Abstract

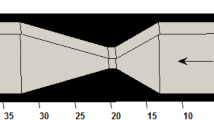

The performance of a vertical water jet system with a downcomer for bubble generation has been investigated experimentally. The aeration rate was controlled using perforated throat Venturi with 2, 4, 8, and 16 holes of 1 mm diameter each. Moreover, the bubble plume size and the Sauter mean diameter (SMD) were investigated by image processing obtained from a high-speed camera and a particle sizer algorithm. The void fraction and the entrained gas flow as a function of the liquid flow rate were also studied. A new correlation for the entrained gas flow rate as a function of the Froude number and the ratio of the perforation to throat area is proposed, with high accuracy. The effect of liquid flow on the bubble diameter was analysed for different levels of perforations using probability density function (PDF). The bubble penetration depth was also shown for different perforations at different liquid flow rates. The penetration depth increases significantly with the liquid superficial velocity. The Sauter mean diameter decreases linearly with the liquid superficial velocity as well as the void fraction. The results demonstrate an influence of the number of aspiration holes on the size of the bubbles generated such that the Sauter mean diameter increases with the increasing number of holes in the perforated section. The proposed controlled Venturi flow rate and confined plunging jet system technique is tested in this paper for the first time in the literature and shows considerable potential for controlling water aeration.

Similar content being viewed by others

Abbreviations

- A Aeration :

-

The total cross section of the aspiration holes, m2

- A Throat :

-

The cross section of the Venturi throat, m2

- D :

-

The Venturi inlet and the downcomer pipe diameter, m

- d 0 :

-

The Venturi throat diameter, m

- d :

-

The air bubble diameter, m

- g :

-

The acceleration of gravity

- Q G :

-

Gas volumetric flow rate, m3/s

- Q L :

-

Liquid volumetric flow rate, m3/s

- U :

-

The liquid velocity in the Venturi throat, m/s

- U lS :

-

Liquid superficial velocity, m/s

- α :

-

The downcomer pipe inclination

- β :

-

Throat-to-pipe diameter ratio; (d0/D)

- ρ :

-

Density, kg/m3

- µ :

-

Dynamic viscosity, kg.m/s

- Re:

-

Reynolds number

- Fr:

-

Froude number

- G:

-

Gas

- L:

-

Liquid

- SMD:

-

Sauter mean diameter, mm

- PDF:

-

Probability density function

- FPS:

-

Frames per second

- CP:

-

Conductance probe

References

Al-Anzi BS (2020) Effect of primary variables on a confined plunging liquid jet reactor. Water (Switzerland) 12(3):764

Amiri TY, Moghaddas JS, Moghaddas Y (2011) A jet mixing study in two phase gas-liquid systems. Chem Eng Res Des 89(3):352–366

Baawain MS, Gamal El-Din M, Smith DW (2012) Characterizing two inclined circular water jets plunging into an aeration tank. Int J Multiph Flow 40:158–165

Baylar A, Ozkan F (2006) Applications of Venturi principle to water aeration systems. Environ Fluid Mech 6:341–357

Baylar A, Emiroglu ME, Mualla O (2006) The development of aeration performance with different typed nozzles in a vertical plunging water jet system. Int J Sci Technol 1:51–63

Evans GM, Biń AK, Machniewski PM (2001) Performance of confined plunging liquid jet bubble column as a gas-liquid reactor. Chem Eng Sci 56(3):1151–1157

Horiguchi N, Yoshida H, Uesawa S et al (2013) Research and development of self-priming venturi scrubber for filter venting : preliminary analysis and observation of hydraulic. Int Conf Nucl Eng 6:1–6

Huang J, Sun L, Liu H et al (2020) A review on bubble generation and transportation in Venturi-type bubble generators. Exp Comput Multiph Flow 2:123–134

Huang J, Sun L, Mo Z et al (2021) Experimental investigation on the effect of throat size on bubble transportation and breakup in small Venturi channels. Int J Multiph Flow 142:103737

International Organization for Standardization (2003) Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full—Part 4: Venturi tubesitle. ISO 5167–5164

Khayat O, Afarideh H (2021) Numerical investigation of non-newtonian liquid-gas flow in venturi flow meter using computational fluid dynamics. Iran J Sci Technol Trans Mech Eng 45:393–401

Kumar P, Karthik RR, Singh SK (2022) Experimental investigation of cavity dynamics in convergent-divergent nozzle in sheet mode. Iran J Sci Technol Trans Mech Eng 46:327–334

Lee CH, Choi H, Jerng DW et al (2019) Experimental investigation of microbubble generation in the Venturi nozzle. Int J Heat Mass Transf 136:1127–1138

Lee CH, Wongwises S, Jerng DW, Ahn HS (2021) Experimental study on breakup mechanism of microbubble in 2D channel. Case Stud Therm Eng 28:101523

Li J, Song Y, Yin J, Wang D (2017) Investigation on the effect of geometrical parameters on the performance of a Venturi type bubble generator. Nucl Eng Des 325:90–96

Li C, Zhang J, He J, Luo P (2022) Gas-liquid hydrodynamics in a self-suction jet reactor with or without swirling addition. Chem Eng Sci 247:117059

Mishra RK, Deswal S (2018) Flow characteristics of multiple plunging jets towards treatment of water and wastewater. J Water Process Eng 22:147–154

Ohkawa A, Kusabiraki D, Kawai Y et al (1986) Some flow characteristics of a vertical liquid jet system having downcomers. Chem Eng Sci 41(9):2347–2361

Ozkan F, Ozturk M, Baylar A (2006) Experimental investigations of air and liquid injection by Venturi tubes. Water Environ J 20:114–122

Song Y, Wang D, Yin J et al (2019) Experimental studies on bubble breakup mechanism in a Venturi bubble generator. Ann Nucl Energy 130:259–270

Yamagiwa K, Ohmae Y, Hatta Dahlan M, Ohkawa A (1991) Activated sludge treatment of small-scale wastewater by a plunging liquid jet bioreactor with cross-flow filtration. Bioresour Technol 37(3):215–222

Yin J, Li J, Li H et al (2015) Experimental study on the bubble generation characteristics for an Venturi type bubble generator. Int J Heat Mass Transf 91:218–224

Zeghloul A, Bouyahiaoui H, Azzi A et al (2020a) Experimental investigation of the vertical upward single- and two-phase flow pressure drops through gate and ball valves. J Fluids Eng 142(2):1–14

Zeghloul A, Azzi A, Ghendour N (2021) Design and construction of a turbine flowmeter based on the Hall effect to measure volumetric air flow rate. Mater Biomater Sci 4(1):86–92

Zeghloul A, Messilem A, Ghendour N, et al (2020b) Theoretical study and experimental measurement of the gas liquid two-phase flow through a vertical Venturi meter. Proc IMechE Part C J Mech Eng Sci 0:1–18

Zhang Y, Xu C, Yao Q (2022) The velocity variation characteristics of the flow field and the related structural parameter optimization of the direct jet nozzle. Iran J Sci Technol Trans Mech Eng 46:347–357

Zhao L, Mo Z, Sun L et al (2017) A visualized study of the motion of individual bubbles in a Venturi-type bubble generator. Prog Nucl Energy 97:74–89

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeghloul, A., Al-Sarkhi, A. & Ghendour, N. Improved Aeration Using Perforated Venturi Throat of a Vertical Liquid Jet System with Downcomer. Iran J Sci Technol Trans Mech Eng 48, 163–175 (2024). https://doi.org/10.1007/s40997-023-00655-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40997-023-00655-9