Abstract

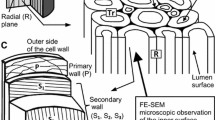

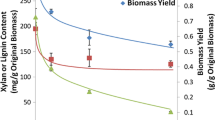

Cellulose, hemicellulose, and lignin molecules in poplar wood are interwoven to form a dense network-like structure, which prevents their degradation into oligomers for the preparation of biomass-based materials and chemicals. Therefore, it is necessary to use a pretreatment process to decompose the complex matrix. In this study, ultrasound-assisted xylanase treatment was used for poplar wood pretreatment. The effects of different parameters, such as enzyme treatment time, enzyme dosage, and ultrasound time on soluble substances and the surface of the cell wall were systematically investigated. The optimal conditions for the degradation of hemicellulose and lignin in poplar wood were a treatment time of 60 min and a xylanase dosage of 25 U/g. Ultrasound-assisted xylanase treatment improved the efficiency of removing hemicellulose. The contents of glucose, xylose, and lignin were increased by 34.73%, 32.01%, and 59.65%, respectively, with the ultrasound-assisted xylanase treatment. In addition, a least-squares model was constructed to describe the dissolution behavior of component, which is helpful to guide the subsequent conversion and utilization of poplar wood biomass.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Liu W, Liu K, Du H, Zheng T, Zhang N, Xu T, Pang B, Zhang X, Si C, Zhang K (2022) Cellulose nanopaper: fabrication, functionalization and applications. Nano-Micro Lett 14:104. https://doi.org/10.1007/s40820-022-00849-x

Yang S, Shi C, Qu K, Sun Z, Li H, Xu B, Huang Z, Guo Z (2023) Electrostatic self-assembly cellulose nanofibers/MXene/nickel chains for highly stable and efficient seawater evaporation and purification. Carbon Lett 33:2063–2074. https://doi.org/10.1007/s42823-023-00540-0

Ruan J, Chang Z, Rong H, Alomar T, Zhu D, AlMasoud N, Liao Y, Zhao R, Zhao X, Li Y, Xu BB, Guo Z, El-Bahy Z, Li H, Zhang X, Ge S (2023) High-conductivity nickel shells encapsulated wood-derived porous carbon for improved electromagnetic interference shielding. Carbon 213:118208. https://doi.org/10.1016/j.carbon.2023.118208

Wang Y, Liu K, Zhang M, Xu T, Du H, Pang B, Si C (2023) Sustainable polysaccharide-based materials for intelligent packaging. Carbohyd Polym 313:120851. https://doi.org/10.1016/j.carbpol.2023.120851

Wang Y, Xu T, Liu K, Zhang M, Cai X-M, Si C (2023) Biomass-based materials for advanced supercapacitor: principles, progress, and perspectives. Aggregate. https://doi.org/10.1002/agt2.428

Zhang H, Li S, Hang H, Wang R, Cheng C, Fedorovich KV, Mai X (2023) Mildew-resistant wood building materials with titanium oxide nanosheet. Eng Sci 21:816. https://doi.org/10.30919/es8e816

Xu T, Liu K, Sheng N, Zhang M, Liu W, Liu H, Dai L, Zhang X, Si C, Du H, Zhang K (2022) Biopolymer-based hydrogel electrolytes for advanced energy storage/conversion devices: properties, applications, and perspectives. Energy Storage Mater 48:244–262. https://doi.org/10.1016/j.ensm.2022.03.0137

Zhang H, Wang R, Wang L, Li S, Yuan Y, Wang N, Chen S, Mai X (2023) Super-hydrophobic wood composite with plexiglass coating. Eng Sci 23:865. https://doi.org/10.30919/es8d865

Yang Y, Zhang L, Zhang J, Ren Y, Huo H, Zhang X, Huang K, Rezakazemi M, Zhang Z (2023) Fabrication of environmentally, high-strength, fire-retardant biocomposites from small-diameter wood lignin in situ reinforced cellulose matrix. Adv Compos Hybrid Mater 6(4):140. https://doi.org/10.1007/s42114-023-00721-5

Rao MVSSTS, Muralikrishna G (2006) Hemicelluloses of ragi (finger millet, Eleusine coracana, Indaf-15): isolation and purification of an alkali-extractable arabinoxylan from native and malted hemicellulose B. J Agric Food Chem 54:2342–2349. https://doi.org/10.1021/jf058144q

Liu K, Du H, Zheng T, Liu W, Zhang M, Liu H, Zhang X, Si C (2021) Lignin-containing cellulose nanomaterials: preparation and applications. Green Chem 23:9723–9746. https://doi.org/10.1039/D1GC02841C

Xu T, Wang Y, Liu K, Zhao Q, Liang Q, Zhang M, Si C (2023) Ultralight MXene/carbon nanotube composite aerogel for high-performance flexible supercapacitor. Adv Compos Hybrid Mater 6:108. https://doi.org/10.1007/s42114-023-00675-8

Liang Q, Liu K, Xu T, Wang Y, Zhang M, Zhao Q, Zhong W, Cai X-M, Zhao Z, Si C (2023) Interfacial modulation of Ti3C2Tx MXene by cellulose nanofibrils to construct hybrid fibers with high volumetric specific capacitance. Small. https://doi.org/10.1002/smll.202307344

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4(1):1–19. https://doi.org/10.1186/s40643-017-0137-9

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Biores Technol 262:310–318. https://doi.org/10.1016/j.biortech.2018.04.099

Yang Y, Kang X, Yang Y, Ye H, Jiang J, Zheng G et al (2023) Research progress in green preparation of advanced wood-based composites. Adv Compos Hybrid Mater 6(6):202. https://doi.org/10.1007/s42114-023-00770-w

Hu F, Ragauskas A (2012) Pretreatment and lignocellulosic chemistry. BioEnergy Research 5:1043–1066. https://doi.org/10.1007/s12155-012-9208-0

Foster BL, Dale BE, Doran-Peterson JB (2001) Enzymatic hydrolysis of ammonia-treated sugar beet pulp. Appl Biochem Biotechnol 91–93:269–282. https://doi.org/10.1385/abab:91-93:1-9:269

Saha BC, Qureshi N, Kennedy GJ, Cotta MA (2016) Biological pretreatment of corn stover with white-rot fungus for improved enzymatic hydrolysis. Int Biodeterior Biodegrad 109:29–35. https://doi.org/10.1016/j.ibiod.2015.12.020

Zheng Y, Liu H, Yan L, Yang H, Dai L, Si C (2023) Lignin-based encapsulation of liquid metal particles for flexible and high-efficiently recyclable electronics. Adv Funct Mater. https://doi.org/10.1002/adfm.202310653

Wang B, Zhang H-R, Huang C, Xiong L, Luo J, Chen X (2024) Study on non-isothermal crystallization behavior of isotactic polypropylene/bacterial cellulose composites. RSC Adv 7:42113–42122. https://doi.org/10.1039/C7RA07731A

Liu H, Xu T, Liu K, Zhang M, Liu W, Li H, Du H, Si C (2021) Lignin-based electrodes for energy storage application. Ind Crops Prod 165:113425. https://doi.org/10.1016/j.indcrop.2021.113425

Kang F, Jiang X, Wang Y, Ren J, Xu BB, Gao G, Huang Z, Guo Z (2023) Electron-rich biochar enhanced Z-scheme heterojunctioned bismuth tungstate/bismuth oxyiodide removing tetracycline. Inorg Chem Front 10:6045–6057. https://doi.org/10.1039/D3QI01283B

Si C-L, Kim J-K, Bae Y-S, Li S-M (2009) Phenolic compounds in the leaves of Populus ussuriensis and their antioxidant activities. Planta Med 75:1165–1167. https://doi.org/10.1055/s-0029-1185476

Duan Y, Yang H, Liu K, Xu T, Chen J, Xie H, Du H, Dai L, Si C (2023) Cellulose nanofibril aerogels reinforcing polymethyl methacrylate with high optical transparency. Adv Compos Hybrid Mater 6:123. https://doi.org/10.1007/s42114-023-00700-w

Liu W, Lin Q, Chen S, Yang H, Lui K, Pang B, Xu T, Si C (2023) Microencapsulated phase change material through cellulose nanofibrils stabilized Pickering emulsion templating. Adv Compos Hybrid Mater 6:149. https://doi.org/10.1007/s42114-023-00725-1

Singh G, Capalash N, Kaur K, Puri S, Sharma P (2016) Enzymes: applications in pulp and paper industry. In Agro-industrial wastes as feedstock for enzyme production, (Elsevier). https://doi.org/10.1016/B978-0-12-802392-1.00007-1

Torres CE, Negro C, Fuente E, Blanco A (2012) Enzymatic approaches in paper industry for pulp refining and biofilm control. Appl Microbiol Biotechnol 96:327–344. https://doi.org/10.1007/s00253-012-4345-0

Wang Y, Ji X-X, Liu S, Tian Z, Si C, Wang R, Yang G, Wang D (2022) Effects of two different enzyme treatments on the microstructure of outer surface of wheat straw. Adv Compos Hybrid Mater 5:934–947. https://doi.org/10.1007/s42114-021-00395-x

Liu W, Du H, Zhang M, Liu K, Liu H, Xie H, Zhang X, Si C (2020) Bacterial cellulose-based composite scaffolds for biomedical applications: a review. ACS Sustain Chem Eng 8:7536–7562. https://doi.org/10.1021/acssuschemeng.0c00125

Cui J, Sun H, Chen R, Sun J, Mo G, Luan G, Lu X (2023) Multiple routes toward engineering efficient cyanobacterial photosynthetic biomanufacturing technologies. Green Carbon 1:210–226. https://doi.org/10.1016/j.greenca.2023.11.004

Hou H, Huang X, Du Z, Guo J, Wang M, Xu G, Geng C, Zhang Y, Wang Q, Lu X (2023) Integration of biological synthesis & chemical catalysis: bio-based Plasticizer trans-Aconitates. Green Carbon 1:20–32. https://doi.org/10.1016/j.greenca.2023.08.001

Xu T, Du H, Liu H, Liu W, Zhang X, Si C, Liu P, Zhang K (2021) Advanced nanocellulose-based composites for flexible functional energy storage devices. Adv Mater 33:2101368. https://doi.org/10.1002/adma.202101368

Liu H, Du H, Zheng T, Liu K, Ji X, Xu T, Zhang X, Si C (2021) Cellulose based composite foams and aerogels for advanced energy storage devices. Chem Eng J 426:130817. https://doi.org/10.1016/j.cej.2021.130817

Shirsath SR, Sonawane SH, Gogate PR (2012) Intensification of extraction of natural products using ultrasonic irradiations-a review of current status. Chem Eng Process 53:10–23. https://doi.org/10.1016/j.cep.2012.01.003

Cheng X, Zhang M, Xu B, Adhikari B, Sun J (2015) The principles of ultrasound and its application in freezing related processes of food materials: a review. Ultrason Sonochem 27:576–585. https://doi.org/10.1016/j.ultsonch.2015.04.015

Liu K, Du H, Liu W, Zhang M, Wang Y, Liu H, Zhang X, Xu T, Si C (2022) Strong, flexible, and highly conductive cellulose nanofibril/PEDOT:PSS/MXene nanocomposite films for efficient electromagnetic interference shielding. Nanoscale 14:14902–14912. https://doi.org/10.1039/D2NR00468B

Chen J, Jiang Q, Yang G, Wang Q, Fatehi P (2017) Ultrasonic-assisted ionic liquid treatment of chemithermomechanical pulp fibers. Cellulose 24:1483–1491. https://doi.org/10.1007/s10570-016-1180-y

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker DJ (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure 1617(1):1–16

Sui Y, Cui Y, Wang Y, Zeb S, Sun G (2021) A green and efficient way to improve sugar recovery of wheat straw by ultrasonic-assisted xylanase pretreatment. Biomass Convers Biorefin 13:7067–7078. https://doi.org/10.1007/s13399-021-01623-6

Li W, Sun H, Wang G, Sui W, Dai L, Si C (2023) Lignin as a green and multifunctional alternative to phenol for resin synthesis. Green Chem 25:2241–2261. https://doi.org/10.1039/D2GC04319J

Liu K, Liu W, Li W, Duan Y, Zhou K, Zhang S, Ni S, Xu T, Du H, Si C (2022) Strong and highly conductive cellulose nanofibril/silver nanowires nanopaper for high performance electromagnetic interference shielding. Adv Compos Hybrid Mater 5:1078–1089. https://doi.org/10.1007/s42114-022-00425-2

Liu W, Zhang S, Liu K, Yang H, Lin Q, Xu T, Song X, Du H, Bai L, Yao S, Si C (2023) Sustainable preparation of lignocellulosic nanofibrils and cellulose nanopaper from poplar sawdust. J Clean Prod 384:135582. https://doi.org/10.1016/j.jclepro.2022.135582

Thygesen A, Oddershede J, Lilholt H, Thomsen AB, Ståhl K (2005) On the determination of crystallinity and cellulose content in plant fibres. Cellulose 12:563–576. https://doi.org/10.1007/s10570-005-9001-8

Guo X, Cheng G (2022) Moderate-dimensional inferences on quadratic functionals in ordinary least squares. J Am Stat Assoc 117(540):1931–1950. https://doi.org/10.1080/01621459.2021.1893177

Li W, Wang G, Sui W, Xu T, Li Z, Parvez AM, Si C (2022) Facile and scalable preparation of cage-like mesoporous carbon from lignin-based phenolic resin and its application in supercapacitor electrodes. Carbon 196:819–827. https://doi.org/10.1016/j.carbon.2022.05.053

Liao H, Ying W, Li X, Zhu J, Xu Y, Zhang J (2022) Optimized production of xylooligosaccharides from poplar: a biorefinery strategy with sequential acetic acid/sodium acetate hydrolysis followed by xylanase hydrolysis. Biores Technol 347:126683. https://doi.org/10.1016/j.biortech.2022.126683

Zheng L, Yu P, Zhang Y, Wang P, Yan W, Guo B, Huang C, Jiang Q (2021) Evaluating the bio-application of biomacromolecule of lignin-carbohydrate complexes (LCC) from wheat straw in bone metabolism via ROS scavenging. Int J Biol Macromol 176:13–25. https://doi.org/10.1016/j.ijbiomac.2021.01.103

Xu T, Song Q, Liu K, Liu H, Pan J, Liu W, Dai L, Zhang M, Wang Y, Si C, Du H, Zhang K (2023) Nanocellulose-assisted construction of multifunctional MXene-based aerogels with engineering biomimetic texture for pressure sensor and compressible electrode. Nano-Micro Lett 15:98. https://doi.org/10.1007/s40820-023-01073-x

Zhao B, Xu J, Chen B, Cao X, Yuan T, Wang S, Charlton A, Sun R (2018) Selective precipitation and characterization of lignin–carbohydrate complexes (LCCs) from Eucalyptus. Planta 247:1077–1087. https://doi.org/10.1007/s00425-018-2842-9

Yuan S, Ji X, Ji H, Tian Z, Chen J (2019) An optimum combined severity factor improves both the enzymatic saccharification yield and the functional lignin structure. Cellulose 26:4731–4742. https://doi.org/10.1007/s10570-019-02442-9

Donohoe BS, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2008) Visualizing lignin coalescence and migration through maize cell walls following thermochemical pretreatment. Biotechnol Bioeng 101:913–925. https://doi.org/10.1002/bit.21959

Li J, Lu Y, Yang D, Sun Q, Liu Y, Zhao H (2011) Lignocellulose aerogel from wood-ionic liquid solution (1-allyl-3-methylimidazolium chloride) under freezing and thawing conditions. Biomacromol 12(5):1860–1867. https://doi.org/10.1021/bm200205z

Liu H, Xu T, Liang Q, Zhao Q, Zhao D, Si C (2022) Compressible cellulose nanofibrils/reduced graphene oxide composite carbon aerogel for solid-state supercapacitor. Adv Compos Hybrid Mater 5:1168–1179. https://doi.org/10.1007/s42114-022-00427-0

Liu H, Xu T, Cai C, Liu K, Liu W, Zhang M, Du H, Si C, Zhang K (2022) Multifunctional superelastic, superhydrophilic, and ultralight nanocellulose-based composite carbon aerogels for compressive supercapacitor and strain sensor. Adv Func Mater 32:2113082. https://doi.org/10.1002/adfm.202113082

Liu W, Liu K, Wang Y, Lin Q, Liu J, Du H, Pang B, Si C (2022) Sustainable production of cellulose nanofibrils from Kraft pulp for the stabilization of oil-in-water Pickering emulsions. Ind Crops Prod 185:115123. https://doi.org/10.1016/j.indcrop.2022.115123

Zhang M, Duan Y, Chen T, Qi J, Xu T, Du H, Si C (2023) Lignocellulosic materials for energy storage devices. Ind Crops Prod 203:117174. https://doi.org/10.1016/j.indcrop.2023.117174

Liu W, Pang B, Zhang M, Lv J, Xu T, Bai L, Cai X-M, Yao S, Huan S, Si C (2024) Pickering multiphase materials using plant-based cellulosic micro/nanoparticles. Aggregate. https://doi.org/10.1002/agt2.486

Wang Y, Xu T, Liu K, Zhang M, Zhao Q, Liang Q, Si C (2023) Nanocellulose-based advanced materials for flexible supercapacitor electrodes. Ind Crops Prod 204:117378. https://doi.org/10.1016/j.indcrop.2023.117378

Zhang M, Wang Y, Liu K, Liu Y, Xu T, Du H, Si C (2023) Strong, conductive, and freezing-tolerant polyacrylamide/PEDOT:PSS/cellulose nanofibrils hydrogels for wearable strain sensors. Carbohyd Polym 305:120567. https://doi.org/10.1016/j.carbpol.2023.120567

Liu K, Du H, Liu W, Liu H, Zhang M, Xu T, Si C (2022) Cellulose nanomaterials for oil exploration applications. Polym Rev 62:585–625. https://doi.org/10.1080/15583724.2021.2007121

Liu W, Du H, Liu H, Xie H, Xu T, Zhao X, Liu Y, Zhang X, Si C (2020) Highly efficient and sustainable preparation of carboxylic and thermostable cellulose nanocrystals via FeCl3-catalyzed innocuous citric acid hydrolysis. ACS Sustain Chem Eng 8:16691–16700. https://doi.org/10.1021/acssuschemeng.0c06561

Zhao Q, Xu T, Zhang M, Liu H, Du H, Si C (2023) Zn@cellulose nanofibrils composite three-dimensional carbon framework for long-life Zn anode. Ind Crops Prod 194:116343. https://doi.org/10.1016/j.indcrop.2023.116343

Ding F (2023) Least squares parameter estimation and multi-innovation least squares methods for linear fitting problems from noisy data. J Comput Appl Math 426:115107. https://doi.org/10.1016/j.cam.2023.115107

Barratt ST, Boyd SPJEO (2021) Least squares auto-tuning. Eng Optim 53(5):789–810. https://doi.org/10.1080/0305215X.2020.1754406

Chen K, Lin Y, Wang Z, Ying Z (2016) Least product relative error estimation. J Multivar Anal 144:91–98. https://doi.org/10.1016/j.jmva.2015.10.017

De Hoop L, Viaene KP, Schipper AM, Huijbregts MA, De Laender F, Hendriks AJ (2017) Time-varying effects of aromatic oil constituents on the survival of aquatic species: deviations between model estimates and observations. Environ Toxicol Chem 36(1):128–136. https://doi.org/10.1002/etc.3508

Griffiths WE, Hill RC (2022) On The Power Of The F-test for hypotheses in a linear model. Am Stat 76(1):78–84. https://doi.org/10.1080/00031305.2021.1979652

Ma C, Yang L, Li W, Yue J, Li J, Zu Y (2014) Ultrasound-assisted extraction of arabinogalactan and dihydroquercetin simultaneously from Larix gmelinii as a pretreatment for pulping and papermaking. PLoS ONE 9(12):e114105. https://doi.org/10.1371/journal.pone.0114105

Funding

This work was supported by the National Natural Science Foundation of China (No. 32230070), Natural Science Foundation of Shandong Province of China (No. ZR2021ZD38), Jinan Innovation Team (No. 2021GXRC023, 202228044), the QUTJBZ Program (No. 2022JBZ01-05), and the Taishan Scholars Program and Taishan Industrial Experts Program.

Author information

Authors and Affiliations

Contributions

Jiaxin Qu designed the research and wrote the manuscript. Zhongjian Tian sorted the data and figures. Fangfang Zhang discussed the results. Chuanling Si discussed the experiments and results. Xingxiang Ji supervised the manuscript. All authors have given approval for the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qu, J., Tian, Z., Zhang, F. et al. Effect of ultrasound-assisted xylanase pretreatment on the soluble substances of poplar wood and its model construction. Adv Compos Hybrid Mater 7, 77 (2024). https://doi.org/10.1007/s42114-024-00871-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-024-00871-0