Abstract

This study produced a non-standard alloy of 85% Mg, 13.5% Al, and 1.5% Si by weight. In-depth microstructural, chemical, and morphological analyses of the secondary β phases formed in the MgAlSi alloy were conducted. The formation processes of the intermetallic phases were also examined. Image processing was applied to the obtained microstructures using the Image-J program. The average alloy had a matrix α phase to secondary β phase ratio of approximately 60/40. Furthermore, a dry and corrosive wear test were applied to the MgAlSi alloy by means of reciprocating motion. The wear rate was calculated to be at least 0.00137 mm3/Nm, indicating that the unique MgAlSi ternary alloy produced had very high wear resistance due to the presence of intermetallic phases.

Similar content being viewed by others

References

Xu, C.X., H. Ju, and Y. Zhou. Effect of Ca on Microstructure and Properties of Mg-Al-Si Alloys. in Advanced Materials Research. 2011. Trans Tech Publ.

J. Bian et al., Research on the effect of Sr and Zr on microstructure and properties of Mg–4Zn alloy. Int. J. Metalcast. 15(4), 1483–1498 (2021). https://doi.org/10.1007/s40962-021-00576-w

P. MÖ, Magnesium alloying, some potentials for alloy development. J. Jpn. Inst. Light Metals 42(12), 679–686 (1992)

F. Froes, D. Eliezer, E. Aghion, The science, technology, and applications of magnesium. J. Min. Metals Mater. Soc. (TMS) 50(9), 30–34s (1998)

Furuya, H., et al. Applications of magnesium alloys for aerospace structure systems. in Materials Science Forum. 2000. Trans Tech Publ.

M. Bamberger, G. Dehm, Trends in the development of new Mg alloys. Annu. Rev. Mater. Res. 38, 505–533 (2008)

X.-N. Gu, Y.-F. Zheng, A review on magnesium alloys as biodegradable materials. Front. Mater. Sci. 4(2), 111–115 (2010)

F. Witte, The history of biodegradable magnesium implants: a review. Acta Biomater. 6(5), 1680–1692 (2010)

B. Mordike, T. Ebert, Magnesium: properties-applications-potential. Mater. Sci. Eng. A 302(1), 37–45 (2001)

M. Paradis, A.M. Samuel, H.W. Doty et al., Inclusion measurement and identification in Mg-based alloys: application of the Brightimeter technique. Int. J. Metalcast. 12(1), 2–19 (2018). https://doi.org/10.1007/s40962-016-0130-7

Z. Zhang, Development of magnesium-based alloys for elevated temperature applications (Genie Universities, Quebec, 2000)

H. Friedrich, S. Schumann, Research for a “new age of magnesium” in the automotive industry. J. Mater. Process. Technol. 117(3), 276 (2001)

H. Zengin, Role of Sr in microstructure, hardness and biodegradable behavior of cast Mg–2Zn–2Ca–0.5 Mn (ZXM220) alloy for potential implant application. Int. J. Metalcast. 14(2), 442–453 (2020). https://doi.org/10.1007/s40962-019-00366-5

Y. Lee, A. Dahle, D. St John, The role of solute in grain refinement of magnesium. Metall. Mater. Trans. A 31A(11), 2895–2906 (2000)

M.E. Moussa, S. El-Hadad, A. Nofal, Influence of Si addition on the microstructure, hardness and elevated-temperature sliding wear behavior of AX53 magnesium alloy. Int. J. Metalcast. 16(1), 385–398 (2022). https://doi.org/10.1007/s40962-021-00611-w

M. Bamberger, Structural refinement of cast magnesium alloys. Mater. Sci. Technol. 17(1), 15–24 (2013)

P. Wan, L. Tan, K. Yang, Surface modification on biodegradable magnesium alloys as orthopedic implant materials to improve the bio-adaptability: a review. J. Mater. Sci. Technol. 32(9), 827–834 (2016)

Westengen, H. and H. Rashed (2016) Magnesium Alloys: Alloy and Temper Designation System. Magnesium Alloys: Properties and Applications. Elsevier. 1-4.

Z. Ma, C. Li, J. Du et al., Grain refinement of Mg–Al alloys inoculated by MgO powder. Int. J. Metalcast. 13(3), 674–685 (2019). https://doi.org/10.1007/s40962-018-0287-3

S. Saha, C. Ravindran, Grain refinement of AZ91E and Mg-9 WT% Al binary alloys using zinc oxide. Int. J. Metalcast. 9(1), 33–42 (2015). https://doi.org/10.1007/BF03355600

M.B. Kannan, E. Koc, M. Unal, Biodegradability of β-Mg17Al12 phase in simulated body fluid. Mater. Lett. 82, 54–56 (2012)

R.R. Kulkarni et al., Phase dissolution of γ-Mg17Al12 during homogenization of as-cast AZ80 Magnesium alloy and its effect on room temperature mechanical properties, in Magnesium Technology 2012. (Springer, Berlin, 2012), pp.543–548

K. Korgiopoulos, B. Langelier, M. Pekguleryuz, Mg17Al12 phase refinement and the improved mechanical performance of Mg-6Al alloy with trace erbium addition. Mater. Sci. Eng. A 812, 141075 (2021)

L. Zhu et al., Multiscale design of α-Al, eutectic silicon and Mg2Si phases in Al–Si–Mg alloy manipulated by in situ nanosized crystals. Mater. Sci. Eng. A 802, 140627 (2021)

M. Khorasanian et al., Effect of addition of silver and chilled casting on corrosion behavior of AZ91 magnesium alloy. Int. J. Metalcast. 15(4), 1184–1196 (2021). https://doi.org/10.1007/s40962-020-00558-4

Y. Sun, H. Ahlatci, Mechanical and wear behaviors of Al–12Si–XMg composites reinforced with in situ Mg2Si particles. Mater. Des. 32(5), 2983–2987 (2011)

B. Çiçek, Y. Sun, A study on the mechanical and corrosion properties of lead added magnesium alloys. Mater. Design 37, 369–372 (2012)

B. Çiçek, H. Ahlatçı, Y. Sun, Wear behaviours of Pb added Mg–Al–Si composites reinforced with in situ Mg2Si particles. Mater. Des. 50, 929–935 (2013)

Cui, P., et al., Effect of La/Nd ratio on the microstructure and corrosion behaviors of squeeze-cast Mg–Al–Zn–La–Nd alloys. Int. J. Metalcast. 1-15 (2022). https://doi.org/10.1007/s40962-022-00767-z

Y. Carbonneau et al., On the observation of a new ternary MgSiCa phase in Mg-Si alloys. Metall Mater Trans. 29(6), 1759 (1998)

S. Candan, E.J.T.O.N.M.S.O.C. Candan, A comparative study on corrosion of Mg–Al–Si alloys. Trans. Nonferrous Metals Soc. Chin. 27(8), 1725–1734 (2017)

J. Senf et al., Corrosion and galvanic corrosion of die casted magnesium alloys. Magnes. Technol. 2000, 136–142 (2000)

F.J.P.D.I. Zanotto, Corrosion behaviour of the AZ31 magnesium alloy and surface treatments for its corrosion protection. Pubblicazioni dello IUSS. 3(1), 1–159 (2009)

E. El Sawy et al., Corrosion of Mg, AS31 and AZ91 alloys in nitrate solutions. J. Alloy. Compd. 492(1–2), 69–76 (2010)

A. Atrens et al., Review of Mg alloy corrosion rates. J. Magnes. Alloy. 8(4), 989–998 (2020)

J. Miao et al., Interphase boundary segregation of silver and enhanced precipitation of Mg17Al12 Phase in a Mg–Al–Sn–Ag alloy. Scr. Mater. 154, 192–196 (2018)

E. Savitsky, V. Baton, Mechanical properties of alloys of the magnesium—cadmium system. Russ. Chem. Bull. 1(3), 383–387 (1952)

R. Ferrier, D. Herrell, Conduction in amorphous magnesium-bismuth alloys. Phil. Mag. 19(160), 853–868 (1969)

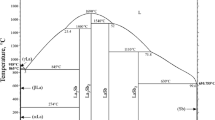

N. Chakraborti, H. Lukas, Thermodynamic optimization of the Mg-Al-Si phase diagram. Calphad 16(1), 79–86 (1992)

Q. Li et al., Experimental study and phase diagram calculation in Al–Zn–Mg–Si quaternary system. J. Alloy. Compd. 501(2), 282–290 (2010)

B. Cicek, T. Aydogmus, Y. Sun, A basic study on artificial aging in Mg–10Al12Si+1Pb alloy. Mater. Res. Express 7(1), 016588 (2020)

Kainer, K, F. V. Buch, The current state of technology and potential for further development of magnesium applications. J. Magnes. Alloy: 1–22 (2003)

Barber L.P., Characterization of the solidification behavior and resultant microstructures of magnesium-aluminum alloys in Materials Science & Engineering, Worcester Polytechnic Institute, 2004

I. Polmear, Recent developments in light alloys. Mater. Trans. 37(1), 12–31 (1996)

L.-N. Zhang et al., The effect of selected alloying element additions on properties of Mg-based alloy as bioimplants: a literature review. Front. Mater. Sci. 7(3), 227–236 (2013)

M. Wolff et al., Metal injection molding (MIM) of magnesium and its alloys. Metals 6(5), 118 (2016)

K.A. Kumar et al., Dry sliding wear behaviour of Mg–Si alloys. Wear 303(1–2), 56–64 (2013)

J. An et al., Dry sliding wear behavior of magnesium alloys. Wear 265(1–2), 97–104 (2008)

Y. Zhang et al., Friction and wear behavior of as-cast Mg–Zn–Y quasicrystal materials. Mater. Sci. Eng. A 472(1–2), 59–65 (2008)

A.W.J.M.S. El-Morsy, E. A, Dry sliding wear behavior of hot deformed magnesium AZ61 alloy as influenced by the sliding conditions. Mater. Sci. Eng. A 473(1–2), 330–335 (2008)

T. Chen et al., Wear behavior of thixoformed AZ91D magnesium alloy: a comparison with permanent mould cast alloy. Mater. Sci. Eng. A 445, 477–485 (2007)

Vander Voort G., Metallography of Magnesium and its Alloys. Buehler Tech-Notes, Vol. 4(2) 2015

X. Ma et al. In-situ synthesis of a1n/mg matrix composites, 2011

P.P. Seth, O. Parkash, D.J.R.a. Kumar, Structure and mechanical behavior of in situ developed Mg2Si phase in magnesium and aluminum alloys–a review. RSC adv. 10(61), 37327–37345 (2020)

Y. Zhang et al, Microstructural evolution and mechanical properties of as-cast Mg-12Zn alloys with different Al additions. Mat. Res. 23(1), (2020)

Q. Wang, C. Davidson, Solidification and precipitation behaviour of Al–Si–Mg casting alloys. J. Mater. Sci. 36(3), 739–750 (2001)

Y. Zhao et al., Phase-field simulation for the evolution of solid/liquid interface front in directional solidification process. J. Mater. Sci. Technol. 35(6), 1044–1052 (2019)

S. Chowdhury et al., Microstructure and mechanical properties of fiber laser welded and diode laser welded AZ31 magnesium alloy. Metall. Mater. Trans. A 42, 1974–1989 (2011)

M. Esmaily et al., Fundamentals and advances in magnesium alloy corrosion. Prog. Mater. Sci. 89, 92–193 (2017)

K. Kadali et al., Dissolution kinetics of Mg17Al12 eutectic phase and its effect on corrosion behavior of as-cast AZ80 magnesium alloy. Jom 71(7), 2209–2218 (2019)

J. Choi, W. Kim, Significant effects of adding trace amounts of Ti on the microstructure and corrosion properties of Mg–6Al–1Zn magnesium alloy. J. Alloy. Compd. 614, 49–55 (2014)

P. Zhang, S. Li, Z. Zhang, General relationship between strength and hardness. Mater. Sci. Eng. A 529, 62–73 (2011)

H. Bu et al., Cold spray blended Al+ Mg17Al12 coating for corrosion protection of AZ91D magnesium alloy. Surf. Coat. Technol. 207, 155–162 (2012)

H. Mathur, V. Maier-Kiener, S. Korte-Kerzel, Deformation in the γ-Mg17Al12 phase at 25–278 C. Acta Mater. 113, 221–229 (2016)

K. Hagihara, K. Hayakawa, K. Miyoshi, Inducement of kink-band formation in directionally solidified Mg/Mg17Al12 eutectic alloy-Inspired by the deformation behavior of the long-period stacking ordered (LPSO) phase. Mater. Sci. Eng. A 798, 140087 (2020)

N. Bochvar et al., Kinetics of phase precipitation in Al–Mg–Si alloys subjected to equal-channel angular pressing during subsequent heating. J. Alloy. Compd. 881, 160583 (2021)

J. Li et al., Electrochemical behavior of Mg–Al-Zn–In alloy as anode materials in 3.5 wt% NaCl solution. Electrochim Acta 238, 156–167 (2017)

A. Zafari, H. Ghasemi, R. Mahmudi, Tribological behavior of AZ91D magnesium alloy at elevated temperatures. Wear 292, 33–40 (2012)

R. Trezona, D. Allsopp, I.J.W. Hutchings, Transitions between two body and three body abrasive wear influence of test conditions in the microscale abrasive wear test. Wear 225, 205–214 (1999)

Y. Zhang, X. Yin, F.J.C.S. Yan, Effect of halide concentration on tribocorrosion behaviour of 304SS in artificial seawater. Corros. Sci. 99, 272–280 (2015)

S. Jhamb et al., A comprehensive analysis on magnesium-based alloys and metal matrix composites for their in-vitro biocompatibility (Taylor & Francis, Oxfordshire, 2022), pp.1–34

T. Rajmohan, S. Vijayabhaskar, D. Vijayan, Multiple performance optimization in wear characteristics of Mg-SiC nanocomposites using grey-fuzzy algorithm. SILICON 12(5), 1177–1186 (2020)

A.S. Vanli, B.O. Küçükyıldırım, A. Akdoğan, Wear behavior of SiC reinforced AZ91 magnesium matrix composites fabricated by high pressure die casting, in 19th International Metallurgy & Materials Congress (IMMC2018), Istanbul 2018

M. Dargusch et al., The effect of silicon content on the microstructure and creep behavior in die-cast magnesium AS alloys. Metall Mater Trans A 35, 1905–1909 (2004)

D.K. Dwivedi, R. Sharma, A.J.I.J.O.C.M.R. Kumar, Influence of silicon content and heat treatment parameters on mechanical properties of cast AlSiMg alloys. Int. J. Cast Metals Res. 19(5), 275–282 (2006)

Acknowledgement

We would like to thank the Scientific Research Projects Department of karabuk University for this project (Project no: KBÜBAP-22-DS-028). Also we would like to thank the laboratory staff of the Hitit University Physics Department for expanding this study. We would also like to present my respects to Karabük University Materials-Research-Development-Center (MARGEM) management.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cicek, B., Elen, L., Koc, E. et al. Investigation of Intermetallic Phase Fractions and Dry-corrosive Wear Properties in Mg–Al–Si Ternary Alloy. Inter Metalcast 18, 331–342 (2024). https://doi.org/10.1007/s40962-023-00992-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-00992-0