarchical micro/nano structures and modification with low surface energy reagents [17, 18]. Surface of materials with hierarchical micro/nano structures can help to increase hydrophobicity during superhydrophobic modification process. Hydrophobic surface with denser micro/nano structures exhibits more hydrophobic property [19]. For well construction of hierarchical micro/nano structures, the top-down (plasma treatment, lithography, chemical etching, laser-texturing and so on) [20,21,22] and bottom-up (spray coating, hydrothermal/solvothermal, crystallization, etc. [23,24,25,26]. The top-down methods are complicated and usually expensive because large instruments or substrate selectively are typically required. On the contrary, bottom-up methods have been broadly investigated due to their flexibility in selecting substrates and controlling experimental parameters, and also have ability in the preparation of hierarchical micro/nano structures via self-structuralizing process.

Various crystals are used to construct hierarchical micro/nano structures for superhydrophobic modification via bottom-up approaches, such as CuO [27], ZnO [28], Fe2O3 [29], etc. Metal–Organic Frameworks (MOFs) are a class of novel porous organic/inorganic hybrids via coordination of metal ions and organisms [9]. The MOFs have attracted great attention in applications of oil/water separation for their porosity, adsorption ability and tunability [30]. For example, Zhang et al. [31] constructed non-activated MOF coating layer on metal mesh to prepare stable superhydrophobic material. The synthesis procedures were conducted via solvothermal method at high temperature and the obtained superhydrophobic material can be utilized to separate various oil/water mixtures with efficiency greater than 95%. Cai and collaborators [32] prepared self-healable superhydrophobic MOF via one step approach using 1H, 1H, 2H, 2H- perfluorodecyltriethoxysilane to decrease surface energy. The superhydrophobic MOF can be used to separate water-in-oil emulsions and also has potential application to treat sewage. For MOF based superhydrophobic materials, low surface energy reagents were required to decrease surface energy whatever the reagents acted as organic liker during preparation of MOFs or external modification after construction of MOFs. Stearic Acid (STA), a biocompatible hydrophobic reagent with low surface energy, can decrease surface energy by itself, or react with metal ions forming stearate leading to lower surface energy [33]. STA can be used to further decrease surface energy of MOF particles for superhydrophobic modification [34]. However, the MOF based superhydrophobic materials lack of durability for applications, and also hierarchical structures came from the MOF moieties. In addition, there lacks of evidence that MOF can assist self-assembly of STA or stearate to from hierarchical structures.

Herein, we report a simple bottom-up method to prepare durable Superhydrophobic Stainless Steel Mesh (SH-SSM) by in-situ modification with imidazole-based MOF and STA moieties. The MOF particles assist to the formation of zinc stearates and self-assembly of zinc stearates. The mechanism was systematically investigated. The SH-SSM can maintain its superhydrophobicity by immersing in water as well as after undergoing dynamic pressures such as water flow flushing and water drop impact. In addition, the SH-SSM shows excellent self-cleaning performance and dusts on SH-SSM surface can be easily removed by running water. Moreover, the SH-SSM can be used to separate heavy oil/water and light oil/water mixtures with separation efficiency greater than 97.0% even after 20 cycles. Thus, we not only develop an environment benign approach to fabricate durable SH-SSM, but also produce a promising self-cleaning superhydrophobic material to treat water pollutions caused by oils.

2 Experimental Section

2.1 Materials

SSM (400 #) was purchased from a local store. Zinc chloride (ZnCl2 ,99.95%), STA (98%), dichloromethane, n-hexane, petroleum ether, anhydrous ethanol with AR grade were obtained from Kelong Chemical Co. Ltd. Imidazole (C3H4N2, Im, AR) was bought from Sangon Biotech. All of the materials were used as received.

2.2 Preparation of SH-SSM

25 mL 40 mM zinc ion solution and 25 mL 160 mM imidazole solution were prepared freshly, and mixed together quickly in a baker at room temperature. SSM pieces were put into the baker and maintained for 24 h. After immersion time of 24 h, the meshes were taken out and washed with water strongly for several times to remove unreacted chemicals; and then the meshes were dried at 45 °C. The dried meshes were immersed in STA ethanolic solution (2 wt%) for 24 h to decrease surface energy. And the corresponding superhydrophobic SSM was named as SH-SSM.

2.3 Characterizations

Crystalline information was recorded via X-Ray Diffractor (XRD, Bruker D8 advance, Cu-Kα radiation, 0.154 nm). FEI Inspect F50 Field Emission Scanning Electron Microscope (FE-SEM, 10 kV) was utilized to determine surface morphologies. Chemical structures were determined via X-ray Photoelectron Spectrum (XPS, AXIS SUPRA). A FCA2000A water contact testing machine (AFES Co. Ltd, Shanghai, China) was chosen to detect WCAs and SAs. 3 µL water drop was used and at least five positions were tested to obtain mean values. Oil–water separation experiments were performed by pouring oil–water mixtures (V:V = 1:1) into modified falcon tube with superhydrophobic mesh. Each separation of water/oils was repeated for at least twenty times.

3 Results and Discussion

3.1 Preparation Mechanism Analysis of SH-SSM

As shown in Fig. 1, the SH-SSM was prepared by a facial immersion method without any heating process for oil water separation. The MOF particles were first grown on the mesh via coordination and self-assembly of Zn ions and imidazole. And then the MOF modified mesh was further treated with STA to decrease surface energy for superhydrophobic modification. XRD profile was conducted to confirm the crystalline information of the mesh after MOF and STA modifications, and results are shown in Fig. 2. The SSM, which is treated with Zn ions and imidazole, has characteristic diffractive peaks at 2θ of 10–55º. This result is in accordance with XRD result of Zeolitic Imidazolate Framework-4 (ZIF-4, also originated from the reaction of imidazole and Zn2+) [35], which indicates the MOF particles are successfully modified on the SSM. MOF modified SSM (MOF-SSM) was immersed in STA solution for superhydrophobic modification. XRD profile of corresponding SH-SSM shows significant difference comparing with MOF-SSM. The characteristic diffractive peaks for MOF particles are disappeared. And diffractive peaks for zinc stearate can be found for SH-SSM. These results suggest zinc stearates are formed when the MOF-SSM is treated with STA and MOF particles are decomposed.

XPS was further applied to investigate surface chemistry of SH-SSM. N element cannot be found by XPS measurement (Fig. 3a), which means the MOF particles are decomposed during the treatment of STA process, and is coincidence with XRD result. More importantly, typical binding energy at 288.8 eV (Fig. 3b) belongs to zinc stearate. Thus, we can conclude that MOF particles are first grown on SSM and decomposed during STA immersion process forming zinc stearates.

The MOF particles are decomposed during superhydrophobic modification can be explained by the unstable behavior crystallization of MOF. In reported works, the ZIF-4 crystals usually obtained via solvothermal synthesis at temperature higher than 100 ºC (sometimes reach 180 ºC) [36, 37]. For the synthesis condition in this work, the crystals are grown in aqueous solution at ambient temperature. Thus, the crystallization structures of MOF in this work are not perfect or stable as those synthesized under high temperature, which leads to easy decomposition of MOF particles during STA treatment.

3.2 Surface Morphologies

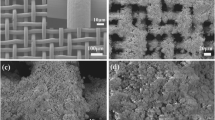

Surface morphologies were recorded by FE-SEM. Frames of pristine mesh were clean and smooth without any obvious micro/nano structures. In present work, MOF particles were designed to be grown on SSM, and polyhedral structures can be found on MOF-SSM (Fig. 4a). After modification with STA, the polyhedral structures are missing, while novel micro/nano structures can be seen on SH-SSM surface (Fig. 4b). Some hierarchical structures are grown on the frame of the SSM, and some structures are located among the frames (located in the holes of the SSM). These structures were composed of nano/micro scale flower-like sheets with thickness varying from 20 nm to hundreds of nanometers. As calculated, average sheet thicknesses of the nano/micro scale flowers are 74, 86, 88, 90, and 94 nm for MOF-SSMs with STA immersion time of 5 min, 10 min, 20 min, 2 h, and 8 h, respectively. These hierarchical nano/micro sheets can increase original surface roughness of SSM, which may help to realize extreme water repellence.

We performed more experiments to investigate the transition of morphology. As shown in Fig. 5, with the increase in immersion time, polyhedral structures are disappearing, and nano/micro flower-like sheet morphologies can be obviously seen once immersion time reaches 5 min. When STA immersion time reaches 2 h, polyhedral structures cannot be seen again, whereas more nano sheet like morphologies are formed on the surface of SSM. Nano sheet like morphologies are becoming more homogenous and aggregated with STA immersion time.

Based on XRD, XPS and FE-SEM results, the possible mechanism is proposed here and shown in Fig. 6: unstable crystalline MOF particles are first grown on the surface of SSM. The zinc ions are reacted with STA forming zinc stearates, and the zinc stearates self-assemble and precipitate on surface of SSM via electronic static interactions during STA ethanolic solution immersion process.

3.3 Wettability in Air and Under Water

Surface wettability in air and under water was systematically investigated. Effects of STA treating time on WCAs were first investigated. As shown in Fig. 7, WCAs increase with STA immersion time of MOF-SSM when immersion time < 20 min. When immersion time of STA greater than 20 min, the STA treated MOF-SSM becomes superhydrophobic with WCA greater than 150º. More importantly, the WCAs are maintained even through the immersion time is increased to 24 h.

The above results can be ascribed to the morphology changes of the MOF-SSM after STA immersion with time. As shown in Figs. 4 and 5, the hierarchical flower-like sheets formed with increase in STA immersion time. And thickness of the sheets becomes larger with STA immersion time. And the whole surface becomes uniform when STA immersion time reaches 24 h. Increase hierarchical can increase surface hydrophobicity; therefore, the WCA values increase with STA immersion time.

Due to the uniform nano sheet like morphologies and mono-phase composition of micro/nano structure based on XPS, XRD and FE-SEM results for sample obtained at 24 h (STA immersion time). The superhydrophobic SSM (SH-SSM) obtained at 24 h is chosen for further investigation.

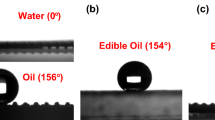

The dichloromethane was chosen here for better analysis of surface wettability toward oil. When run wettability under water, the sample pieces were placed in a transparent container, and water was poured into the container to fill over the samples. Corresponding results for wettability in air and under water are summarized in Fig. 8. For pristine SSM, the surface of the pristine SSM is hydrophobic in air with WCA of 113.5 ± 0.5° (Fig. 8a), while is oleophilic in air with oil contact angle (OCA) near 0º (Fig. 8b). Once the pristine SSM is immersed in water, the surface of pristine SSM becomes oleophobic with OCA of 127.5 ± 1.0º (Fig. 8c). After modification with MOF and STA, the SSM becomes superhydrophobic with WCA of 158.0 ± 1.2° (Fig. 8d) and SA of 4.3 ± 0.6º (Figures not shown here). The superhydrophobicity of the MOF and STA modified SSM is ascribed to the low surface energy of STA and surface hierarchical micro/nano structures. The deionized water drops and methyl blue dyed water drops stand on the surface of SH-SSM as spheres, and could easily roll down without water residuals left when the surface is tilted; however, the SH-SSM is still oleophilic in air and oil drop spreads immediately once the oil drop contacts the surface of SH-SSM (Fig. 8e). It should be pointed out that the oleophilicity of SH-SSM is maintained even the SH-SSM is submerged in water (Fig. 8f). The oleophilicity of SH-SSM can be ascribed to the superhydrophobicity of SH-SSM, which leads to form air pockets between water and SH-SSM surface. The air pockets can help the oil phase contacts SH-SSM surface and then spread over the surface. Thus, we can conclude that the SH-SSM shows high affinity to oil even under water, and also suggests the SH-SSM may have the ability to separate oil/water due to the opposite wetting behavior.

Air pockets are further confirmed by silver sheen, and the silver sheen experiment can also approve stability of superhydrophobicity of SH-SSM under static water pressure. The SH-SSM was immersed in water for a while, and a bright silver sheen picture was observed at a special shooting angle (Fig. 9a). The surface of SH-SSM was still dry without water wetting or penetration suggesting excellent stable superhydrophobicity of the SH-SSM. This extreme non-wetting state is originated from the hierarchical structure of superhydrophobic surface [38]. Superhydrophobic hierarchical structures of superhydrophobic material could form air pockets when the material is submerged in water, leading to light refringences and diffuse reflections. Thus, silver sheen can be seen at a certain viewing angle.

Dynamic methods were applied to further evaluate stability of superhydrophobicity. A 3 µL water drop was felled off under gravity force from a height of 6 cm. The drop bounced back immediately without water residuals or water wetting/penetration once the drop hit SH-SSM surface (Fig. 9b and Video S1). After several fell off and bounce back processes, the water drop stood on the SH-SSM surface as a typical sphere, and rolled off once the SH-SSM was tilted. In addition, continuous water flow was applied to flush SH-SSM surface, and the water flow left the surface without surface damage or water residuals even through the SH-SSM was bent (Fig. 9c and Video S2). More importantly, the SH-SSM was still superhydrophobic after continuous water flow flushing. In addition, the SH-SSM was placed in boiling water bath for 2 h, and then taken out for WCA test (Figures not shown). Result shows WCA of SH-SSM can still up to 146.8 ± 0.6º showing highly hydrophobic property. These results indicate that the SH-SSM show excellent stability of superhydrophobicity against dynamic treatments.

3.4 Self-Cleaning Test

Superhydrophobic materials have potential self-cleaning property. For self-cleaning property, stable superhydrophobicity and low water adhesion for superhydrophobic materials are required. Thus, self-cleaning property of the SH-SSM was performed by the removal of artificial dusts. As shown in Fig. 10 and Video S3, hydroxymethyl cellulose powders were chosen as artificial dusts and put the tilted SH-SSM surface. Water drops were fell off from the top side to bottom side. The artificial dusts were swept away along with running water drops, showing excellent self-cleaning performance of the SH-SSM. As mentioned above, the SH-SSM owes excellent stability of superhydrophobicity and low water adhesion with water easy running behavior. These characters help the SH-SSM realize self-cleaning property.

3.5 Oil/Water Separation

Both of heavy oils (density greater that of water) and light oils (density lower than that of water) could cause heavy environmental pollutions and energy waste. SH-SSM may be applied to eliminate oils from oil/water mixtures due to its opposite wetting behaviors to water and oil. Thus, oil/water separations were further performed to investigate oil/water separation ability of the SH-SSM. Dichloromethane, hexane and petroleum ether were applied as heavy and light oils. Representative separation processes of heavy oil (dichloromethane)/water and light oil (hexane)/water are shown in Fig. 11 and Video S4, and the separations were only driven by gravity force. Water phase was dyed blue using methyl blue and oil phase was dyed red via oil-red O. For heavy oil/water separation, the mixture was poured into the separation apparatus. The water phase was restricted on the upper side of the apparatus, whereas the oil phase penetrated the SH-SSM quickly. Separation efficiency (S) was calculated via the Eq. (1): [39]

where Co and Cp (g/mL) are contents of oil in the feed and filtered water, respectively. The separation efficiencies for dichloromethane/water are calculated around 99.80% at early five separation processes, and weights of oil/water were kept as the same for each cycle. Moreimportantly, the separation experiment was run for a couple of times to evaluate cyclic purification ability. And results show the separation efficiency is greater than 97% after twenty cycles (Fig. 12).

Separations of hexane/water mixtures and petroleum ether/water mixtures were performed at the same time. Results show the separation efficiencies for the separations of above mixtures are 99.99% and 99.99%, respectively. Similarly, the SH-SSM has separation efficiencies of 98.25% and 98.75% toward hexane/water and petroleum ether/water after twenty cyclic separation process, respectively. More importantly, at early five cycles, the separation efficiencies for all of the dichloromethane/water, hexane/water, and petroleum ether/water are greater than 99.50%. It should be pointed out that the SH-SSM is still superhydrophobic with WCA of 156.4 ± 0.6º and SA of 4.9 ± 1.1º after 20 cycles of hexane/water separation. WCAs are 158.4 ± 1.2º and 152.3 ± 1.5º as well as SAs are 4.5 ± 0.4º and 6.5 ± 0.5º for 20 separation cycles of petroleum ether and dichloromethane, respectively. There does not show any declines of superhydrophobicity of the SH-SSM before and after 20 cycles of oil/water separations.

The permeate flux (F) is another key parameter for oil/water separation, and is obtained according to Eq. (2) [40]:

where F is the permeate flux (L m−2 h−1), V is the volume of oil that permeates through membrane (L), A is the effective membrane area (m2), and ∆t is separation time (h). The F values of dichloromethane, hexane and petroleum ether are 2.5 × 105 L m−2 h−1, 1.7 × 105 L m−2 h−1, and 1.8 × 105 L m−2 h−1, respectively. Together with separation efficiency results, we can conclude that the SH-SSM has huge ability to be used to separate heavy (or light) oils/water with high separation efficiency and high flux. The results also suggest the SH-SSM can be utilized to well separate a large amount of oil/water mixtures in a short time, and can be circularly applied.

4 Conclusions

In conclusion, we successfully prepared durable SH-SSM with WCA of 158.0 ± 1.2° and SA of 4.3 ± 0.6º by the treatment of MOF and STA. The MOF particles were first grown on the surface of SSM and then induced to form zinc stearates. The zinc stearates self-assembled on the SSM surface forming nano/micro scale sheet like morphology with sizes of 20 to hundreds of nanometers. The corresponding SH-SSM can maintain its superhydrophobicity under when the SH-SSM is immersed in water and hit by continuous water flashing or water drop, showing excellent stability of superhydrophobicity. More importantly, the SH-SSM has WCA of 146.8 ± 0.6º after boiling water bath for 2 h. The SH-SSM also exists outstanding self-cleaning performance and the dusts of surface of SH-SSM can be easily removed by running water drops. In addition, the SH-SSM can be used to separate heavy oil/water and light oil/water mixtures without prewetting procedure. The results show the separation efficiencies a greater than 99.70% for the dichloromethane/water, hexane/water, and petroleum ether mixtures. It should be noted that even if the separation processes are repeated for 20 times, the separation efficiencies for above oil/water mixtures are still greater than 98.25% for light oil/water, and 99.70% for heavy oil/water mixtures, respectively. Thus, we not only develop a simple method to fabricate durable SH-SSM, but also obtain an oil/water separation material that has high separation flux and efficiency as well as cyclic utilization ability.

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

Gupta, R. K., Dunderdale, G. J., England, M. W., & Hozumi, A. (2017). Oil/water separation techniques: A review of recent progresses and future directions. Journal of Materials Chemistry A, 5, 16025–16058.

Singh, B., Kumar, S., Kishore, B., & Narayanan, T. N. (2020). Magnetic scaffolds in oil spill applications. Environmental Science, 6, 436–463.

Rasouli, S., Rezaei, N., Hamedi, H., Zendehboudi, S., & Duan, X. L. (2021). Superhydrophobic and superoleophilic membranes for oil-water separation application: A comprehensive review. Materials and Design, 204, 109599.

Wu, P., Jiang, L. Y., He, Z., & Song, Y. (2017). Treatment of metallurgical industry wastewater for organic contaminant removal in China: Status, challenges, and perspectives. Environmental Science: Water Research and Technology, 3, 1015–1031.

Liu, W. C., Wang, Q. H., & Peng, Q. Y. (2019). Research on oil spill emergency disposal technology. Proceedings of the international field exploration and development conference 2017 (pp. 1445–1459). Singapore: Singapore city.

Etchepare, R., Oliveira, H., Azevedo, A., & Rubio, J. (2017). Separation of emulsified crude oil in saline water by dissolved air flotation with micro and nanobubbles. Separation and Purification Technology, 186, 326–332.

Lee, T. H., Tsang, D. C. W., Chen, W. H., Verpoort, F., Sheu, Y. T., & Kao, C. M. (2019). Application of an emulsified polycolloid substrate biobarrier to remediate petroleum-hydrocarbon contaminated groundwater. Chemosphere, 219, 444–455.

Harif, T., Khai, M., & Adin, A. (2012). Electrocoagulation versus chemical coagulation: Coagulation/flocculation mechanisms and resulting floc characteristics. Water Research, 46, 3177–3188.

Dalapati, R., Nandi, S., Gogoi, C., Shome, A., & Biswas, S. (2021). Metal–organic framework (MOF) derived recyclable, superhydrophobic composite of cotton fabrics for the facile removal of oil spills. ACS Applied Materials and Interfaces, 13, 8563–8573.

Sun, B., Zhang, F. M., Gao, M., Zhao, S., Wang, J. R., Zhang, W., Wang, Z., & Wang, J. X. (2020). Superhydrophilic stainless steel mesh for oil–water separation with long-term durability, impressive corrosion resistance, and abrasion resistance. Advanced Engineering Materials, 22, 2000262.

Zhang, J., Zhang, L., Zhao, J. G., Qu, W. S., & Wang, Z. X. (2019). A facile and mild strategy to fabricate an underwater superoleophobic and underoil superhydrophobic mesh with outstanding anti-viscous oil-fouling properties for switchable high viscosity oil/water separation. Green Chemistry, 21, 5080–5089.

Dai, J. D., Wang, L. L., Wang, Y., Tian, S. J., Tian, X. H., Xie, A. T., Zhang, R. L., Yan, Y. S., & Pan, J. M. (2020). Robust nacrelike graphene oxide–calcium carbonate hybrid mesh with underwater superoleophobic property for highly efficient oil/water separation. ACS Applied Materials and Interfaces, 12, 4482–4493.

Tian, D. L., Zhang, X. F., Tian, Y., Wu, Y., Wang, X., Zhai, J., & Jiang, L. (2012). Photo-induced water–oil separation based on switchable superhydrophobicity–superhydrophilicity and underwater superoleophobicity of the aligned ZnO nanorod array-coated mesh films. Journal of Materials Chemistry, 22, 19652–19657.

Yong, J. L., Huo, J. L., Chen, F., Yang, Q., & Hou, X. (2018). Oil/water separation based on natural materials with super-wettability: Recent advances. Physical Chemistry Chemical Physics, 20, 25140–25163.

Yin, K., Chu, D. K., Dong, X. R., Wang, C., Duan, J. A., & He, J. (2017). Femtosecond laser induced robust periodic nanoripple structured mesh for highly efficient oil-water separation. Nanoscale, 9, 14229–14235.

Xiao, C. M., Si, L. X., Liu, Y. M., Guan, G. Q., Wu, D. H., Wang, Z. D., & Hao, X. G. (2016). Ultrastable coaxial cable-like superhydrophobic mesh with self-adaption effect: Facile synthesis and oil/water separation application. Journal of Materials Chemistry A, 4, 8080–8090.

Li, J., Kang, R. M., Tang, X. H., She, H. D., Yang, Y. X., & Zha, F. (2016). Superhydrophobic meshes that can repel hot water and strong corrosive liquids used for efficient gravity-driven oil/water separation. Nanoscale, 8, 7638–7645.

Wang, P., Li, Z. Q., Xie, Q., Duan, W., Zhang, X. C., & Han, H. L. (2021). A passive anti-icing strategy based on a superhydrophobic mesh with extremely low ice adhesion strength. Journal of Bionic Engineering, 18, 55–64.

Bayer, I. S., Tiwari, M. K., & Megaridis, C. M. (2008). Biocompatible poly(vinylidene fluoride)/cyanoacrylate composite coatings with tunable hydrophobicity and bonding strength. Applied Physics Letters, 93, 173902.

Barshilia, H. C., & Gupta, N. (2014). Superhydrophobic polytetrafluoroethylene surfaces with leaf-like micro-protrusions through Ar + O2 plasma etching process. Vacuum, 99, 42–48.

Nanda, D., Sahoo, A., Kumar, A., & Bhushan, B. (2019). Facile approach to develop durable and reusable superhydrophobic/superoleophilic coatings for steel mesh surfaces. Journal of Colloid and Interface Science, 535, 50–57.

Zhang, L., Zhang, C., Tang, J. R., Hao, B., & Wang, M. Y. (2021). Investigation of anticorrosive performance of oil-infused slippery and superhydrophobic brass surfaces by laser texturing. Journal of Bionic Engineering, 18, 1157–1167.

Ahamad, N., Mohammad, A., Rinawa, M. L., Sadasivuni, K. K., & Gupta, P. (2021). Correlation of structural and mechanical properties for Al-Al2O3-SiC hybrid metal matrix composites. Journal of Composite Materials, 55, 3267–3280.

Ahamad, N., Mohammad, A., Sadasivuni, K. K., & Gupta, P. (2020). Structural and mechanical characterization of stir cast Al–Al2O3–TiO2 hybrid metal matrix composites. Journal of Composite Materials, 54, 2985–2997.

Zhang, J. X., Zhang, L. G., & Gong, X. (2021). Large-scale spraying fabrication of robust fluorine-free superhydrophobic coatings based on dual-sized silica particles for effective antipollution and strong buoyancy. Langmuir, 37, 6042–6051.

Wei, D. W., Wei, H., Gauthier, A. C., Song, J., Jin, Y., & Xiao, H. (2020). Superhydrophobic modification of cellulose and cotton textiles: Methodologies and applications. Journal of Bioresources and Bioproducts, 5, 1–15.

Li, J., Liu, X. H., Ye, Y. P., Zhou, H. D., & Chen, J. M. (2011). Fabrication of superhydrophobic CuO surfaces with tunable water adhesion. The Journal of Physical Chemistry C, 115, 4726–4729.

Rezayi, T., & Entezari, M. H. (2016). Toward a durable superhydrophobic aluminum surface by etching and ZnO nanoparticle deposition. Journal of Colloid and Interface Science, 463, 37–45.

Song, L. J., Hu, J., Huang, X. F., Zhong, L., Pei, Y. B., Wu, L. B., & Zhang, X. Y. (2020). Superhydrophobic self-healing coatings comprised of hemispherical particles arrays decorated by fluorocarbon-coated nanoscale Fe2O3 rods and SiO2 particles. ACS Applied Nano Materials, 3, 10342–10348.

Ying, T., Su, J. F., Jiang, Y. J., Ni, L. Y., Jiang, X., Ke, Q. F., & Xu, H. (2022). Superhydrophobic MOFs decorated on hierarchically micro/nanofibrous membranes for high-performance emulsified oily wastewater separation and cationic dyes adsorption. Journal of Materials Chemistry A, 10, 829–845.

Zhang, G. L., Zhang, J. H., Su, P. C., Xu, Z. H., Li, W. B., Shen, C., & Meng, Q. (2017). Non-activation MOF arrays as a coating layer to fabricate a stable superhydrophobic micro/nano flower-like architecture. Chemical Communications, 53, 8340–8343.

Cai, Y. H., Chen, D. Y., Li, N. J., Xu, Q. F., Li, H., He, J. G., & Lu, J. M. (2019). Superhydrophobic metal–organic framework membrane with self-repairing for high-efficiency oil/water emulsion separation. ACS Sustainable Chemistry and Engineering, 7, 2709–2717.

Si, Y. F., Guo, Z. G., & Liu, W. M. (2016). A robust epoxy resins @ stearic acid-Mg(OH)2 micronanosheet superhydrophobic omnipotent protective coating for real-life applications. ACS Applied Materials and Interfaces, 8, 16511–16520.

Meng, W., Feng, Z. J., Li, F., Li, T. H., & Cao, W. (2016). Porous coordination polymer coatings fabricated from Cu3(BTC)2·3H2O with excellent superhydrophobic and superoleophilic properties. New Journal of Chemistry, 40, 10554–10559.

Dai, M., Shen, J. X., Zhang, J. Y., & Li, G. D. (2017). A novel separator material consisting of zeoliticimidazolate framework-4 (ZIF-4) and its electrochemical performance for lithium-ions battery. Journal of Power Sources, 369, 27–34.

Zhang, J. Y., Qiao, A., Tao, H. Z., & Yue, Y. Z. (2019). Synthesis, phase transitions and vitrification of the zeolitic imidazolate framework: ZIF-4. Journal of Non-Crystalline Solids, 525, 119665.

Tan, J. C., Civalleri, B., Erba, A., & Albanese, E. (2015). Quantum mechanical predictions to elucidate the anisotropic elastic properties of zeolitic imidazolate frameworks: ZIF-4 vs ZIF-ZnI. CrystEngComm, 17, 375–382.

Li, Y., Zhang, Z. Z., Ge, B., Men, X. H., & Xue, Q. J. (2016). One-pot, template-free synthesis of a robust superhydrophobic polymer monolith with an adjustable hierarchical porous structure. Green Chemistry, 18, 5266–5272.

Wang, R. X., Zhao, X. T., Jia, N., Cheng, L. J., Liu, L. F., & Gao, C. J. (2020). Superwetting oil/water separation membrane constructed from in situ assembled metal–phenolic networks and metal–organic frameworks. ACS Applied Materials and Interfaces, 12, 10000–10008.

Li, J., Xu, C. C., Guo, C. Q., Tian, H. F., Zha, F., & Guo, L. (2018). Underoil superhydrophilic desert sand layer for efficient gravity-directed water-in-oil emulsions separation with high flux. Journal of Materials Chemistry A, 6, 223–230.

Acknowledgements

This work is financially supported by the Double Subject Construction Plan (2021993379).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no known competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (AVI 1629 kb)

Supplementary file2 (AVI 1175 kb)

Supplementary file3 (AVI 824 kb)

Supplementary file4 (AVI 3184 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, C., Luo, Y., Zhou, L. et al. Fabrication of Durable Superhydrophobic Stainless Steel Mesh with Nano/Micro Flower-Like Morphologies for Self-Cleaning and Efficient Oil/Water Separation. J Bionic Eng 19, 1615–1624 (2022). https://doi.org/10.1007/s42235-022-00231-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-022-00231-y