Abstract

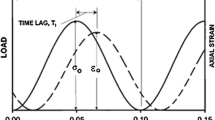

In this paper, laboratory experiments were conducted on two different asphalt mixes, one using the Marshall mix design method (MMD) and the second using modified Marshall mix design (3M) method. The 3M method is based on the incorporation of two factors, the new asphalt binders (performance grade) and the Superpave gyratory compactor (SGC) as in Superpave mix design method, into the traditional MMD method. All specimens had the same mixtures of aggregate gradation incorporated with two different compaction methods and two asphalt grades using two different classification methods: asphalt cement binder (B60-70) based on the penetration test (Pen system) and PG 70-10 based on performance grade system (PG). However, there were some errors at low temperature (− 25, − 10 °C) and high temperature (54 °C), so these values may be discarded. The tension–compression complex modulus test |E*| is dependent on temperature and loading frequency. Thus, the results of this test will give a more accurate representation of the absolute value of the tension–compression complex modulus test |E*| that defines the elastic properties of a linear viscoelastic material subjected to a sinusoidal loading. In addition, 2-complex modulus (E*) and phase angles (ΦE*) in the test have been measured at temperatures of − 25, − 10, − 5, 10, 25, 35 and 54 °C as well as frequencies of 25, 10, 5, 1, 0.5 and 0.1 Hz. The value of the dynamic modulus reflects the stiffness of the mixture and its resistance to deformation at a designated frequency and temperature. The results show an improvement in the |E*| in the modified 3M mix over the traditional MMD mix. The 3M method using asphalt binder PG 70-10 and gyratory compactor (SGC) as in Superpave mix design method, improves the |E*| of the asphalt mixture in HA climate. As well, intrinsic characteristics related to binder properties, aggregate gradation and compaction method in HA climate have the most significant effect on the predicted |E*|.

Similar content being viewed by others

References

Perraton D, Di Benedetto H, Sauzéat C, Hofko B, Graziani A, Nguyen QT, Pouget S, Poulikakos LD, Tapsoba N, Grenfell J (2016) 3Dim experimental investigation of linear viscoelastic properties of bituminous mixtures. Mater Struct 49(11):4813–4829

Nguyen QT, Di Benedetto H, Sauzéat C (2015) Linear and nonlinear viscoelastic behaviour of bituminous mixtures. Mater Struct 48(7):2339–2351

Nguyen QT, Di Benedetto H, Sauzéat C, Tapsoba N (2012) Time temperature superposition principle validation for bituminous mixes in the linear and nonlinear domains. J Mater Civ Eng 25(9):1181–1188

Gudmarsson A, Ryden N, Di Benedetto H, Sauzéat C (2015) Complex modulus and complex Poisson’s ratio from cyclic and dynamic modal testing of asphalt concrete. Constr Build Mater 88:20–31

Hall MR, Dehdezi PK, Dawson AR, Grenfell J, Isola R (2011) Influence of the thermophysical properties of pavement materials on the evolution of temperature depth profiles in different climatic regions. J Mater Civ Eng 24(1):32–47

Zhao Y, Liu H, Bai L, Tan Y (2012) Characterization of linear viscoelastic behavior of asphalt concrete using complex modulus model. J Mater Civ Eng 25(10):1543–1548

Yusupov B, Qiu Y, Ding H, Rahman A (2019) Temperature and material behaviour effects on dynamic responses of asphalt concrete trackbed. Int J Rail Transp. https://doi.org/10.1080/23248378.2019.1628671

Pellinen TK, Witczak MW (2002) Stress dependent master curve construction for dynamic (complex) modulus (with discussion). J Assoc Asph Paving Technol 71:281–309

Yi J, Shen S, Muhunthan B, Feng D (2014) Viscoelastic-plastic damage model of porous asphalt mixtures. Harbin Gongye Daxue Xuebao/J Harbin Inst Technol 46(2):66–71

Bazzaz M, Darabi MK, Little DN, Garg N (2018) A straightforward procedure to characterize nonlinear viscoelastic response of asphalt concrete at high temperatures. Transp Res Rec 2672(28):481–492

Bagampadde U, Kaddu D, Kiggundu BM (2013) Evaluation of rheology and moisture susceptibility of asphalt mixtures modified with low density polyethylene. Int J Pavement Res Technol 6(3):217–224

Witczak MW (1999) A comparison of the dynamic (complex) modulus test (E*) and indirect diametral test (Mr) for AC mixtures. White paper report, NCHRP

Singh D, Zaman M, Commuri S (2011) Evaluation of predictive models for estimating dynamic modulus of hot-mix asphalt in Oklahoma. Transp Res Rec J Transp Res Board 2210:57–72

Nasr D, Pakshir AH (2019) Rheology and storage stability of modified binders with waste polymers composites. Road Mater Pavement Des 20(4):773–792

Castillo D, Gamez A, Al-Qadi I (2019) Homogeneous versus heterogeneous response of a flexible pavement structure: strain and domain analyses. J Eng Mech 145(9):4019068

Loulizi A, Flintsch GW, Al-Qadi IL, Mokarem D (2006) Comparing resilient modulus and dynamic modulus of hot-mix asphalt as material properties for flexible pavement design. Transp Res Rec 1970(1):161–170

Ameri M, Yeganeh S, Valipor PE (2019) Experimental evaluation of fatigue resistance of asphalt mixtures containing waste elastomeric polymers. Constr Build Mater 198:638–649

Tetteh N (2018) Rheological evaluation of field-aged asphalt cements. A thesis submitted to the Department of Chemistry in conformity with the requirements for the degree of Master of Science. Queen’s University, Kingston, Ontario, Canada

El Atrash K, Assaf GJ (2018) The effect of several parameters on the behavior of asphalt mixture in Libya. In: Civil infrastructures confronting severe weathers and climate changes conference, 2018, pp 11–21

Perraton D, Di Benedetto H, Sauzéat C, Hofko B, Graziani A, Nguyen QT, Pouget S, Poulikakos LD, Tapsoba N, Grenfell J (2018) 3Dim experimental investigation of linear viscoelastic properties of bituminous mixtures. Mater Struct 49(11):4813–4829

Gong F, Liu Y, Zhou X, You Z (2018) Lab assessment and discrete element modeling of asphalt mixture during compaction with elongated and flat coarse aggregates. Constr Build Mater 182:573–579

Gandi A, Carter A, Singh D (2017) Rheological behavior of cold recycled asphalt materials with different contents of recycled asphalt pavements. Innov Infrastruct Solut 2(1):45

Cerni G, Bocci E, Cardone F, Corradini A (2017) Correlation between asphalt mixture stiffness determined through static and dynamic indirect tensile tests. Arab J Sci Eng 42(3):1295–1303

Baaj H (2002) Comportement à la fatigue des matériaux granulaires traités aux liens hydrocarbones. Lyon, INSA

Sanditov DS, Razumovskaya IV (2018) New approach to justification of the Williams–Landel–Ferry equation. Polym Sci Ser A 60(2):156–161

Acknowledgements

It is with great joy and lightness of spirit that I offer my deepest regards to my friends who have assisted and supported me in countless ways as I journeyed through the process of undertaking, creating and completing this paper. Then, I must express my gratitude to Professor Gabriel Assaf for giving me a wonderful opportunity to continue my studies at École de technologie supérieure and for being such an inspiring supervisor.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El Atrash, K.S., Assaf, G.J. Performance testing of asphalt paving mixtures for hot condition using tension–compression test. Innov. Infrastruct. Solut. 5, 3 (2020). https://doi.org/10.1007/s41062-019-0252-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-019-0252-x