Abstract

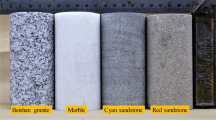

In this study, tensile crack growth of granite ring specimens has been determined using a novel testing apparatus. Also, Abacuses software (XFEM) has been used for numerical modeling of the crack growth and stress concentrations around the hole. For this purpose, a ring-shaped specimen with internal diameter of 60 mm and external diameters of 120 mm was prepared. These specimens tested by new testing device. The direct tensile tests were carried out on rock specimens using the new load transferring device called seesaw device. The ring tests were performed in Laboratory to observe the tensile strengths of the rock specimens. The results of the ISRM ring tests have been compared with the results obtained from the seesaw device test, which showed that the tensile strength obtained by the ring test is 18% higher than the measured tensile strength of the seesaw. These specimens were also modelled in Abaqus based on the extended finite element method (XFEM). Comparing the experimental and numerical values of the rocks’ tensile strengths validated the research scheme of this research. In the ring test, the failure mode occurs along the vertical axis surrounding the edges of the hole. Also, XFEM show that the tensile force was distributed in the right and the left of the hole in seesaw test. Numerical outputs have a good similarity with experimental seesaw test.

Similar content being viewed by others

References

Akazawa T (1943) New test method for evaluating internal stress due to compression of concrete: the splitting tension test. J Japan Soc Civil Eng 29:777–787

Albaijan I, Mahmoodzadeh A, Flaih LR, Ibrahim HH, Alashker Y, Mohammed AH (2023) Evaluating the tensile strength of reinforced concrete using optimized machine learning techniques. Eng Fract Mech 292:109677. https://doi.org/10.1016/j.engfracmech.2023.109677

Aliha MRM, Ebneabbasi P, Karimi HR, Nikbakht E (2021) A novel test device for the direct measurement of tensile strength of rock using ring shape sample. Int J Rock Mech Min Sci 139:104649. https://doi.org/10.1016/j.ijrmms.2021.104649

Álvarez-Pérez J, Mesa-Lavista M, Chávez-Gómez JH, Fajardo-San MG (2021) Experimental investigation on tensile strength of hollow concrete blocks. Mater Struct 54:164. https://doi.org/10.1617/s11527-021-01761-3

ASTM (2008b) D3967-08: standard test method for splitting tensile strength of intact rock core specimens. ASTM International, West Conshohocken

ASTM (2008a) D2936-08: standard test method for direct tensile strength of intact rock core specimens. ASTM Inter-national, West Conshohocken

ASTM (2016) D3967-16: Standard test method for splitting tensile strength of intact rock core specimens. ASTM International West Conshohocken, PA, USA

Berrenbaum R, Brodie I (1959) Measurement of the tensile strength of brittle materials. Brit J Appl Phys 10:281–286

Brace WF (1964) Brittle fracture of rocks. In: Judd WR (Eds.) Proceedings of the International conference on state of stress in the earth’s crust. Elsevier, New York, pp 111–174

Brook D (1993) The measurement and estimation of basic rock strength. rock Testing and Site Characterization. Elsevier, pp 41–66. https://doi.org/10.1016/B978-0-08-042066-0.50009-4

Carneiro FLLB (1943) A new method to determine the tensile strength of concrete. In: Proceedings of the 5th Meeting of the Brazilian association for technical rules

Cui Z, Qian S, Zhang G, Maochu Z (2021) An experimental investigation of the influence of loading rate on rock tensile strength and split fracture surface morphology. Rock Mech Rock Eng 54:1969–1983. https://doi.org/10.1007/s00603-021-02368-4

Diederichs MS, Kaiser PK (1999) Tensile strength and abutment relaxation as failure control mechanics in underground excavations. Int J Rock Mech Min Sci 36:69–96

Efe T, Demirdag S, Tufekci K, Sengun N, Altindag R (2021) Estimating the direct tensile strength of rocks from indirect tests. Arab J Geosci 14(14):1–23. https://doi.org/10.1007/s12517-021-07539-9

Erarslan N, Williams DJ (2012) Experimental, numerical and analytical studies on tensile strength of rocks. Int J Rock Mech Min Sci 49(1):21–30

Feng D, Tian L, Peng C (2011) Study of longitudinal cracking during settlement of soil based on extended finite element method. Eng Mech 28(5):149–154

Fries TP, Belytschko T (2000) The extended/generalized finite element methods: an overview of the method and its applications. Int J Numer Met Eng 84(3):1–6

Fu JW, Haeri H, Yavari MD, Sarfarazi V, Marji MF, Guo M (2021) A linear elastic fracture mechanics analysis of the pre-cracked concrete failure mechanism under modes I, II, III, and IV loading conditions. Strength Mater 53:784–796. https://doi.org/10.1007/s11223-021-00344-5

Fu JW, Sarfarazi V, Naderi AA, Haeri H, Marji MF, Li T (2022) Physical test for analysis of failure behavior of embedded notches. Strength Mater 54:1145–1154. https://doi.org/10.1007/s11223-023-00489-5

Golewski GL (2023a) Mechanical properties and brittleness of concrete made by combined fly ash, silica fume and nanosilica with ordinary Portland cement. AIMS Mater Sci 10(3):390–404

Golewski GL (2023b) Concrete composites based on quaternary blended cements with a reduced width of initial microcracks. Appl Sci 13:7338. https://doi.org/10.3390/app13127338

Golewski GL (2023c) The phenomenon of cracking in cement concretes and reinforced concrete structures: the mechanism of cracks formation, causes of their initiation, types and places of occurrence, and methods of detection—a review. Buildings 13:765. https://doi.org/10.3390/buildings13030765

Golewski GL (2023d) Effect of coarse aggregate grading on mechanical parameters and fracture toughness of limestone concrete. Infrastructures 8:117. https://doi.org/10.3390/infrastructures8080117

Golewski GL (2023e) Study of strength and microstructure of a new sustainable concrete incorporating pozzolanic materials. Struct Eng Mech Struct Eng Mech 86(4):431–444

Gorski B (1993) Tensile testing apparatus. United States Patent, 5193396

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond 221A:163–198

Guan F, Li Y, Gao G, Zachert H, Eichhoff G, Beroya-Eitner MA (2022) Horizontal compression test: a proposed method for indirect determination of tensile strength of stiff soils and soft rocks. Front Earth Sci 10:839073. https://doi.org/10.3389/feart.2022.839073

Haimson BC, Cornet FH (2003) ISRM suggested methods for rock stress estimation—Part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int J of Rock Mech Min Sci 40:1011–1020

Hedayat A, Ochoa F, Khasawneh Y (2015) Numerical simulation of crack initiation and growth in rock specimens containing a flaw under uniaxial compression. In: Proceedings of the 49th US Rock Mechanics Symposium, San Francisco

Hibbitt H, Karlsson B, Sorensen P (2012) ABAQUS theory manual, version 6.12, Pawtucket, Rhode Island, USA

Hoek E (1964) Fracture of anisotropic rock. J S Afr Inst Min Metall 64(10):501–518

ISRM (1978) Suggested methods for determining tensile strength of rock materials. Int J Rock Mech Min Sci Geomech Abstr 15(3):99–103

Jaeger JC, Cook NGW (1976) Fundamental of Rock Mechanics, 2nd edn. Chapman and Hall, London

Jiang R, Duan K, Zhang Q (2022) Effect of heterogeneity in micro-structure and micro-strength on the discrepancies between direct and indirect tensile tests on brittle rock. Rock Mech Rock Eng 55:981–1000. https://doi.org/10.1007/s00603-021-02700-y

Kaklis K, Maurigiannakis S, Agioutantis Z, Istantso C (2009) Influence of specimen shape on the indirect tensile strength of transversely isotropic dionysos marble using the three- point bending test. Strain 45:393–399

Klanphumeesri S (2010) Direct tension testing of rock specimens. Masters of Engineering Tshesis, Suranaree University of Technology

Komurlu E, Demir S (2020) Determination of direct tensile strength values of rock materials by a new test method of drilled disc tension. Period Polytechn Civil Eng 64(1):33–41

Li D, Wong LNY (2012) The Brazilian disc test for rock mechanics applications: review and new insights. Rock Mech Rock Eng 46:269–287

Li D, Li B, Han Z, Zhu Q (2020) Evaluation on rock tensile failure of the brazilian discs under different loading configurations by digital image correlation. Appl Sci 10:5513. https://doi.org/10.3390/app10165513

Liao WC, Chen PS, Hung CW, Wagh SK (2020) An innovative test method for tensile strength of concrete by applying the strut-and-tie methodology. Materials 13(12):2776. https://doi.org/10.3390/ma13122776

Liu J, Lyu C, Lu G, Shi X, Li H, Liang C, Deng C (2022) Evaluating a new method for direct testing of rock tensile strength. Int J Rock Mech Min Sci 160:105258. https://doi.org/10.1016/j.ijrmms.2022.105258

Mariani S, Perego U (2003) Extended finite element method for quasi-brittle fracture. Int J Numer Meth Eng 58(1):103–126

Markides CF, Pazis DN, Kourkoulis SK (2012) The Brazilian disc under non-uniform distribution of radial pressure and friction. Int J Rock Mech Min Sci 50(1):47–55

Myer LR, Kemeny JM, Zheng Z, Suarex R, Ewy RT, Cook NGW (1992) Extensile cracking in porous rock under differential compressive stress. Micromechanical modeling of quasi-brittle materials behavior. Appl Mech Rev 45(8):263–280

Nilimaa J, Nilforoush R (2023) A direct tensile strength testing method for concrete from existing structures. Civil Eng 4:333–344. https://doi.org/10.3390/civileng4010019

Nistor I, Pantalé O, Caperaa S (2008) Numerical implementation of the eXtended finite element method for dynamic crack analysis. Adv Eng Softw 39(7):573–587

Pandit GS (1970) Discussion on the paper, concrete rings for determining tensile strength of concrete. ACI J 1970:847–848

Sarfarazi V, Haeri H, Ebneabbasi P, Bagher shemirani A, Hedayat A, (2018) determination of tensile strength of concrete using a novel apparatus, construction and building materials. Construct Build Mater 166:817–832

Sengun N, Altindag R (2013) Prediction of specific energy of carbonate rock in industrial stones cutting process. Arab J Geosci 6:1183–1190

Shams G, Rivard P, Moradian O (2023) Tensile strength and failure behavior of rock-mortar interfaces: direct and indirect measurements. J Rock Mech Geotechn Eng. https://doi.org/10.1016/j.jrmge.2023.04.013

Stacey TR (1981) A simple extension strain criterion for fracture of brittle rock. Int J Frac 18:469–474

Taponnier P, Brace WF (1976) Development of stress-induced microcracks in Westerly granite. Int J Rock Mech Min Sci and Geomech Abstr 13(4):103–112

Tavallali A, Vervoort A (2010) Failure of layered sandstone under Brazilian test conditions: effect of micro-scale parameters on macro-scale behaviour. Rock Mech Rock Eng 43(5):641–653

Turan M, Uzun Yaylacı E, Yaylacı M (2023) Free vibration and buckling of functionally graded porous beams using analytical, finite element, and artificial neural network methods. Arch Appl Mech 93:1351–1372. https://doi.org/10.1007/s00419-022-02332-w

Uzun Yaylacı E, Oner E, Yaylacı M, Ozdemir ME, Abushattal A, Birinci A (2022) Application of artificial neural networks in the analysis of the continuous contact problem. Struct Eng Mech 84(1):35–48. https://doi.org/10.12989/SEM.2022.84.1.035

Uzun Yaylacı E, Yaylacı M, Ozdemir ME, Terzi M, Ozturk S (2023) Analyzing the mechano-bactericidal effect of nano-patterned surfaces by finite element method and verification with artificial neural networks. Adv Nano Res 15(2):165–174. https://doi.org/10.12989/ANR.2023.15.2.165

Wu Y, Zhou Y (2022) Splitting tensile strength prediction of sustainable high-performance concrete using machine learning techniques. Environ Sci Pollut Res 29:89198–89209. https://doi.org/10.1007/s11356-022-22048-2

Xiong LX, Chen HJ (2020) Effects of high temperatures and loading rates on the splitting tensile strength of jointed rock mass. Geotech Geol Eng 38:1885–1898. https://doi.org/10.1007/s10706-019-01137-z

Yaylacı M, Öner E, Adıyaman G, Öztürk Ş, Uzun Yaylacı E, Ahmet B (2023a) Analyzing of continuous and discontinuous contact problems of a functionally graded layer: theory of elasticity and finite element method. Mech Based Des Struct Mach. https://doi.org/10.1080/15397734.2023.2262562

Yaylacı M, Uzun Yaylacı E, Ozdemir ME, Ozturk S, Sesli H, 2023b, Vibration and buckling analyses of FGM beam with edge crack: finite element and multilayer perceptron methods

Zhang L, Jing H, Liu H, Yin Q, Meng Y (2023) Effects of a weak interlayer zone on the indirect tensile strength and failure characteristics of rock. Environ Earth Sci 82:59. https://doi.org/10.1007/s12665-022-10741-x

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Haeri, H., Sarfarazi, V., Ebneabbasi, P. et al. Assessing the Tensile Crack Growth in Rock Involves Employing a Seesawing Apparatus and its Calibrating Through XFEM: A New Approach. Iran J Sci Technol Trans Civ Eng (2024). https://doi.org/10.1007/s40996-023-01334-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40996-023-01334-0