Abstract

Nucleosides modification via conventional cross-coupling has been performed using different catalytic systems and found to take place via long reaction times. However, since the pandemic, nucleoside-based antivirals and vaccines have received widespread attention and the requirement for rapid modification and synthesis of these moieties has become a major objective for researchers. To address this challenge, we describe the development of a rapid flow-based cross-coupling synthesis protocol for a variety of C5-pyrimidine substituted nucleosides. The protocol allows for facile access to multiple nucleoside analogues in very good yields in a few minutes compared to conventional batch chemistry. To highlight the utility of our approach, the synthesis of an anti-HSV drug, BVDU was also achieved in an efficient manner using our new protocol.

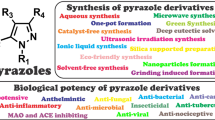

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nucleosides are privileged structural motifs with a wide array of biological activity, that has led to significant investment in their syntheses over the past few decades. The current Covid-19 pandemic and the potential of nucleosides as therapeutics have further enhanced their appeal [1, 2]. The presence of nucleoside scaffolds in a variety of antiviral and anticancer drugs such as acyclovir, remdesivir, penciclovir, emtricitabine and clofarabine has contributed greatly towards the rapid developments taking place in this field (Fig. 1a, b) [3]. Functionalization of the nucleoside base also provides access to useful biological probes that could exhibit enhanced fluorescent properties than the parent nucleosides (Fig. 1c) [4].

The introduction of aromatic or heteroaromatic functionalities on the nucleosides (that help enhance the fluorescent properties) via metal-catalyzed cross-coupling reactions [5, 6] (especially palladium-catalyzed Suzuki-Miyaura coupling) has been extensively explored [7, 8]. Contributions by the research groups of Len [9,10,11,12], Shaughnessy [13,14,15,16], Lakshman [17,18,19,20,21,22] and many others [18,19,20,21,22] are acknowledged for their advances in the area of nucleoside modification. We have also been active in the development of several catalytic systems (palladium-based) allowing efficient cross-coupling [23,24,25,26,27,28,29,30]. Starting with [Pd(imidate)2(PTA)2] [31,32,33] allowing the Suzuki-Miyaura cross-coupling of all four nucleosides, PTABS (KapdiPhos) [34,35,36,37,38,39,40,41,42,43,44,45] in combination with Pd(II) precursor allowing the isolation via column-free procedure (as well as catalyst recyclability), SerrKap palladacycle [46, 47] as a phosphine-free catalyst and recently, [Pd(sacc)2(THPEN)] [48] another example of water-soluble phosphine-free catalyst promoting the coupling to take place at ambient temperature (Scheme 1).

Despite the tremendous developments that have taken place in this area of research, most catalytic processes are time consuming (conventional flask conditions) and are plagued with the formation of unwanted by-products (hydrodehalogenation of the halonucleosides), which leads to lower product yields. Purification procedures for the isolation of the desired product involve the employment of large amounts of solvent and silica [49].

To overcome these limitations, we herein report the expedient synthesis of C5 modified 2’-deoxyuridine (or cytidine) analogues using a plugged flow reactor bringing about a significant reduction in the reaction time as well as the usage of the solvent with the isolation of the product via a column-free protocol. With the whole procedure performed under non-inert conditions (without N2 gas), the flow catalytic protocol provides a definite advantage over conventional conditions requiring a rigorous inert atmosphere. The scale-up potential of our approach was also demonstrated on a multigram synthesis of an antiviral nucleoside.

Results and discussion

Palladium-catalyzed Suzuki-Miyaura cross-couplings have been an essential tool for the synthesis of many functionalised molecules including modified nucleoside analogues [50]. The ease of employing and handling of the boronic acids as well as the ready availability of these reagents makes Suzuki-Miyaura couplings a preferred protocol. Several catalytic systems have been developed over the years for the functionalization of nucleosides in a variety of solvents and in many cases a single catalytic system wasn’t available for transformation of all 4 natural nucleosides [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45]. This problem was overcome by our group through the development of catalytic systems that were able to functionalize all 4 nucleosides efficiently (see Scheme 1). Performing the catalytic reactions in reaction vessels (Schlenck tubes or round bottom flasks) is a common practice but often fails at higher concentrations making the scale-up difficult [51]. The catalytic processes may require product isolation via column chromatographic purification involving large quantities of volatile organic solvents. Therefore, process improvements for more efficient cross-coupling are warranted.

Flow chemistry [52,53,54,55,56] involving the employment of continuous-flow reactors in the past decade has proven to be a powerful alternative to batch reactor systems to increase both yields and selectivity [57] in chemical reactions. This technological advancement has proven to be advantageous as it allows reactions to be performed under safe working conditions [58, 59] (hazardous and reactive substrates can also be handled safely) [60, 61], as well as shortening the process time compared to the batch process. Furthermore, automation of parameters such as temperature and pressure can help with reproducibility in continuous flow reactors compared to classical batch techniques [62, 63]. Research groups of Ley [64,65,66], Kappe [67,68,69], Noel [70,71,72] have made significant contributions to the microreactor flow technology for synthesis. More recently, the Hilton group has been using microreactor flow technology [73,74,75] popular with both chemical and process engineers [76, 77].

For the development of an expeditious catalytic process for nucleoside modification, we, therefore, decided to employ the above-mentioned flow methodology. The following set-up was used for performing the screening as well as the scope for the Suzuki-Miyaura cross-coupling of 5-iodo-2’-deoxyuridine (I-dU) or 5-iodo-2’-deoxycyidine (I-dC) with heteroarylboronic acids using SerrKap Palladacycle catalyst in H2O:EtOH solvent system (Fig. 2).

The correct choice of solvent was necessary to maintain the homogeneity of the reaction mixture as any solid particle formation during the reaction could be detrimental to the flow system leading to channel blockage. The use of H2O:EtOH (2:1) as a solvent system allowed the catalytic transformation between I-dU (1a) and 3-methoxyphenyl boronic acid (2a) with SerrKap palladacycle in the conventional Schlenck conditions under inert N2 atmosphere without any solid formation and was therefore applicable to continuous flow as the catalytic solution was observed to be completely homogeneous throughout the reaction. The product 3a was isolated (84%) upon column chromatography. A small amount of hydro-dehalogenated starting material (3a’, 10%) was also obtained (Scheme 2). We also performed a similar reaction at 60 °C for 30 minutes under air (rather than an inert N2 atmosphere) to check the effect of the conditions on the reaction performed Schlenck conditions. The reaction was found to lead to product formation, but only 15% product was formed along with trace amounts of deiodinated starting material and the remaining material was determined to be 5-iodo-2’-deoxyuridine, suggesting the reduction in catalytic activity of the SerrKap palladacycle under the given conditions.

We envisaged that flow chemistry may speed-up the reaction time and thus avoid the formation of undesired 3a’ which had proven difficult to separate. First, the internal reactor volume was estimated by injecting a dilute solution of KMnO4 (0.1 M) into the flow system. Passing the solution at a rate of 1.0 mL/min provided an overall internal reactor volume of 17.5 mL using 4 circular disk reactors (shown in Fig. 2).

Second, the screening of various catalytic conditions for the Suzuki-Miyaura cross-coupling of I-dU with 3-methoxyphenyl boronic acid indicated SerrKap to be the best choice of catalyst. For the flow set-up, I-dU, SerrKap palladacycle and base (K3PO4) were dissolved in H2O:EtOH (3:2) and pumped via injector 1, while injector 2 was used for 3-methoxyphenyl boronic acid in H2O:EtOH (3:2). The temperature of the reactor block was maintained at 60 °C (improved solubility of the substrate observed at 60 °C). Both solutions were pumped using an air-pump without the use of nitrogen gas.

The flow-reaction was tested first at 0.5 mol% of SerrKap palladacycle at a flow rate of 0.7 mL/min (9–10 kPa) for 25 minutes providing only 20% product (Entry 1, Table 1). An increase in the catalyst concentration to 1.0 mol% brought about a slight increase in yield (35%, Entry 2, Table 1). The impact of reagent concentration was next explored as a more diluted reaction mixture (8 mL as compared to 6 mL in the previous two entries of H2O:EtOH solvent mixture) provided further increases in the product formation (45%, Entry 3, Table 1). Increasing the solvent volume to 12 mL further improved the reactivity (65%, Entry 4, Table 1). Next, to assess the effect of solvent flow rate by varying the pressure, it was increased from 9 to 10 kPa (0.7 mL/min) in the previous entries to 15–16 kPa (1.0 mL/min) for Entry 5. However, lower yield (52%) prompted us to further optimize the reaction dilution (15 mL) resulting in higher yield of 86% (Entry 6, Table 1). Encouraged by the improvement in yield, we increased the flow rate (2 mL/min) to reduce the overall reaction time. Although the yield of the desired product did not appreciably improve, reduction in the total reaction time was achieved (Entry 7, Table 1). Attempts to reduce catalyst concentration impacted the reactivity adversely. Therefore, it was best to continue further optimization of the reaction with 1.0 mol% of SerrKap palladacycle (Entries 8–9, Table 1). The replacement of inorganic base K3PO4 with another base K2CO3 or organic base Et3N or DBU brought about reduction in the product yield (Entries 10–12, Table 1). All the previous reactions were performed using 1.6 equiv. of 3-methoxyphenyl boronic acid with respect to the starting I-dU. It was observed that the reduction in the amount of the boronic acid to 1.3 equiv. did not affect the catalytic efficiency, but any further reduction (1.2 eq.) led to a lower yield of the product (Entries 13–16, Table 1). Base concentration (K3PO4) was found to affect the catalytic reactivity positively with 1.05 eq. providing higher product yield (95%, Entry 18, Table 1).

Under the fully optimized catalytic conditions with 1.0 mol% SerrKap palladacycle, at a flow rate of 2.0 mL/min (pressure of 35–36 kPa), 60 °C reaction temperature, reaction of I-dU with 3-methoxyphenyl boronic acid (1.3 eq.) and K3PO4 (1.05 eq.) as the base proceeded in less than 9 minutes in 95% yield. Compared to the same reaction performed in a reaction flask, it required 3.0 hrs under nitrogen atmosphere and column chromatographic purification for the isolation of the cross-coupled product (due to the presence of the dehalogenated byproduct). The flow chemistry protocol saved time and obviated the need for an inert nitrogen atmosphere. Significantly shorter reaction time enabled reduction (undetectable) of dehalogenated product in all the performed reactions. The separation of product was simplified from the trace amount of starting material by washing with water.

To further demonstrate the utility of this protocol, additional examples of arylboronic acids were tested as coupling partners. 4-Thiomethylphenylboronic acid (2b), 3,5-dimethylphenyl boronic acid (2c) 4-fluorophenylboronic acid (2d) and 3-methylphenylboronic acid (2e) were evaluated as the nucleophilic coupling partners furnishing the products in good (73–82%) yield (3b-e, Scheme 3). Good yields were also observed for 4-methoxyphenylboronic acid (2 g), 4-biphenyl boronic acid (2 h), 3-benzofuranyl boronic acid (2i) and 2-naphthylboronic acid (2j) (3f-j, Scheme 3). Given the short reaction time, this protocol may find utility in generating a library of compounds for rapid SAR study.

Like uridine, C5 derivatives of cytidine have also found applications as possible fluorescent or bioprobes [78,79,80] by the introduction of aromatic functionalities. Suzuki-Miyaura cross-coupling methodology [81] has proven to be the most applicable in this endeavour. A typical catalytic protocol for the coupling of 5-iodo-2’-deoxycytidine (I-dC) with arlyboronic acid proceeds with relatively lower reactivity compared to its uridine counterpart partly due to the more electron-rich nature of the heterocyclic ring that resists the attack of the nucleophile as a part of the catalytic coupling pathway. We have in recent years demonstrated the capability of several of our catalytic systems to efficiently couple I-dC with different arylboronic acids [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48]. However, the reaction has been relatively slower than uridine coupling processes (up to 24 hrs). Below, we have demonstrated one such Suzuki-Miyaura cross-coupling of I-dC (1b) with 3-methoxyphenylboronic acid (2a) with SerrKap palladacycle [34,35,36,37,38,39,40,41,42,43,44,45] (1.0 mol%) in a H2O:EtOH solvent system under an inert nitrogen atmosphere at 60 °C. Although good reactivity was observed under the conditions, the reaction takes 24 hrs to provide 76% of the coupled product (4a) with 14% of the dehalogenated product 4a’(Scheme 4). Isolation of the product 4a required column chromatography. Longer reaction times compounded by lower reactivity of the cytidine substrate leads to higher amount of 4a’. This could be avoided if speed of the reaction is enhanced as demonstrated with the uridine examples. We also performed a similar reaction at 60 °C for 30 minutes under air (rather than inert N2 atmosphere) to check the effect of the conditions on the reaction performed Schlenck conditions. No product formation was observed when the reaction was performed for only 30 minutes, which provides an impetus for the employment of flow chemistry methodology to expedite the catalytic reaction via higher molecular interactions.

To investigate the feasibility of coupling I-dC with 3-methoxyphenyl boronic acid, reaction screening studies were conducted. After a thorough investigation that would promote the coupling to proceed in a relatively faster reaction time, not requiring the use of inert nitrogen atmosphere and avoiding chromatographic isolation of the product, the optimum conditions were obtained with 1.0 mol% SerrKap catalyst at a flow rate of 0.6 mL/min (H2O:EtOH, 12 + 8 mL) and pressure of 8–9 kPa, which provided best yield of 90% in 29 minutes (Table 2). The application of flow catalytic conditions has once again improved the reactivity and drastically reduced the reaction time and allowed the reaction to be conducted in air rather than maintaining inert conditions.

The coupling of I-dC with different arylboronic acids was next explored. Rapid conversion of the starting material was observed in all cases with most substrates converting efficiently to the respective coupled products in good to excellent yields irrespective of the substituents on the arylboronic acid moiety or the nucleophilicity of the reagents utilized (Scheme 5). Electron-donating substituents such as MeO, MeS, Me or naphthyl reacted well, while 4-fluorophenyl boronic acid also provided comparable yield of the desired cross-coupled product. Isolation of the products in all the cases was done via a column-free technique, which also sets the stage for performing the flow catalytic reaction in a continuous manner to demonstrate the potential for possible commercial scale-up.

Rapid synthesis of modified nucleoside analogues is synthetically useful and certainly opens an opportunity to extensively apply flow chemistry-based catalytic methodologies [82] not only for the synthesis of coupled products (as mentioned in this report) but also performing rapid multistep synthetic strategies for a variety of nucleoside-based commercially relevant drugs [83]. nContributions from Jamiso [84] and Watts [85, 86] laboratories need special mention for the development of several flow chemistry-based scale-up protocols for bio-active nucleosides. Inspired by this effort, we further envisaged performing gram scale synthesis of 3 k via semi-continuous flow methodology by injecting the reaction solutions multiple times and isolating the cross-coupled product at the end.

The same IKA Flow set-up was used for the scale-up study. Conditions such as the catalyst concentration, flow rate or the pressure used for carrying out the reaction were kept the same but multiple injections (18 times) with a slightly increased concentration of the substrates were injected. Each run required 8 minutes 35 seconds with a collection time of 5 minutes 20 seconds between each run to make sure the reaction mixture from the previous run is completely eluted. After a semi-continuous run of 2 hrs and 42 minutes, the reaction mass collected (180 mL) was further processed for the column-free isolation of the coupled product giving a combined yield of 1.67 g. Based on the concentration of starting material utilized, an overall yield of 79% was obtained (see SI material for details) (Table 3).

Suzuki-Miyaura cross-coupling of nucleosides has certainly been utilized extensively for the base modification. Whereas, Heck alkenylation reaction allowing the introduction of alkenyl functionality on the base part of the nucleosides is yet another useful transformation [87]. Being one of the key steps in the synthesis of the potent anti-Herpes simplex virus drug, (E)-5-(2-bromovinyl)-2’-deoxyuridine (BVDU or brivudine) [88, 89] as well as the ‘Ruth linker’[90]-(a C5 pyrimidine nucleoside analogue used commonly for the introduction of a reactive amine functionality into oligonucleotide sequences), the Heck reaction does present scientists with an opportunity to incorporate various functionalities with ease and provide straightforward access to many functional molecules [91, 92].

In comparison to the Suzuki-Miyaura cross-couplings, Heck reactions are relatively slower and require longer reaction times, higher catalyst loading as well as inert conditions to avoid deactivation of the catalyst. Introduction of the developed flow catalytic protocol (see Vide Infra) would most certainly help overcome these challenges. Isolation of the product using column-free method would also make this protocol more sustainable. Before proceeding with the employment of flow reactor for expediting the catalytic process, it was necessary to perform a typical Heck reaction in a flask containing I-dU (1a) and styrene (5a) with SerrKap palladacycle and K3PO4 as the base in a EtOH:H2O (1:1) system under an inert N2 atmosphere (to avoid any precipitation of the product). Reaction was followed by TLC for completion and after 15 hours the product was isolated by column chromatographic purification to obtain 90% isolated yield. Absence of any hydrodehalogenated product was a major positive point but the time taken for the process to be completed is a cause of concern as well as the necessity of inert atmosphere. We also performed a similar reaction at 80 °C for 30 minutes under air (rather than inert N2 atmosphere) to check the effect of the conditions on the reaction performed under Schlenck conditions. No product formation was observed when the reaction was performed for only 30 minutes (Scheme 6 and 7).

To address these issues, Heck alkenylation was next performed using the flow reactor to achieve rapid synthesis of useful analogues of uridine nucleoside. Injector 1 contained a solution of I-dU, SerrKap palladacycle (1.0 mol%) and base in H2O:EtOH (1:2), while injector 2 consisted of a solution containing styrene in H2O:EtOH (1:2). The flow reactor was pressurised using an air pump and, therefore, an inert N2 atmosphere requirement was not necessary. The conditions used to optimize the catalytic reaction varying the parameters such as concentration, pressure, base as well as the temperature are summarized in Table 4. The best conditions are shown in Entry 17 (Table 4) allowing the conversion of I-dU to be quantitative in 29 minutes at a rate of 0.6 mL/min. Compared to the conventional flask chemistry process, the flow protocol works at a much faster rate without the requirement of an inert atmosphere making it a more practical protocol and provides an opportunity to extensively apply the same for other nucleoside modifications.

The completion of Heck alkenylation under an hour is an exciting prospect, which prompted us to test few other substrates (substituted styrenes) to further validate the methodology. Substituted styrenes such as 4-methylstyrene and 4-bromostyrene were coupled with I-dU using the developed flow protocol in a H2O:EtOH solvent system. With excellent yields obtained for both the substrates, flow chemistry application to nucleoside modification certainly has major benefits and warrants further exploration of this platform.

Successfully converting flask chemistry (Suzuki or Heck reactions of nucleosides) into a flow protocol requires a lot of careful planning and analysis of conditions for obtaining the desired outcome. All the reactions undertaken till now were single step catalytic processes with isolation of the product via simple filtration rather than column chromatographic purification. We, therefore, decided to explore the possibility of applying the developed protocol to the synthesis of an antiviral drugs, Brivudine (BVDU). BVDU is an important antiviral drug used for the treatment of Herpes Simplex virus (HSV) and commonly prepared in 3 steps as per the literature reports (research groups of Len [87], Kapdi [92]). Synthesis of BVDU initiates with the Heck alkenylation of I-dU with methyl acrylate followed by the hydrolysis of the ester to acid (carboxyvinyl uridine, CVU) and finally NBS promoted decarboxylative bromination (see SI material). Several challenges are associated with this protocol such as: purification (for 2 out of the 3 steps) using column chromatography leading to an enormous amount of solvent usage, requirement of inert atmosphere and with the whole process taking ~2 days for execution (~70% overall yield) making it industrially unattractive (Scheme 8).

Intervention of flow chemistry to tackle the above problem certainly is an attractive alternative to the flask reaction. However, we identified that along with the employment of flow chemistry, all the steps could be performed simultaneously without performing purification procedures for each step as was done in the previous reports. This would help reduce the solvent usage drastically and the final isolation of BVDU (end of the 3rd step) could be performed without the employment of column chromatography. Such a strategy would also certainly reduce the time required for the synthesis as well as boost the overall yield of the desired product.

Scheme 9 details the strategy employed for BVDU synthesis that initiates with the Heck alkenylation of I-dU with methyl acrylate using SerrKap palladacycle (1.0 mol%), K3PO4 (1.2 equiv.) in H2O:EtOH (1:1) solvent system at 80 °C. Previously developed flow reaction conditions were employed by maintaining the pressure at 8–9 kPa using an air-pump and a rate of 0.6 mL/min to provide complete conversion of the cross-coupled product in 29 minutes. This certainly is a major advancement compared to the reaction times reported in the literature (8–10 hrs) as well as the mild reaction conditions employed. The reaction mixture thus obtained was subsequently carried forward without the isolation of the intermediate (Heck reaction coupled product). The second step of the reaction scheme involves the base-catalyzed hydrolysis of the coupled acrylate ester to the corresponding acid using NaOH as the base in H2O:EtOH solvent system at 15–16 kPa and a rate of 1.0 mL/min. Ester hydrolysis is an extremely rapid reaction either under flask conditions or flow. The step I catalytic mixture when subjected to the basic hydrolysis conditions provided complete conversion of the ester to the corresponding acid (flask condition: 3 hrs; plugged flow: 17 mins 30 sec).

The final step of the reaction sequence is an important one involving the base-mediated decarboxylation followed by bromination using N-bromosuccinimide (NBS) as the bromine source. A flask reaction was initially performed by carrying forward the reaction solution obtained after step II with the addition of K2CO3 as the base and NBS for bromination. It was observed that within 15 minutes of addition of all the reagents, a white coloured solid started precipitating out of the reaction mixture. Analysis of the precipitated solid revealed it to be the desired product BVDU. The reaction mixture was allowed to stir for 30 minutes, and the solution was filtered to obtain BVDU as a white solid after washing with water and EtOH. This simple procedure provided analytically pure BVDU in 86% yield in an overall reaction time not exceeding 3 hours (compared to 2 days for the conventional reaction conditions reported in literature) and saving large amounts of solvents and making the process practical and easy for scale-up (Scheme 9).

Conclusion

Modification of natural nucleosides using conventional catalytic processes has several limitations and are not suitable for the development of rapid synthetic transformations. Herein, we have been able to successfully overcome several problems such as: a) reduction in by-products, b) dramatic reduction in the reaction time, c) column-free isolation of products for the modification of I-dU and I-dC via Suzuki-Miyaura and Heck coupling reactions with an IKA plugged-flow reactor. The developed methodology was further tested for the synthesis of a commercially useful antiviral drug, Brivudine (BVDU) introducing plugged flow reactor for the first two processes followed by the conventional synthetic step, but all done in a one-pot procedure without the isolation of intermediates and still obtaining >85% isolated yield of the analytically pure product. To the best of our knowledge, this work is the first example of flow chemistry utilizing the affordable bench-top IKA reactor. Looking ahead, these advances in flow system will embed catalysis as a green sustainable, cost-effective method for the manufacturing of nucleoside-based drug molecules.

Experimental section

General procedure for Suzuki Miyaura cross-coupling of 5-iodo-2’-deoxyuridine 1a and (hetero)aryl boronic acid R

A Fresh solution of 5-iodo-2’-deoxyuridine 1a (177 mg, 0.5 mmol), SerrKap palladacycle (4.5 mg 1 mol%), and Anhydrous potassium phosphate (111 mg, 0.525 mmol, 1.05 eq) in 7.5 ml water: Ethanol (2:1) injection loop A (loop volume ≈ 7.5 ml) and A Fresh solution of (Hetero)aryl boronic acid R (0.65 mmol, 1.3 eq) in 7.5 ml water: Ethanol (2:1) injection loop B (loop volume ≈ 7.5 ml), were injected through the 3D printed Circular Disk reactors (CDRs) at 60 °C (Flow rate ≈ 2.0 mL/min, pressure ≈ 35–36 kPa) with a residence time of (8 min 45 sec) (4 CDRs) to give the product 3a-j. The resulting solution was concentrated under reduced pressure to get insoluble precipitated on cooling which was further washed out by 2 × 5 ml n-hexane and 2 × 5 ml cold ethanol and recrystallized the product in water: ethanol (1.1) to give the desired cross-coupled product 3a-j solids.

General procedure for Suzuki Miyaura cross-coupling of 5-iodo-2’-deoxycytidine 1b and (hetero)aryl boronic acid R

A Fresh solution of 5-iodo-2’-deoxycytidine 1b (177 mg, 0.5 mmol), SerrKap palladacycle (4.5 mg 1 mol%), and Anhydrous potassium phosphate (111 mg, 0.525 mmol, 1.05 eq) in 10 ml water: Ethanol (3:2) injection loop A (loop volume ≈ 10 ml) and A Fresh solution of (Hetero)aryl boronic acid R (0.65 mmol, 1.3 eq) in 10 ml water: Ethanol (3:2) injection loop B (loop volume ≈ 10 ml), were injected through the 3D printed Circular Disk reactors (CDRs) at 60 °C (Flow rate ≈ 0.6 ml/min, pressure ≈ 8–9 kPa) with a residence time of (29 min) (4 CDRs) to give the product 4a-j. The resulting solution was concentrated under reduced pressure to get insoluble precipitated on cooling which was further washed out by 2 × 5 ml n-hexane and 2 × 5 ml cold ethanol and recrystallized the product in ethanol-water (1:1) to give the desired cross-coupled product 4a-j solids.

General procedure for heck alkenylation of 5-iodo-2’-deoxyuridine1a with styrene 5a-c

A Fresh solution of 5-iodo-2’-deoxyuridine 1a (177 mg, 0.5 mmol), SerrKap palladacycle (4.5 mg 1 mol%), and Anhydrous potassium phosphate (111 mg, 0.525 mmol, 1.05 eq) in 7.5 ml water: Ethanol (1:2) injection loop A (loop volume≈7.5 ml) and A Fresh solution of styrene 5a-c (0.85 mmol, 1.7 eq) in 7.5 ml water: Ethanol (1:2) injection loop B (loop volume≈ 7.5 ml), were injected through the 3D printed Circular Disk reactors (CDRs) at 80 °C (Flow rate ≈ 0.6 ml/min, pressure ≈ 8–9 kPa) with a residence time of (29 min) (4 CDRs) to give the addition product 6a-c. The resulting solution was concentrated under reduced pressure to get insoluble precipitated on cooling which was further washed out by 2 × 5 ml n-hexane and 2 × 5 ml cold chloroform and recrystallized the product in ethanol-water (1:1) to give the desired cross-coupled product 6a-c solids.

Multi-gram scale-up of Suzuki-Miyaura cross-coupling of 5-iodo-2-deoxyuridine with 2-benzofuranyl boronic acid using SerrKappalldacycle under semi-continuous flow conditions.

A Fresh solution of 5-iodo-2’-deoxyuridine 1a (354 mg, 1 mmol), SerrKap palladacycle (9 mg 1 mol%), and Anhydrous potassium phosphate (222 mg, 1.05 mmol, 1.05 eq) in 15 ml water: Ethanol (2:1) was prepared and A Fresh solution of 2-benzofuranyl boronic acid 2 k (1.3 mmol, 1.3 eq, 0.086 M) in 15 ml water: Ethanol (2:1) was prepared. Each 5 ml solution was injected through injection loop A (loop volume ≈ 5 ml) and injection loop B (loop volume ≈ 5 ml) respectively, were injected through the 3D printed Circular Disk reactors (CDRs) at 60 °C (Flow rate ≈ 2.0 mL/min, pressure ≈ 35–36 kPa) with a residence time of (8 min 45 sec) (4 CDRs) to give the product 3 k. The resulting solution was collected in a test tube and the experiment was repeated several times as shown in Table 3 to get the desired product. The resulting solution was concentrated under reduced pressure to get insoluble precipitated on cooling which was further washed out by 2 × 50 ml n-hexane and 2 × 50 ml cold ethanol and recrystallized the product in water: ethanol (1.1) to give the desired cross-coupled product 3 k solids.

BVDU synthesis using a combination of plugged flow and batch reaction conditions

A Fresh solution of 5-iodo-2’-deoxyuridine 1a (177 mg, 0.5 mmol), SerrKap palladacycle (4.5 mg 1 mol%), and Anhydrous potassium phosphate (111 mg, 0.525 mmol, 1.05 eq) in 7.5 ml water: Ethanol (1:2) injection loop A (loop volume ≈ 7.5 ml) and A Fresh solution of methyl acrylate 5d (77 ul, 0.85 mmol, 1.7 eq) in 7.5 ml water: Ethanol (1:2) injection loop B (loop volume ≈ 7.5 ml), were injected through the 3D printed Circular Disk reactors (CDRs) at 80 °C (Flow rate ≈ 0.6 ml/min, pressure ≈ 8–9 kPa) with a residence time of (29 min) (4 CDRs) to give the product 6d. The resulting 15 ml solution was collected and used for the next step without any purification. Solution of 6d 3 ml in injection loop A (loop volume ≈ 3 ml) and 3 ml of 1 M NaOH solution in injection loop B (loop volume ≈ 3 ml) were injected through the 3D printed Circular Disk reactors (CDRs) at 30 °C (Flow rate ≈ 1 ml/min, pressure ≈ 15–16 kPa) with a residence time of (17.5 min) (4 CDRs) to give the 6 ml solution which was stirred in a flask for 5 min. The second step was repeated 5 times to get the total resulting 30 ml solution of product. This resulting solution was adjusted to pH 4–6 with dropwise addition of 1 M HCl 7. Then in the resulting solution of 7, N-bromosuccinimide (89 mg, 0.5 mmol, 1 eq), Anhydrous potassium phosphate (212 mg, 1 mmol, 2 eq) was added and stirred at room temperature for 20 min. Observed Milky white precipitate was washed out with 2 × 5 ml cold ethanol and then 2 × 5 ml water to obtain BVDU 8 as a white solid (143 mg 86 %).

Spectral analysis of the synthesized compounds have been submitted in the Supporting Information.

References

Galmarini CM, Mackey JR, Dumontet C (2002) Nucleoside analogues and nucleobases in cancer treatment. Lancet Oncol 3:415–424

Pruijssers AJ, Denison MR (2019) Nucleoside analogues for the treatment of coronavirus infection. Curr Opin Virol 35:57–62

de Clercq E (1981) Nucleoside analogues as antiviral agents. Acta Microbiol Acad Sci Hung 28:289–306

Tanpure AA, Pawar MG, Srivatsan SG (2013) Fluorescent nucleoside analogs: Probes for investigating Nucleic acid structure and function. Isr J Chem 53:366–378

Kapdi AR, Maiti D, Sanghvi YS (2018) Palladium-catalyzed modification of nucleosides, nucleotides and oligonucleotides. Elsevier, New York

Herve G, Len C (2015) Aqueous microwave-assisted cross-coupling reactions applied to unprotected nucleosides. Front Chem 3:1–3

Gayakhe V, Bhilare S, Yashmeen A, Fairlamb IJS, Kapdi AR (2018) In: Kapdi AR, Maiti D, Sanghvi YS (eds) Palladium-catalyzed modification of nucleosides, nucleotides and oligonucleotides. Elsevier, New York

Herve G, Len C (2015) Heck and Sonogashira couplings in aqueous media application to unprotected nucleosides and nucleotides. Sustain Chem Process 3:1–14

Len C, Enderlin G (2015) Synthesis of C-aryl nucleoside analogues. Molecules 20:4967–4997

Hervé G, Len C (2014) First ligand-free, microwaves-assisted, Heck cross-coupling reaction in sole water on nucleoside - Application to the synthesis of antiviral BVDU. RSC Adv 4:46926–46929

Enderlin G, Sartori G, Hervé G, Len C (2013) Synthesis of 6-aryluridines via Suzuki-Miyaura cross-coupling reaction at room temperature under aerobic ligand-free conditions in neat water. Tetrahedron Lett 54:3374–3377

Gallagher-Duval S, Hervé G, Sartori G, Enderlin G, Len C Improved microwave-assisted ligand-free Suzuki-Miyaura cross-coupling of 5-iodo-2’-deoxyuridine in pure water. New J Chem 37:1989–1995

Shaughnessy KH (2009) Hydrophilic ligands and their applications in aqueous-phase metal-catalyzed reactions. Chem Rev 109:643–710

Shaughnessy K (2018) In: Kapdi AR, Maiti D, Sanghvi YS (eds) Palladium-catalyzed modification of nucleosides, nucleotides and oligonucleotides. Elsevier, New York

Shaughnessy KH (2022) Covalent modification of nucleobases using water-soluble palladium catalysts. Chem Rec 22:e202200190

Shaughnessy KH (2015) Palladium-catalyzed modification of unprotected nucleosides, nucleotides and oligonucleotides. Molecules 20:9419–9454

Lakshman MK (2005) Synthesis of biologically important nucleoside analogs by palladium-catalyzed C-N bond formation. Curr Org Synth 2:83–112

Nair V, Turner GA, Chamberlain SD (1987) Novel approaches to functionalized nucleosides via palladium-catalyzed cross-coupling with organostannanes. J Am Chem Soc 109:7223–7224

Fresnau N, Hiebel M-A, Agrofoglio L, Berteina-Rabouin S (2012) Efficient synthesis of unprotected C-5-aryl/heteroaryl-2-deoxyuridine via a Suzuki-Miyaura reaction in aqueous media. Molecules 17:14409–14417

Polak P, Cossy J (2022) Ni-catalyzed cross-coupling of 2-iodoglycals and 2-iodoribals with Grignard reagent: A route to 2-C-glycosides and 2'-C-nucleosides. Chem Eur J 28:e202104311

Maverick MA, Gaillard M, Vasseur J-J, Debart F, Smietana M (2022) Direct access to unique C-5-acyl modified nucleosides through Liebeskind-Srogl cross-coupling reaction. Eur J Org Chem 2022:e202101061

Wei Y, Lam J, Diao T (2021) Synthesis of C-acyl furanosides via the cross-coupling of glycosyl esters with carboxylic acids. Chem Sci 12:11414–11419

Serrano JL, García L, Pérez J, Pérez E, Galiana JM, García J, Martínez M, Sánchez G, da Silva I (2011) New cyclometallated precursors of unsubstituted N-phenylpyrazole [{Pd(phpz)(μ-X)}2] (X = AcO or OH) and study of their reactivity towards selected ligands. Dalton Trans 40:156–168

Sánchez G, García J, Meseguer D, Serrano JL, García L, Pérez J, López G (2003) Synthesis and characterisation of cyclometallated palladium(II) complexes with phosphine-carboxylate and phosphine-amide ligands. Dalton Trans:4709–4717

Fairlamb IJS, Taylor RJK, Serrano JL, Sanchez G (2006) Halide and pseudohalide effects in Pd-catalyzed cross-coupling reactions. New J Chem 30:1695–1704

Serrano JL, Fairlamb IJS, Sánchez G, García L, Pérez J, Vives J, López G, Crawforth CM, Taylor RJK (2004) Palladacyclopentadiene complexes with mono- and didentate imidato ligands: synthesis, hemilabile behaviour and catalytic application in the Stille reaction. Eur J Inorg Chem:2706–2715

Fairlamb IJS, Kapdi AR, Lee AF, Sánchez G, López G, Serrano JL, García L, Pérez J, Pérez E (2004) Mono- and binuclear cyclometallated palladium(II) complexes containing bridging (N,O-) and terminal (N-) imidate ligands: air stable, thermally robust and recyclable catalysts for cross-coupling processes. Dalton Trans:3970–3981

Crawforth CM, Fairlamb IJS, Kapdi AR, Serrano JL, Taylor RJK, Sánchez G (2006) Air-stable, phosphine-free anionic palladacyclopentadienyl catalysts: remarkable halide and pseudohalide effects in Stille coupling. Adv Synth Catal 348:405–412

Serrano JL, García L, Pérez J, Pérez E, García J, Sánchez G, Sehnal P, De Ornellas S, Williams TJ, Fairlamb IJS (2011) Synthesis and characterization of imine-palladacycles containing imidate “pseudohalide” ligands: efficient Suzuki–Miyaura cross-coupling precatalysts and their activation to give Pd0Ln species (L = Phosphine). Organometallics 30:5095–5109

Kapdi AR, Dhangar G, Serrano JL, Pérez J, García L, Fairlamb IJS (2014) [Pd(C∧N)(X)(PPh3)] palladacycles react with 2,4,6-trifluorophenyl boronic acid to give stable transmetallation products of the type [Pd(C∧N)(2,4,6-F3C6H2)(PPh3)]. Chem Commun 50:9859–9861

Kapdi AR, Gayakhe V, Sanghvi YS, García J, Lozano P, da Silva I, Pérez J, Serrano JL (2014) New water soluble Pd-imidate complexes as highly efficient catalysts for the synthesis of C5-arylated pyrimidine nucleosides. RSC Adv 4:17567–17572

Gayakhe V, Ardhapure AV, Kapdi AR, Sanghvi YS, Serrano JL (2016) Water-soluble Pd–imidate complexes: broadly applicable catalysts for the synthesis of chemically modified nucleosides via Pd-catalyzed cross-coupling. J Org Chem 81:2713–2729

Gayakhe V, Ardhapure AV, Kapdi AR, Sanghvi YS, Serrano JL, Schulzke C (2016) C-C bond formation: synthesis of C5 substituted pyrimidine and C8 substituted purine nucleosides using water soluble Pd-imidate complex. Curr Protoc Nucleic Acid Chem 65:1.37.1–1.37.15

Bhilare S, Gayakhe V, Ardhapure AV, Sanghvi YS, Schulzke C, Borozdina Y, Kapdi AR (2016) Novel water-soluble phosphatriazenes: versatile ligands for Suzuki–Miyaura, Sonogashira and Heck reactions of nucleosides. RSC Adv 6:83820–83830

Bhilare S, Bandaru S, Kapdi AR, Sanghvi YS, Schulzke C (2018) Pd/PTABS: An efficient water-soluble catalytic system for the amination of 6-chloropurine ribonucleoside and synthesis of alogliptin. Curr Protoc Nucleic Acids Chem 74:e58

Bhilare S, Muthry Bandaru S, Shah J, Chrysochos N, Schulzke C, Sanghvi YS, Kapdi AR (2018) Pd/PTABS: Low temperature etherification of chloroheteroarenes. J Org Chem 83:13088–13102

Murthy Bandaru S, Bhilare S, Chryosochos N, Gayakhe V, Trentin I, Schulzke C, Kapdi AR (2018) Pd/PTABS: catalyst for room temperature amination of heteroarenes. Org Lett 20:473–476

Murthy Bandaru S, Bhilare S, Cardozo J, Chrysochos N, Schulzke C, Sanghvi YS, Gunturu KC, Kapdi AR (2019) Pd/PTABS: low-temperature thioetherification of chloro(hetero)arenes. J Org Chem 84:8921–8940

Bhilare S, Shah J, Gaikwad V, Gupta G, Sanghvi YS, Bhanage BM, Kapdi AR (2019) Pd/PTABS: An efficient catalytic system for the aminocarbonylation of nucleosides. Synthesis 51:4239–4248

Shet H, Parmar U, Bhilare S, Kapdi AR (2021) A comprehensive review of the caged phosphines: Synthesis catalysis and future perspective. Org Chem Front 8:1599–1656

Shet H, Bhilare S, Sanghvi YS, Kapdi AR (2020) Development in the synthesis of efficient palladium catalysts for the modification of nucleosides, heteroarenes with commercial scalability. Molecules 25:1645

Bhilare S, Murthy Bandaru S, Schulzke C, Kapdi AR (2021) 1,3,5-Triaza-7-phosphaadamantane (PTA) derived caged phosphines for palladium-catalyzed selective functionalization of nucleosides and heteroarenes. Chem Rec 21:188–203

Parmar U, Somvanshi D, Kori S, Desai A, Dandela R, Maity DK, Kapdi AR (2021) Cu(II)/PTABS: Versatile Water-Soluble Recyclable Catalyst System for Pd-Free Room Temperature Amination of Chloroheteroarenes in Water. J Org Chem 86:8900–8925

Shet H, Patel M, Sanghvi YS, Waikar JM, More PM, Kapdi AR (2022) Room Temperature Dialkylamination of ChloroHeteroarenes Using Cu(II)/PTABS Catalytic System. Chem Asian J. https://doi.org/10.1002/asia.202201006

Kapdi AR, Sahu R (2022) PTABS: a unique water-soluble π-acceptor caged phosphine. Synlett. https://doi.org/10.1055/a-1988-1861

Serrano JL, Garcia L, Perez J, Lozano P, Correia J, Sanghvi YS, Kapdi AR (2020) Water-soluble imine-palladacycles as phosphine-free efficient precatalysts for low temperature Suzuki-Miyaura synthesis of nucleoside analogues. Organometallics 39:4479–4490

Kori S, Khandagale D, Sanghvi YS, Serrano JL, Lozano P, Kapdi AR (2022) Suzuki-Miyaura, Heck, and amidation of DMT-protected 5-iodo-2’-deoxyuridine via palladium-catalyzed reactions. Curr Protoc Nucleic Acid Chem. https://doi.org/10.1002/cpz1.502

Serrano JL, Pérez A, Pérez J, Lozano P, Gaware S, Kori S, Dandela R, Sanghvi YS, Kapdi AR (2022) Quadrol- Pd(II) complexes: phosphine-free precatalysts for the room-temperature Suzuki-Miyaura synthesis of nucleoside analogues in aqueous media. Dalton Trans 51:2370–2384

Thavornpradit S, Killough JM, Bergbreiter DE (2020) Minimizing solvent waste in catalytic reactions in highly recyclable hydrocarbon solvents. Org Biomol Chem 18:4248–4256

Biteau N, Hervin V, Roy V, Agrofoglio LA (2018) In: Kapdi AR, Maiti D, Sanghvi YS (eds) Palladium-catalyzed modification of nucleosides, nucleotides and oligonucleotides. Elsevier, New York

Bhilare S, Kori S, Shet H, Balaram G, Mahendar K, Sanghvi YS, Kapdi AR (2020) Scale-up of a Heck alkenylation reaction: Application to the synthesis of an amino-modified nucleoside “Ruth Linker”. Synthesis PSP 52:3595–3603

Gambacorta G, Sharley JS, Baxendale IR (2021) A comprehensive review of flow chemistry techniques tailored to the flavours and fragrance industries. Beilstein J Org Chem 17:1181–1312

Guidi M, Seeberger PH, Gilmore K (2020) How to approach flow chemistry. Chem Soc Rev 49:8910–8932

Plutschack MB, Pieber B, Gilmore K, Seeberger PH (2017) The Hitchhiker’s guide to flow chemistry. Chem Rev 117:11796–11893

Noel T, Cao Y, Laudadio G (2019) The fundamentals behind the use of flow reactors in electrochemistry. Acc Chem Res 52:2858–2869

Buglioni L, Raymenants F, Slattery A, Zondag SDA, Noel T (2022) Technological innovations in photochemistry for organic synthesis: Flow chemistry, high throughput experimentation, scale-up and photochemistry

Kobayashi S (2015) Flow “fine” synthesis: High yielding and selective organic synthesis by flow methods. Chem Asian J 11:425–436

Muschelknautz S, Wellenhofer A (2003) Flow reaction forces upon blowdown of safety valves. Chem Engg Tech 26:797–803

Gutmann B, Cantillo D, Kappe CO (2015) Continuous flow technology- A tool for the safe manufacturing of active pharmaceutical ingredients. Angew Chem Int Ed 54:6688–6728

Spennacchio M, Colella M, Andresini M, Dibenedetto RS, Graziano E, Aramini A, Degennaro L, Luisi R (2023) Unlocking geminal fluorohaloalkanes in nucleophilic fluoroalkylation chemistry: generation and trapping of lithiumfluorocarbenoids enabled by flow microreactors. Chem Commun. https://doi.org/10.1039/D2CC06717J

Colella M, Nagaki A, Luisi R (2020) Flow technology for the genesis and use of (highly) reactive organometallic reagents. Chem Eur J 26:19–32

Panariello L, Damilos S, du Toit H, Wu G, Radhakrishnan ANP, Parkin IP, Gavriilidis A (2020) Highly reproducible, high yield flow synthesis of gold nanoparticles based on a rational reactor design exploiting the reduction of passivated Au(III). React Chem Eng 5:663–676

Razzaq T, Kappe CO (2010) Continuous flow organic synthesis under high temperature/pressure conditions. Chem Asian J 5:1274–1289

Ley SV, Chen Y, Robinson A, Otter B, Godineau E, Battilocchio C (2021) A comment on continuous flow technologies within the agrochemical industry. Org Process Res Dev 25:713–720

Pastre JC, Murray D, Browne DL, Brancaglion GA, Galaverna RS, Pilli RA, Ley SV (2020) Integrated batch and continuous flow process for the synthesis of Goniothalamin. ACS Omega 5:18472–18483

Watanabe E, Chen Y, May O, Ley SV (2020) A practical method for continuous production of sp3-rich compounds from (hetero)aryl halides and redox-active esters. Chem Eur J 26:186–191

Bianchi P, Williams JD, Kappe CO (2020) Oscillatory flow reactors for synthetic chemistry applications. J Flow Chem 10:475–490

Dallinger D, Gutmann B, Kappe CO (2020) The concept of “chemical generators”: On-site demand production of hazardous reagents in continuous flow. Acc Chem Res 53:1330–1341

Cantillo D, Kappe CO (2017) Halogenation of organic compounds using continuous flow and microreactor technology. React Chem Eng 2:7–19

Wen Z, Pintossi D, Nuno M, Noël T (2022) Membrane-based TBADT recovery: increasing the sustainability of continuous-flow photocatalytic HAT transformations. Nat Commun 13:6147

Bajada MA, Sanjosé-Orduna J, Di Liberto G, Tosoni S, Pacchioni G, Noël T, Vilé G (2022) Interfacing single-atom catalysis with continuous-flow organic electrosynthesis. Chem Soc Rev 51:3898–3925

Mazzarella D, Pulcinella A, Bovy L, Broersma R, Noël T (2021) Rapid and direct photocatalytic C(sp3)–H acylation and arylation in flow. Angew Chem Int Ed 60:21277–21282

van Melis CG, Penny MR, Garcia AD, Petti A, Dobbs AP, Hilton ST, Lam K (2019) Supporting-electrolyte-free electrochemical methoxymethylation of alcohols using a 3D-printed electrosynthesis continuous flow. Cell System ChemElectroChem 6:41

Penny MR, Rao ZX, Peniche BF, Hilton ST (2019) Modular 3D printed compressed air driven continuous-flow systems for chemical synthesis. Eur J Org Chem:3783–3787

Rao ZX, Patel B, Monaco A, Cao ZJ, Barniol-Xicota M, Pichon E, Ladlow M, Hilton ST (2017) 3D-Printed polypropylene continuous-flow column reactors: exploration of reactor utility in S N Ar reactions and the synthesis of bicyclic and tetracyclic heterocycles. Eur J Org Chem 6499–6504

Musci P, Colella M, Sivo A, Romanazzi G, Luisi R, Degennaro L (2020) Flow microreactor technology for taming highly reactive chloroiodomethyllithium carbenoid: Direct and chemoselective synthesis of α-chloroaldehydes. Org Lett 22:3623–3627

Koenig SG, Sneddon HF (2017) Recent advances in flow chemistry in the pharmaceutical industry. Green Chem 19:1418–1419

Wang Y, Chen T, Zhang Z, Ni Y (2018) Cytidine-stabilized copper nanoclusters as a fluorescent probe for sensing of copper ions and hemin. RSC Adv 8:9057–9062

Kovaliov M, Segal M, Fischer B (2013) Fluorescent p-substituted phenyl-imidazolo-cytidine analogues. Tetrahedron 69:3698–3705

Fuchtbauer AF, Preus S, Borjesson K, McPhee SA, Lilley DMJ, Wilhelmsson LM (2017) Fluorescent RNA cytosine analogue-an internal probe for detailed structure and dynamics investigations. Sci Rep 7:2393

Yan N, He Y, Wen H, Lai F, Yin D, Cui H (2018) A Suzuki-Miyaura method for labelling proliferating cells containing incorporated BrdU. Analyst 143:1224–1233

Filippo M, Baumann M (2021) Continuous flow synthesis of anticancer drugs. Molecules 26:6992

Benitez-Mateos AI, Paradisi F (2022) Sustainable flow synthesis of (bulky) nucleoside drugs by a novel and highly stable nucleoside phosphorylase immobilized on reusable supports. ChemSusChem 15:e202102030

Breen CP, Nambiar AMK, Jamison TF, Jensen KF (2021) Ready, set, flow! Automated continuous synthesis and optimization. Trends Chem 3:373–386

Mandala D, Chada S, Watts P (2017) Semi-continuous multi-step synthesis of lamivudine. Org Biomol Chem 15:3444–3454

Sagandira CR, Akwi FM, Sagandira MB, Watts P (2021) Multistep continuous flow synthesis of stavudine. J Org Chem 86:13934–13942

Delbecq F, Len C (2018) In: Kapdi AR, Maiti D, Sanghvi YS (eds) Palladium-catalyzed modification of nucleosides, nucleotides and oligonucleotides. Elsevier, New York

Desgranges C, Razaka G, Rabaud M, Bricaud H, Balzarini J, De Clercq E (1983) Phosphorolysis of (E)-5-(2-bromovinyl)-2'-deoxyuridine (BVDU) and other 5-substituted-2'-deoxyuridines by purified human thymidine phosphorylase and intact blood platelets. Biochem Pharmacol 32:3583–3590

De Clercq E (2004) Discovery and development of BVDU (brivudin) as a therapeutic for the treatment of herpes zoster. Biochem Pharmacol 68:2301–2315

Jablonski E, Moomaw EW, Tullis RH, Ruth JL (1986) Preparation of oligodeoxynucleotide-alkaline phosphatase conjugates and their use hybridization probes. Nucleic Acids Res 14:6115–6128

Kapdi AR, Ardhapure A, Sanghvi YS (2015) Modulation of the electronic properties of non-innocent (E,E)-Dibenzylideneacetone for palladium(0)-mediated heck-alkenylation of 5-Iodo-2’-deoxyuridine and scale-up studies. Synthesis 47:1163–1169

Kapdi AR, Ardhapure A, Sanghvi YS, Serrano JL, Sánchez J, García J, Lozano P (2015) Pd-imidate complexes as recyclable catalysts for the synthesis of C5-alkenylated pyrimidine nucleosides via Heck cross-coupling reaction. RSC Adv 5:24558–24563

Acknowledgements

The authors would like to thank IKA India for allowing us to use the flow equipment described herein.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

SH is the inventor of the IKA FLOW that was commercialised and sold by IKA.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 3799 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gaware, S., Kori, S., Serrano, J.L. et al. Rapid plugged flow synthesis of nucleoside analogues via Suzuki-Miyaura coupling and heck Alkenylation of 5-Iodo-2’-deoxyuridine (or cytidine). J Flow Chem 13, 293–310 (2023). https://doi.org/10.1007/s41981-023-00265-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-023-00265-1