Abstract

This paper presents a flexible framework that aims at estimating the risk of structural failure in sewer pipes by utilizing limited or imperfect data. To this end, classical risk analysis is enhanced by incorporating fuzzy logic and multi-criteria decision making. To account for the multi-dimensionality of collapse risk at the pipe level as a decision parameter, its distinct impacts on the environment, traffic and road condition, and quality of life are taken into account. The proposed method is applied to the sewer network of Tehran, the capital of Iran. Results show how the integration of different risk indexes can influence the criticality of pipelines for the selection of rehabilitation activities. While using the first individual risk index, only considering the risk posed to the natural environment by a collapsing pipe in terms of contamination, approximately half of the pipe lengths are classified as extremely critical by the clustering algorithm. However, when the integrated risk is calculated, this cluster encompasses only approximately 30% of the total pipe length. With a database that contains various levels of uncertainty (from 10 to 60%), the predictive reproducibility for the exact same risk cluster is above 20% and above 50% for the same or only marginally better or worse. Furthermore, pipelines that are predicted to have a better risk class than the situation without considering uncertainty, thereby underestimating the likelihood of failures or consequences, are below 15%, showing a measure of quite good robustness. Considering the budget constraints of utilities, the proposed method can be applied to any urban, aiding in the identification of high-risk sections. Nevertheless, incorporating physical validation might be beneficial for further improving the analysis.

Similar content being viewed by others

1 Introduction

Sewer pipes, which represent one of the most capital-intensive urban assets [1] and serve as the primary means of transporting wastewater, require periodic inspection and rehabilitation. In times of limited budgets, asset management has become a focus over new designs and construction [2]. In this regard, decision-makers need to have access to well-structured models that enable them to prioritize their assets for inspection and rehabilitation activities in a proactive manner. The implementation of such a prioritization process allows utilities to effectively allocate their limited budget towards critical assets. This results in more efficient utilization of resources and improves the management of infrastructure assets. Currently available frameworks, based on pipe failure prediction models [3, 4] or pipe deterioration models [5,6,7,8], offer valuable insights to wastewater utility managers regarding the probability of failure and allow a prediction of the condition of pipelines in their districts. However, relying solely on these models can lead to inappropriate management decisions, as they often assume all elements of the pipe network are of equal strategic importance, which is rarely the case [9]. Therefore, to prioritize network components in a more rational way, it is essential to consider the consequences of failure (CoF) in combination with a failure/deterioration prediction [10] in a risk-based approach. It is crucial to consider the consequences because failures in more vulnerable parts of networks can result in significant and sometimes devastating outcomes, such as pathogen spill, pollution of groundwater and waterways, damaging critical buildings and roads, and disruption of other essential services. Consequently, frameworks that incorporate risk assessment can help improve resource allocation and enhance the management of sewer pipes [11, 12].

Researchers have provided different definitions of risk. However, they all share certain common characteristics. Risk can be described as an unexpected future event characterized by significant uncertainties that can have adverse effects on planned objectives [13]. That means that risk refers to the likelihood of an event causing undesirable consequences [14]. Accordingly, in the context of sewer pipe asset risk assessment, there are two primary components [11]: (1) predicting the condition of pipes or, more broadly, assessing the likelihood of failure (LoF), and (2) identifying and estimating CoF. Various models have been developed to evaluate the risk of sewer pipes failure, employing techniques such as Bayesian belief networks [15], regression and probability theory [16, 17], and fuzzy logic [18,19,20]. Nevertheless, previous studies have often overlooked the simultaneous consideration of the following points:

Shortcoming I: In-situ evaluations of conditions can often contain remarkable errors [21,22,23]. Consequently, the efficiency of condition prediction models, which rely on significant and precise data, as well as the efficiency of inspection plans, can be adversely affected [24, 25]. This situation worsens when the quality of available data is low, there is a high percentage of missing values, or the network has recently been put into operation, and there is no condition assessment data or only ones with the same condition class. Thus, a flexible framework is required to utilize the available limited or imperfect data from pipes for estimating their LoF.

Shortcoming II: Due to the challenges associated with obtaining sufficient historical data for probabilistic analysis, qualitative risk assessment methodologies that rely on expert judgment are gaining popularity [13]. However, human decision-making inherently involves ambiguity, making it unrealistic to express such decision variables with absolute numerical values. Besides, uncertainties are a non-separable part of any risk assessment process [26, 27], and disregarding them can result in an inefficient assessment [13]. Previous research has not adequately addressed this aspect [e.g., [28, 29]], while it must be a crucial consideration in any proposed risk assessment framework.

Shortcoming III: Previous studies have often treated the CoF as crisp variables [9, 11], overlooking their intangible nature. Even in studies that considered their fuzzy nature [18], there was a limited exploration into the specific details and types of these consequences (e.g., environmental, social, or economic). Consequences were merely expressed as a single generalized value, and their criticality was described using a qualitative scale with nine grades, ranging from extremely low to extremely high. However, these studies did not provide further information regarding the evaluation process. Then, the development of a framework capable of independently considering each of the CoF, incorporating their inherent uncertainties, and providing an explicit evaluation procedure is of utmost importance.

Shortcoming IV: Previous studies [9, 11] have utilized risk matrices to interpret the estimated risk by mapping the LoF and its associated consequences. Such matrices are often employed to simplify the process and make it easily understandable for the decision-maker. However, risk matrices also have the following limitations [30]: poor resolution, potential errors in assigning rates, suboptimal allocation of resources, and the subjective interpretation required for both input and output. Accordingly, it is advisable to consider adopting a more suitable approach for classifying risk values (RVs).

It should be highlighted that previous research [18, 31] has often overlooked the potential benefits of incorporating a Geographical Information System (GIS) into the risk assessment process. In some cases, GIS was only partially implemented, such as utilizing proximity tools [32]. While by leveraging GIS and including a broader range of information, such as environmental characteristics like soil type, the precision, and comprehensiveness of risk assessments can be significantly enhanced. It is worth noting that combining multicriteria decision analysis with GIS not only serves as an effective tool for making critical decisions is designing, evaluating, and prioritizing possible alternative courses of action [33,34,35], but also, in the context of buried infrastructures, incorporating GIS can assist companies in the development of integrated multi-infrastructure asset management. This enables utilities to cost-effectively manage public assets [36].

This paper aims to accomplish the following main objectives: (1) introduce a flexible framework that utilizes the limited/imperfect available data to estimate the risk of structural failure in sewer pipes by estimating its components (namely LoF and CoF); (2) address the uncertainties inherent in the recorded/registered data as well as in the decision-making process; (3) analyze various aspects connected to the risk of structural failure in sewer pipes by categorizing the consequences into different groups. To achieve this, we propose a hierarchical risk assessment model based on fuzzy logic, inspired by the work of Le Gauffre and Cherqui [37]. This model prioritizes pipes for inspection and rehabilitation based on their risk values. It leverages GIS and incorporates uncertainties in the input data and expert opinions to estimate the LoF and CoF using Fuzzy membership functions (FMFs). A detailed description of the risk assessment method is provided in the subsequent section, followed by its application to a comprehensive case study conducted in Tehran, Iran. Results demonstrate the benefits of adopting the proposed framework in prioritizing infrastructure assets for inspection/rehabilitation activities. Furthermore, the framework exhibits stability even in the presence of uncertain data, as evidenced by the case study conducted.

2 Material and Methods

Figure 1 illustrates the comprehensive flowchart of the proposed risk assessment method. The method consists of four key phases: (1) data collection, (2) identification of effective factors on risk components and estimation of their relative importance, (3) calculation of risk at the pipe level based on the pre-defined FMFs, and (4) clustering of sewer pipes based on their defuzzified values and creating risk maps. These four phases are described in detail in the subsequent sub-section. The description of the step-by-step approach includes justifications for their necessity, which are linked to the shortcomings identified in the introduction. Furthermore, references to relevant research are provided when appropriate to support the methodology.

Step 1—Phase 1 (addressing shortcoming V): Data should be collected from various sources, including wastewater utility pipeline mapping system, municipality land use maps, and maps of major surface and groundwater resources provided by the regional water company. This data collection process should encompass both the characteristics of the pipes (such as age, length, diameter, and material) and the surrounding environment (including road types, soil classification, groundwater levels, and proximity to critical buildings). Here, the data collection phase is based on the GIS, which is an ideal tool for gathering and organizing diverse spatial information data.

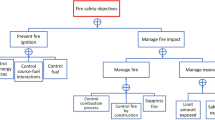

Step 2—Phase 2 (addressing shortcoming III): The factors that influence LoF and CoF are derived from the data collected in Phase 1, utilizing a hierarchical structure as depicted in Fig. 2. The estimation of LoF is based on the most common and well-repeated affecting factors extracted from a deep analysis of the existing literature (including references [38,39,40,41,42,43,44]). These factors are categorized according to suggestions proposed by Davies et al. [5], as illustrated in Fig. 2 at level 1. Besides, since expressing the CoF in monetary terms can often be challenging, municipalities may find it beneficial to develop quantitative indices for measuring the consequences of failure. These indices can facilitate comparisons and help identify areas that are most susceptible to potential failures.

Accordingly, in the proposed method, environmental and socio-economic impacts were categorized into three distinct classes, namely ‘Environmental impact’, ‘Traffic and road’, and ‘Life quality and public/private property’, as illustrated in Fig. 2 at level 2. Given the limited availability of information on the consequences of pipe failure [45], well-known components of CoF were identified through an extensive review of previous research [11, 15, 31, 45, 46]. It is important to emphasize that the proposed hierarchical structure allows for the incorporation of any relevant factors collected by utilities, without limitations. It enables the inclusion of additional factors that can contribute to a more comprehensive assessment of risk.

Step 3—Phase 2 (addressing shortcomings I and III): Each effective factor needs to be evaluated at the pipe level. In general, many wastewater utilities face challenges in accessing precise and high-quality data, and some essential data, such as environmental and socio-economic consequences, can be intangible in nature. To address these limitations, a fuzzy approach was adopted in this study. The concept of fuzzy theory, initially introduced by Zadeh [47], allows for objects to have membership values between 0 and 1, representing the degree of membership. A value of 0 indicates that the object is not a member of the fuzzy set, while a value of 1 indicates full membership. Intermediate values lie between these extremes. This method can effectively handle vague, imprecise, and ambiguous input information [48, 49].

The current paper utilized the triangular fuzzy number (TFN) for this purpose due to its simplicity and familiarity [13]. Figure 3 provides a visual representation of the suggested TFNs for “Pipe depth” and “Traffic density”. It should be mentioned that the classification of parameter values is based on suggestions from previous studies. For example, Sousa et al. [50] classified pipe depths between 2 and 5 m as medium depth, which has the lowest impact on sewer pipe structural failure compared to higher and lower depth values. Similarly, Salman and Salem [9] proposed that local roads should be considered low-traffic roads, which also have a lower impact on sewer pipe structural failure compared to heavily trafficked roads such as highways. Hence, these defined classes were mapped to the lowest defined fuzzy number in the present study, represented as (0, 0, 3). The fuzzy classifications for all parameters are presented in Table S1 and Table S2 (Supplemental Materials A). It should be noted that the sum of memberships does not necessarily have to add up to 1. Moreover, while fuzziness is an objective aspect in simulation, the presentation of FMFs is subjective, there is no unique rule for determining suitable FMFs.

Suggested fuzzy membership function for a Pipe depth; b Traffic density (Note: the y-axis is the membership value, and the x-axis is the performance value adopted in this study and for all of the factors is divided between 0 and 10 and it is dimensionless; Please see Supplemental Materials A. As these parameters were classified very differently in previous studies, authors consider some level of uncertainty while defining fuzzy sets for them.)

Step 4—Phase 2 (addressing shortcoming II): According to Figs. 1 and 2, estimating individual risks requires considering the influence of each effective factor on the LoF and CoF. Therefore, it is necessary to determine the relative importance of each parameter in the hierarchical structure. One of the multi-criteria decision analysis methods successfully used in different decision-making problems and has been increasingly used in the last two decades is the Analytic Hierarchy Process (AHP) [51, 52]. However, some critics raised concerns regarding AHP’s inability to deal with the inherent uncertainties and imprecision in translating a decision-maker’s perception into precise numerical values [53]: Inaccurate perception of relative importance by an expert can easily impact the assigned weights [54]. To address these concerns and enhance result accuracy, AHP can be integrated with fuzzy logic. The Fuzzy Analytic Hierarchy Process (FAHP) combines the advantages of conventional AHP, such as handling a combination of qualitative and quantitative data, providing a hierarchical structure, uncomplicated decomposition, and enabling pairwise comparison, with the ability to handle approximate information and uncertainty inherent in human thinking [55]. Besides, by incorporating linguistic variables and fuzziness, FAHP ensures a more realistic evaluation [56]. Therefore, FAHP was adopted here to estimate the relative importance of parameters. In this regard, the fuzzy relative weight of elements (Ws) in each level (as shown in Fig. 2) is calculated through the following steps [53]:

Pairwise comparison matrices are established for each group of factors in the hierarchy structure (Eq. 1). In this step, experts are requested to conduct pairwise comparisons and indicate which of the two elements is more important, based on the proposed scale in Fig. 4.

where \({\widetilde{a}}_{ij}\): denotes the fuzzy relative weight of element i compared to element j, and n: is the total number of elements in each comparison set. To ensure the overall coherence of the experts’ judgments, the consistency ratio (CR) of the pairwise comparison matrix needs to be assessed before proceeding to the next step [57].

Calculate the fuzzy geometric mean and fuzzy weight of each element through Eqs. 2 and 3, respectively [53, 57]:

where \({\widetilde{a}}_{in}\): denotes the fuzzy relative weight of element i in comparison to element n, \({\widetilde{r}}_{i}\): is the geometric mean of the fuzzy comparison values for element i compared to each of the other elements, and \({\widetilde{W}}_{i}\): is the normalized fuzzy weight of ith element, which can be represented by a TFN: \({\widetilde{W}}_{i}=({LW}_{i}, {MW}_{i},{UW}_{i})\), where \({LW}_{i}\), \({MW}_{i}\), and \({UW}_{i}\): show the lower, middle, and upper values of the fuzzy weight number, respectively. In the equations above, the symbol ⊗ denotes the multiplication of fuzzy numbers. It is worth mentioning that the process of determining weights can be continued until defuzzified weight numbers are obtained (as suggested by Chen et al. [53]). However, in the present study, since we are working with fuzzy weights, this process is stopped at this point and no further steps are taken.

Standard fuzzy arithmetic and Vertex methods are the two most important computational solutions for implementing the fuzzy extension principle [58, 59]. However, standard fuzzy arithmetic has a main drawback in that it accumulates input uncertainties, resulting in large and unrealistic uncertainty bounds in fuzzy outputs [60]. To elaborate, after multiple system simulation steps, the fuzziness of the results tends to produce unrealistically large values. On the other hand, the Vertex method also has inherent disadvantages, such as complex calculation [61]. To overcome these limitations, Nasseri et al. [60] incorporated fuzzy approximate reasoning into their proposed approach, achieving a reasonable level of uncertainty propagation from model parameters to outputs [60]. Moreover, the efficiency of this method surpasses that of the Vertex method. Therefore, the novel fuzzy arithmetic method proposed by Nasseri et al. [60] was adopted in the present study. The key components of this method are explained below.

Assume the symbolic operator “Θ” denotes one of the four arithmetic operations (addition, subtraction, multiplication, or division). Also, let \(\widetilde{A}\), \(\widetilde{B}\), and \(\widetilde{C}\) be three fuzzy numbers with crisp values a, b, and c, respectively. In this context, \(\widetilde{C}=\widetilde{A}\Theta \widetilde{B}\) is defined as Eq. 4:

where the expression \(\left[a\Theta {\mu }_{B}(x)\right]\): demonstrates the impact of the crisp value a on the fuzzy number \(\widetilde{B}\) and “V”: means “OR” fuzzy operator, which functions similarly to the “OR” operator in Mamdani fuzzy inference [60]. Here, it is assumed that the fuzziness of \(\widetilde{C}\) is equal to the maximum fuzziness of the input numbers \(\widetilde{A}\) and \(\widetilde{B}\).

Step 5—Phase 3 (addressing shortcoming III): Once the relative fuzzy weights (Wj and Wji) were obtained, the fuzzy value of each CoF and LoF group (Fig. 2, level 2) is calculated using Eqs. 5 and 6:

where \({\widetilde{AF}}_{j}\): is the fuzzy aggregated factor for jth effective group in each of the risk components (likelihood or consequence), \({\widetilde{W}}_{ji}\) and \({\widetilde{V}}_{ji}\): are the fuzzy weight and fuzzy value of the ith factor in the jth effective group, respectively. In the following equation, \({\widetilde{CR}}_{k}\): is the kth fuzzy component of the risk and \({\widetilde{W}}_{j}\): is the fuzzy weight of the jth fuzzy aggregated factor. For example, in the present study based on Fig. 2, j = 1 for each consequence group, but j = 3 for LoF. It is noteworthy that in the proposed method of this study if some of the effective factors related to the pipe’s failure (or its consequences) are missing for a group of pipes, LoF and CoF can still be estimated for them by considering other available effective factors.

Step 6—Phase 3: Subsequently, to calculate fuzzy individual risks, LoF and CoF should be multiplied [31]. Accordingly, the individual risks for each pipe are calculated by multiplying the risk components (likelihood and consequences) employing Eq. 4 (Fig. 2, Level 3).

Step 7—Phase 3 (addressing shortcoming II): To determine the fuzzy combined risk (Fig. 2, Level 4), the relative importance of individual risks needs to be estimated. Two different approaches were adopted and compared here: in the first method, individual risks are compared by defining management criteria and using FAHP. The fuzzy comparison matrix is created by gathering expert opinions (similar to Eq. 1). Then, fuzzy relative weights of individual risks are calculated based on Eq. 3. In the second approach, different individual risks receive dynamic fuzzy weights that reflect the impact of each RV. This means that for each pipe, the minimum weight (from a user-defined set of weights) is assigned to a risk evaluated as non-critical, and the maximum weight is assigned to an extremely critical risk. Accordingly, the middle classes are assigned weights that lie between these two extremes. This concept, first suggested by Elsawah et al. [31], implies that the higher RVs tend to deteriorate to the next level more rapidly. Afterward, the fuzzy-weighted individual risks are integrated, and the fuzzy combined risk is calculated at the pipe level using Eq. 7.

where \(\widetilde{R}\): is the fuzzy combined risk, \({\widetilde{R}}_{i} and {\widetilde{W}}_{i}\): are fuzzy individual risks and their corresponding fuzzy relative weights, respectively.

Step 8—Phase 4: The fuzzy combined risk is then defuzzified. Various defuzzification methods have been proposed, including the centroid, bisector, middle of maximum, etc. [62]. In the present study, the centroid method, which is the most used defuzzification approach [63], was employed to calculate the crisp combined RV (Eq. 8).

where \({RV}_{crisp}\): is the crisp value of combined risk, and f(x): is the area under the fuzzy membership curve. It should be emphasized that the centroid technique considers both the shape and distribution of the fuzzy set. On the other hand, other approaches such as the middle of maximum approach ignore the distribution and importance of other components in favor of concentrating just on the peak values of the membership function.

Step 9—Phase 4 (addressing shortcomings IV and V): Finally, to enhance the comprehensibility of the combined RVs for decision-makers, they are clustered using the K-means algorithm, considering classes proposed in Table 1, and then mapped in GIS. The main advantage of cluster analysis is grouping similar data. As a result, revealing patterns that may not have been apparent previously and facilitating decision-making. In the following section, a real case study is investigated to illustrate the application of the proposed method. It should be emphasized that this study solely focuses on the assessment of pipe collapse risk.

3 Case Study

To evaluate the practicality of the proposed fuzzy risk assessment method, real data from the second sub-district of District 2 of Tehran Water and Wastewater Company (as shown in Fig. 5) were used to estimate the risk of failure for each sewer pipe section and classify them for inspection and replacement (as depicted in Fig. 1, phase 1).

Studied area (Blue, green, and orange lines specify sub-districts number 1, 2, and 3, respectively; NW: Region with smaller diameters than 400 mm) [64]

The case study encompasses a network with a total length of over 45 km, with the majority of the sewer pipes being constructed within the last 15 years. It represents a relatively new section of Tehran’s sewer network, representative of many other parts of the city. Therefore, limited data was available concerning the condition of the pipes, as no visual inspection survey had been conducted. This poses challenges for the utility when it comes to prioritizing inspection and rehabilitation efforts. Throughout the course of this research, the absence of decision-support tools resulted in the random selection of sections for maintenance activities, often leading to unnecessary actions being undertaken. It should be emphasized that the focus of the present study was on pipes with a diameter higher than 400 mm. However, to demonstrate the versatility of the proposed method, a portion of the network (referred to as NW in Fig. 5) with smaller diameters was also examined.

To form the first level of hierarchy (as illustrated in Fig. 2), pipe information was extracted from an existing capital asset inventory maintained within ESRI ArcGIS (Fig. 1, phase 2). Some examples of this information are presented in Fig. 6. It is worth mentioning that the contractor’s grade was taken into consideration as an indicator of the pipeline installation quality. Data regarding the pipes’ environment was obtained from other available datasets, such as Tehran municipality’s land use information layers and layers of major surface and groundwater resources information provided by Tehran regional water company. These data were carefully reviewed for consistency, and whenever possible, incomplete data were either completed by referring to other accessible resources or estimated based on the information available for adjacent pipes. For instance, if the soil type data was missing for a particular pipe, it was assumed to be the same as that of the nearest pipe. This procedure was carried out by the authors through a case-by-case analysis to address each instance of missing data. In addition, to calculate distance-related parameters, the Euclidean distance and zonal statistics tools of ESRI’s Arc toolbox were employed (e.g., distance to critical buildings).

4 Results

To commence the fuzzy risk assessment, the physical and environmental characteristics of the pipes were fuzzified using the suggested FMFs (refer to Supplemental Materials A). It is worth mentioning that using crisp values to evaluate the attributes of the pipes, as adapted in Baah et al. [11], could lead to inaccurate assessment, as the hard cut of the data can result in an abrupt classification of the objects [65]. Based on the suggestion of Biswas and Zaman [13], incorporating the knowledge of experts with diverse backgrounds and disciplines in similar projects is crucial for the risk assessment process. Therefore, a questionnaire (see Supplemental Materials B) was prepared and distributed among university professors, consultants, and contractors working in the wastewater industry in Tehran. They were asked to make pairwise comparisons to determine the relative importance (weights) of different factors based on their expertise and the suggested values in Fig. 4. Eventually, 32 questionnaires were received, with university professors accounting for 25%, consultants and contractors for 35%, and personnel of the wastewater department of Tehran for 40% of the respondents. In the present study, weights were assigned to experts based on their experience, knowledge, and expertise to aggregate their judgments. For example, university professors and experts with more than 15 years of related field work received a weight of 0.5; while experts with 5 to 15 years of experience and those with less than five years of experience were assigned weights of 0.33 and 0.17, respectively. According to FAHP results, the criteria of wastewater type, pipe depth, and road type were identified as the most influential factors affecting the LoF. It should be noted that CR values of all comparisons were checked and found to be less than 0.1, ensuring the coherence of the expert judgments.

Concerning the CoF, the evaluation identified soil contamination, service interruption of critical buildings, and a drop in people’s work efficiency and comfort as the three most significant consequences. Subsequently, using the collected information, the overall fuzzy Lof and CoF for each pipe were calculated using Eqs. 5 and 6 (refer to Fig. 1 and Phase 3). It is worth noting that in cases where there is sufficient recorded data available regarding past structural failures of sewer pipes in the network (which is typically applicable to older networks), probabilistic methods can be utilized as an alternative approach to estimate the LoF (please refer to Anbari et al. [15] for further details).

Utility managers usually base their decisions on the combined RV. However, examining the criticality of pipes under individual risks can provide them with a more transparent perspective. Therefore, it is necessary to understand the criticality of pipe states for each risk before calculating the combined risk. To accomplish this, the values of individual risks were defuzzified and clustered using the K-means algorithm, as described in Table 1. Figures 7a–c present a snapshot of the pipe network based on different individual risk indices in GIS. Regarding these figures, pipes tend to show higher criticality under the first individual risk index: Risk of environmental contamination induced by the collapse of a pipe. Approximately 50% of the total pipe length clustered in risk group number 3, extremely critical (Fig. 8). One main reason for this is the coarse-grained soil type in this region, which allows polluted wastewater to spread easily in the event of pipe collapse giving a high CoF value. Based on Fig. 7a, a significant portion of the primary transmission pipes, which have larger diameters, fall under this category. This is because these pipes carry a substantial amount of sewage, and in the event of a structural failure, can swiftly contaminate the surrounding areas. On the contrary, when only considering the risk of annoyance of life quality and increased public expenditure induced by the collapse of a pipe, nearly 60% of pipes were classified in cluster number 1 (Fig. 8). In this case, the ending and main collective branches generally have higher RV because if they collapse, nearly all customers would face wastewater drainage problems (Fig. 7c). Less than 30% of pipes were grouped as extremely critical when subjected to the evaluation of traffic disturbance and road damage (Figs. 7b and 8). In this case, the risk of pipeline failure affecting local streets was relatively low due to the limited traffic volume. Conversely, most of the main streets fall under the moderately/extremely critical categories.

Risk maps of sewer pipe collapse in GIS a Risk of environmental contamination induced by the collapse of a pipe; b Risk of traffic disturbance and road damage induced by the collapse of a pipe; c Risk of annoyance of life quality and increased public expenditure induced by the collapse of a pipe; d Combined risk under Scenario 1 (with 3 clusters); e Combined risk under Scenario 2 (with 3 clusters); f Combined risk under Scenario 3 (with 3 clusters); g Combined risk under Scenario 4 (with 3 clusters). Some of the differences between Figs. d–g were encircled

To obtain the fuzzy combined risk, the fuzzy individual risk indices need to be integrated. As discussed in the methodology section, two different approaches were used for this purpose. In the first approach, experts compared individual risks based on three predefined risk management criteria (Table 2) to estimate their relative severity (relative weights) from different managerial perspectives. Here, 3 management criteria were introduced: The specific risk in question presents a significant threat, with the potential for severe consequences and detrimental impacts on various aspects of the affected area or system (Scenario 1), minimizing the risk necessitates significant financial investments to cover the required costs associated with mitigation measures, preventive actions, and necessary infrastructure upgrades (Scenario 2)”, and utilities face various challenges and obstacles in effectively managing the associated risk, including limited resources, complex regulatory frameworks, technological limitations, etc. (Scenario 3)”. Table 2 presents the details of the obtained fuzzy weights under each scenario by analyzing the collected questionnaires. Based on this table, for instance, from the point of the jeopardy of the risk, the collapse of the pipe will have the biggest impact on traffic disturbances and road, according to experts; therefore, it has the greatest influence on the calculated combined risk under this scenario.

Considering the weights provided in Table 2 and calculating the weighted sum of individual risks under each scenario, the fuzzy combined risk for each pipe asset was calculated, defuzzified, and subsequently mapped in GIS (Fig. 7d–f). Based on these figures and Fig. 8, the aggregation of individual risk indices under the three scenarios yielded almost identical results: about 30% of pipes’ length classified as extremely critical. The minor differences are encircled (Fig. 7d–f). According to the results, based on the weights obtained in Table 2, changing the scenario does not significantly affect the risk cluster for most of the pipes. However, integrating the risk indices resulted in a different distribution of clusters compared to the individual risk indices. For instance, when considering the first individual risk index (Risk of environmental contamination induced by the collapse of a pipe), approximately half of the pipe lengths were classified as extremely critical. However, after calculating the integrated risk, the percentage reduced to approximately 30% of the pipe lengths falling into this cluster. Another example is the decrease in the percentage of the pipes classified as non-critical, which decreased from ~ 60% (under the third individual risk index) to approximately 40% after integrating the individual risks.

In the second approach (which will be referred to as scenario 4 from here on), the weights assigned to each risk were pre-defined and had a fuzzy value ranging from (1, 1, 3) to (7, 9, 11) (similar to Fig. 4). These weights are assigned based on individual risk values to reflect their impact/importance when calculating the combined risk. This means that a minimum weight of (1, 1, 3) was assigned to low individual risk values (not critical), while a maximum weight of (7, 9, 11) was assigned to very high individual risk values (extremely critical). The results obtained in scenario 4 were close to those of the earlier three scenarios mentioned above (Fig. 7d–f), with a slight difference: it tended to classify approximately 15% more pipe lengths in cluster 3, which represents the extremely critical (Figs. 7g and 8). This indicates that assets with higher risk values are more likely to degenerate to the next level compared to those with lower risk values. Therefore, it can be inferred that the clusters presented in this method have the potential to provide a more realistic representation and a more accurate reflection of the actual risk levels.

One of the main reasons for this resemblance could be the low number of clusters. To test this hypothesis, the integrated risks were classified into 5 clusters. It should be noted that here 2 intermediate classes were added to the categories of Table 1; Partially critical: If there is a budget available, risk should be monitored to identify any changes or developments; and High critical: Risk requires high attention, although immediate inspection/rehabilitation activities may not be necessary. By comparing Figs. 8 and 9, the results of increasing the number of clusters are revealed. According to Fig. 9, for instance, in Scenario 3, roughly 55% of pipes fall into the non-critical category (cluster no.1), which is 4, 2, and 2 times greater than the corresponding values in Scenarios 1, 2, and 4, respectively. Likewise, the length of pipes in the fifth cluster (extremely critical) in Scenario 1 is very close to Scenario 2, but 1.5 and 3 times higher than Scenarios 3 and 4, respectively. Similar comparisons can be made for other clusters.

4.1 Impact of Uncertain Data

To validate the assertion that the proposed method can deal with uncertain data, the values in the existing database were assumed to be certain. Subsequently, to generate a database with x% uncertainty, the value of x% of all effective factors on LoF and its consequences (Fig. 2, level 1) were randomly misplaced into other available categories (according to Table S1 and Table S2), where they did not belong. The changing procedure was continued until the cumulative number of selected factors exceeded the target percentage (x%). As it is out of the scope of the present study, to read more in detail about this procedure, please refer to Roghani et al. [25]. In the current study, x% varies from 10 to 60% at 10% intervals. This range was selected to cover networks of different ages, including newer networks with the possibility of accessing more accurate data and older networks with low-quality data. It should be emphasized that to obtain the combined RV at the pipe level, the steps were the same as those mentioned in the methodology section, using the same weights for the factors as before.

Moreover, to integrate individual risks and calculate combined RV, scenario 4 (dynamic weights) was adopted here as a more realistic approach. The defuzzified combined RV was clustered into 5 classes to provide a more transparent ranking. Figure 10 provides a comprehensive comparison of the reproducibility of the defuzzified RV cluster numbers. According to this figure, the assigned cluster for each pipe can be categorized into one of the following 4 categories in comparison to its original cluster:

-

1-

If a cluster is precisely predicted→Predicted accurately

-

2-

If a cluster is predicted with a difference of 1 cluster (higher or lower) → Predicted marginally inaccurately

-

3-

If it is predicted with a difference of 2 clusters higher (lower) compared to its original risk cluster → Predicted slightly inaccurately

-

4-

If it is predicted with a difference of 3 or 4 clusters higher (lower) compared to its original risk cluster → Predicted inaccurately

Based on this figure, as the percentage of the uncertainty of input data increases, the percentage of accurate risk cluster prediction decreases to some extent (from 32 to 22%). It should be noted that even in the worst case where all input data have 60% uncertainty, the risk cluster was accurately predicted for 22% of the pipes. The introduction of uncertainty in the input data also led to overestimation errors in risk clustering. In other words, the risk status of some pipes was estimated to be worse compared to their original risk value, resulting in their placement in higher-numbered clusters: blue segments in Fig. 10). In the present case study, this error is in the range of 27–40%. It should be noted that this type of error impedes the reproducibility level of cluster prediction but does not pose any hazard in the district. However, it can result in increased operational expenditures for inspection and/or maintenance tasks. The segments on the far right of Fig. 10, which are anticipated to be worse than the situation without uncertainty, however, may result in an emergence of more unneeded expenses in comparison to the other two segments. On the other hand, pipes whose risk cluster has been underestimated (meaning their risk cluster is predicted to be lower than their original risk cluster) may increase the potential for failure and consequences in the region if they are ignored during maintenance activities. According to Fig. 10, this error (represented by a combination of yellow, orange, and red segments) increases with the level of uncertainty, ranging from 35 to 46%, and then reduced to 39% for 50% and 60% uncertainty levels. In general, the occurrence of this type of error in predicting the risk class in the presence of uncertainty is higher compared to the previous error when applying the method proposed in this study. However, pipes in the far-left segments in Fig. 10, whose risk class is predicted to be better than the condition without uncertainty, and have a higher potential for failures or consequences if ignored, account for less than 15% in most cases.

In reality, the quality of each effective parameter varies, and each parameter may have different levels of uncertainty. Therefore, another uncertainty scenario was examined, where there was 75% uncertainty in intangible parameters (e.g., Drop in people’s work efficiency and comfort due to delays, odor, and noise), and 25% uncertainty in the rest. It can be seen that the risk cluster is accurately predicted for 21% of the pipes, similar to the cases with 50% and 60% uncertainty in all parameters. However, compared to the aforementioned instances, the percentage of pipes with an underestimated risk cluster has increased (similar to the case of 20% uncertainty in all parameters), while there are fewer pipes with an overestimated risk cluster in this case, providing a sufficient measure of robustness in the prioritization process.

5 Discussions

Risk and uncertainty are often not considered in the decision-making on sewer rehabilitation [32], which can lead to inefficient planning. Besides, because of the limited available data, water and wastewater utilities must often combine experts’ opinions and available data with a suitable risk assessment method. In the present study, employing fuzzy logic and multi-criteria decision-making, the effectiveness of a classical risk analysis approach was enhanced. The method improves upon existing methods in several ways. First, it offers a more pragmatic way to prioritize sewer assets for maintenance activities, especially for the utilities that suffer from a limited amount of available data and is not enough to build deterioration models, identify main explanatory factors, etc. As a potential solution, in assessing the likelihood of failure, the presented method uses information commonly available to municipalities (e.g., age, pipe length, burial depth, etc.). In addition, it provides an easy way to assess and incorporate the consequences of failure in the decision-making framework for sewer network maintenance.

The use of fuzzy logic in this study was important because of the taking epistemic uncertainty of the risk assessment process into account. In fact, this method addresses uncertainties in the risk assessment process by (a) using FMFs to evaluate effective risk factors and (b) using TFNs to compare elements in the hierarchical structure to determine their relative weights. Any attempts which adjust uncertainty in decision-making models improve the results’ accuracy. Moreover, the GIS, as a useful auxiliary geospatial tool that accepts various types of data, was integrated into the method to provide classified risks’ visual representation. Accordingly, decision-makers can easily compare the risk of failure index for the different sections, visually identify sewer-pipe assets in immediate need of attention and track the results of changes in the values of the parameters.

The proposed approach was implemented and tested in a full-case study: the second sub-district of District 2 of Tehran Water and Wastewater Company. To estimate the likelihood and the consequences of failure, the most important 20 effective factors were extracted, and the hierarchical structure for risk assessment was formed. Then, the relative importance of each extracted factor on the LoF and CoF was obtained through the FAHP method and by distributing a questionnaire among the experts. In the next step, to investigate more comprehensively the overall risk of collapse at the pipe level, three distinct individual risks were defined: (1) Risk of environmental contamination induced by the collapse of a pipe; (2) Risk of traffic disturbance and road damage induced by the collapse of a pipe; (3) Risk of annoyance of life quality and increased public expenditure induced by the collapse of a pipe. Results indicated that nearly 50% of the whole pipes’ length clustered as critical under the first individual risk index: Risk of environmental contamination induced by the collapse of a pipe. The coarse-grained soil type prevalent in the region could be a leading cause for concern, as a collapsed pipe can quickly disperse and contaminate the surrounding environment. This is especially worrisome for the primary transmission pipes with larger diameters, which carry a substantial amount of sewage and can lead to swift contamination in case of structural failure. Nevertheless, the conditions surrounding the pipes in various networks can vary, resulting in different levels of individual risk and criticality levels compared to other networks (for example, please see the results of [15]). It should be highlighted that the availability and inclusion of at least some data would significantly help this numerical investigation. If such data are accessible, they are of great importance in improving how the situation is understood and enabling a more thorough and trustworthy analysis.

Then, to aggregate individual risk indices and obtain the fuzzy combined risk, two different weighting scenarios were set: (1) Comparing individual risks based on predefined management criteria; (2) Utilizing dynamic fuzzy weights. The integration of risk indices led to a different cluster distribution than individual risk indices, which could be considered the actual reporting of the asset priority since this composite index provides an overview of all individual indices. However, regardless of the scenarios, the outcome of this aggregation was almost the same. The insufficient number of clusters could contribute to this problem as it may result in the need to force disconnected data groups to conform to a single, larger cluster. Therefore, to see the effect of the number of clusters in improving the resolution of risk groups, combined RVs were clustered into 5 groups. Results revealed that increasing clusters led to a more transparent sewer pipe assets ranking in the studied area. Notably, adopting clustering methods to classify pipe failure’s risk instead of other common approaches (like risk matrix) gives more reassurance to decision-makers about the correctness of their decisions. As the former partitions a data set into subsets (called clusters) so that data within the same cluster are as similar as possible and data within different clusters are as different as possible [66]. Whereas the risk matrix is static and provides the decision-maker with a non-meticulous classification: the probability, consequences, and risk level classes are independent of the studied data characteristics (read more on this topic in [67]). It should be highlighted that automatic decisions for the optimal number of clusters can be a promising solution to avoid misinterpretation of the clustering results. As this topic is out of the scope of this article, readers are encouraged to refer to related publications (e.g., [68]).

In addition, to investigate the effect of various levels of data uncertainty on the final outputs, the value of the effective factor on LoF and its consequences were intentionally misplaced randomly into the categories where they did not belong (for specified percentages of them). This analysis proved that the risk cluster was correctly predicted for more than 20% of the pipes, even in the worst case. Furthermore, pipelines whose risk class is predicted better than the situation in which there is no uncertainty and whose potential for failures or consequences might be greater in them in the case of ignorance, are mostly below 15%. On the other hand, given various levels of uncertainty, the proportion of pipes that are predicted to be in a worse risk condition than the situation without uncertainty (predicted with 3 or 4 clusters higher) is around 10%. This might lead to an increase in unnecessary inspection and/or maintenance costs. Moreover, by examining a scenario with 75% uncertainty in parameters that are intangible and 25% uncertainty in the rest (as a more realistic case), the risk cluster is correctly predicted for 20% of the pipes, which is comparable to the situations when there is 50% or 60% uncertainty in all factors. Here, the number of pipes with an underestimated risk cluster has increased compared to the aforementioned cases, while the number of pipes with an overestimated risk cluster has decreased.

6 Conclusion

-

Given the challenges of accessing buried infrastructure, the high cost of CCTV inspections, and the potentially severe consequences of sewer pipeline failure, it is crucial to develop methods for assessing the risk of failure in sewer pipelines and prioritizing their inspection and/or rehabilitation.

-

The proposed method in this study is expected to assist managers and decision-makers in picking out critical sewer segments and prioritizing them for inspection/rehabilitation activities, considering uncertainties in the risk assessment process, especially when there is a lack of data to build a deterioration model, identify main explanatory factors, etc.

-

Although it may not be the best framework from the point of precision due to the problem of incomplete datasets in wastewater collection networks, the combination of incomplete data and expert opinions remains one of the only options for proactive maintenance.

-

For future studies, as failure mechanisms are assumed to be the same everywhere in this study, they are suggested to be included in the framework. Accordingly, the module for selecting the best rehabilitation method should be added to the method structure.

-

An evaluation of the other infrastructures is also suggested to be added to the proposed framework (e.g., water and road networks sharing the same corridor as sewer pipes) to create a integrated multi-asset management. With this objective in mind, it is highly recommended to include at least a couple of cases in which utilities record the risk of accidents after their occurrence. This would enable the validation process through measurement of the proximity between the results obtained from the present method and the actual reality.

Data Availability

All models or codes generated or used during the study are available from the corresponding author by request. However, the database is proprietary/confidential in nature and may only be provided with restrictions.

References

Kirkham R, Kearney PD, Rogers KJ, Mashford J (2000) PIRAT—a system for quantitative sewer pipe assessment. Int J Robot Res 19(11):1033–1053. https://doi.org/10.1177/02783640022067959

Tscheikner-Gratl F, Caradot N, Cherqui F, Leitão JP, Ahmadi M, Langeveld JG, Clemens F (2019) Sewer asset management–state of the art and research needs. Urban Water J 16(9):662–675. https://doi.org/10.1080/1573062X.2020.1713382

Carvalho G, Amado C, Brito RS, Coelho ST, Leitão JP (2018) Analysing the importance of variables for sewer failure prediction. Urban Water J 15(4):338–345. https://doi.org/10.1080/1573062X.2018.1459748

Del Giudice G, Padulano R, Siciliano D (2016) Multivariate probability distribution for sewer system vulnerability assessment under data-limited conditions. Water Sci Technol 73:751–760. https://doi.org/10.2166/wst.2015.546

Davies JP, Clarke BA, Whiter JT, Cunningham RJ (2001) Factors influencing the structural deterioration and collapse of rigid sewer pipes. Urban Water J 3(1):73–89. https://doi.org/10.1016/S1462-0758(01)00017-6

Kleiner Y, Sadiq R, Rajani B (2006) Modelling the deterioration of buried infrastructure as a fuzzy Markov process. J Water Supply 55:67–80. https://doi.org/10.2166/aqua.2006.074

Micevski T, Kuczera G, Coombes P (2002) Markov model for storm water pipe deterioration. J Infrastruct Syst 8(2):49–56. https://doi.org/10.1061/(ASCE)1076-0342(2002)8:2(49)

Wirahadikusumah R, Abraham D, Iseley T (2001) Challenging issues in modeling deterioration of combined sewers. J Infrastruct Syst 7:77–84. https://doi.org/10.1061/(ASCE)1076-0342(2001)7:2(77)

Salman B, Salem O (2011) Risk assessment of wastewater collection lines using failure models and criticality ratings. J Pipeline Syst Eng Pract 3(3):68–76. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000100

Li X, Wang J, Abbassi R, Chen G (2022) A risk assessment framework considering uncertainty for corrosion-induced natural gas pipeline accidents. J Loss Prev Process Ind 75:104718. https://doi.org/10.1016/j.jlp.2021.104718

Baah K, Dubey B, Harvey R, McBean E (2015) A risk-based approach to sanitary sewer pipe asset management. Sci Total Environ 505:1011–1017. https://doi.org/10.1016/j.scitotenv.2014.10.040

Le Gauffre P, Joannis C, Vasconcelos E, Breysse D, Gibello C, Desmulliez JJ (2007) Performance indicators and multi-criteria decision support for sewer asset management. J Infrastruct Syst 13(2):105–114. https://doi.org/10.1061/(ASCE)1076-0342(2007)13:2(105)

Biswas TK, Zaman K (2019) A fuzzy-based risk assessment methodology for construction projects under epistemic uncertainty. Int J Fuzzy Syst 21(4):1–20. https://doi.org/10.1007/s40815-018-00602-w

Tepe S, Kaya İ (2019) A fuzzy-based risk assessment model for evaluations of hazards with a real-case study. Hum Ecol Risk Assess. https://doi.org/10.1080/10807039.2018.1521262

Anbari MJ, Tabesh M, Roozbahani A (2017) Risk assessment model to prioritize sewer pipes inspection in wastewater collection networks. J Environ Manag 190:91–101. https://doi.org/10.1016/j.jenvman.2016.12.052

Hahn MA, Palmer RN, Merrill MS, Lukas AB (2002) Expert system for prioritizing the inspection of sewers: knowledge base formulation and evaluation. J Water Resour Plan Manag 128(2):121–129. https://doi.org/10.1061/(ASCE)0733-9496(2002)128:2(121)

Salman B, Salem O (2011) Modeling failure of wastewater collection lines using various section-level regression models. J Infrastruct Syst 18(2):146–154. https://doi.org/10.1061/(ASCE)IS.1943-555X.0000075

Kleiner Y, Sadiq R, Rajani B (2004a) Modeling failure risk in buried pipes using fuzzy Markov deterioration process. In: ASCE Int Conf on Pipeline Engineering and Construction, 1–12. https://doi.org/10.1061/40745(146)7

Tagherouit WB, Bennis S, Bengassem J (2011) A fuzzy expert system for prioritizing rehabilitation of sewer networks. Comput Aided Civ Infrastruct Eng 26(2):146–152. https://doi.org/10.1111/j.1467-8667.2010.00673.x

Kleiner Y, Rajani B, Sadiq R (2007) Sewerage infrastructure: fuzzy techniques to manage failures. Wastewater reuse-risk assessment, decision-making and environmental security. Springer, Dordrecht, pp 241–252. https://doi.org/10.1007/978-1-4020-6027-4_24

Caradot N, Rouault P, Clemens F, Cherqui F (2018) Evaluation of uncertainties in sewer condition assessment. Struct Infrastruct Eng 14(2):264–273. https://doi.org/10.1080/15732479.2017.1356858

Moradi S, Zayed T, Nasiri F, Golkhoo F (2020) Automated anomaly detection and localization in sewer inspection videos using proportional data modeling and deep learning–based text recognition. J Infrastruct Syst 26(3):04020018. https://doi.org/10.1061/(ASCE)IS.1943-555X.0000553

Dirksen J, Clemens FHLR, Korving H, Cherqui F, Gauffre PL, Ertl T, Plihal H, Müller K, Snaterse CTM (2013) The consistency of visual sewer inspection data. Struct Infrastruct Eng 9(3):214–228. https://doi.org/10.1080/15732479.2010.541265

Ahmadi M, Cherqui F, De Massiac JC, Le Gauffre P (2014) Influence of available data on sewer inspection program efficiency. Urban Water J 11(8):641–656. https://doi.org/10.1080/1573062X.2013.831910

Roghani B, Cherqui F, Ahmadi M, Le Gauffre P, Tabesh M (2019) Dealing with uncertainty in sewer condition assessment: impact on inspection programs. Autom Constr 103:117–126. https://doi.org/10.1016/j.autcon.2019.03.012

Dutta P (2015) Uncertainty modeling in risk assessment based on Dempster-Shafer theory of evidence with generalized fuzzy focal elements. Fuzzy Inf Eng 7(1):15–30. https://doi.org/10.1016/j.fiae.2015.03.002

Olsson R (2007) In search of opportunity management: Is the risk management process enough? Int J Proj Manag 25(8):745–752. https://doi.org/10.1016/j.ijproman.2007.03.005

Daher S, Zayed T, Elmasry M, Hawari A (2018) Determining relative weights of sewer pipelines’ components and defects. J Pipeline Syst Eng Pract. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000290

Yasseri SF, Mahani RB (2011) Pipeline risk assessment using analytic hierarchy process (AHP). In Int Conf on Offshore Mechanics and Arctic Engineering. Netherlands. 44366:1–11. https://doi.org/10.1115/OMAE2011-49033

Cox L (2008) What’s wrong with risk matrices? Risk Anal 28(2):497–512. https://doi.org/10.1111/j.1539-6924.2008.01030.x

Elsawah H, Bakry I, Moselhi O (2016) Decision support model for integrated risk assessment and prioritization of intervention plans of municipal infrastructure. J Pipeline Syst Eng Pract. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000245

Ghavami SM, Borzooei Z, Maleki J (2020) An effective approach for assessing risk of failure in urban sewer pipelines using a combination of GIS and AHP-DEA. Process Saf Environ Prot 133:275–285. https://doi.org/10.1016/j.psep.2019.10.036

Chen Y, Yu J, Khan S (2010) Spatial sensitivity analysis of multi-criteria weights in GIS-based land suitability evaluation. Environ Model Softw 25(12):1582–1591. https://doi.org/10.1016/j.envsoft.2010.06.001

Feizizadeh B, Blaschke T (2013) GIS-multicriteria decision analysis for landslide susceptibility mapping: comparing three methods for the Urmia lake basin. Iran Nat Hazards 65(3):2105–2128. https://doi.org/10.1007/s11069-012-0463-3

Gbanie SP, Tengbe PB, Momoh JS, Medo J, Kabba VTS (2013) Modelling landfill location using geographic information systems (GIS) and multi-criteria decision analysis (MCDA): case study Bo, Southern Sierra Leone. Appl Geogr 36:3–12. https://doi.org/10.1016/j.apgeog.2012.06.013

Daulat S, Rokstad MM, Klein-Paste A, Langeveld J, Tscheikner-Gratl F (2022) Challenges of integrated multi-infrastructure asset management: a review of pavement, sewer, and water distribution networks. Struct Infrastruct Eng. https://doi.org/10.1080/15732479.2022.2119480

Le Gauffre P, Cherqui F (2009) Sewer rehabilitation criteria evaluated by fusion of fuzzy indicators. 3rd Leading-edge Conf. on Strategic Asset management (LESAM), IWA & AWWA, Miami, USA

Ana EV, Bauwens W (2010) Modeling the structural deterioration of urban drainage pipes: the state-of-the-art in statistical methods. Urban Water J 7(1):47–59. https://doi.org/10.1080/15730620903447597

Chughtai F, Zayed T (2008) Infrastructure condition prediction models for sustainable sewer pipelines. J Perform Constr Facil 22(5):333–341. https://doi.org/10.1061/(ASCE)0887-3828(2008)22:5(333)

El-Housni H, Ouellet M, Duchesne S (2017) Identification of most significant factors for modeling deterioration of sewer pipes. Can J Civ Eng 45(3):215–226. https://doi.org/10.1139/cjce-2015-0293

Kuliczkowska E (2016) Risk of structural failure in concrete sewers due to internal corrosion. Eng Fail Anal 66:110–119. https://doi.org/10.1016/j.engfailanal.2016.04.026

Sægrov S (2006) Computer aided rehabilitation of sewer and storm water networks. CARE-S. IWA publishing. https://doi.org/10.2166/9781780402390

Rokstad MM, Ugarelli RM (2015) Evaluating the role of deterioration models for condition assessment of sewers. J Hydroinf 17(5):789–804. https://doi.org/10.2166/hydro.2015.122

Ugarelli RM, Selseth I, Le Gat Y, Rostum J, Krogh AH (2013) Wastewater pipes in Oslo: from condition monitoring to rehabilitation planning. Water Pract Technol 8(3–4):487–494. https://doi.org/10.2166/wpt.2013.051

Vladeanu GJ (2018) Wastewater Pipe Condition and Deterioration Modeling for Risk-Based Decision-Making. PhD thesis. College of Engineering and Science, Louisiana Tech University, USA

Çelik T, Kamali S, Arayici Y (2017) Social cost in construction projects. Environ Impact Assess Rev 64:77–86. https://doi.org/10.1016/j.eiar.2017.03.001

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353. https://doi.org/10.1016/S0019-9958(65)90241-X

Balezentiene L, Streimikiene D, Balezentis T (2013) Fuzzy decision support methodology for sustainable energy crop selection. Renew Sust Energ Rev 17:83–93. https://doi.org/10.1016/j.rser.2012.09.016

Kahraman C, Kaya İ (2010) Investment analyses using fuzzy probability concept. Technol Econ Dev Econ 16(1):43–57. https://doi.org/10.3846/tede.2010.03

Sousa V, Silva M, Veigas T, Matos J, Martins J, Teixeira A (2007). Technical management of sewer networks: A simplified decision tool. In: 2nd Leading Edge Conference on Strategic Asset Management (LESAM), IWA, Lisbon, Portugal

Abdel-malak FF, Issa UH, Miky YH, Osman EA (2017) Applying decision-making techniques to civil engineering projects. Beni Suef Univ J Basic Appl Sci 6(4):326–331. https://doi.org/10.1016/j.bjbas.2017.05.004

Mardani A, Jusoh A, Zavadskas EK (2015) Fuzzy multiple criteria decision-making techniques and applications–two decades review from 1994 to 2014. Expert Syst Appl 42(8):4126–4148. https://doi.org/10.1016/j.eswa.2015.01.003

Chen VY, Lien HP, Liu CH, Liou JJ, Tzeng GH, Yang LS (2011) Fuzzy MCDM approach for selecting the best environment-watershed plan. Appl Soft Comput 11(1):265–275. https://doi.org/10.1016/j.asoc.2009.11.017

Feizizadeh B, Blaschke T (2013) Land suitability analysis for Tabriz County, Iran: a multi-criteria evaluation approach using GIS. J Environ Plan Manag 56(1):1–23. https://doi.org/10.1080/09640568.2011.646964

Kahraman C, Cebeci U, Ruan D (2004) Multi-attribute comparison of catering service companies using fuzzy AHP: the case of Turkey. Int J Prod Econ 87(2):171–184. https://doi.org/10.1016/S0925-5273(03)00099-9

Liu Y, Eckert CM, Earl C (2020) A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Syst Appl 161:113738. https://doi.org/10.1016/j.eswa.2020.113738

Buckley JJ (1985) Fuzzy hierarchical analysis. Fuzzy Sets Syst 17(3):233–247. https://doi.org/10.1016/0165-0114(85)90090-9

Hanss M (2005) Applied fuzzy arithmetic: an introduction with engineering applications. Springer-Verlag, Berlin

Dong W, Shah HC (1987) Vertex method for computing functions of fuzzy variables. Fuzzy Sets Syst 24(1):65–78. https://doi.org/10.1016/0165-0114(87)90114-X

Nasseri M, Ansari A, Zahraie B (2014) Uncertainty assessment of hydrological models with fuzzy extension principle: evaluation of a new arithmetic operator. Water Resour Res 50(2):1095–1111. https://doi.org/10.1002/2012WR013382

Hashmi S (2014) Comprehensive materials processing. Elsevier, Oxford. https://doi.org/10.1016/b978-0-08-096532-1.01060-8

Chakraverty S, Sahoo DM, Mahato NR (2019) Defuzzification. Concepts of soft computing. Springer, Singapore. https://doi.org/10.1007/978-981-13-7430-2_7

Wang K (2001) Computational intelligence in agile manufacturing engineering. Agile manufacturing The 21st century competitive strategy. Elsevier, Oxford, pp 297–315. https://doi.org/10.1016/B978-008043567-1/50016-4

Tehran wastewater company (2019) Network coverage areas, Tehran, Iran

Lin I, Loyola-González O, Monroy R, Medina-Pérez MA (2021) A review of fuzzy and pattern-based approaches for class imbalance problems. Appl Sci 11(14):6310. https://doi.org/10.3390/app11146310

Belli F, Beyazit M, Güler N (2012) Event-oriented, model-based GUI testing and reliability assessment—approach and case study. Adv Comput 85:277–326. https://doi.org/10.1016/B978-0-12-396526-4.00006-0

He L, Chen Y, Liu L (2013) A risk matrix approach based on clustering algorithm. J Appl Sci 13(20):4188–4194. https://doi.org/10.3923/jas.2013.4188.4194

Jung Y, Park H, Du DZ et al (2003) A decision criterion for the optimal number of clusters in hierarchical clustering. J Glob Optim 25:91–111. https://doi.org/10.1023/A:1021394316112

Acknowledgements

The author would like to express his sincere gratitude to Associate Professor Franz Tscheikner-Gratl for his significant efforts as a technical editor for this journal paper. His exhaustive review, wise comments, and attention to detail have greatly enhanced the manuscript’s quality and clarity. The author also wants to express their sincere appreciation to the anonymous reviewers for their careful analysis, helpful criticism, and insightful ideas that significantly improved this paper.

Funding

Open access funding provided by NTNU Norwegian University of Science and Technology (incl St. Olavs Hospital - Trondheim University Hospital).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All other authors have no conflicts of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Roghani, B., Tabesh, M. & Cherqui, F. A Fuzzy Multidimensional Risk Assessment Method for Sewer Asset Management. Int J Civ Eng 22, 1–17 (2024). https://doi.org/10.1007/s40999-023-00888-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-023-00888-4