Abstract

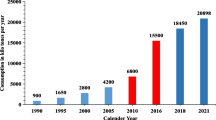

The polyethylene terephthalate bottles used for cold drinks are disposed of as waste material worldwide, causing environmental pollution. For remedial measures to address this issue, the wasted polyethylene terephthalate bottles were recycled and used as pelletized aggregates in concrete. For performance evaluation, concrete with recycled ethylene terephthalate aggregates, with volume fractions of 5%, 10%, 15%, 20%, 25%, and 30%, was tested and compared with regular concrete. Laboratory tests were conducted to assess—composite and conventional concrete’s fundamental mechanical properties, thermal conductivity, and ductility. The test results revealed that with the increase in recycled ethylene terephthalate aggregates, the workability of the concrete significantly decreases along with other associated mechanical properties. Considering the limited compressive strength, Polyethylene Terephthalate (PET) based concrete can be used in concrete elements, which requires the lower compressive strength value specified by the ACI code. Due to the lower unit weight and thermal conductivity value, this composite concrete can be used for up to 30% in the construction industry, subject to the lower value of desired strength.

Similar content being viewed by others

References

Islam MJ, Meherier MS, Islam AR (2016) Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr Build Mater 125:946–951

Khan Z et al (2021) Utilization of marble wastes in clay bricks: a step towards lightweight energy efficient construction materials. Civil Eng J 7(09):1488–1500

Frigione M (2010) Recycling of PET bottles as fine aggregate in concrete. Waste Manag 30(6):1101–1106

Tayyab S, Ullah A, Shah K, Mehmood F, Gul A (2018) Influence of reduced water cement ratio on behaviour of concrete having plastic aggregate. Civil Eng J 4(12):2971–2977

Thakur S, Chaudhary J, Sharma B, Verma A, Tamulevicius S, Thakur VK (2018) Sustainability of bioplastics: opportunities and challenges. Curr Opin Green Sustain Chem 13:68–75

Wen B, Zhang L, Niu D, Gao G, Kang Y, Luo D (2021) Mechanical performance of confined autoclaved fly-ash-brick masonry walls under cyclic loading. Appl Sci 11(22):10560

Kawai K, Tasaki T (2016) Revisiting estimates of municipal solid waste generation per capita and their reliability. J Mater Cycles Waste Manage 18:1–13

Liang Y, Tan Q, Song Q, Li J (2021) An analysis of the plastic waste trade and management in Asia. Waste Manag 119:242–253

Panyakapo P, Panyakapo M (2008) Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag 28(9):1581–1588

Siddique R, Khatib J, Kaur I (2008) Use of recycled plastic in concrete: a review. Waste Manag 28(10):1835–1852

Basuhi R, Moore E, Gregory J, Kirchain R, Gesing A, Olivetti EA (2021) Environmental and economic implications of US postconsumer plastic waste management. Resour Conserv Recycl 167:105391

Fiksel J (2006) A framework for sustainable materials management. JOM 58:15–22

Jo B-W, Park S-K, Park J-C (2008) Mechanical properties of polymer concrete made with recycled PET and recycled concrete aggregates. Constr Build Mater 22(12):2281–2291

Rebeiz K (1995) Time-temperature properties of polymer concrete using recycled PET. Cement Concr Compos 17(2):119–124

Ochi T, Okubo S, Fukui K (2007) Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cement Concr Compos 29(6):448–455

Pivák A, Pavlíková M, Záleská M, Reiterman P, Barnat-Hunek D, Pavlík Z (2022) Magnesia-based cement composites with recycled waste tire rubber filler. In: Presented at the AIP conference proceedings. AIP Publishing LLC, p 070003

Silva D, Betioli A, Gleize P, Roman H, Gomez L, Ribeiro J (2005) Degradation of recycled PET fibers in Portland cement-based materials. Cem Concr Res 35(9):1741–1746

Ali K et al (2023) Influence of recycled plastic incorporation as coarse aggregates on concrete properties. Sustainability 15(7):5937

Pan Z, Wu C, Liu J, Wang W, Liu J (2015) Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr Build Mater 78:397–404

Naaman A, Reinhardt H (2003) High performance fiber reinforced cement composites HPFRCC-4: international RILEM workshop: Ann Arbor, Michigan, June 16–18, 2003. Mater Struct 36:710–712

Segre N, Joekes I (2000) Use of tire rubber particles as addition to cement paste. Cem Concr Res 30(9):1421–1425

Rahman MM, Alam K (2022) Impact of industrialization and non-renewable energy on environmental pollution in Australia: Do renewable energy and financial development play a mitigating role? Renew Energy 195:203–213

Marzouk OY, Dheilly R, Queneudec M (2007) Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag 27(2):310–318

Gogineni A, Panday IK, Kumar P (2023) Predictive modelling of concrete compressive strength incorporating GGBS and alkali using a machine-learning approach. Asian J Civ Eng 25:699–709

Steiger R, Hurd M (1978) Lightweight insulating concrete for floors and roof decks. Concrete Constr 23(7):411–422

Yudina A (2019) Enhancing technological processes in building construction and reconstruction by means of new technologies. Asian J Civ Eng 20(5):727–732

Afzali-Naniz O, Mazloom M (2019) Assessment of the influence of micro-and nano-silica on the behavior of self-compacting lightweight concrete using full factorial design. Asian J Civ Eng 20:57–70

Al-Awabdeh FW, Al-Kheetan MJ, Jweihan YS, Al-Hamaiedeh H, Ghaffar SH (2022) Comprehensive investigation of recycled waste glass in concrete using silane treatment for performance improvement. Results Eng 16:100790

Milling A, Mwasha A, Martin H (2020) Exploring the full replacement of cement with expanded polystyrene (EPS) waste in mortars used for masonry construction. Constr Build Mater 253:119158

Hannawi K, Kamali-Bernard S, Prince W (2010) Physical and mechanical properties of mortars containing PET and PC waste aggregates. Waste Manag 30(11):2312–2320

Kim SB, Yi NH, Kim HY, Kim J-HJ, Song Y-C (2010) Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cement Concr Compos 32(3):232–240

Sambangi A, Eluru A (2022) Role of copper slag on improvement of strength, quality and durability of high-strength self-compacting concrete: an industrial waste. Asian J Civ Eng 23(6):961–971

Ghaly AM, Gill MS (2004) Compression and deformation performance of concrete containing postconsumer plastics. J Mater Civ Eng 16(4):289–296

Pilz H (2014) Criteria for eco-efficient (sustainable) plastic recycling and waste management. GmbH Hietzinger Hauptstrasse, Vienna

Himo R, Zéhil G-P, Ghnatios C (2019) 2D modeling of the thermal conductivity of XLPE-modified concrete. In: Presented at the Congrès Français de Thermique

Záleská M, Pavlíková M, Pokorný J, Jankovský O, Pavlík Z, Černý R (2018) Structural, mechanical and hygrothermal properties of lightweight concrete based on the application of waste plastics. Constr Build Mater 180:1–11

Basha SH, Kaushik HB (2015) Evaluation of nonlinear material properties of fly ash brick masonry under compression and shear. J Mater Civ Eng 27(8):04014227

Ahmad F, Jamal A, Mazher KM, Umer W, Iqbal M (2022) Performance evaluation of plastic concrete modified with e-waste plastic as a partial replacement of coarse aggregate. Materials 15(1):175

Farina I, Moccia I, Salzano C, Singh N, Sadrolodabaee P, Colangelo F (2022) Compressive and thermal properties of non-structural lightweight concrete containing industrial byproduct aggregates. Materials 15(11):4029

Saikia N, de Brito J (2013) Waste polyethylene terephthalate as an aggregate in concrete. Mater Res 16:341–350

Nuaklong P et al (2021) Enhancement of mechanical properties of fly ash geopolymer containing fine recycled concrete aggregate with micro carbon fiber. J Build Eng 41:102403

Saikia N, De Brito J (2012) Use of plastic waste as aggregate in cement mortar and concrete preparation: a review. Constr Build Mater 34:385–401

Ferreira L, De Brito J, Saikia N (2012) Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr Build Mater 36:196–204

Akçaözoğlu S, Atiş CD, Akçaözoğlu K (2010) An investigation on the use of shredded waste PET bottles as aggregate in lightweight concrete. Waste Manag 30(2):285–290

Awolusi TF, Oguntayo DO, Aladegboye OJ, Azab M, Deifalla AF (2023) Optimization of concrete containing polyethylene terephthalate powder and rice husk ash using response surface methodology. J Eng 2023

Gul A, Tayyab S, Ullah A, Shan K, Mehmood F, Haq F (2019) W/C reduction for flexural strengthening of RC beams having plastic aggregate. Stavební obzor-Civ Eng J 28(2)

Gu L, Ozbakkaloglu T (2016) Use of recycled plastics in concrete: a critical review. Waste Manag 51:19–42

Abu-Saleem M, Zhuge Y, Hassanli R, Ellis M, Rahman M, Levett P (2021) Evaluation of concrete performance with different types of recycled plastic waste for kerb application. Constr Build Mater 293:123477

Mushtaq F et al (2022) Performance optimization approach of polymer modified asphalt mixtures with PET and PE wastes: a safety study for utilizing eco-friendly circular economy-based SDGs concepts. Polymers 14(12):2493

Nizamani JA (2020) Assessment of different hazards and vulnerabilities with sparse data in coastal city of Karachi, Pakistan

Khan F, Ahmed W, Najmi A, Younus M (2019) Managing plastic waste disposal by assessing consumers’ recycling behavior: the case of a densely populated developing country. Environ Sci Pollut Res 26:33054–33066

Tamoor M, Samak NA, Xing J (2022) Pakistan toward achieving net-zero emissions: policy and roadmap. ACS Sustain Chem Eng 11:368–380

Shaw R (2015) Urban risk and reduction approaches in Pakistan. In: Disaster risk reduction approaches in Pakistan, pp 295–314

Ijaz S, Miandad M, Mehdi S, Anwar MM, Rahman G (2021) Solid waste management as a response to urban flood risk in Gujrat city, Pakistan. Malays J Soc Space 17(1):1–13

Maitlo G et al (2022) Plastic waste recycling, applications, and future prospects for a sustainable environment. Sustainability 14(18):11637

Kumar A, Agrawal A (2021) A review on plastic waste assessment and its potential use as building construction material. Sustain Urban Arch Sel Proc VALUE 2020:37–52

Bartolotta JF, Hardy SD (2021) Ban the bag: support for plastic bag reduction strategies in Northeast Ohio. J Contemp Water Res Educ 174(1):61–84

Attique S et al (2022) Fe-POM/attapulgite composite materials: Efficient catalysts for plastic pyrolysis. Waste Manag Res 40(9):1433–1439

Mahar A, Malik RN, Qadir A, Ahmed T, Khan Z, Khan MA (2007) Review and analysis of current solid waste management situation in urban areas of Pakistan. In: Presented at the proceedings of the international conference on sustainable solid waste management, Citeseer, p 36

Almeshal I, Tayeh BA, Alyousef R, Alabduljabbar H, Mohamed AM, Alaskar A (2020) Use of recycled plastic as fine aggregate in cementitious composites: a review. Constr Build Mater 253:119146

Mohan R et al (2023) Performance of recycled Bakelite plastic waste as eco-friendly aggregate in the concrete beams. Case Stud Constr Mater 18:e02200

Mohammed AA (2017) Flexural behavior and analysis of reinforced concrete beams made of recycled PET waste concrete. Constr Build Mater 155:593–604

Belmokaddem M, Mahi A, Senhadji Y, Pekmezci BY (2020) Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr Build Mater 257:119559

Ferrotto MF, Asteris PG, Borg RP, Cavaleri L (2022) Strategies for waste recycling: the mechanical performance of concrete based on limestone and plastic waste. Sustainability 14(3):1706

Sharma R, Bansal PP (2016) Use of different forms of waste plastic in concrete—a review. J Clean Prod 112:473–482

American Society for Testing and Materials (2009) ASTM C 150: standard specification for Portland cement. ASTM Philadelphia

Van Krevelen DW, Te Nijenhuis K (2009) Properties of polymers: their correlation with chemical structure; their numerical estimation and prediction from additive group contributions. Elsevier

Dixon DE et al. (1991) Standard practice for selecting proportions for normal heavyweight, and mass concrete (ACI 211.1-91) Reapproved 1997

Záleská M, Pavlíková M, Čítek D, Pavlík Z (2019) Evaluation of the size effect of waste tyre rubber particles on properties of lightweight rubber concrete. In: Presented at the IOP conference series: materials science and engineering. IOP Publishing, p 012043

ASTM C39 (2020) ASTM C39/C39M-99-standard test method for compressive strength of cylindrical concrete specimens

ASTM C138/C138M-17a (2017) Standard test method for density (unit weight), yield, and air content (gravimetric) of concrete

ASTM A (2011) C496/C496M-17, Standard test method for splitting tensile strength of cylindrical concrete specimens ASTM C-496. ASTM International, West Conshohocken, p 2011

ASTM C78 (2020) Standard test method for flexural strength of concrete (using simple beam with third-point loading). In: Presented at the American society for testing and materials, pp 19428–2959

ASTM C (2012) ASTM C 469 annual book of ASTM standards, V. 4.02. ASTM International, West Conshohocken

Choi YW, Kim YJ, Shin HC, Moon HY (2006) An experimental research on the fluidity and mechanical properties of high-strength lightweight self-compacting concrete. Cem Concr Res 36(9):1595–1602

ASTM Standard C642-13 (2010) Standard test method for density, absorption, and voids in hardened concrete

Akçaözoğlu S, Akçaözoğlu K, Atiş CD (2013) Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos B Eng 45(1):721–726

Ismail ZZ, Al-Hashmi EA (2008) Use of waste plastic in concrete mixture as aggregate replacement. Waste Manage 28(11):2041–2047

Ries J, Crocker D, Sheetz S (2010) Guide for structural lightweight-aggregate concrete reported by ACI Committee 213

Gavela S et al. (2004) A study of concretes containing thermoplastic wastes as aggregates. In: Presented at the proceedings international RILEM conference on the use of recycled materials in buildings and structures. Barcelona, Spain, pp 911–918

Akçaözoğlu S, Ulu C (2014) Recycling of waste PET granules as aggregate in alkali-activated blast furnace slag/metakaolin blends. Constr Build Mater 58:31–37

Rahman MJ, Setiawan A, Ihsan M (2020) Examining polyethylene terephthalate (pet) as artificial coarse aggregates in concrete. Civil Eng J 6(12):2416–2424

Senthil Kumar K, Baskar K (2015) Recycling of E-plastic waste as a construction material in developing countries. J Mater Cycles Waste Manag 17:718–724

Güleç A, Oğuzhanoğlu MA (2021) Fluorite mineral waste as natural aggregate replacement in concrete. J Build Pathol Rehabil 6(1):26

Yesilata B, Isıker Y, Turgut P (2009) Thermal insulation enhancement in concretes by adding waste PET and rubber pieces. Constr Build Mater 23(5):1878–1882

Gulec A, Kose MM, Gogus MT (2020) An analysis of the usability of prefabricated cage-reinforced composite beams with self-compacting and lightweight concrete under flexural loads. Constr Build Mater 255:119274

Gulec A, Kose MM, Gogus MT (2021) Experimental investigation of flexural performance of T-section prefabricated cage reinforced beams with self-compacting concrete. In: Presented at the structures, Elsevier, pp 2190–2197

Tantala MW, Lepore JA, Zandi I (1996) Quasi-elastic behavior of rubber included concrete (RIC) using waste rubber tires. In: Presented at the proceedings of the international conference on solid waste technology and management, p 8

Chandra S, Berntsson L (2002) Lightweight aggregate concrete. Elsevier

Acknowledgements

The authors are grateful to the Higher Education Commission (HEC) Islamabad and University of Engineering and Technology Peshawar for their support in this research study.

Author information

Authors and Affiliations

Contributions

Conceptualization, KS, AG, YA, and TA; methodology, MA, KS, TA, AG and SWK; validation, TA, KS, AG, SWK and MA; formal analysis, TA; investigation, SWK, TA, AG, S.I and MA; resources, YA; writing—original draft preparation, KS, AG, SI, TB, and MA; writing—review and editing, AG, TB, and MA, project administration, KS.

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Ethical approval

The article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this study no formal consent was required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shahzada, K., Gul, A., Alqaryouti, Y. et al. Strength evaluation of sustainable concrete incorporating pelletized plastic aggregates: a remedy for growing plastic wastes issue. Innov. Infrastruct. Solut. 9, 174 (2024). https://doi.org/10.1007/s41062-024-01488-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-024-01488-4