Abstract

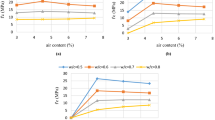

An experimental study was carried out to develop empirical models for predicting the mechanical properties of high-strength concrete (HSC), incorporating the joint effects of silica fume, coarse aggregates type, water-to-cementitious materials ratio (W/CM), and curing time. A total of 45 HSC mixing designs containing five levels of silica fume (0%, 5%, 10%, 15%, and 20% of cementitious material), three W/CM (0.4, 0.3, and 0.24), and three coarse aggregate types (calcareous, andesite, and quartzite) were made. The results revealed that in HSC with quartzite aggregate at a W/CM of 0.24 and 15% silica fume, the highest tensile, flexural, and compressive strengths were obtained as 143 MPa, 12 MPa, and 8 MPa, respectively. The highest modulus of elasticity was recorded at a W/CM of 0.24 and 10% silica fume. Multivariate regression analysis was used to predict the mechanical properties of the HSC after incorporating the effects of W/CM, curing time, percentage of silica fume replacement, and aggregate type. The models were verified with independent experiments and their credibility was proven at an error of less than 10%.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the Isfahan University of Technology (IUT) but restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly available. Data are, however, available from the authors upon reasonable request and with permission of the Isfahan University of Technology (IUT).

References

Aarup B, Klinghoffer O (1996) Effect of microcracks on durability of ultra high-strength concrete. Spec Publ Royal Soc Chem 183:611–622

ACI Committee 211 (2000) Recommended practice for selecting proportions for normal and heavyweight, (ACI 211–89), ACI manual of concrete practice. American Concrete Institute, Detroit

ACI 211.4R.93 (2000) Guide for selecting proportions for high-strength concrete with portland cement and fly ash, ACI manual of concrete practice, Part 1. American Concrete Institute, Detroit

ACI Committee 363 (2000) State-of-the-art report on high-strength concrete, (ACI 363 R-84), ACI manual of concrete practice. American Concrete Institute, Detroit

Afroughsabet V, Ozbakkaloglu T (2015) Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr Build Mater 94:73–82

Aitcin P-C, Mehta P-K (1990) Effect of Coarse-Aggregate Characteristics on & Mechanical Properties of High-Strength Concrete. ACI Mater J 87(2):103–107

ASTM C494–92 (1997) Standard specification for chemical admixtures for concrete. American Society for Testing and Materials, West Conshohocken

ASTM C33–93 (1997) Standard specification for concrete aggregate. American Society for Testing and Materials, West Conshohocken

ASTM D2938-95 (1997) Standard test method for unconfined compressive strength of intact rock core specimens. American Society for Testing and Materials, West Conshohocken, pp 279–281

ASTM D3148-93 (1997) Standard test method for elastic moduli of intact rock core specimens in uniaxial compression. American Society for Testing and Materials, West Conshohocken

ASTM C39–96 (1997) Standard test method for compressive strength of cylindrical concrete specimens. American Society for Testing and Materials, West Conshohocken

ASTM C617–94 (1997) Standard practice for capping cylindrical concrete specimens. American Society for Testing and Materials, West Conshohocken

ASTM C469–94 (1997) Standard test method for static modulus of elasticity and poisson's ratio of concrete in compression. American Society for Testing and Materials, West Conshohocken

ASTM C496–94 (1997) Standard test method for splitting tensile strength of cylindrical concrete specimens. American Society for Testing and Materials, West Conshohocken

Bahmani H, Mostofinejad D, Dadvar SA (2020a) Mechanical properties of ultra-high performance fiber-reinforced containing synthetic and mineral fibers. ACI Mater J 117(3):155–168

Bahmani H, Mostofinejad D, Dadvar SA (2020b) Effects of synthetic fibers and different levels of partial cement replacement on mechanical properties of UHPFRC. J Mater Civ 32(12):04020361

Bahmani H, Mostofinejad D (2022) Microstructure of ultra-high performance concrete (UHPC)-a review study. J Build Eng 50:104118

Bahmani H, Mostofinejad D, Dadvar SA (2022) Fiber type and curing environment effects on the mechanical performance of UHPFRC containing zeolite. Iran J Sci Technol Trans Civ Eng 46:4151–4167

Baalbaki W, Aitcin P-C, Ballivy G (1992) On Predicting Modulus of Elasticity in High-Strength Concrete. ACI Mater J 89(5):517–520

Behnood A, Ziari H (2008) Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem Concr Compos 30(2):106–112

Beushausen H, Dittmer T (2015) The influence of aggregate type on the strength and elastic modulus of high strength concrete. Constr Build Mater 74:132–139

Berntsson L, Chandra S, Kutti T (1990) Principles and factors influencing high-strength concrete production. Concr Inter 12:59–62

Dadvar SA, Mostofinejad D, Bahmani H (2020) Strengthening of RC columns by ultra-high performance fiber reinforced concrete (UHPFRC) jacketing. Constr Build Mater 235:117485

Dadvar SA, Mostofinejad D, Bahmani H (2021) Strengthening of reinforced concrete columns with combined ultra-high-performance fiber-reinforced concrete and glass fiber-reinforced polymer jacketing. ACI Struct J 118(5):285–297

Dotto JMR, De Abreu AG, Dal Molin DCC, Müller IL (2004) Influence of silica fume addition on concretes physical properties and on corrosion behavior of reinforcement bars. Cem Concr Compos 26(1):31–39

Eshaghi-Milasi S, Mostofinejad D, Saljoughian A, Bahmani H (2022) Behavior of RC columns strengthened with UHPFRC jackets through grooving method under eccentric loading: a comparative evaluation of steel and synthetic macro fibers in UHPFRC. Struct Concr 23:1–20

Ezeldin AS, Balaguru PN (1992) Normal- and high-strength fiber-reinforced concrete under compression. J Mater Civ Eng 4:415–429

Giaacio G, Rocco C, Violini D, Zappitelli J, Zerbino R (1992) High-strength 8 concretes incorporating different coarse aggregates. ACI Mater J 89(3):242–246

Gjorv OE, Monteiro JM, Mehta P-K (1990) Effect of condensed silica fume on the steel-concrete bond. ACI Mater J 87(6):573–580

Gutierrez AP, Canovas MF (1996) High-performance concrete: requirements for constituent materials and mix proportioning. ACI Mater J 93(3):231–241

Iravani S (1996) Mechanical properties of high-performance concrete. ACI Mater J 93(5):416–426

Khan MI, Lynsdale CJ (2002) Strength, permeability, and carbonation of high-performance concrete. Cem Concr Res 32:123–131

Khanzadi M, Behnood A (2009) Mechanical properties of high-strength concrete incorporating copper slag as coarse aggregate. Constr Build Mater 23:2183–2188

Khayat KH, Bickley JA, Hooton RD (1995) High-strength concrete properties derived from compressive strength values. Cement, Concrete Aggregates CCAGDP 17(2):126–133

Larrard F, Belloc A (1997) The Influence of aggregate on the compressive strength of normal and high-strength concrete. ACI Mater J 94(5):417–426

Limaye RG (1996) Admixtures for high-strength concrete. Indian Concr J 70(12):689–691

Luciano JJ, Nami CK, Deigado JR (1991) A novel approach to developing high-strength concrete. Concr Int 13(5):25–29

Mazloom M, Ramezanianpour AA, Brooks JJ (2004) Effect of silica fume on mechanical properties of high-strength concrete. Cem Concr Compos 26:347–357

Moreno J (1990) The state of the art of high-strength concrete in Chicago, 225 W Wacker Drive. Concr Inter 12:35–39

Mostofinejad D, Hosseini SM, Nader Tehrani B, Hosseinian SM (2021) Empirical models for prediction of frost resistance of normal-and high-strength concretes. Iran J Sci Technol Trans Civ Eng 45:2107–2131

Mostofinejad D, Reisi M (2012) A new DEM-based method to predict packing density of coarse aggregates considering their grading and shapes. Construct Build Mater 35:414–420

Mostofinejad D, Moosaie I, Eftekhar M, Hesami E (2022) Ultra-high performance hybrid polyvinyl alcohol-polypropylene fiber-reinforced cementitious composites with augmented toughness and strain-hardening behavior. Iran J Sci Technol Trans Civ Eng 46:1997–2009

Mostofinejad D, Nozhati M (2005) Prediction of the modulus of elasticity of high strength concrete. Iran J Sci Technol B 29:311–321

Müller HS, Haist M (2012) New types of high performance concretes – potentials for innovations in concrete construction. In: Fardis MN (ed) Innovative materials and techniques in concrete construction. Springer Netherlands, Dordrecht, pp 43–58. https://doi.org/10.1007/978-94-007-1997-2_3

Persson B (1996) Hydration and strength of high performance concrete. Adv Cem Based Mater 3(3–4):107–123. https://doi.org/10.1016/S1065-7355(96)90043-7

Sata V, Jaturapitakkul C, Kiattikomol K (2007) Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr Build Mater 21:1589–1598

Safiuddin Md, West JS, Soudki KA (2010) Hardened properties of self-consolidating high performance concrete including rice husk ash. Cem Concr Comp 32(9):708–717. https://doi.org/10.1016/j.cemconcomp.2010.07.006

Singh S, Nagar R, Agrawal V, Rana A, Tiwari A (2016) Sustainable utilization of granite cutting waste in high strength concrete. J Cleaner Prod 116:223–235

Shannag MJ (2000) High strength concrete containing natural pozzolan and silica fume. Cem Concr Compos 22(6):399–406

Travani S (1996) Mechanical Properties of High-Performance Concrete. ACI Mater J 93(5):416–426

Zareei SA, Ameri F, Shoaei P, Bahrami N (2019) Recycled ceramic waste high strength concrete containing wollastonite particles and micro-silica: a comprehensive experimental study. Constr Build Mater 201:11–32

Author information

Authors and Affiliations

Contributions

DM: Conceptualization, Methodology, Supervision, Writing—Review & Editing. HB: Conceptualization, Investigation, Visualization, Methodology, Validation, Writing—Original Draft. SEM: Investigation, Writing—Original Draft. MN: Resources, Investigation, Methodology.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mostofinejad, D., Bahmani, H., Eshaghi-Milasi, S. et al. Empirical Relationships for Prediction of Mechanical Properties of High-Strength Concrete. Iran J Sci Technol Trans Civ Eng 47, 315–332 (2023). https://doi.org/10.1007/s40996-022-01023-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-022-01023-4