Abstract

The widespread use of concrete has raised concerns about the consumption of its raw materials. To address this issue, researchers are actively exploring alternative waste materials to reduce the environmental impact of the construction industry. With this objective current study aims to investigate potential use of waste polyethylene terephthalate (PET) bottle cap aggregates on the characteristics of concrete, both in its fresh and hardened states. Three variations of modified waste PET aggregates (PETA): full (F), half (H), and quarter (Q), with the aim of evaluating their suitability as replacements for conventional coarse aggregates (CCA) was examined. The research assesses the effects of different PETA proportions (3%, 5%, and 8%) on concrete workability, compressive strength, splitting tensile strength, and flexural strength. The findings reveal that PETA-F and PETA-H adversely affect workability, primarily due to their larger surface area and difficulty in achieving homogeneous blending with other ingredients. In contrast, PETA-Q exhibits superior workability. The use of PETA-Q results in reduced compressive strength due to its smaller size and limited load-bearing capacity. Notably, PETA-H demonstrates improved compressive strength after 28 days. Interestingly, PETA-Q shows enhancements in splitting tensile and flexural strength, making it the top-performing alternative for fresh and hardened concrete properties. Overall, this research indicates that PETA-Q is most suitable for sustainable concrete production. Furthermore, the application of a multi-criteria decision-making tool validates our findings and determines that a 5% replacement of CCA with PETA is optimal, as higher replacements result in strength reduction. The utilization of PETA not only minimizes CCA consumption but also contributes to the development of eco-friendly, sustainable concrete. This study underscores the potential of environmentally conscious concrete and encourages the adoption of sustainable solutions for plastic waste management.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Concrete, as a fundamental construction material for infrastructure development, wields substantial potential for environmental impact. It ranks among the most extensively employed man-made substances on a global scale, prompting growing concerns about the over consumption of raw materials in concrete manufacturing. Comprising two pivotal constituents - an inert filler and a binding agent - concrete forms a chemically interlinked, rigid structure. Cement serves as the critical binding component, while coarse and fine aggregates provide the load-bearing strength. The worldwide construction industry is actively investigating alternative materials for concrete to mitigate reliance on conventional raw materials, given concrete’s diverse applications and adaptability. Recent research has demonstrated promising outcomes in employing polyethylene plastic waste as a feasible substitute for traditional aggregates in concrete [1, 2].

Annually, the global production of non-recyclable plastic waste amounts to millions of tons, with the majority ending up in landfills or contaminating the world’s oceans. In the context of India, plastic consumption has experienced a substantial upswing, rising from 6,800 kilo tonnes in 2010 to approximately 20,898 kilo tonnes in 2021. This signifies a remarkable 2.28-fold increase in consumption between 2010 and 2016, as illustrated in Fig. 1 [3].

Plastic consumption annually from year 1990 to 2021 [3]

The adoption of plastic recycling entails energy consumption, thereby contributing to heightened environmental pollution on land, in the oceans, and in the atmosphere. The increased production of single-use plastic items and the management of waste disposal have emerged as significant global environmental challenges. Plastics are classified into two primary categories based on polymer properties: thermosetting plastics and thermoplastics [4]. Among them, PET (polyethylene terephthalate) polymer stands out for its extensive application in packaging, including bottled drinking water, and various products due to its durable semi-crystalline nature, exceptional mechanical strength, and robust resistance to hydrolysis, chemicals, and solvents, along with commendable tensile strength [5]. The ease of utilizing PET bottles has led to a surge in demand, consequently making their waste management a pressing concern [6].

In recent years, several experiments have explored the replacement of natural aggregates in cementitious composites with waste plastic aggregates. These experiments encompass various approaches, such as shredding and altering the geometric characteristics of heated and melted PET plastic. Incorporating these waste plastics in construction projects significantly reduces the density and overall weight of the resultant concrete structures [7]. Reusing waste plastics in construction is regarded as one of the most efficient disposal methods among the multitude of recycling management strategies. The integration of used PET bottles as filler materials in concrete offers opportunities for recycling these waste materials. Many studies have explored the application of PET bottle fibers as structural concrete reinforcements, albeit at the cost of a reduction in primary strength and a concurrent improvement in flexibility [8].

Numerous experimental investigations, employing life cycle assessment techniques [9, 10], have evaluated concrete incorporating varying proportions of powdered PET, indicating that a 5% substitution yielded the most improved strength [11, 12]. These investigations have also addressed performance, optimization [13], and chemical surface treatment of PET fibers, revealing their role in enhancing concrete properties [14]. Notably, the alteration of PET waste shape allows precise size matching with natural sand, with an increase in PET aggregate content leading to a decrease in mortar consistency [15]. The use of PET waste and recycled materials has become increasingly prevalent in lightweight mortars and lightweight concrete [16, 17]. The geometric attributes of PET fibers have a negligible impact on concrete workability, while the use of thinner-diameter fibers enhances workability [18]. Furthermore, studies incorporating 10% recycled PET granules as a replacement for fine aggregate have demonstrated improvements in concrete properties, especially up to approximately 10% volumetric replacement [19,20,21,22].

The incorporation of PET-aggregates in concrete, in any form, invariably leads to a reduction in compressive strength. However, the compressive strength development of concrete containing various PET-aggregates exhibits behavior akin to that of conventional concrete. No discernible differences in the mechanism of flexural failure were observed when PET waste concrete was used for monolithic and hybrid beams [23, 24]. The utilization of PET bottle shredding material as a substitute for fine aggregate yielded improved workability and strength at lower replacement percentages. Nevertheless, an increase in the percentage of replacement correlated with a decrease in strength [25,26,27]. The inclusion of Bakelite waste in concrete represents a sustainable approach to waste management and promotes the use of environmentally friendly construction materials. However, as the replacement ratio for coarse aggregate increases, the mechanical properties of the concrete deteriorate [28, 29].

In the contemporary world, decision-making is of paramount importance for achieving optimal outcomes while balancing conflicting criteria to attain specific objectives. To tackle this challenge, advanced techniques such as Multi-Criteria Decision Making (MCDM) tools have been developed, leading to a paradigm shift in civil engineering applications [30]. These tools facilitate the evaluation of performance by considering technological, economic, and environmental factors. The objective of incorporating MCDM tools in civil engineering is to advocate for a sustainable approach to material design in the construction sector. These tools play a pivotal role in determining concrete mixtures by considering various inputs and selecting the most suitable alternative through different MCDM methods. The final decision-making process hinges on the alternatives presented [31]. Some studies introduce an intelligent multi-criteria decision-making model to handle complex construction scenarios, incorporating expert judgments. It proposes a decision hierarchy for method selection and demonstrates the models feasibility, providing a valuable tool for decision-making in underground construction [32]. Also a decision-making method for identifying optimal risk-control schemes for excavation engineering projects utilizing the fuzzy VIKOR method and triangular fuzzy sets was implemented based on engineering experience and environmental factors [33].

Numerous studies have assessed the properties of concrete incorporating PET-aggregates through experimentation. Typically, raw PET obtained from recycling programs has been manipulated or heated, and then shaped artificially using a specific mechanism or post-processing method. This, in turn, consumes energy and utilizes a minor amount of natural resources, contributing to pollution. The fundamental purpose and innovation of this study are to evaluate the benefits of using raw PET waste as a coarse aggregate in concrete, facilitating a sustainable construction process in the context of modern infrastructure development and smart cities. Replacement percentages of conventional coarse aggregates (CCA) with PET aggregates were set at 3%, 5%, and 8% without any preheat treatment or shredding. PET waste in the form of full bottle caps was adopted as a replacement for CCA, capitalizing on the natural shape of the bottle cap body and configuring it into half and quarter shapes. Additionally, the Analytical Hierarchy Process (AHP), a Multi-Criteria Decision Making (MCDM) tool, is employed to recommend the most suitable concrete mix based on strength properties. Analytic Hierarchy Process (AHP) is often favored over other Multi-Criteria Decision-Making (MCDM) tools due to its flexibility in structuring decision problems hierarchically, ease of use through pairwise comparisons ability to handle both quantitative and qualitative criteria, transparency in decision-making, and widespread acceptance and application across various applications. The findings aim to provide a more sustainable material for the production of environmentally friendly concrete with minimal alteration of waste and a reduction in post-processing treatment, thereby mitigating land and water pollution. The management of these substantial quantities of plastic waste, however, presents a significant environmental challenge.

2 Experimental program

2.1 Mixture materials

Portland pozolana cement (PPC) of 43 grade, the most common cementitious component for concrete, has been employed in the design. For concrete making, 20mm-sized quarry stones are employed as conventional coarse aggregates (CCA) together with natural river sand as fine aggregate (FA). Before being used in the concrete mix, the material was first cleaned to eliminate presence of any dirt. Prior test such as specific gravity, water absorption capacity was measured using Indian standard techniques using IS 2386 (Part IV) – 1963 and IS 1489 (Part I)-1991 [34, 35].

Table 1 represents physical properties of raw materials used for mix design of concrete.

2.2 Modified PETA

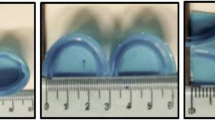

In this experimentation waste packaged drinking water bottle were collected from local restaurants and hotels and the bottle caps was segregated from collected waste. The segregated caps were then cleaned and open dried in an enamel try for 24 h. The full (F) caps were then cut into half (H) and quarter (Q) shape approximately 28mm in diameter and adopted for experimentation by a replacement of 3%, 5% and 8% with CCA with varying shapes. Figure 2 shows the geometry of modified PETA used in the experimentation according to shape alterations. Here the post processing, per-heating or shredding of waste plastic is completely eliminated and the collected PET bottle cap are directly used by making variation in the surface configuration of PETA. The detailed work chart illustrating the experimental flow is represented in Fig. 3.

2.3 Design mix

Four mixture types with the natural CCA substituted with PETA by 3%, 5% and 8% were chosen in order to evaluate the performance of PET aggregate on the fresh and harden characteristics of concrete. Due to the difference in specific gravity between natural CCA and PETA, the volumetric design technique was adopted. Here, full cap PETA, half cap PETA, and quarter cap PETA concrete was compared to Normal M25 concrete, which served as the controls specimen.

In the concrete mix design, each combination had the same kind of Portland pozolana cement (PPC) of 43 grade and river sand as fine aggregate. Based on the findings of earlier tests on the core raw materials, an experimentation mix design for M25 concrete adopting IS10262:2009 [36] was designed and implemented. In Table 2, the weighted average mix proportions for each mix for a concrete volume of one cubic meter are listed. The concrete mix was created with a water cement ratio of 0.50 and a target strength of 25 MPa at 28 days. The proportions of cement, fine aggregate, coarse aggregate, and water/cement followed the formula 1:2.09:2.83:0.5 for the concrete mix design.

2.4 Test performed

-

i.

Workability- Utilizing the slump cone test method [37], flow ability of each freshly mixed mixture was assessed. Concrete was poured into a surface-leveled slump cone during the mixing of various concrete blends, and it was then tamped for every interval of concrete filling. The slump value was then calculated as the height difference between the cone and sample after the cone had been lifted.

-

ii.

Compressive (CS) and Splitting tensile strength (STS) - After 28 days of fully immersed water-curing, tests for concrete compressive strength and splitting tensile strength were conducted. Typical size molds were used for the experiments as per [38]. Loading was then induced gradually and constantly at a standard rate until the corresponding failure load occurs. The compressive strength and splitting tensile strength was then calculated for each mix blend adopted for experimentation.

-

iii.

Flexural strength (FS)-A total of 24 beam specimens (100mm × 100mm × 500mm) were cast, cured for 28 days and tested for two-point load and simply supported condition. The necessary failure load was then progressively and consistently applied at a standard rate. During testing, fracture patterns were noted and crack initiation and propagation were observed visually. The experimental summarized test findings are presented in Table 3 and its significance is explained in the discussion.

3 Results and discussions

3.1 Workability

Figure 4 illustrates the results of the slump test conducted on the investigated concrete mixtures. Notably, an increase in the percentage of PETA (Polyethylene Terephthalate Aggregates) replacement in the mix correlates with a reduction in the slump value. This observation aligns with prior research findings reported by Edmund et al. [7], Lee et al. [14], and Islam et al. [5]. The diminished slump is attributed to the sub optimal bonding between PETA and the concrete matrix, primarily caused by the smooth surface texture of PETA. Initially, a controlled mixture was meticulously formulated to achieve a 100 mm slump. However, as the PETA replacement percentage rises, both PEAT-F and PETA-H exhibit a declining slump. This decrease in workability can be ascribed to the larger diameter of PEAT-F and PETA-H aggregates and their inability to blend effectively with the other concrete matrix constituents. It becomes evident that an escalation in the surface area of PETA leads to a commensurate decrease in workability. Interestingly, the slump value for PETA-Q remains nearly identical to that of the controlled concrete, signifying excellent workability. This congruence with results obtained by Bamigboye et al. [4] suggests that the shape of PETA-Q closely matches that of the natural aggregate, thereby contributing to its favorable workability. Consequently, a smaller PETA surface area is associated with improved concrete flow, as evidenced in this study.

3.2 Compressive and splitting tensile strengths

The evaluation of concrete quality places significant emphasis on its compressive strength, a pivotal and fundamental parameter. The results of the tests, as summarized in Table 3, indicate that the replacement of Conventional Coarse Aggregates (CCA) with Polyethylene Terephthalate Aggregates (PETA) leads to an enhancement in both compressive strength and splitting tensile strength, but only up to a 5% substitution level. This observation concurs with the findings of Umasabor and Daniel. After a curing period of 28 days, it is noteworthy that H-PA (Hybrid PETA Aggregates) exhibited the highest compressive strength, reaching 31.348 MPa. This superior performance is attributed to the efficient packing of PEAT-F (Full PETA) and PETA-H (Half PETA) in conjunction with CCA within the concrete matrix. In contrast, PETA-Q (Quarter PETA) displayed a decrease in compressive strength when compared to the control specimens and other combinations. These outcomes align with the experimental results reported by Bamigboye et al. [4], Islam et al. [5], and Edmund et al. [7]. The decrease in strength can be ascribed to the relatively smaller size of PETA particles within the concrete, which fails to effectively contribute to load shearing, consequently leading to early concrete crushing. The variation in compressive strength of the designed PETA-modified concrete mixes is graphically illustrated in Fig. 5. Regarding splitting tensile strength, a negative correlation with the surface area of PETA is observed, coupled with a marginal increase in response to changes in the shape of PETA. This relationship is depicted in Fig. 6. The finer surface texture and expanded surface area of PETA, which result in sub optimal bonding at the interface and the accumulation of free water, have also been identified as factors contributing to the decline in tensile strength. These observations align with the findings of Bamigboye et al. [4] and Islam et al. [16].

In comparison to the controlled mixture, PETA-Q (Quarter PETA) exhibited a remarkable improvement in strength, ranging from 16 to 22%. After 28 days of curing, PETA-Q achieved a peak strength of 3.325 MPa. In this context, the smaller size and shape of PETA-Q particles serve as fibrous materials within the concrete mixture, augmenting its splitting behavior. A visual representation of the cylindrical specimen following the test is presented in Fig. 7. Unlike PETA-Q and PETA-H (Half PETA), no indications of sudden, brittle concrete failure were observed, suggesting an enhancement in the durability of the fractured concrete. These observations align with the findings of Fakhruddin et al. [24] and Aocharoen et al. [27].

3.3 Flexural strength

Figure 8 illustrates the flexural behavior of beams subjected to a two-point load system using a Universal Testing Machine, following 28 days of curing. The experiment involved untreated plain M25 grade concrete beam specimens, measuring 100 mm × 100 mm × 500 mm, without reinforcement. These beams were treated with PETA to evaluate the bending strength of the concrete. The results presented in Fig. 8 reveal that, after 28 days, PETA-Q (Quarter PETA) exhibited an impressive maximum strength of 4.452 MPa, nearly double the strength of the controlled beam. This enhancement can be attributed to the smaller size and shape of PETA-Q particles, which function as fibrous materials within the mixture, reducing the propagation of fractures and leading to improved bending strength. These findings contradict the results reported by Umasabor and Daniel [11], Islam et al. [16], and Fakhruddin et al. [24].

When comparing PETA-Q to PETA-H (Half PETA) and PEAT-F (Full PETA), PETA-Q demonstrated a 26% and 90% increase in flexural strength, respectively. Notably, the flexural strength of PEAT-F was found to be comparable to that of the controlled beam, implying a higher likelihood of voids in the concrete, which compromise the cohesion of the matrix. Figure 9 provides a visual representation of the tested beam specimens, along with the fracture dispersion pattern induced during testing. It is evident that in the controlled beam, the fracture initiates at the center and follows a vertical bending crack, while in the PETA-modified concrete beam specimen, the crack moves toward the support as inclined crack. Furthermore, it can be observed that the crack initially displays a semi-vertical orientation up to one-third of the beam’s depth on the tension side before transitioning into a shear fracture-like behavior below the point load.

4 Application of analytical hierarchy process for selecting best concrete mix design

The Analytical Hierarchy Process (AHP) is a critical tool in the selection of the most suitable concrete mix parameter from a range of available options. Figure 10 illustrates the hierarchical structure of the AHP analysis used to identify the best mix parameter for PETA concrete, considering various criteria and alternatives. These tools are instrumental in prioritizing available options and facilitating the selection of the optimal decision from among the accessible alternatives. The AHP approach adheres to a hierarchical structure, with the ultimate goal positioned at the top, criteria at the second level, and alternatives at the lowest level. AHP stands out as the most widely employed mathematical model for resolving intricate and challenging decision-making problems. These tools excel in determining the highest priority among the offered alternatives. Notably, when conflicts arise in decision-making, one of the significant advantages of AHP is its ability to rank options while adhering to the defined objectives.

The following steps were implemented to determine the weight of the mix for all the combinations tested in the experimentation:

-

i.

In the initial AHP step, a pairwise comparison of the experimental observations for attributes ‘i’ and ‘j’ as detailed in Table 3 is conducted, employing the normalization technique. When an attribute is compared to itself, it is invariably assigned the value 1, resulting in the main diagonal elements of the pairwise comparison matrix being equal to 1. An excerpt of the pairwise matrix for the compressive strength parameter is provided in Table 4 with matrix size M = 12.

-

ii.

The geometric mean of each row in the comparison matrix is computed, and the geometric means of the rows are normalized to ascertain the relative normalized weight of each attribute as given in Eqs. 1 and 2.

$$\mathrm{Geometric \,mean \,}({{\text{GM}}}_{{\text{j}}})={[\prod\nolimits_{{\text{j}}=1}^{{\text{M}}}{\text{bij}}]}^{1/{\text{M}}}$$(1)$$\mathrm{Weight\, of \,each \,attribute}=\mathrm{ Wj }=\left[{{\text{GM}}}_{{\text{j}}} / \sum\nolimits_{{\text{j}}=1}^{{\text{M}}}{\text{GMj}}\right]$$(2) -

iii.

Three PETA aggregate shapes were tested for compressive, splitting tensile, and flexural strength of concrete, with comparisons made to conventional concrete strength. By examining the weight obtained for the compressive strength of concrete, it becomes evident that PETA-H holds the highest weight (0.10) for the mix, positioning it as the top-ranking choice for compressive strength.

-

iv.

Analogous steps from i to iii were executed for splitting tensile and flexural strength evaluations of PETA concrete in comparison to conventional concrete. The most suitable alternatives for each test are highlighted in Tables 4, 5 and 6, and they are visually presented in Figs. 11 and 12.

-

v.

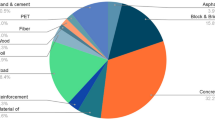

Figure 13 displays the maximum weights of alternatives for all tested mix combinations. The most appropriate mix parameter among the various combinations experimented with is ranked, and PETA-Q emerges as the top choice in the list.

-

vi.

As depicted in Fig. 13, it is notably evident that the highest weight is attributed to the 5% replacement of Conventional Coarse Aggregates (CCA) with PETA. Furthermore, out of the three tests conducted, the maximum weight is observed for PETA-Q and PETA-H types of aggregates. The triangular shape of PETA contributes to effective particle packing, rendering the concrete denser and subsequently enhancing its strength.

-

vii.

Here it is evident that, though the compressive strength of PETA concrete is improved by adding PETA-H the remaining two strengths have shown improvement using PETA-Q. Here the PETA of smaller shape acts like and fiber in the matrix resisting the crack initiation and thus improvement in the strength. If the weight for compressive strength of PETA-Q is observed from Table 4 and Fig. 11a the weight is equal to 0.096 which is almost equals with 0.10 and therefore concluded as the best suitable shape of PETA.

4.1 Field applications of AHP

The application of Multi-Criteria Decision-Making (MCDM) tools can provide significant advantages in the process of material selection for concrete production. These tools enable the consideration of a multitude of factors, encompassing aspects such as strength, sustainability, physical properties, shape and size, and feasibility, when making informed decisions. In particular, the Analytic Hierarchy Process (AHP) offers a systematic and structured approach to the comparative assessment and prioritization of different formulations of PET-based concrete, with a specific focus on its mechanical strength. This comprehensive evaluation involves the examination of various variables, including the shape of PET aggregates, the extent of substitution, and diverse mechanical strength properties. By harnessing the capabilities of AHP, the primary objective is to discern the most suitable concrete mixture from the available alternatives, taking into account a range of critical factors. Furthermore, the AHP methodology can be effectively deployed in practical field applications, facilitating the simplification of material selection processes and the refinement of material choices for concrete production.

5 Conclusions

This experimental study aimed to enhance the performance of materials and structures while retaining the use of conventional coarse aggregates by integrating discarded PET bottle caps into structural concrete. A significant impetus behind this investigation was the promotion of sustainable concrete production and the realization of environmental benefits through the effective utilization of this waste material. Furthermore, the study sought to validate the experimental findings by employing a multi-criteria decision-making optimization tool to address conflicting alternatives. The following conclusions are drawn from this research:

-

1.

PETA (Polyethylene Terephthalate Aggregates) with a smaller surface area exhibits workability comparable to that of the controlled mix. This enables optimal flow and improved compaction, resulting in denser concrete with enhanced strength properties. PETA-Q, in particular, maintains a similar slump as the controlled mix, signifying that a larger surface area and a higher percentage of PETA have a detrimental effect on concrete workability, leading to harsher mixes and reduced strength in the final product.

-

2.

Compressive strength (CS) improves up to a 5% replacement of conventional coarse aggregate (CCA). In this context, PETA-H demonstrates the highest CS value of 33.190 MPa. When combined with CCA, PETA-H offers a mix with improved workability, reduced PETA surface area, and enhanced CS. Since the CS values for PETA-H and PETA-Q are nearly identical, it can be inferred that PETA-F decreases concrete strength by reducing density, aggregate content, and ultimately resulting in lighter concrete.

-

3.

The addition of PETA has a marginal impact on splitting tensile strength (STS) and flexural strength (FS). In this scenario, PETA-Q outperforms PETA-F and PETA-H. A maximum STS of 3.325 MPa, which is 22.24% higher than the standard concrete cylinder after 28 days, was observed. Additionally, the maximum FS is approximately double that of CCA concrete, measuring 4.45 MPa. This increase in strength is attributed to the fact that smaller PETA shapes function as fibrous materials, enhancing particle packing and overall strength.

-

4.

The application of a Multi-Criteria Decision-Making (MCDM) tool facilitated the ranking of the most suitable mix type among the tested trial mixes, taking into consideration various test parameters. It is concluded that PETA-Q, with an optimal 5% replacement of CCA, significantly enhances concrete strength and is ranked as the most suitable mix.

This study underscores the positive impacts of incorporating PETA in concrete, leading to improved structural properties, addressing CCA scarcity, and mitigating pollution stemming from discarded plastic bottles through sound waste management practices.

6 Limitations and scope for future work

The integration of PET waste in concrete production may not be universally suitable for all types of cement. The results of the experimental investigation emphasize that the replacement of conventional coarse aggregate with PET aggregates is most effective up to a 5% replacement ratio. Beyond this threshold, a noticeable decline in the mechanical properties of the concrete is observed. It’s worth noting that the tested concrete in this study was plain cement concrete, and variations may arise when dealing with reinforced cement concrete (RCC). In light of the limitations identified in this research, the following areas merit consideration for future studies.

-

1.

Further experiments are recommended to explore the generalization of these findings to reinforced cement concrete (RCC). This extension of the research can provide insights into the behavior of PET aggregates in a more complex and structurally demanding environment.

-

2.

The influence of different shapes of PET aggregates on the mechanical properties of concrete can be systematically investigated by varying the shapes and conducting comprehensive tests. This approach can yield a deeper understanding of how the geometry of PET aggregates impacts concrete performance.

-

3.

Exploring the long-term durability of concrete incorporating PET aggregates and evaluating the economic feasibility of this approach for large-scale applications are excellent avenues for further investigation. This area of study can delve into the long-term performance, resilience, and resistance of PET-modified concrete in various environmental conditions, providing valuable insights into its potential for sustainable construction.

Availability of data and materials

The authors declare that the data supporting the findings of this study are available within the paper.

Abbreviations

- PET:

-

Polyethylene terephthalate

- PETA:

-

Polyethylene terephthalate aggregates

- CCA:

-

Conventional coarse aggregates

- PETA-F:

-

Polyethylene terephthalate aggregates-full shaped

- PETA-H:

-

Polyethylene terephthalate aggregates-half shaped

- PETA-Q:

-

Polyethylene terephthalate aggregates-quarter shaped

- MCDM:

-

Multi criteria decision making

- AHP:

-

Analytical hierarchy process

- PPC:

-

Portland pozolana cement

- FA:

-

Fine aggregates

- CS:

-

Compressive strength

- STS:

-

Splitting tensile strength

- FS:

-

Flexural strength

References

Gayake SB, Desai AK (2022) A literature review identifying the scope for utilization of waste polyethylene terephthalate bottle fibers in concrete for enhancing structural properties, sustainable building materials and construction. In: Lecture notes in civil engineering, vol 222. Springer. https://doi.org/10.1007/978-981-16-8496-8_45

Mosa AM, Jawad IT, Salem LA (2018) Modification of the properties of warm mix asphalt using recycled plastic bottles. Int J Eng 31(9):1514–1520. https://doi.org/10.5829/ije.2018.31.09c.06

Statista (2021) India plastic consumption from year 1990 to 2021 in kilo tones per year. https://www.statista.com/statistics/1154434/India-net-plastic-consumption

Bamigboye G, Tarverdi K, Adigun D, Daniel B, Okorie U, Adediran J (2022) An appraisal of the mechanical, micro structural, and thermal characteristics of concrete containing waste PET as coarse aggregate. Clean Waste Syst 1(September 2021):100001. https://doi.org/10.1016/j.clwas.2022.100001

Islam MJ, Meherier MS, Islam AKMR (2016) Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr Build Mater 125:946–951. https://doi.org/10.1016/j.conbuildmat.2016.08.128

Tavakoli D, Hashempour M, Heidari A (2018) Use of waste materials in concrete: a review. Pertanika J Sci Technol 26(2):499–522

Edmund TSJ, Jun Hon C, Hejazi F, Jaafar MS (2019) Waste plastic as partial replacement for aggregates- a review. IOP Conf Ser Earth Environ Sci 357(1):012018. https://doi.org/10.1088/1755-1315/357/1/012018

Kim SB, Yi NH, Kim HY, Kim JHJ, Song YC (2010) Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cement Concr Compos 32(3):232–240. https://doi.org/10.1016/j.cemconcomp.2009.11.002

Gravina RJ, Xie T, Bennett B, Visintin P (2021) HDPE and PET as aggregate replacement in concrete: life-cycle assessment, material development and a case study. J Build Eng 44(August):103329. https://doi.org/10.1016/j.jobe.2021.103329

Chandran V, Raj TM, Lakshmanan T, Kumar MS (2015) Influence of different fillers on natural rubber composites to assess mechanical performance. Int J Eng 28(6 (C)):932–939. https://doi.org/10.5829/idosi.ije.2015.28.06c.14

Umasabor RI, Daniel SC (2020) The effect of using polyethylene terephthalate as an additive on the flexural and compressive strength of concrete. Heliyon 6(8):e04700. https://doi.org/10.1016/j.heliyon.2020.e04700

Tamrin, Nurdiana J (2021) The effect of recycled hdpe plastic additions on concrete performance. Recycling 6(1):1–19. https://doi.org/10.3390/recycling6010018

Shiuly A, Hazra T, Sau D, Maji D (2022) Performance and optimization study of waste plastic aggregate based sustainable concrete – a machine learning approach. Clean Waste Syst 2(April):100014. https://doi.org/10.1016/j.clwas.2022.100014

Lee ZH, Paul SC, Kong SY, Susilawati S, Yang X (2019) Modification of waste aggregate PET for improving the concrete properties. Adv Civ Eng 2019:6942052. https://doi.org/10.1155/2019/6942052

Coppola B, Courard L, Michel F, Incarnato L, Di Maio L (2016) Investigation on the use of foamed plastic waste as natural aggregates replacement in lightweight mortar. Compos B Eng 99:75–83. https://doi.org/10.1016/j.compositesb.2016.05.058

Islam MJ, Shahjalal M, Haque NMA (2022) Mechanical and durability properties of concrete with recycled polypropylene waste plastic as a partial replacement of coarse aggregate. J Build Eng 54(February):104597. https://doi.org/10.1016/j.jobe.2022.104597

Casanova-del-Angel F, Vázquez-Ruiz JL (2012) Manufacturing light concrete with PET aggregate. ISRN Civ Eng 2012:1–10. https://doi.org/10.5402/2012/287323

Marthong C (2015) Effects of PET fiber arrangement and dimensions on mechanical properties of concrete. IES J A Civ Struct Eng 8(2):111–120. https://doi.org/10.1080/19373260.2015.1014304

Liu T, Nafees A, Khan S, Javed MF, Aslam F, Alabduljabbar H, Xiong JJ, Ijaz Khan M, Malik MY (2022) Comparative study of mechanical properties between irradiated and regular plastic waste as a replacement of cement and fine aggregate for manufacturing of green concrete. Ain Shams Eng J 13(2):101563. https://doi.org/10.1016/j.asej.2021.08.006

Kangavar ME, Lokuge W, Manalo A, Karunasena W, Frigione M (2022) Investigation on the properties of concrete with recycled polyethylene terephthalate (PET) granules as fine aggregate replacement. Case Stud Constr Mater 16(February):e00934. https://doi.org/10.1016/j.cscm.2022.e00934

Garg A, Biswas S (2020) Determination of strength characteristics of concrete by partial replacement of aggregates with e waste and hdpe granules. J Xi’an Univ Archit Technol 2(2):90–108

Beiram AAH, Al-Mutairee HMK (2022) Effect of using waste rubber as partial replacement of coarse aggregate on torsional strength of square reinforced concrete beam. Int J Eng Trans B 35(2):397–405. https://doi.org/10.5829/ije.2022.35.02b.16

Saikia N, De Brito J (2013) Waste polyethylene terephthalate as an aggregate in concrete. Mater Res 16(2):341–350. https://doi.org/10.1590/S1516-14392013005000017

Fakhruddin, Irmawaty R, Djamaluddin R (2022) Flexural behavior of monolith and hybrid concrete beams produced through the partial replacement of coarse aggregate with PET waste. Structures 43(July):1134–1144. https://doi.org/10.1016/j.istruc.2022.07.015

Bamigboye GO, Tarverdi K, Umoren A, Bassey DE, Okorie U, Adediran J (2021) Evaluation of eco-friendly concrete having waste PET as fine aggregates. Clean Mater 2(July):100026. https://doi.org/10.1016/j.clema.2021.100026

Dawood AO, AL-Khazraji H, Falih RS (2021) Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud Constr Mater 14:e00482. https://doi.org/10.1016/j.cscm.2020.e00482

Aocharoen Y, Chotickai P (2023) Compressive mechanical and durability properties of concrete with polyethylene terephthalate and high-density polyethylene aggregates. Clean Eng Technol 12(February):100600. https://doi.org/10.1016/j.clet.2023.100600

Alqahtani FK (2022) Technical Assessment of Green lightweight concrete containing manufactured plastic aggregates. J Build Eng 50(December 2021):104169. https://doi.org/10.1016/j.jobe.2022.104169

Mohan R, Chakrawarthi V, Nagaraju TV, Avudaiappan S, Awolusi TF, Roco-Videla Á, Azab M, Kozlov P (2023) Performance of recycled Bakelite plastic waste as eco-friendly aggregate in the concrete beams. Case Stud Constr Mater 18:e02200. https://doi.org/10.1016/j.cscm.2023.e02200

Noryani M, Sapuan SM, Mastura MT (2018) Multi-criteria decision-making tools for material selection of natural fibre composites: a review. J Mech Eng Sci 12(1):3330–3353

Martínez IN, Albiñana JM, Piqueras VY (2018) Multi-criteria decision making techniques in civil engineering education for sustainability. In: Proceedings of ICERI2018 conference, November 2018. pp 9798–9807

Lin S-S, Zhou A, Shen S-L (2023) Optimal construction method evaluation for underground infrastructure construction. Autom Constr 132:104921. https://doi.org/10.1016/j.autcon.2023.104921

Lin S-S, Zhou A, Shen S-L (2023) A decision approach on risk-control scheme recognition for karst excavation engineering. Can Geotech J 60(9):1300–1314. https://doi.org/10.1139/cgj-2022-0508

IS 2386 (Part IV): 1963. Methods for Test of Aggregates for Concrete - Mechanical Properties. New Delhi: Bureau of Indian Standards; 1997.

IS 1489 (Part I): 1991. Portland Pozzolana Cement - Specifications. New Delhi: Bureau of Indian Standards; 1993.

IS 10262: 2009. Concrete Mix Proportioning - Guidelines. New Delhi: Bureau of Indian Standards; 2009.

IS 7320: 1974. Specifications for Concrete Slump Test Apparatus. New Delhi: Bureau of Indian Standards; 2008.

IS 516: 1959. Methods of Test for Strength of Concrete. New Delhi: Bureau of Indian Standards; 2004.

Funding

The authors did not receive any financial support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

*Sudhir Bahaskarrao Gayake- Conceptualization, Methodology, Formal analysis, Validation, Investigation, Writing - Original Draft. Dr. Atul K. Desai- Writing - Review & Editing, Supervision, Project administration.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gayake, S.B., Desai, A.K. Multi-criteria decision making tool for sustainable concrete production using waste polyethylene terephthalate bottle cap aggregates. Smart Constr. Sustain. Cities 2, 7 (2024). https://doi.org/10.1007/s44268-024-00031-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44268-024-00031-9