Abstract

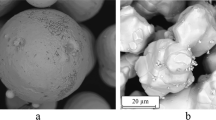

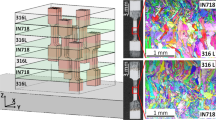

Additive manufacturing is emerging as a promising technology for fabrication of compositionally graded materials, especially ceramic coatings over metals. The compositionally graded materials are potential candidates for minimizing residual stresses due to abrupt changes in the thermo-physical properties at the metal–ceramic joints. The performance of these additively manufactured compositionally graded materials depends on the microstructure of each layer and the residual stress distribution. This work presents the results of a study on one such additively deposited metal–ceramic combination, NiCr–YSZ, which finds wide applications in thermal barrier coatings. The composites of NiCr–YSZ with varying YSZ contents viz. 15%, 35% and 65% in NiCr were additively deposited on Ni-base superalloy substrate. The deposits were studied for microstructural characteristics and phase analysis. Thermo-physical properties, such as coefficient of thermal expansion and thermal diffusivity, were also evaluated for NiCr–YSZ composites. Further, NiCr–YSZ material combination was additively deposited as discrete interface and as compositionally graded deposits. The through-thickness residual stresses across the build direction were experimentally determined using micro-focus XRD technique and compared.

Similar content being viewed by others

References

Balla VK, Bandyopadhyay PP, Bose S, Bandyopadhyay A (2007) Compositionally graded yttria-stabilized zirconia coating on stainless steel using laser engineered net shaping (LENS™). Scripta Mater 57:861–864

Bandyopadhyay PP, Balla VK, Bose S, Bandyopadhyay A (2007) Compositionally graded aluminium oxide coatings on stainless steel using laser processing. J Am Ceram Soc 90:1989–1991

Bhattacharya A, Maurice D (2019) Residual stresses in functionally graded thermal barrier coatings. Mech Mater 129:50–56

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Zhang W (2018) Additive manufacturing of metallic components—process, structure and properties. Prog Mater Sci 92:112–224

Feng H, Meng Q, Zhou Y, Jia D (2005) Spark plasma sintering of functionally graded material in Ti-TiB2-B system. Mater Sci Eng A 397:92–97

Griffith ML, Ensz MT, Puskar JD, Robino CV, Brooks JA, Philliber JA, Hofmeister WH (2000) Understanding the microstructure and properties of components fabricated by laser engineered net shaping (LENS). Mater Res Soc Symp Proc 625:9

Han CJ, Li Y, Wang Q, Cai DS, Wei QS, Yang L, Shi YS (2018) Titanium/hydroxyapatite (Ti/HA) gradient materials with quasi-continuous ratios fabricated by SLM: material interface and fracture toughness. Materials Design 141:256–266

Hofmeister W, Griffith ML (2001) Solidification in direct metal deposition by LENS processing. J Metals 53(9):30–34

Khor KA, Gu YW (2000) Thermal properties of plasma sprayed functionally graded thermal barrier coatings. Thin Solid Films 104(372):13

Kumar G, Balo S, Dhoble A, Singh J, Singh R, Srivastava D, Samajdar I (2017) Through-thickness deformation gradient in a part—pilgered zirconium tube: experimental measurements and numerical validation. Metall Mater Transact A 48A:2844

Lima CR, Guilemany JM (2007) Adhesion improvements of thermal barrier coatings with HVOF thermally sprayed bond coats. Surf Coat Technol 201(8):4694–4701

Miyamoto Y, Kaysser WA, Rabin BH, Kawasaki A, Ford RG (1999) Functionally graded materials. Springer

Wang Y, Li M, Suo H (2012) Mechanical properties of YSZ thermal barrier coatings with segmented structure. Surf Eng 28:329–332

Yan L, Chen Y, Liou F (2020) Additive manufacturing of functionally graded metallic materials using laser metal deposition. Addit Manuf 31:100901

Zhang Y, Bandyopadhyay A (2018) Direct fabrication of compositionally graded Ti-Al2O3 multi-material structure using laser engineered net shaping. Addit Manuf 21:104–111

Acknowledgements

The authors gratefully acknowledge the financial support provided by DRDO (project DMR295). Encouragement and support provided by Directory, DMRL to carry out this research work is acknowledged. The authors are grateful to by Dr. Indradev Samajdar, Professor, IIT Bombay and his team for their support in the evaluation of residual stresses. The authors acknowledge the support provided by Light alloy casting group, Failure analysis and Electron microscopy groups of DMRL during different stages of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Savitha, U., Srinivas, V., Reddy, G.J. et al. Laser-Based Directed Energy Deposition of Functionally Graded Metal–Ceramic (NiCr–YSZ) System. Trans Indian Natl. Acad. Eng. 6, 1111–1118 (2021). https://doi.org/10.1007/s41403-021-00282-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41403-021-00282-3