Abstract

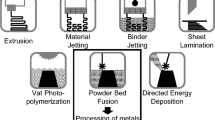

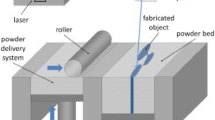

Selective laser melting method occupies a special place in powder bed fusion technology. The growing widespread interest in this technique is due to its several favorable benefits. The final near to net-shape product, which has up to 99.9% relative density is the key advantage. With the extensive applicable materials, PBF–LM has feasible economic benefits. This review paper covers important aspects of SLM technology development. Initially, in the material section, the most common metals and metal alloys are investigated. Research works on various aspects of titanium, nickel, and iron usage are presented. Additionally, less popular aliminium, copper, and magnesium are also discussed. The next area is the latest (after 2018) process parameter optimization methods. Application fields such as; aerospace, structure fabrication, medicine, dentistry, and automobile are also included. Moreover, relevant figures of various applications are presented. The last chapter highlights the innovations made after 2018 in the field of PBF–LM.

Similar content being viewed by others

References

ASTM (2015) ASTM52900-15 standard terminology for additive manufacturing general principlesterminology, ASTM International, West Conshohocken. PA 3:5

Faludi J, Bayley C, Bhogal S, Iribarne M (2015) Comparing environmental impacts of additive manufacturing vs traditional machining via life-cycle assessment. Rapid Prototyping J 21:14–33. https://doi.org/10.1108/RPJ-07-2013-0067

Kreiger M, Pearce JM (2013) Environmental life cycle analysis of distributed three-dimensional printing and conventional manufacturing of polymer products. ACS Sustain Chem Eng 1:1511–1519. https://doi.org/10.1021/sc400093k

Le Bourhis F, Kerbrat O, Dembinski L, Hascoet J-Y, Mognol P (2014) Predictive model for environmental assessment in additive manufacturing process. Proc CIRP 15:26–31. https://doi.org/10.1016/j.procir.2014.06.031

Gibson I, Rosen D, Stucker B, Khorasani M (2014) Additive manufacturing technologies. Springer

N. Hopkinson, R. Hague, P. Dickens (2006) Rapid manufacturing, An Industrial Revolution for the Digital Age. Chichister, England: John Wiley and Sons, Ltd.

Ivanova O, Williams C, Campbell T (2013) Additive manufacturing (AM) and nanotechnology: promises and challenges. Rapid Prototyping J. https://doi.org/10.1108/RPJ-12-2011-0127

Melchels FPW, Domingos MAN, Klein TJ, Malda J, Bartolo PJ, Hutmacher DW (2012) Additive manufacturing of tissues and organs. Prog Polym Sci 37:1079–1104. https://doi.org/10.1016/j.progpolymsci.2011.11.007

Flodberg G, Pettersson H, Yang L (2018) Pore analysis and mechanical performance of selective laser sintered objects. Addit Manuf 24:307–315. https://doi.org/10.1016/j.addma.2018.10.001

Launhardt M, Wörz A, Loderer A, Laumer T, Drummer D, Hausotte T, Schmidt M (2016) Detecting surface roughness on SLS parts with various measuring techniques. Polym Testing 53:217–226. https://doi.org/10.1016/j.polymertesting.2016.05.022

R. Singh, A. Gupta, O. Tripathi et al., Powder bed fusion process in additive manufacturing: An overview, Materials Today: Proceedings, https://doi.org/10.1016/j.matpr.2020.02.635.

Ż. A. Mierzejewska, W. Markowicz. Selective laser sintering—binding mechanism and assistance in medical applications, Advances in materials science, vol. 15, no. 3 (45), September 2015

D. Dev Singh, T. Mahender, Avala Raji Reddy, Powder bed fusion process: a brief review. Materials Today 46 (2021) 350–355.

Yap CY, Chua CK, Dong ZL, Liu ZH, Zhang DQ, Loh LE, Sing SL (2015) Review of selective laser melting: Materials and applications. Appl Phys Rev 2:041101. https://doi.org/10.1063/1.4935926

Park H-S, Nguyen D-S (2017) Study on flaking behavior in selective laser melting process. Procedia CIRP 63:569–572

Agapovichev A, Sotov A, Kokareva V, Smelov V Possibilities and limitations of titanium alloy additive manufacturing. MATEC Web of Conferences; 2018: EDP Sciences. p. 01064. https://doi.org/10.1051/matecconf/201822401064

Dongdong Gu, Hagedorn Y-C, Meiners W, Meng G, Batista RJS, Wissenbach K, Poprawe R (2012) Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater 60(2012):3849–3860

Naa T-W et al.(2018) Effect of laser power on oxygen and nitrogen concentration of commercially pure titanium manufactured by selective laser melting, Materials Characterization

Kim WR et al. Fabrication of porous pure titanium via selective laser melting under low-energy-density process conditions, Materials and Design 195 (2020) 109035

Edson Santos FA, Kitamura Y, Osakada K, Shiomi M. Mechanical properties of pure titanium models processed by selective laser melting, 180–186

Tarik Hasib M, Ostergaard HE, Liu Q, Li X, Kruzic JJ, Tensile and fatigue crack growth behavior of commercially pure titanium produced by laser powder bed fusion additive m a n u f a c t u r i n g , Additive Manufacturing, https://doi.org/10.1016/j.addma.2021.102027

Antony K, Reghunathan Rakeshnath T, Study on selective laser melting of commercially pure titanium powder, Proc IMechE Part B 00(0)

Zhang B, Liao H (2013) Christian coddet microstructure evolution and density behavior of CP Ti parts elaborated by self-developed vacuum selective laser melting system. Appl Surf Sci 279:310–316

. Attar H, Calin M,Zhang LC,Scudino S,Eckert J, Manufacture by selective laser melting and mechanical behavior of commercially pure titanium, Materials Sci Eng A593(2014)170–177

Yang X, Zhang Z, Wenping Gu, Wang B, Fan Y, Miao Q, Zhao S, Xie Bo (2020) Fabrication of ultra-low-cost pure Ti by selective laser melting using the mixed powders of hydride-dehydride titanium powders treated by ball milling and spherical powders. Powder Metall. https://doi.org/10.1080/00325899.2020.1847848

Attar H, Ehtemam-Haghighi S, Kent D, Wu X, Dargusch MS, Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes, Materials Sci Eng A, https://doi.org/10.1016/j.msea.2017.08.103

Song Bo, Dong S, Zhang B, Liao H, Coddet C (2012) Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater Des 35:120–125

Qiu C, Adkins NJE, Attallah MM,Microstructure and tensile properties of selectively laser-melted and of PREHed laser-melted Ti–6Al–4V , Materials Sci Eng A578(2013)230–239

Ginestra P, Ferraro RM, Zohar-Hauber K, Abeni A, Giliani S, Ceretti E (2020) Laser S Melting and electron beam melting of Ti6Al4V for orthopedic applications: a comparative study on the applied building direction. Materials 13:5584

Cao S, Zou Y, Lim CVS, Wu X(2021), Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: process, post-process treatment, microstructure, and property, Light: Advanced Manufacturing 2:20

Vrancken B, Thijs L, Kruth J-P, Van Humbeeck J (2012) Heat treatment of Ti6Al4V produced by selective laser melting: microstructure and mechanical properties. J Alloy Compd 541:177–185

Simonelli M,Tse YY,Tuck C (2014) Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V, Mater Sci Eng A616:1–11

Leuders S, Thцne M, Riemer A, Niendorf T, Trцster T, Richard HA, Maier HJ (2013) On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int J Fatigue 48:300–307

Thywill Ccphas Dzogbewu (2021) Laser powder bed fusion of Ti6Al4V-xCu: process parameters. J Metals Mater Min 31(2):62–70

Zhang X, Mao B, Mushongera L, Kundin J, Liao Y (2021) Laser powder bed fusion of titanium aluminides: an investigation on site-specific microstructure evolution mechanism. Mater Design 201:109501

Li S, Yang J, Wang Z (2021) Multi-laser powder bed fusion of Ti-6.5Al-2Zr-Mo-V alloy powder: Defect formation mechanism and microstructural evolution. Powder Technol 384:100–111

Huang S, Sing SL, de Looze G, Wilson R, Yeong WY (2020) Laser powder bed fusion of titanium-tantalum alloys: Compositions and designs for biomedical applications. J Mech Behavr Biomed Materials 108:103775

Wang JC, Liu YJ, Qin P, Liang SX, Sercombe TB, Zhang LC (2019) Selective laser melting of Ti–35Nb composite from elemental powder mixture: Microstructure, mechanical behavior and corrosion behavior. Mater Sci Eng, A 760:214–224

Hj Y, Abolhasani D, Tw H, Lee T, Kim JH, Moon YH (2020) Fabrication of porous titanium parts by powder bed fusion of Ti–TiH2 blended powder. J Mater Restechnol 9(3):3026–3037

AlMangour B, Grzesiak D, Yang J-M (2017) In-situ formation of novel TiC-particlereinforced 316L stainless steel bulk-form composites by selective laser melting. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2017.01.149

Colombo-Pulgarın JC, Biffi CA, Vedani M, Celentano D, Sa´ nchez-Egea A, Boccardo AD, Ponthot J-P, Beta Titanium alloys processed by laser powder bed fusion: a review, J Materials Eng Performance 30(9):2021—6365

Yen Yap C, Kenneth Tan H, Du Z, Kai Chua C, Dong Z (2017) Selective laser melting of nickel powder, Rapid Prototyping J, 23(4), https://doi.org/10.1108/RPJ-01-2016-0006

Li R, Liu J, Shi Y, Wang Li, Jiang W (2012) Balling behavior of stainless steel and nickel powder during selective laser melting process. Int J Adv Manuf Technol 59:1025–1035

Khoo ZX, Liu Y, An J, Chua CK, Shen YF, Kuo CN (2018) A review of selective laser melted NiTi Shape Memory Alloy. Materials 11:519. https://doi.org/10.3390/ma11040519

Andani MT, Saedi S, Sadi Turabi A, Karamooz M, Haberland C, Karaca H, Elahinia M Mechanical and shape memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting. J Mech Behav Biomed Mater https://doi.org/10.1016/j.jmbbm.2017.01.047

Shishkovsky I, Yadroitsev I, Smurov I (2012) Direct selective laser melting of nitinol powder. Phys Procedia 39:447–454

Haberland C, Meier H, Frenzel J, On the properties of ni-rich niti shape memory parts produced by selective laser melting, In: Proceedings of the ASME 2012 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, 19–21, 2012, Stone Mountain, Georgia, USA

Dadbakhsh S, Speirs M, Kruth J-P, Schrooten J, Luyten J, Van Humbeeck J,Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts, Adv Eng Materials 2014, 16(9)

Chekotu JC, Groarke R, O’Toole K, Brabazon D (2019) Advances in selective laser melting of nitinol shape memory alloy part production, Materials 12: 809. doi:https://doi.org/10.3390/ma12050809

Dadbakhsh S, Speirs M, Kruth J-P, Van Humbeeck J, Influence of SLM on shape memory and compression behaviour of NiTi scaffolds, CIRP Annals—Manufacturing Technology

Zhao Y, Taya M, Kang Y, Kawasaki A (2005) Compression behavior of porous NiTi shape memory alloy. Acta Mater 53:337–343

Bormann T, Müller B, Schinhammer M, Kessler A, Thalmann P, de Wild M (2014) Microstructure of selective laser melted nickel–titanium. Materialscharacterization 94:189–202

Shih-Fu Ou, Peng B-Y, Chen Y-C, Tsai M-H (2018) Manufacturing and characterization of NiTi alloy with functional properties by selective laser melting. Metals 8:342. https://doi.org/10.3390/met8050342

Haberland C, Elahinia M, Walker JM, Meier H, Frenzel J (2014) On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing, Smart Mater Struct 23: 104002 (13pp)

Walker JM, Haberland C, Taheri Andani M, Ersin Karaca H, Dean D, Elahinia M Process development and characterization of additively manufactured nickel–titanium shape memory parts, J Intell Material Syst Struct

Domashenkov A, Doubenskaia M, Smurov I, Smirnov M, Travianov A Selective laser melting of NiTi powder, Lasers in Manufacturing Conference 2017

Polozov I, Popovich A (2021) Microstructure and mechanical properties of NiTi-based eutectic shape memory alloy produced via selective laser melting in-situ alloying by Nb. Materials 14:2696. https://doi.org/10.3390/ma14102696

Jangali Satish G, Gaitonde VN, Kulkarni VN Traditional and non-traditional machining of nickel-based superalloys: a brief review, Materials Today 44 (2021) 1448–1454

Sanchez S, Smith P, Xu Z, Gaspard G, Hyde CJ, Wits WW, Ashcroft IA, Chen H, Clare AT (2021) Powder bed fusion of nickel-based superalloys: a review, Int J Mach Tools Manuf 165: 103729

Sufiiarov VS, Borisov EV, Polozov IA (2015) Selective laser melting of the inconel 718 nickel superalloy. Appl Mech Materials 698:333–338

Ivanov D, Travyanov A,Petrovskiy P, Cheverikin V, Alekseeva E, Khvan A, Logachev I Evolution of structure and properties of the nickelbased alloy EP718 after theSLMgrowth and after different types of heat and mechanical treatment (2010), https://doi.org/10.1016/j.addma.2017.10.015

Balbaa M, Mekhiel S, Elbestawi M, McIsaac J (2020) On selective laser melting of Inconel 718: Densification, surface roughness, and residual stresses. Mater Des 193:108818

Liu X, Wang K, Ping Hu, He X, Yan B, Zhao X (2021) Formability, microstructure and properties of inconel 718 superalloy fabricated by selective laser melting additive manufacture technology. Materials 14:991. https://doi.org/10.3390/ma14040991

Wang X, Keya T, Chou K (2016) Build height effect on the inconel 718 parts fabricated by selective laser melting. Proc Manuf 5:1006–1017

Tian Z, Zhang C, Wang D, Liu W, Fang X, Wellmann D, Zhao Y, Tian Y (2020) A review on laser powder bed fusion of inconel 625 nickel-based alloy, Appl Sci. 10: 81. doi:https://doi.org/10.3390/app10010081

Leary M, Mazur M, Williams H, Yang E, Alghamdi A, Lozanovski B, Zhang X, Shidid D, Farahbod-Sternahl L, Witt G, Kelbassa I, Choong P, Qian Ma, Brandt M (2017) Inconel 625 lattice structures manufactured by selective laser melting (SLM): mechanical properties, deformation and failure modes. Jmade. https://doi.org/10.1016/j.matdes.2018.06.010

Hu X-A, Zhao G-L, Liu F-C, Liu W-X Microstructure and mechanical behavior of Inconel 625 alloy processed by selective laser melting at high temperature up to 1000C, Rare Met.

Mazur M, Benoit M, Easton M, Brandt M (2020) Selective laser melting of Inconel 625 alloy with reduced defect formation. J Laser Appl 32:022058

Kim K-S, Kang T-H, Kassner ME, Son K-T, Lee K-A, High-temperature tensile and high cycle fatigue properties of inconel 625 alloy manufactured by laser powder bed fusion, Additive Manufacturing (2020), https://doi.org/10.1016/j.addma.2020.101377

Qin S, Novak TC, Vailhe MK, Liu Z-K, Beese AM (2021) Plasticity and fracture behavior of Inconel 625 manufactured by laser powder bed fusion: Comparison between as-built and stress relieved conditions. Mater Sci Eng, A 806:140808

Kreitcberg A, Brailovski V, Turenne S (2017) Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of inconel 625 alloy processed by laser powder bed fusion. Mater Sci Eng A 689:1–10

Li X, Yi D, Liu B, Zhang J, Yang X, Wan C, Feng Y, Bai P, Liu Y, Qian M (2020) Graphene-strengthened inconel 625 alloy fabricated by selective laser melting, Mater Sci Eng A 798 140099

Bermingham DCM, Kent D, Demir AG, Previtali B, Dargusch MS (2018) Comparative study of pure iron manufactured by selective laser melting, laser metal deposition, and casting processes, Adv Eng Mater: 1900049

Palousek D, Pantelejev L, Zikmund T, Koutny D (2017) Processing of nearly pure iron using 400w selective laser melting—initial study, MM Sci J

Lejček P, Roudnicka M, Čapek J, Dvorsky D, Drahokoupil J, Šimek D, Čižek J, Svora P, Molnarova O, Vojtěch D (2019) Selective laser melting of pure iron: multiscale characterization of hierarchical microstructure. Mater Charact 154:222–232

Riipinen T, Metsä-Kortelainen S, Lindroos T, Keränen JS, Manninen A, Pippuri-Mäkeläinen J (2019) Properties of soft magnetic Fe-Co-V alloy produced by laser powder bed fusion. Rapid Prototyping Journal. https://doi.org/10.1108/RPJ-06-2018-0136

Goll D, Vogelgsang D, Pflanz U, Hohs D, Grubesa T, Schurr J, Bernthaler T, Kolb D, Riegel H, Schneider G (2018) Refining the microstructure of Fe–Nd–B by selective laser melting, Phys Status Solidi RRL, 1800536

Ikehata H, Mayweg D, Jägle E (2021) Grain refinement of Fe–Ti alloys fabricated by laser powder bed fusion. Mater Des 204:109665

Zhang B, Fenineche N-E, Liao H, Coddet C (2013) Microstructure and magnetic properties of FeeNi alloy fabricated by selective laser melting Fe/Ni mixed powders, J Mater Sci Technol. 29(8), 757e760

Kang N, El Mansori M, Guittonneau F, Liao H, Fu Y et al (2018) Controllable mesostructure, magnetic properties of soft magnetic Fe–Ni–Si by using selective laser melting from nickel coated high siliconsteel powder. Appl Surface Sci Elsevier 455:736–741

Carluccio D, Demir AG, Caprio L, Previtali B, Bermingham MJ, Dargusch MS (2019) The influence of laser processing parameters on the densification and surface morphology of pure Fe and Fe-35Mn scaffolds produced by selective laser melting. J Manuf Process 40:113–121

Shuai C, Yang W, Yang Y, Pan H, He C, Qi F, Xie D, Liang H (2020) Selective laser melted Fe–Mn bone scaffold:microstructure, corrosion behavior and cell response. Mater Res Express 7:015404

Donik Č, Kraner J, Kocijan A, Paulin I, Matjaž G (2021) Evolution of the ε and γ phases in biodegradable Fe–Mn alloys produced using laser powder‑bed fusion, Scientific Reports 11:19506

Yan X, Gao S, Chang C, Liao H, Liu M (2020) Microstructure and tribological property of selective laser melted Fe–Mn–Al–C alloy. Mater Lett 270:127699

Ferretto I, Kim D, Della Ventura NM, Shahverdi M, Lee W, Leinenbach C (2021) mLaser powder bed fusion of a Fe–Mn–Si shape memory alloy. Additive Manuf 46:102071

Clemens Ewald F, Brenne F, Gustmann T, Vollmer M, Krooß P (2021) Niendorf T, Laser powder bed fusion processing of Fe-Mn-Al-Ni shape memory alloy—on the effect of elevated platform temperatures. Metals 11:185. https://doi.org/10.3390/met11020185

Niendorf T, Brenne F, Krooя P, Vollmer M, Guёnther J, Schwarze D, and Biermann H, microstructural evolution and functional properties of Fe-Mn-Al-Ni shape memory alloy processed by selective laser melting, Metals Mater Soc ASM Int 2016

Eliasu A, Czekanski A, Boakye-Yiadom S (2021) Effect of laser powder bed fusion parameters on the microstructural evolution and hardness of 316L stainless steel. Int J Adv Manuf Technol 113:2651–2669

Choo H, Sham K-L, Bohling J, Ngo A, Xiao X, Ren Y, Depond PJ, Matthews MJ, Garlea E (2018) Effect of laser power on defect, texture, and microstructure of a laser powder bed fusion processed 316L stainless steel. Jmade. https://doi.org/10.1016/j.matdes.2018.12.006

Afkhami S, Dabiri M, Piili H (2021) Timo Bj¨ork, Effects of manufacturing parameters and mechanical post-processing on stainless steel 316L processed by laser powder bed fusion. Mater Sci Eng, A 802:140660

Leicht A, Fischer M, Klement U, Nyborg L, Hryha E Increasing the productivity of laser powder bed fusion for stainless steel 316l through increased layer thickness. J Materials Eng Performance,

Ansari P, Rehma AU, Pitir F, Veziroglu S, Kumar Mishra Y, Cenk Aktas O, Salamci MU (2021) Selective laser melting of 316l austenitic stainless steel: detailed process understanding using multiphysics simulation and experimentation, Metals 11: 1076. https://doi.org/10.3390/met11071076

Nesma T. Aboulkhair⁎, Marco Simonelli, Luke Parry, Ian Ashcroft, Christopher Tuck,Richard Hague, 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting, Progress in Materials Science 106 (2019) 100578

Zhang J, Song B, Wei Q, Bourell D, Shi Y, A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends, J Materials Sci amp; Technology (2018), https://doi.org/10.1016/j.jmst.2018.09.004

Sercombe TB, Li X (2016) Selective laser melting of aluminium and aluminium metal matrix composites: review. Mater Technol 31(2):77–85. https://doi.org/10.1179/1753555715Y.0000000078

Wang Z, Ummethal R, Singh N, Tang S, Suryanarayana C (2020) Jürgen eckert and konda gokuldoss prashanth. Selective Laser Melting Aluminum Alloys Materials 13:4564. https://doi.org/10.3390/ma13204564

Manfredi D, Bidulský R (2017) Laser powder bed fusion of aluminum alloys, Acta Metallurgica Slovaca, 23(3): 276–282

Jiang Qi, Zhang P, Zhishui Yu, Shi H, Di Wu, Yan H, Ye X, Qinghua Lu, Tian Y (2021) A review on additive manufacturing of pure copper. Coatings 11:740. https://doi.org/10.3390/coatings11060740

Jadhav SD, Dadbakhsh S, Goossens L, Kruth J-P, Van Humbeeck J, Vanmeensel K (2019) Influence of selective laser melting process parameters on texture evolution in pure copper. J Materials Process Tech 270:47–58

Gargarella P, Shyinti Kiminami C, Marchezini Mazzer E, Daniel Cava R, Albuquerque Basilioa L, Bolfarini C, José Botta W, Eckert J, Gustmann T, Pauly S (2015) Phase formation, thermal stability and mechanical properties of a Cu-Al-Ni-Mn shape memory alloy prepared by selective laser melting, Mater Res; 18(Suppl 2): 35-38

Mazzer EM, Kiminami CS, Gargarella P, Cava RD, Basilio LA, Bolfarini C, Botta WJ, Eckert J, Gustmann T, Pauly S (2014) Atomization and selective laser melting of a Cu-Al-Ni-Mn shape memory alloy. Mater Sci Forum 802:343–348

Gustmann T, dos Santos JM, Gargarella P, Ku¨hn U, Van Humbeeck J, Pauly S Properties of Cu-based shape-memory alloys prepared by selective laser melting, Shap Mem Superelasticity

Manakari V, Parande G, Gupta M (2017) Selective laser melting of magnesium and magnesium alloy powders: a review. Metals 7:2. https://doi.org/10.3390/met7010002

Mahesh Savalani Jorge Martinez Pizarro M, (2016),"Effect of preheat and layer thickness on selective laser melting (SLM) of magnesium", Rapid Prototyping Journal, Vol. 22 Iss 1 pp. 115 – 122

Ng CC, Savalani MM, Lau ML, Man HC (2011) Microstructure and mechanical properties of selective laser melted magnesium. Appl Surf Sci 257:7447–7454

Wei K, Gao M, Wang Z, Zeng X Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy, Materials Sci Eng A, https://doi.org/10.1016/j.msea.2014.05.092

Karunakaran R, Ortgies S, Tamayol A, Bobaru F, Sealy MP (2020) Additive manufacturing of magnesium alloys. Bioactive Materials 5:44–54

Marrey M, Malekipour E, El-Mounayri H, Faierson EJ (2019) A framework for optimizing process parameter. Proc Manuf 34:505–515

Yuana S, Li J, Yao X, Zhu J, Xiaojun Gu, Gao T, Yingjie Xu, Zhang W (2020) Process parameter optimization framework for the selective laser melting of hastelloy X alloy considering defects and solidification crack occurrence. Addit Manuf 34:101182

Kitano H, Kusano M, Tsujii M, Yumoto A, Watanabe M (2021) Intelligent optimization system for powder bed fusion of processable thermoplastics. Curr Comput-Aided Drug Des 11:578. https://doi.org/10.3390/cryst11060578

Li Z, Kucukkoc I, Zhang DZ, Liu F Optimising the process parameters of selective laser melting for the fabrication of Ti6Al4V alloy, Rapid Prototyping J https://doi.org/10.1108/RPJ-03-2016-0045

Baturynska I, Semeniuta O, Martinsen K (2018) Optimization of process parameters for powder bed fusion additive manufacturing by combination of machine learning and finite element method: a conceptual framework. Procedia CIRP 67:227–232

Nguyen DS, Seok Pa H r, Lee CM (2020) Optimization of selective laser melting process parameters for Ti-6Al-4V alloy manufacturing using deep learning, J Manuf Process 55: 230–235.

Lo Y-L, Liu B-Y, Tran H-C,Optimized hatch space selection in double-scanning track selective laser melting process, Int J Adv Manuf Technol

Vilanova M, Escribano-García R 1, Guraya T, San Sebastian M (2020) Optimizing laser powder bed fusion parameters for IN-738LC by Response surface method, Materials, 13: 4879

Terner M, Ricordel T, Cho J-H, Lee J-S, The response surface methodology for optimizing the process parameters of selective laser melting.

Ma Z, Zhang K, Ren Z, Zhang DZ, Tao G, Haisheng Xu (2020) Selective laser melting of CueCreZr copper alloy: parameter optimization, microstructure and mechanical properties. J Alloy Compd 828:154350

Yonehara M, Ikeshoji T-T, Nagahama T, Mizoguchi T, Tano M, Yoshimi T, Kyogoku H (2020) Parameter optimization of the high-power laser powder bed fusion process for H13 tool steel. Int J Adv Manuf Technol 110:427–437

Bajaj P, Wright J, Todd I, Jagle EA (2018) Predictive process parameter selection for selective laser melting manufacturing:applications to high thermal conductivity alloys. Addit Manuf. https://doi.org/10.1016/j.addma.2018.12.003

Ahsan F, Razmi J, Ladani L (2022) Process parameter optimization in metal laser-based powder bed fusion using image processing and statistical analyses. Metals 12:87

Seabraa M, Azevedob J, Araújoa A, Reisa L, Pinto E, Alvesc N, Santosd R, Mortáguab JP, Selective laser melting (SLM) and topology optimization for lighter aerospace components, Proc Struct Integrity 1 (2016) 289–296

Shi G, Guan C, Quan D, Dongtao Wu, Tang L, Gao T (2020) An aerospace bracket designed by thermo-elastic topology optimization and manufactured by additive manufacturing. Chin J Aeronaut 33(4):1252–1259

Brandt M, Sun S, Leary M, Feih S, Elambasseril J, Liu Q (2013) High-value SLM aerospace components: from design to manufacture. Adv Mater Res 633:135–147

Bamberg J, Zenzinger G, Ladewig A In-process control of selective laser melting by quantitative optical tomography, 19th world conference on non-destructive testing (WCNDT 2016), 13–17 June 2016 in Munich, Germany (WCNDT 2016), (2016)

Liu F, Jingchao W, Zhi T, Bin L, Yue G, Zhang DZ An aerospace integrated component application based on selective laser melting: design, fabrication and FE simulation, Solid Freeform Fabrication 2018: Proceedings of the 29th Annual International.

Blakey-Milner B, Gradl P, Snedden G, Brooks M, Pitot J, Lopez E, Leary M, Berto F, du Plessis A (2021) Metal additive manufacturing in aerospace: a review. Mater Des 209:110008

Meng L, Zhang W, Quan D, Shi G, Tang L, Hou Y, Breitkopf P, Zhu J, Gao T (2019) From topology optimization design to additive manufacturing: today’s success and tomorrow’s roadmap, Arch Comput Methods Eng.

Jyothish Kumar L, Krishnadas Nair CG Current trends of additive manufacturing in the aerospace industry, advances in 3d printing & additive manufacturing technologies. Springer, Singapore. https://doi.org/10.1007/978-981-10-0812-2_4

Gradl P, Greene SE, Protz C, Bullard B, Buzzell J, Garcia C, Wood J, Cooper K, Hulka J, Osborne R Additive manufacturing of liquid rocket engine combustion devices: a summary of process developments and hot-fire testing results, conference: 2018 Joint Propulsion Conference, (2018).

Smith M, Cantwell WJ, Guan Z, Tsopanos S,Theobald MD, Nurick GN, Langdon GS, The quasi-static and blast response of steel lattice structures, Journal of Sandwich Structures and Materials 13(4) 479–501

Ushijima K, Cantwell WJ, Mines R, Tsopanos S, Smith M, An investigation into the compressive properties of stainless steel micro-lattice structures, J Sandwich Struct Materials 13(3) 303–329

Gumruk R, Mines RAW (2013) Compressive behaviour of stainless steel micro-lattice structures. Int J Mech Sci 68:125–139

Contuzzi N, Campanelli SL, Casavola C, Lamberti L (2013) Manufacturing and characterization of 18Ni marage 300 lattice components by selective laser melting, Materials, 6.

Yan C (2012) LiangHao, AhmedHussein, DavidRaymont, Evaluations of cellular lattice structures manufactured using selective laser melting. Int J Mach Tools Manuf 62:32–38

Jia D, Li F, Zhang Y (2020) 3D-printing process design of lattice compressor impeller based on residual stress and deformation. Sci Rep 10:600. https://doi.org/10.1038/s41598-019-57131-1

Santorinaios M, Brooks W, Sutcliffe CJ, Mines RAW, Crush behavior of open cellular lattice structures manufactured using selective laser melting, High Performance Structures and Materials III.

Brenne F, Niendorf T, Maier HJ (2013) Additively manufactured cellular structures: impact of microstructure and local strains on the monotonic and cyclic behavior under uniaxial and bending load. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2013.03.013

Hussein R, Anandan S, Spratt M, Newkirk JW, Chandrashekhara K, Heath M, Walker M(2020) Effective elastic moduli of metal honeycombs manufactured using selective laser melting, Rapid Prototyping J 26(5): 971–980.

Zhang Y, Liu T, Ren H, Maskery I, Ashcroft I (2018) Dynamic compressive response of additively manufactured AlSi10Mg alloy hierarchical honeycomb structures. Compos Struct. https://doi.org/10.1016/j.compstruct.2018.04.021

Hemerson de Moraes P, Olate S, Cantín M, Freitas Assis A, Santos E, de Oliveira Silva F, de Oliveira Silva L (2015) Anatomical reproducibility through 3D printing in cranio-maxillo-facial defects, Int J Morphol 33(3):826–830

Bibb R, Eggbeer D, Evans P, Bocca A, Sugar A, (2009) Rapid manufacture of custom-fitting surgicalguides, Rapid Prototyping J 15(5):346 – 354 Permanent link to this document: https://doi.org/10.1108/13552540910993879

Kalayu Mekonen Abate, Aamer Nazir and Jeng-Ywan Jeng , Design, optimization, and selective laser melting of vin tiles cellular structure-based hip implant, Int J Adv Manuf Technol (2021) 112:2037–2050

Neha Sharma, Daniel Ostas, Horatiu Rotar, Philipp Brantner and Florian Markus Thieringer ,Design and Additive Manufacturing of a Biomimetic Customized Cranial Implant Based on Voronoi Diagram, Frontiers in Physics, 12(2021).

Mazher I. Mohammed, Angus P. Fitzpatrick, and Ian Gibson, (2017), ”Customised Design of a Patient Specific 3D Printed Whole Mandible Implant,” in The International Conference on Design and Technology, KEG, pages 104–111. DOI https://doi.org/10.18502/keg.v2i2.602.

Edelmann A, Dubis M, Hellmann R (2020) Selective laser melting of patient individualized osteosynthesis plates—digital to physical process chain. Materials 13:5786. https://doi.org/10.3390/ma13245786

Wang Di, Wang Y, Shibiao Wu, Lin H, Yang Y, Fan S, Cheng Gu, Wang J, Song C (2017) Customized a Ti6Al4V bone plate for complex pelvic fracture by selective laser melting. Materials 10:35. https://doi.org/10.3390/ma10010035

Yajie Lu, Guojing C, Zuoyao L, Minghui Li, Chuanlei Ji, Fengwei W, Li Huanzhang Lu, Jianxi WZ, Jing Li (2019) Novel 3D-printed prosthetic composite for reconstruction of massive bone defects in lower extremities after malignant tumor resection. J Bone Oncol 16:100220

Ira Goldsmith, Peter Llewelyn Evans, Heather Goodrum, James Warbrick-Smith and Thomas Bragg, Chest wall reconstruction with an anatomically designed 3-D printed titanium ribs and hemi-sternum implant, 3D Printing in Medicine (2020) 6:26.

L.E.Murr, Metallurgy principles applied to powder bed fusion 3D printing/additive manufacturing of personalized and optimized metal and alloy biomedical implants: an overview, J m a t e r r e s t e c h n o l . 2 0 2 0;9(1):1087–1103.

Yongqiang Yang Jian-bin Lu Zhi-Yi Luo Di Wang, (2012),"Accuracy and density optimization in directly fabricating customized orthodontic production by selective laser melting", Rapid Prototyping Journal, Vol. 18 Iss 6 pp. 482 – 489

Vandenbroucke B, Kruth J-P (2007) Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyping Journal 13(4):196–203

Averyanova M, Bertrand P, Verquin B (2011) Manufacture of Co-Cr dental crowns and bridges by selective laser melting technology. Virtual Phys Prototyping 6(3):179–185

T.Laoui, E.Santos, K.Osakada, M.Shiomi, M.Morita, S.K.Shaik, N.K.Tolochko, F.Abe, and M.Takahashi , Properties of titanium dental implant models made by laser processing, Proc. IMechE Vol. 220 Part C: J. Mechanical Engineering Science.

Jaafar Abduo, Michael Curtis, Vandana Budhwar, Joseph Palamara, Influence of novel implant selective laser melting framework design on mechanical durability of acrylic veneer, Clin Implant Dent Relat Res. 2018;1–7.

Yanjin Lu, Gan Y, Lin J, Guo S, Songquan Wu, Lin J (2017) Effect of laser speeds on the mechanical property and corrosion resistance of CoCrW alloy fabricated by SLM. Rapid Prototyping Journal 23(1):28–33

Marit Øilo, Harald Nesse, Odd Johan Lundberg and Nils Roar Gjerdet, Mechanical properties of cobalt-chromium 3-unit fixed dental prostheses fabricated by casting, milling, and additive manufacturing, The journal of prosthetic dentistry.

Dzhendo Dzhendov, Tsanka Dikova, Application of selective laser melting in manufacturing of fixed dental prostheses, J of IMAB. 2016, vol. 22, issue 4

Duhn C, Thalji G, Al-Tarwaneh S, Cooper LF (2021) A digital approach to robust and esthetic implant overdenture construction. J Esthet Restor Dent 33:118–126

Wang Di, Wang Y, Yang Y, Jianbin Lu, Zhenlong Xu, Li S, Lin K, Zhang D (2019) Research on design optimization and manufacturing of coating pipes for automobile seal based on selective laser melting. J Materials Process Tech 273:116227

H.Everett, Slm solutions 3d prints Porsche e-drive housing on NXG X11 600, 3DPrinting industry, Dec. 2020, Accessed on: Nov 2021. [Online]. https://3dprintingindustry.com/news/slm-solutions-3d-prints-porsche-e-drive-housing-on-nxg-x11-600-181483/

R.Haria,Porsche green-lights 3d printed spare parts for classic cars, 3DPrinting industry, Feb. 2018, Accessed on: Nov 2021. [Online]. https://3dprintingindustry.com/news/porsche-green-lights-3d-printed-spare-parts-classic-cars-128792/

B.Jackson, Fresh off the 3d printer: metal parts for Mercedes-Benz trucks, 3DPrinting industry, Aug. 2017, Accessed on: Nov 2021. [Onlinehttps://3dprintingindustry.com/news/fresh-off-3d-printer-metal-parts-mercedes-benz-trucks-119701/

Skrynecki N (2010) Kundenorientierte Optimierung des generativen Strahlschmelzprozesses. Aachen, Germany

Ralf Frohwerk, Metal 3D printing is leading the innovations in motor sport,Professional MotorSport World Expo 2019. Rerivied from: https://www.professionalmotorsport-expo.com/downloads/Presentations/G_d3_s0_p3_ralf_frohwerk.pdf

Dongsen Ye, Jerry Ying Hsi Fuh, Yingjie Zhang, Geok Soon Hong, Kunpeng Zhu, In situ monitoring of selective laser melting using plume and spatter signatures by deep belief networks, ISA Transactions, 81 (2018), pp:96–104

N. Eschner, L. Weiser, B. Häfner, G. Lanza,Development of an acoustic process monitoring system for selective laser melting (SLM), Solid Freeform Fabrication 2018: Proceedings of the 29th Annual International

Coeck S, Bisht M, Plas J, Verbist F (2018) Prediction of lack of fusion porosity in selective laser melting based on melt pool monitoring data. Addit Manuf. https://doi.org/10.1016/j.addma.2018.11.015

Bodi Yuan, Brian Giera, Gabe Guss, Manyalibo Matthews, and Sara McMains, Semi-Supervised Convolutional Neural Networks for In-Situ Video Monitoring of Selective Laser Melting, 2019 IEEE Winter Conference on Applications of Computer Vision

Chen D, Wang P, Pan Ri, Zha C, Fan J, Kong S, Li Na, Li J (2021) Zhiqiang ZengResearch on in situ monitoring of selective laser melting: a state of the art review. Int J Adv Manuf Technol 113:3121–3138

Hong Seok Park, Dinh Son Nguyen, Thai Le‑Hong, Xuan Van Tran, Machine learning‑based optimization of process parameters in selective laser melting for biomedical applications, J Intell Manufa

Eckart Uhlmann, Rodrigo Pastl Pontes, ClaudioGeisert, EckhardHohwieler, Cluster identification of sensor data for predictive maintenance in a Selective Laser Melting machine tool, Procedia Manufacturing 24 (2018) 60–65

Germán Omar Barrionuevo, Jorge Andrés Ramos-Grez, Magdalena Walczak, Carlos Andrés Betancourt , Comparative evaluation of supervised machine learning algorithms in the prediction of the relative density of 316L stainless steel fabricated by selective laser melting, Int J Adv Manuf Technol (2021) 113:419–433

Rankouhi B, Jahani S, Pfefferkorn FE, Thoma DJ (2021) Compositional grading of a 316L-Cu multi-material part using machine learning for the determination of selective laser melting process parameters. Addit Manuf 38:101836

Yingyan Chen, HongzeWang, Yi Wu and Haowei Wang, Predicting the Printability in Selective Laser Melting with a Supervised Machine Learning Method, Materials 2020, 13, 5063

Zhang C, Zhu H, Zhiheng Hu, Zhang L, Zeng X (2019) A comparative study on single-laser and multi-laser selective laser melting AlSi10Mg: defects, microstructure and mechanical properties. Mater Sci Eng A 746:416–423

Li Z, Kuai Z, Bai P, Nie Y, Guang Fu, Liu W, Yang S (2019) Microstructure and tensile properties of AlSi10Mg alloy manufactured by multi-laser beam selectivelaser melting (SLM). Metals 9:1337

Heeling T, Wegener K (2018) The effect of multi-beam strategies on selective laser melting of stainless steel 316L. Addit Manuf 22:334–342

Liu C, Yan D, Tan J, Mai Z, Cai Z, Dai Y, Jiang M, Wang P, Liu Z, Li C-C, Lao C, Chen Z (2020) Development and experimental validation of a hybrid selective laser melting and CNC milling system. Addit Manuf 36:101550

Qin LY, Men JH, Zhang LS, Zhao S, Li CF, Yang G, Wang W (2019) Microstructure homogenizations of Ti-6Al-4V alloy manufactured by hybrid selective laser melting and laser deposition manufacturing. Mater Sci Eng, A 759:404–414

Yin S, Yan X, Jenkins R, Chen C, Kazasidis M, Liu M, Kuang M, Lupoi R (2019) Hybrid additive manufacture of 316L stainless steel with cold spray and selective laser melting: Microstructure and mechanical properties. J Mater Process Tech 273:116248

Kalenticsa N, Varela MO, de Seijas S, Griffiths CL, Loge RE (2020) 3D laser shock peening—a new method for improving fatigue properties of selective laser melted parts. Addit Manuf 33:101112

Yu-Che Wu, San C-H, Chang C-H, Lin H-J, Marwan R, Baba S, Hwang W-S (2018) Numerical modeling of melt-pool behavior in selective laser melting with random powder distribution and experimental validation. J Materials Process Tech 254:72–78

Le T-N, Lo Y-L, Lin Z-H (2020) Numerical simulation and experimental validation of melting and solidification process in selective laser melting of IN718 alloy. Addit Manuf 36:101519

Cao L (2019) Numerical simulation of the impact of laying powder on selective laser melting single-pass formation. Int J Heat Mass Transf 141:1036–1048

Lv J, Peng T, Zhang Y, Wang Y (2020) A novel method to forecast energy consumption of selective laser melting processes. Int J Prod Res. https://doi.org/10.1080/00207543.2020.1733126

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ali, M.H., Sabyrov, N. & Shehab, E. Powder bed fusion–laser melting (PBF–LM) process: latest review of materials, process parameter optimization, application, and up-to-date innovative technologies. Prog Addit Manuf 7, 1395–1422 (2022). https://doi.org/10.1007/s40964-022-00311-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00311-9