Abstract

Background

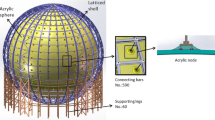

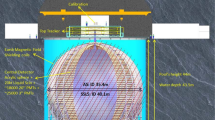

The Jiangmen Underground Neutrino Observatory (JUNO) is a multipurpose neutrino experiment designed to determine neutrino mass hierarchy and precisely measure oscillation parameters and study the solar neutrino, supernova neutrino, geo-neutrino, etc. JUNO’s central detector (CD) has 20 kilo-ton liquid scintillator as target mass, which is contained by a huge acrylic sphere with the inner diameter of 35.4 m, and the acrylic sphere is supported by a stainless steel structure through 590 connecting bars.

Motivation

Part of the connecting bars bear pull force and the other bars bear push force. There is a direct relationship between the stress of connecting bars and that of acrylic sphere. For the installation process of the CD, the pretightening force and axial force of the connecting bars should be monitored with accuracy, and for the filling process and running condition, the precise measurement of axial force can indicate the safety of structure of the CD.

Methods

Statistical method was used to evaluate the performance of measurement schemes, and 4-fiber Bragg grating measurement scheme was determined to be the final scheme, which can get the measurement uncertainty better than 0.7 kN. Performance of different measurement schemes are discussed in detail, and some related finite element analysis and evaluation method are also introduced in this paper.

Similar content being viewed by others

References

Y.F. Li, J. Cao, Y.F. Wang, L. Zhan, Unambiguous determination of the neutrino mass hierarchy using reactor neutrinos. Phys. Rev. D 88, 013008 (2013)

F. An et al., Neutrino physics with JUNO. J. Phys. G 36, 030401 (2016)

Z.M. Wang, JUNO central detector and its prototyping, in XIV International Conference on Topics in Astroparticle and Underground Physics (TAUP 2015) (IOP Publishing, 2015)

M. Li, Z. Guo, M. Yeh et al., Separation of scintillation and cherenkov lights in linear alkyl benzene. Nucl. Instrum. Methods Phys. Res. Sect. A 830, 303–308 (2016)

J. Cheng, Z. Wang, L. Lebanowski et al., Determination of the total absorption peak in an electromagnetic. Nucl. Instrum. Methods Phys. Res. Sect. A 827, 165–170 (2016)

D. Zhou, Z. Zhao, J. Zhao, Prediction of excavation damage zone of a deep tunnel with large size subjected to high in situ stress. Chin. J. Geotech. Eng. 38, 67–72 (2016). (In Chinese)

H. Wei, Z. Wang, S. Chen, Discovery potential for supernova relic neutrinos with slow liquid scintillator detectors (2017), arXiv:1607.01671

T. Adam, et al., JUNO conceptual design report, (2015), arXiv:1508.07166v2 [physics.ins-det]

F.J. Luo, Y.K. Heng et al., PMT overshoot study for the JUNO prototype detector. Chin. Phys. C 9, 89–94 (2016)

Y.Q. Wang, L. Zong, Y.K. Heng et al., Application of an acrylic vessel supported by a stainless-steel truss for the JUNO central detector. Sci. China Technol. Sci. 57(12), 2523–2529 (2014)

H.F. Li et al., Research on design of the main stainless steel structure of JUNO central detector. Build. Struct. 048(020), 92–97 (2018)

J.D. Strachiw, Handbook of Acrylic for Submersibles Hyperbaric Chambers and Aquaria (Best Publishing Company, Flagstaff, 2003), pp. 833–856

X. Yang, Y. Heng, H. Li et al., The design of the small prototype for the central detector of JUNO. Radiat. Detect. Technol. Methods 2(2), 46 (2018)

Z. Wang, Y. Wang, X. Du et al., Study on the fracture properties of the PMMA structure for the JUNO central detector. KSCE J. Civ. Eng. 23(6), 2584–2597 (2019)

Z. Wang, Y. Wang, Z. Wang et al., Design and analysis of a 1-ton prototype of the Jinping Neutrino Experiment. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 855, 81–87 (2017)

Z. Wang, Y. Wang, Y. Heng et al., Bearing capacities of the structure and joint of JUNO central detector. Period. Polytech. Civ. Eng. 60(4), 561–572 (2016)

B. Young, W. Hartono, Compression tests of stainless steel tubular members. J. Struct. Eng. ASCE 128(6), 754–761 (2002)

W. Chen, F. Lu, M. Cheng, Tension and compression tests of two polymers under quasistatic and dynamic loading. Polym. Test. 21(2), 113–121 (2002)

John R. Taylor, An Introduction To Error Analysis (University Science Books, Mill Valley, 1982)

Y.T. Fei, Error Theory and Data Processing (China Machine Press, Beijing, 2015)

Acknowledgements

This work is supported by the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDA100102).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, X., Yang, L., He, W. et al. Research on the measurement of connecting bars’ axial force of JUNO central detector. Radiat Detect Technol Methods 4, 362–371 (2020). https://doi.org/10.1007/s41605-020-00192-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41605-020-00192-y