Abstract

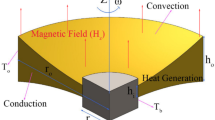

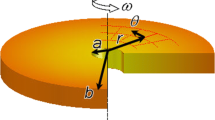

Thermo-elasto-plastic analysis of a rotating disc made of Functionally Graded Materials (FGMs) is studied in this paper using Successive Approximation Method (SAM). The plane stress condition is assumed for formulation of the problem. After computation of effective material properties based on modified mixture rule, the governing equations are derived analytically and then is solved using the Differential Quadratic Method (DQM). After obtaining the displacements and stresses, the yield conditions are calculated by von-Mises failure criteria. The rotating disc is made of an Aluminum–Silicon Carbide functionally graded material. The plastic behavior of Aluminum is considered as strain hardening one. The effects of angular speed, percentage of ceramic particles, particle reinforcement power, and boundary conditions such as temperature gradient on the radial and tangential thermo-elasto-plastic strains, stresses, and equivalent stresses is investigated. The results show that the radial stresses through the disc are significantly less than tangential stresses, therefor the tangential stresses has a significant effect on the equivalent stress and yield conditions.

Similar content being viewed by others

Abbreviations

- \({C}_{ij}\) :

-

Weighting coefficient of n − th order derivative of an arbitrary function

- \(E\) :

-

Young's Modulus

- \(f\) :

-

Fraction of a material's phase

- \(H\) :

-

Plastic modulus

- \(k\) :

-

Thermal conductivity coefficient

- \(n\) :

-

Power of ceramic particles distribution

- \(p\) :

-

Applied load

- \(q\) :

-

Stress to strain transfer ratio

- \(T\) :

-

Temperature

- \(u\) :

-

Displacement

- \(r\) :

-

Radius

- \(\alpha\) :

-

Thermal expansion coefficient

- \(\varepsilon\) :

-

Strain

- \(\theta\) :

-

Arbitrary angle

- \(\nu\) :

-

Poisson's ratio

- \(\rho\) :

-

Density

- \(\sigma\) :

-

Stress

- \(\omega\) :

-

Rotational velocity

- \(1\) :

-

First phase

- \(2\) :

-

Second phase

- \(c\) :

-

Ceramic phase

- \(co\) :

-

Ceramic phase at outer side

- \(cr\) :

-

Critical

- \(e\) :

-

Equal

- \(i\) :

-

Inner side

- \(m\) :

-

Metal phase

- \(o\) :

-

Outer side

- \(r\) :

-

Radial direction

- \(von\) :

-

Von misses

- \(y\) :

-

Yield

- \(z\) :

-

Axial direction

- \(\theta\) :

-

Tangential direction

- \(i\) :

-

Number of step

- \(m\) :

-

Metal phase

- \(p\) :

-

Plastic regime

- SAM:

-

Successive approximation method

- FGM:

-

Functionally graded material

- DQM:

-

Differential quadratic method

- VMP:

-

Variable material property

References

Temesgen A, Singh SB, Thakur P Classical and nonclassical treatment of problems in elastic-plastic and creep deformation for rotating discs. In: Materials Physics and Chemistry, pp. 1–70. Apple Academic Press, 2020.

EkhteraeiToussi, Hamid, Farimani MR (2012) Elasto-plastic deformation analysis of rotating disc beyond its limit speed. In: International Journal of Pressure Vessels and Piping 89: 170–177. https://doi.org/10.1016/j.ijpvp.2011.11.001

Altan G, Topçu M. Thermo-elastic stress of a metal-matrix composite disc under linearly-increasing temperature loading by analytical and FEM analysis. Adv Eng Softw. 2010;41(4):604–10. https://doi.org/10.1016/j.advengsoft.2009.11.007.

You LH, Zhang JJ. Elastic-plastic stresses in a rotating solid disk. Int J Mech Sci. 1999;41(3):269–82. https://doi.org/10.1016/S0020-7403(98)00049-6.

Lu Z, Zhao L, Ding H, Chen L. A dual-functional metamaterial for integrated vibration isolation and energy harvesting. J Sound Vib. 2021;509:116251. https://doi.org/10.1016/j.jsv.2021.116251.

Cheng Z, Liu Y, Jun Zhao Hu, Feng, and Yizhang Wu. Numerical simulation of crack propagation and branching in functionally graded materials using peridynamic modeling. Eng Fract Mech. 2018;191:13–32. https://doi.org/10.1016/j.engfracmech.2018.01.016.

Nikbakht S, Kamarian S, Shakeri M. A review on optimization of composite structures Part II: functionally graded materials. Compos Struct. 2019;214:83–102. https://doi.org/10.1016/j.compstruct.2019.01.105.

Bayat M, Sahari BB, Saleem M, Hamouda AMS, Reddy J. N Thermo elastic analysis of functionally graded rotating disks with temperature-dependent material properties: uniform and variable thickness. Int J Mech Materials Design. 2009;5(3):263–79. https://doi.org/10.1007/s10999-009-9100-z.

Nejad MZ, Rastgoo A, Hadi A. Exact elasto-plastic analysis of rotating disks made of functionally graded materials. Int J Eng Sci. 2014;85:47–57. https://doi.org/10.1016/j.ijengsci.2014.07.009.

Khorsand M, Tang Y. Design functionally graded rotating disks under thermoelastic loads: weight optimization. Int J Press Vessels Pip. 2018;161:33–40. https://doi.org/10.1016/j.ijpvp.2018.02.002.

Jahed H, Dubey RN. An axisymmetric method of elastic-plastic analysis capable of predicting residual stress field. J Pressure Vessel Technol. 1997;119(3):264–73. https://doi.org/10.1115/1.2842303.

Jahed H, Sethuraman R, Dubey RN. A variable material property approach for solving elastic-plastic problems. Int J Press Vessels Pip. 1997;71(3):285–91. https://doi.org/10.1016/S0308-0161(96)00079-8.

Mahdavi E, Akbari Alashti R, Cheloee Darabi A, Alizadeh M (2013) Linear thermoplastic analysis of FGM rotating discs with variable thickness. Iranian J Mech Eng Trans ISME 14(2: 73–87.

Xu X, Karami B, Shahsavari D (2021) Time-dependent behavior of porous curved nanobeam. Int J Eng Sci 160. https://doi.org/10.1016/j.ijengsci.2021.103455

Mousavi AA, Zhang C, Masri SF, Gholipour G (2021) Structural damage detection method based on the complete ensemble empirical mode decomposition with adaptive noise: a model steel truss bridge case study. Struct Health Monitoring 84049609. doi: https://doi.org/10.1177/14759217211013535.

Zhao X, Zhu WD, Li YH. Analytical solutions of nonlocal coupled thermoelastic forced vibrations of micro-/nano-beams by means of Green’s functions. J Sound Vib. 2020;481: 115407. https://doi.org/10.1016/j.jsv.2020.115407.

Zhang B, Chen Y, Wang Z, Li J, Ji H. Influence of mach number of main flow on film cooling characteristics under supersonic condition. Symmetry (Basel). 2021;13(127):127. https://doi.org/10.3390/sym13010127.

Liu C, Gao X, Chi D, He Y, Liang M, Wang H. On-line chatter detection in milling using fast kurtogram and frequency band power. Euro J Mech A Solids. 2021;90: 104341. https://doi.org/10.1016/j.euromechsol.2021.104341.

Zheng Y, Bahaloo H, Mousanezhad D, Mahdi E, Vaziri A, Nayeb-Hashemi H. Stress analysis in functionally graded rotating disks with non-uniform thickness and variable angular velocity. Int J Mech Sci. 2016;119:283–93. https://doi.org/10.1016/j.ijmecsci.2016.10.018.

Yildirim V (2019) Thermomechanical characteristics of a functionally graded mounted uniform disc with/without rigid casing. J Aerospace Technol Manag 11. https://doi.org/10.5028/jatm.v11.1008

Sharma S, Yadav S. Numerical solution of thermal elastic-plastic functionally graded thin rotating disk with exponentially variable thickness and variable density. Therm Sci. 2019;23(1):125–36. https://doi.org/10.2298/TSCI131001136S.

Nayak P, Bhowmick S, Saha KN. Elasto-plastic analysis of thermo-mechanically loaded functionally graded disks by an iterative variational method. Eng Sci Technol Int J. 2020;23(1):42–64. https://doi.org/10.1016/j.jestch.2019.04.007.

Xu J, Wu Z, Chen H, Shao L, Zhou X, Wang S (2021) Triaxial shear behavior of basalt fiber-reinforced loess based on digital image technology. KSCE J Civ Eng, 13 pages. https://doi.org/10.1007/s12205-021-2034-1

Deng H, Chen Y, Jia Y, Pang Y, Zhang T, Wang S, Yin L. Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. J Manuf Process. 2021;64:379–91. https://doi.org/10.1016/j.jmapro.2021.01.024.

Xie J, Chen Y, Yin L, Zhang T, Wang S, Wang L. Microstructure and mechanical properties of ultrasonic spot welding TiNi/Ti6Al4V dissimilar materials using pure Al coating. J Manuf Process. 2021;64:473–80. https://doi.org/10.1016/j.jmapro.2021.02.009.

Nejad MZ, Alamzadeh N, Hadi A. Thermoelastoplastic analysis of FGM rotating thick cylindrical pressure vessels in linear elastic-fully plastic condition. Compos B. 2018;154:410–22. https://doi.org/10.1016/j.compositesb.2018.09.022.

Fan P, Deng R, Qiu J, Zhao Z, Wu S. Well logging curve reconstruction based on kernel ridge regression. Arab J Geosci. 2021;14:1559. https://doi.org/10.1007/s12517-021-07792-y.

Li T, Dai Z, Yu M, Zhang W. Numerical investigation on the aerodynamic resistances of double-unit trains with different gap lengths. Eng Appl Comput Fluid Mech. 2021;15(1):549–60. https://doi.org/10.1080/19942060.2021.1895321.

Fan Z, Ji P, Zhang J, Segets D, Chen D, Chen S. Wavelet neural network modeling for the retention efficiency of sub-15 nm nanoparticles in ultrafiltration under small particle to pore diameter ratio. J Membr Sci. 2021;635: 119503. https://doi.org/10.1016/j.memsci.2021.119503.

Li X, Yang H, Zhang J, Qian G, Yu H, Cai J. Time-Domain Analysis of Tamper Displacement during Dynamic Compaction Based on Automatic Control. Coatings, 2021;11(9). https://doi.org/10.3390/coatings11091092.

Wang D, Ju Y, Shen H, Xu L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr Build Mater. 2019;197:464–73. https://doi.org/10.1016/j.conbuildmat.2018.11.181.

Yang Z, Tam M, Zhang Y, Kitipornchai S, Lv J, Yang J. Nonlinear dynamic response of FG graphene platelets reinforced composite beam with edge cracks in thermal environment. Int J Struct Stab Dyn. 2020;20(14):2043005. https://doi.org/10.1142/S0219455420430051.

Yang Z, Feng C, Jie Yang Yu, Wang JL, Liu A, Jiyang Fu. Geometrically nonlinear buckling of graphene platelets reinforced dielectric composite (GPLRDC) arches with rotational end restraints. Aerosp Sci Technol. 2020;107: 106326. https://doi.org/10.1016/j.ast.2020.106326.

Shiping Zhang, Ronald YS, Pak Junhui Zhang. Three-dimensional frequency-domain Green's functions of a finite fluid-saturated soil layer underlain by rigid bedrock to interior loadings. Int J Geomech. 2021. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002235.

Yang Z, Di Wu, Yang J, Lai S-K, Lv J, Liu A, Jiyang Fu. Dynamic buckling of rotationally restrained FG porous arches reinforced with graphene nanoplatelets under a uniform step load. Thin-Walled Structures. 2021;166: 108103. https://doi.org/10.1016/j.tws.2021.108103.

Huang X, Yang J, Yang Z. Thermo-elastic analysis of functionally graded graphene nanoplatelets (GPLs) reinforced closed cylindrical shells. Appl Math Model. 2021;97:754–70. https://doi.org/10.1016/j.apm.2021.04.027.

Arefi M. Elastic solution of a curved beam made of functionally graded materials with different cross sections. Steel Compos Struct. 2015;18(3):659–72.

Yang Z, Zhao S, Yang J, Lv J, Liu A, Fu J (2020) In-plane and out-of-plane free vibrations of functionally graded composite arches with graphene reinforcements. Mech Adv Materials Struct: 1–11. https://doi.org/10.1080/15376494.2020.1716420

Yang Z, Liu A, Yang J, Lai S-K, Lv J, Jiyang Fu. Analytical prediction for nonlinear buckling of elastically supported FG-GPLRC arches under a central point load. Materials. 2021;14(8):2026. https://doi.org/10.3390/ma14082026.

Mendelson A. Plasticity: theory and application. New York: Macmillan; 1968.

Luo Z, Li X, Shang J, Zhu H, Fang D. Modified rule of mixtures and Halpin-Tsai model for prediction of tensile strength of micron-sized reinforced composites and Young’s modulus of multiscale reinforced composites for direct extrusion fabrication. Adv Mech Eng. 2018;10(7):1687814018785286.

Hine P, Parveen B, Brands D, Caton-Rose F. Validation of the modified rule of mixtures using a combination of fibre orientation and fibre length measurements. Compos A Appl Sci Manuf. 2014;64:70–8. https://doi.org/10.1016/j.compositesa.2014.04.017.

Suresh S, Mortensen A. Functionally graded metals and metal-ceramic composites: part 2 Thermomechanical behaviour. Int Mater Rev. 1997;42(3):85–116. https://doi.org/10.1179/imr.1997.42.3.85.

Bhattacharyya M, Kapuria S, Kumar AN. On the stress to strain transfer ratio and elastic deflection behavior for Al/SiC functionally graded material. Mech Adv Mater Struct. 2007;14(4):295–302. https://doi.org/10.1080/1537649060081791.

Madan R, Bhowmick S, Saha K. A study based on stress-strain transfer ratio calculation using Halpin-Tsai and MROM material model for limit elastic analysis of metal matrix FG rotating disk. FME Transactions. 2020;48(1):204–10.

Vaghefi R. Thermo-elastoplastic analysis of functionally graded sandwich plates using a three-dimensional meshless model. Compos Struct. 2020;242: 112144. https://doi.org/10.1016/j.compstruct.2020.112144.

Saeedi S, Kholdi M, Loghman A, Ashrafi H, Arefi M. Thermo-elasto-plastic analysis of thick-walled cylinder made of functionally graded materials using successive approximation method. Int J Press Vessels Pip. 2021;194: 104481. https://doi.org/10.1016/j.ijpvp.2021.104481.

Cho JR, Tinsley Oden J (2000) Functionally graded material: a parametric study on thermal-stress characteristics using the Crank–Nicolson–Galerkin scheme. Comput Methods Appl Mech Eng 188(1–3): 17–38. https://doi.org/10.1016/S0045-7825(99)00289-3

Chakrabarty J Theory of plasticity. Elsevier, 2012.

Zhong W, Gao F, Ren Y Generalized differential quadrature method for free vibration analysis of a rotating composite thin-walled shaft. Math Prob Eng 2019 (2019). https://doi.org/10.1155/2019/1538329

Zhong W, Gao F, Ren Y Generalized differential quadrature method for free vibration analysis of a rotating composite thin-walled shaft. Math Prob Eng 2019 (2019).

Arshid E, Amir S, Loghman A. Thermal buckling analysis of FG graphene nanoplatelets reinforced porous nanocomposite MCST-based annular/circular microplates. Aerosp Sci Technol. 2021;111: 106561. https://doi.org/10.1016/j.ast.2021.106561.

Singhal P, Bindal G. Generalised differential quadrature method in the study of free vibration analysis of monoclinic rectangular plates. Am J Comput Appl Math. 2012;2(4):166–73. https://doi.org/10.5923/j.ajcam.20120204.05.

Malik M, Civan F. A comparative study of differential quadrature and cubature methods vis-à-vis some conventional techniques in context of convection-diffusion-reaction problems. Chem Eng Sci. 1995;50(3):531–47. https://doi.org/10.1016/0009-2509(94)00223-E.

Golchi, Majid, Mostafa Talebitooti, and Roohollah Talebitooti. "Thermal buckling and free vibration of FG truncated conical shells with stringer and ring stiffeners using differential quadrature method." Mechanics Based Design of Structures and Machines (2019). https://doi.org/10.1080/15397734.2018.1545588

Arshid E, Khorshidvand AR. Free vibration analysis of saturated porous FG circular plates integrated with piezoelectric actuators via differential quadrature method. Thin-Walled Struct. 2018;125:220–33.

Kalali AT, Hassani B, Hadidi-Moud S. Elastic-plastic analysis of pressure vessels and rotating disks made of functionally graded materials using the isogeometric approach. J Theor Appl Mech. 2016;54(1):113–25.

Kalali AT, Hadidi-Moud S. A semi-analytical approach to elastic-plastic stress analysis of FGM pressure vessels. J Solid Mech. 2013;5(1):63–73.

Ye R, Liu P, Shi K, Yan B. State damping control: a novel simple method of rotor UAV with high performance. IEEE access. 2020;8:214346–57. https://doi.org/10.1109/ACCESS.2020.3040779.

Du Y, Pan N, Xu Z, Deng F, Shen Y, Kang H. Pavement distress detection and classification based on YOLO network. The international journal of pavement engineering, 2021;1–14 https://doi.org/10.1080/10298436.2020.1714047.

Zhong Q, Yang J, Shi K, Zhong S, Zhixiong L, Angel SM. Event-Triggered H∞ Load Frequency Control for Multi-Area Nonlinear Power Systems Based on Non-Fragile Proportional Integral Control Strategy. IEEE Trans Intel Transp Syst. 2021. https://doi.org/10.1109/TITS.2021.3110759.

Mou B, Bai Y. Experimental investigation on shear behavior of steel beam-to-CFST column connections with irregular panel zone. Engineering Structures. 2018;168:487–504. https://doi.org/10.1016/j.engstruct.2018.04.029.

Funding

This study was funded by X (4005278/024).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kholdi, M., Saeedi, S., Zargar Moradi, S.A. et al. A successive approximation method for thermo-elasto-plastic analysis of a reinforced functionally graded rotating disc. Archiv.Civ.Mech.Eng 22, 2 (2022). https://doi.org/10.1007/s43452-021-00321-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-021-00321-4