Abstract

C/C-SiC composite has superior performance and widespread applications while its serving temperature is limited to about 1650 °C because of the matrix’s active oxidation. In this paper, zirconium silicide was introduced into the matrix of C/C-SiC composite and a matrix modified C/C-SiC composite was produced using Si–Zr-alloyed reactive melt infiltration. Ablation resistance and behavior of the modified composite were evaluated using an oxyacetylene torch in the oxygen-poor and oxygen-rich environments. It was found that the environment had great impact on the ablation resistance of the composites. The composite presented obviously improved ablation resistance in the oxygen-poor environment compared with that in the oxygen-rich environment. A continuous layer of ZrO2 was generated on the composite’s ablated surface tested in oxygen-poor environment, acting as a protecting layer to avoid the subsequent severe damage. Conversely, the composite tested in oxygen-rich environment was severely ablated and a deep pit was produced on the ablated surface with a discontinuous layer composed of ZrSiO4, ZrO2, and SiO2 without sufficient protection. The damage mechanism of the composites under different environments was discussed. The damage of the composite tested in the oxygen-poor environment was dominated by the oxidation erosion and evaporation of the SiO2 phase, while the composite’s damage tested in the oxygen-rich environment is mainly contributed to the oxidation erosion and blowing away of the liquid ZrO2, ZrSiO4, and SiO2.

Graphical abstract

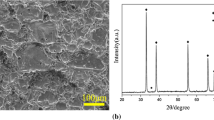

The macro morphologies and XRD analysis of C/C-SiC composite after ablation tests in (a) oxygen poor and (b) oxygen rich environments.

Similar content being viewed by others

References

Zhao ZG, Li KZ, Li W, Liu Q, Kou G, Zhang YL (2018) Preparation, ablation behavior and mechanism of C/C-ZrC-SiC and C/C-SiC composites. Ceram Int 44(7):7481–7490

Almeida RSM, Li Y, Besser B, Xiao P (2019) Damage analysis of 2.5D C/C-SiC composites subjected to fatigue loadings. J Eur Ceram Soc 39(7):2244–2250

Tang C, Dang AL, Li TH, Zhao TK, Li H, Jiao SS (2019) Influence of fiber content on C/C-SiC brake materials fabricated by compression molding and hot sintering. Tribol Int 136:404–411

Krenkel W (2003) Application of fiber reinforced C/C-SiC ceramic. Ceram Forum Int 80(8):31–38

Mei H, Cheng LF, Zhang LT (2006) Thermal cycling damage mechanisms of C/SiC composites in displacement constraint and oxidizing atmosphere. J Am Ceram Soc 89:2330–2334

Tang SF, Deng JY, Wang SJ, Liu WC, Yang K (2007) Ablation behaviors of ultra-high temperature ceramic composites. Mater Sci Eng A 465:1–7

Li L, Wang Y, Cheng L, Zhang L (2011) Preparation and properties of 2D C/SiC–ZrB2–TaC composites. Ceram Int 37:891–896

Zhao YH, Jing J, Chen L, Xu FH, Hou H (2021) Current research status of interface of ceramic-metal laminated composite material for armor protection. Acta Metall Sin 57:1107–1125

Zhang H, Liang X, Hu Y et al (2021) Correlation of C/C preform density and microstructure and mechanical properties of C/C-ZrC-based ultra-high-temperature ceramic matrix composites. Adv Compos Hybrid Mater 4(3):743–750

Wang Z, Dong SM, Ding YS, Zhang XY, Zhou HJ, Yang JS et al (2011) Mechanical properties and microstructures of C/SiC–ZrC composites using T700SC carbon fibers as reinforcements. Ceram Int 37:695–700

Padmavathi N, Kumari S, Bhanu Prasad VV, Subrahmanyama J, Ray KK (2009) Processing of carbon-fiber reinforced (SiC+ZrC) mini-composites by soft-solution approach and their characterization. Ceram Int 35:3447–3454

Hu HF, Wang QK, Chen ZH, Zhang CR, Zhang YD, Wang J (2010) Preparation and characterization of C/SiC–ZrB2 composites by precursor infiltration and pyrolysis process. Ceram Int 36:1011–1016

Li QG, Dong SM, Wang Z, Hu JB, Wu B, Zhou HJ, He P, Yang JS (2013) Fabrication of a ZrC–SiC matrix for ceramic matrix composites via in-situ reaction and its application. Ceram Int 39:877–881

Wang YG, Zhu XJ, Zhang LT, Cheng LF (2012) C/C-SiC-ZrC composites fabricated by reactive melt infiltration with Si0.87Zr0.13 alloy. Ceram Int 38:4337–4343

Tong YG, Bai SX, Zhang H, Chen K (2012) C/C-SiC composite prepared by Si-10Zr alloyed melt infiltration. Ceram Int 38(4):3301–3307

Tong YG, Zhang H, Hu YL, Zhang P, Hua MY, Liang XB, Chen YX, Zhang ZB (2021) RMI-C/C-SiC-ZrSi2 composite serving in inert atmosphere up to 2100 °C: thermal shock resistance microstructure and damage mechanism. Ceram Int 47(14):20371–20378

Zhao D, Zhang CR, Hu HF, Zhang YD (2008) Ablation behavior and mechanism of 3D C/ZrC composite in oxyacetylene torch environment. Compos Sci Technol 71(11):1392–1396

Yan B, Chen ZF, Zhu JX, Zhang JZ, Jiang Y (2009) Effects of ablation at different regions in three-dimensional orthogonal C/SiC composites ablated by oxyacetylene torch at 1800 °C. J Mater Process Technol 209:3438–3443

Chen ZF, Fang D, Miao YL, Yan B (2008) Comparison of morphology and microstructure of ablation centre of C/SiC composites by oxy-acetylene torch at 2900 and 3550 °C. Corros Sci 50:3378–3381

Tong YG, Bai SX, Zhang H, Ye YC (2012) Effect of C/C preform density on microstructure and mechanical properties of C/C-SiC composites prepared by alloyed reactive melt infiltration. Mater Sci Technol 28(12):1505–1512

Schmidt DL (1971) Ablative polymers in aerospace technology. In: D’Alelio GF, Parker JA (eds) Ablative Plastics. Marcel Dekker, New York, pp 1–39

Fang D, Chen ZF, Song YD, Sun ZG (2009) Morphology and microstructure of 2.5 dimension C/SiC composites ablated by oxyacetylene torch. Ceram Int 35:1249–1253

Sun W, Xiong X, Huang BY, Li GD, Zhang HB, Chen ZK, Zheng XL (2009) ZrC ablation protective coating for carbon/carbon composites. Carbon 47(14):3368–3371

Shen XT, Li KZ, Li HJ, Lan FT, Feng T (2009) Effect of ZrO2 from the oxidation of ZrC on ablation of ZrC modified carbon/carbon composites. J Inorg Mater 24:943–947

Funding

Sponsorship was provided by the National Natural Science Foundation of China (Nos. 52005053 and 11902333) and the Natural Science Foundation of Hunan Province of China (Nos. 2019JJ50657 and 2018JJ2426).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tong, Y., Ren, Z., Hu, Y. et al. Damage behavior and mechanism of C/C-SiC composite ablated under different environments. Adv Compos Hybrid Mater 5, 1433–1438 (2022). https://doi.org/10.1007/s42114-021-00387-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00387-x