Abstract

Understanding the correlation of C/C preform density and microstructure and properties of the resulting composites is of great importance for the fast and economical fabrication of ultra-high-temperature ceramic matrix composites by reactive melt infiltration. In this paper, C/C-ZrC composites were prepared by eutectic Zr-Si alloyed melt infiltration using different density C/C composite preforms, and the influence of C/C preform densities on the microstructure and mechanical properties of the composites was investigated. The results showed that the densities of the composites decreased with the increase of the C/C preform densities while the open porosities always kept at small values. The C/C-ZrC composites were generally composed of carbon, ZrC phase, and Zr2Si phase. The microstructure and phase composition of the composites were greatly influenced by C/C preform densities. Flexural strength of the composites initially increased with C/C preform densities, and then decreased reversely. The C/C-ZrC composite reached its highest flexural strength, 241 MPa, when the C/C preform density was 1.28 g/cm3. This work revealed the correlation of C/C preform density and microstructure and mechanical properties of C/C-ZrC composites, and will provide a guidance for performance optimization of reactive melt infiltrated ultra-high temperature ceramic matrix composites.

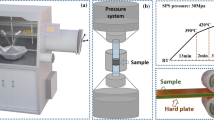

Graphical abstract

The (a): densities and open porosities; (b): XRD patterns; (c): flexural strength of the C/C-ZrC composites prepared by C/C composite preforms with different densities

Similar content being viewed by others

References

Tang SF, Deng JY, Wang SJ, Liu WC, Yang K (2007) Ablation behaviors of ultra-high temperature ceramic composites. Mater Sci Eng A 465:1–7

Corral EL, Walker LS (2010) Improved ablation resistance of C-C composites using zirconium diboride and boron carbide. J Eur Ceram Soc 30:57–64

Tong YG, Bai SX, Hu YL, Liang XB, Ye YC, Qin QH (2018) Laser ablation resistance and mechanism of Si-Zr alloyed melt infiltrated C/C-SiC composite. Ceram Int 44:3692–3698

Savino R, Fumoa MDS, Silvestroni L, Sciti D (2008) Arc-jet testing on HfB2 and HfC-based ultra-high temperature ceramic materials. J Eur Ceram Soc 28:1899–1907

Li SP, Li KZ, Du HY, Zhang SY, Sheng XT (2012) Effect of hafnium carbide content on the ablative performance of carbon/carbon composites as rocket throats. Carbon 51:437–438

Zhao D, Zhang C, Hu H, Zhang Y (2011) Preparation and characterization of three-dimensional carbon fiber reinforced zirconium carbide composite by precursor infiltration and pyrolysis process. Ceram Int 37:2089–2093

Padmavathi N, Kumari S, Bhanu Prasad VV, Subrahmanyam J, Ray KK (2009) Processing of carbon-fiber reinforced (SiC+ZrC) mini-composites by soft solution approach and their characterization. Ceram Int 35:3447–3454

Shen XT, Li KZ, Li HJ, Fu QG, Li SP, Deng F (2011) The effect of zirconium carbide on ablation of carbon/carbon composites under an oxyacetylene flame. Corros Sci 53:105–112

Krenkel W (2001) Cost effective processing of composites by melt infiltration (LSI Process). Ceram Eng Sci Proc 22:443–454

Zou L, Wali N, Yang JM, Bansal NP (2010) Microstructural development of a Cf/ZrC composite manufactured by reactive melt infiltration. J Eur Ceram Soc 30:1527–1535

Wang Y, Zhu X, Zhang L, Cheng L (2011) Reaction kinetics and ablation properties of C/C–ZrC composites fabricated by reactive melt infiltration. Ceram Int 37:1277–1283

Chen SA, Zhang CR, Zhang YD, Hu HF (2014) Influence of pyrocarbon amount in C/C preform on the microstructure and properties of C/ZrC composites prepared via reactive melt infiltration. Mater Design 58:570–576

Zeng Y, Xiong X, Li GD, Chen ZK, Sun W, Wang DN (2013) Microstructure and ablation behavior of carbon/carbon composites infiltrated with Zr–Ti. Carbon 54:300–309

Zhu Y, Wang S, Li W, Zhang S, Chen Z (2012) Preparation of carbon fiber-reinforced zirconium carbide matrix composites by reactive melt infiltration at relative low temperature. Scr Mater 67:822–825

Tong YG, Hu YL, Liang XB, Zhang ZB, Li Y, Chen ZK, Xiong X, Hua MY (2020) Carbon fiber reinforced ZrC based ultra-high temperature ceramic matrix composite subjected to laser ablation: ablation resistance, microstructure and damage mechanism. Ceram Int 46:14408–14415

Adelsberg LM, Cadoff LH, Tobin JM (1966) Kinetics of the zirconium-carbon reaction at temperatures above 2000 ℃. Metall Mater Trans 236973–236977

Funding

The authors were financially supported by the Natural Science Foundation of China (Nos. 52005053, 11902333, and 51805539) and Natural Science Foundation of Hunan Province of China (Nos. 2019JJ50657 and 2018JJ2426).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Liang, X., Hu, Y. et al. Correlation of C/C preform density and microstructure and mechanical properties of C/C-ZrC-based ultra-high-temperature ceramic matrix composites. Adv Compos Hybrid Mater 4, 743–750 (2021). https://doi.org/10.1007/s42114-021-00295-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00295-0