Abstract

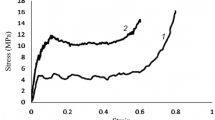

The closed-cell aluminum alloy foams were fabricated by the molten body transitional foaming process. In this research, the closed-cell aluminum foams were successfully fabricated with different zinc contents (4, 8, and 12wt%) using the melt-foaming method and blowing agents. Calcium was used to increase the melt viscosity and CaCO3 was used as a foaming agent. Uniaxial compressions tests were performed on the foams to investigate the effects of zinc addition on the mechanical behavior of fabricated Al–Zn foams. The effects of zinc additions on the foam properties such as density, porosity, pore diameter, yield strength, plateau stress, and energy absorption were investigated. According to the X-ray analysis results, the reaction between Al–Ca–Zn leads to the formation of oxide phases in the melt and increases the melt viscosity and also the cell wall thickness. Foam with 4wt% Zn has a good yield strength and longer plateau region than pure aluminum foam due to the uniform cell structure. The foam density and the absorbed energy per unit volume of Al–Zn foams increase with increasing zinc content to foams.

Similar content being viewed by others

References

M.H. Ghaleh, N. Ehsani, H.R. Baharvandi, High-porosity closed-cell aluminum foams produced by melting method without stabilizer particles. Inter Metalcast (2020). https://doi.org/10.1007/s40962-020-00528-w

H. Gao, C. Xiong, J. Yin et al., Research on dynamic accumulation effect and constitutive model of aluminum foams under dynamic impact. Inter Metalcast 13, 146–157 (2019). https://doi.org/10.1007/s40962-018-0245-0

F. Binesh, J. Zamani, M. Ghiasvand, Ordered structure composite metal foams produced by casting. Inter Metalcast 12, 89–96 (2018). https://doi.org/10.1007/s40962-017-0143-x

Z.G. Li, X.G. Zhang, P. Huang et al., Preparation and properties of open-cell zinc foams as human bone substitute material. China Foundry 16(6), 414–422 (2019). https://doi.org/10.1007/s41230-019-9090-x

F. García-Moreno, Commercial applications of metal foams: Their properties and production. Materials 9(2), 85 (2016). https://doi.org/10.3390/ma9020085

N. Li, Y. Zheng, Novel magnesium alloys developed for biomedical application: a review. J Mater Sci Techn 29(6), 489–502 (2013). https://doi.org/10.1016/j.jmst.2013.02.005

J. Banhart, Metallic foams: challenges and opportunities. Eurofoam 13, 20 (2000)

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, H.N.G. Wadley, Metal foams A Design Guide Butterwoth Heinemann,London 1(23), 119 (2000)

S. Ip, Y. Wang, J. Toguri, Aluminum foam stabilization by solid particles. Canad Metall Quart 3(1), 81–92 (1999)

Y.Wang, Aluminum foam stabilization by solid particles. 1996

Y. Mu, G. Yao, Effect of fly ash particles on the compressive properties of closed-cell aluminum foams. J mater eng perform 19(7), 995–997 (2010). https://doi.org/10.1007/s11665-009-9572-x

X. Xia et al., Compressive properties of closed-cell aluminum foams with different contents of ceramic microspheres. Mater Des 56, 353–358 (2014). https://doi.org/10.1016/j.matdes.2013.11.040

D. Mondal, M. Goel, S. Das, Effect of strain rate and relative density on compressive deformation behaviour of closed cell aluminum–fly ash composite foam. Mater Des 30(4), 1268–2127 (2009). https://doi.org/10.1016/j.matdes.2008.06.059

M. Ghorbani et al., Effect of Mn addition on the microstructure and tensile properties of Al–15% Mg2Si composite. Mater Sci Eng: A 550, 191–198 (2012). https://doi.org/10.1016/j.msea.2012.04.056

J. Hwang, H. Doty, M. Kaufman, The effects of Mn additions on the microstructure and mechanical properties of Al–Si–Cu casting alloys. Mater Sci Eng: A 488(1–2), 496–504 (2008). https://doi.org/10.1016/j.msea.2007.12.026

W.M. Zhao et al., Compressive characteristics of closed cell aluminum foams with different percentagesof Er element. China Foundry 36, 41 (2016). https://doi.org/10.1007/s41230-016-5109-8

T. Miyoshi, T. Mukai, K. Higashi, Energy absorption in closed-cell Al Zn-Mg-Ca-Tifoam. Mater Trans 1778, 1781 (2002). https://doi.org/10.2320/matertrans.43.1778

M. Alizadeh, M. Mirzaei-Aliabadi, Compressive properties and energy absorption behavior of Al–Al2O3 composite foam synthesized by space-holder technique. Mater Des 419, 42 (2012). https://doi.org/10.1016/j.matdes.2011.09.059

W. Deqing, S. Ziyuan, Effect of ceramic particles on cell size and wall thickness of aluminum foam. Mater Sci Eng: A 45, 49 (2003). https://doi.org/10.1016/S0921-5093(03)00557-4

N. Babcsán, D. Leitlmeier, H.-P. Degischer, Foamability of particle reinforced aluminum melt. Mater wiss und Werkstofftech 34(1), 22–29 (2003). https://doi.org/10.1002/mawe.200390011

V. Gergely, R. Jones, T. Clyne, The effect of capillarity-driven melt flow and size of particles in cell faces on metal foam structure evolution. Title Trans JWRI 30, 371 (2001)

O. Prakash, H. Sang, J. Embury, Structure and properties of Al SiC foam. Mater Sci Eng: A 199(2), 195–220 (1995). https://doi.org/10.1016/0921-5093(94)09708-9

K. Kadoi, H. Nakae, Relationship between foam stabilization and physical properties of particles on aluminum foam production. Mater Trans 52(10), 1912–1919 (2011). https://doi.org/10.2320/matertrans.F-M2011817

S.-H. Park et al., Thermophysical properties of Al and Mg alloys for metal foam fabrication. Coll Surf A: Physicochem Eng Aspects 263(1–3), 280–283 (2005). https://doi.org/10.1016/j.colsurfa.2005.02.003

I. Standard, (E)(2011) Mechanical testing of metals—ductility testing—compression test for porous and cellular metals. Ref Number ISO 13314(13314), 1–7 (2011)

L. Huang et al., Effects of scandium additions on mechanical properties of cellular Al basedfoams. Intermetallics 28, 71–76 (2012). https://doi.org/10.1016/j.intermet.2012.03.050

X. Xia et al., The compressive properties of closed-cell aluminum foams with different Mn additions. Mater Des 51, 797–802 (2013). https://doi.org/10.1016/j.matdes.2013.05.008

X. Xia et al., Effect of homogenizing heat treatment on the compressive properties of closed-cell Mg alloy foams. Mater Des 49, 19–22 (2013). https://doi.org/10.1016/j.matdes.2013.01.064

W.H. Yang et al., Mechanical properties and energy absorption capability of closed-cell Al alloy foam. Adv Mater Res Trans Tech Pub 450, 325–328 (2012)

M. Aboraia, R. Sharkawi, M. Doheim, Production of aluminum foam and the effect of calcium carbonate as a foaming agent. J Eng Sci Assiut Univ 39(2), 441–451 (2011)

B.Y. Hur, S.H. Park, A. Hiroshi, Viscosity and surface tension of Al and effects of additional element in Materials Science Forum. Trans Tech Publ 439, 51–56 (2003)

DC. Curran, Aluminium foam production using calcium carbonate as a foaming agent. University of Cambridge (2004)

Z.-L. Song et al., Effects of viscosity on cellular structure of foamed aluminum in foaming process. J mater sci 35(1), 15–20 (2000). https://doi.org/10.1023/A:1004715926692

L.Y. Aguirre-Perales, R.A. Drew, I.-H. Jung, The effect of in situ intermetallic formation on Al-Sn foaming behavior. Metall Mater Trans A 45(9), 3714–3727 (2014). https://doi.org/10.1007/s11661-014-2313-2

T. Wübben, Zur Stabilität flüssiger Metallschäume: Untersuchung des Einflusses fester Partikel auf den Schaumbildungsprozeß unter variierten Schwerkraftbedingungen: VDI-Verla (2004)

M. Weber, Herstellung von Metallschäumen und Beschreibung der Werkstoffeigenschaften (1995)

H. Kumagai et al., Estimation of the stability of foam containing hydrophobic particles by parameters in the capillary model. Agr biological chem 55(7), 1823–1829 (1991). https://doi.org/10.1080/00021369.1991.10870871

J. Banhart, Metal foams: production and stability. Adv Eng Mater 8(9), 781–794 (2006). https://doi.org/10.1002/adem.200600071

A. Ibrahim, Effect of material and processing parameters on the morphology of aluminum foams produced by the PM route (2005)

N. Movahedi, S. Mirbagheri, Comparison of the Energy Absorption of Closed-Cell Aluminum Foam Produced by Various Foaming Agents. Strength Mater 48(3), 444–449 (2016). https://doi.org/10.1007/s11223-016-9783-y

H. Afifi, M. Ahmed, I. El-Galy, (2016), Characterizationof Closed-Cell Aluminum Foams Produced by Melt-Based Technique. in Proceedings of the 17th Int. AMME Conference

B. Jiang, Z. Wang, N. Zhao, Effect of pore size and relative density on the mechanical properties of open cell aluminum foams. Scripta Mater. 56(2), 169–172 (2007). https://doi.org/10.1016/j.scriptamat.2006.08.070

H. Yu et al., Research into the effect of cell diameter of aluminum foam on its compressive and energy absorption properties. Mater Sci Eng: A 454, 542–546 (2007). https://doi.org/10.1016/j.msea.2006.11.091

U. Ramamurty, A. Paul, Variability in mechanical properties of a metal foam. Acta Mater. 52(4), 869–876 (2004). https://doi.org/10.1016/j.actamat.2003.10.021

C. Körner, M. Arnold, R.F. Singer, Metal foam stabilization by oxide network particles. Mater Sci Eng: A 396(1–2), 28–40 (2005). https://doi.org/10.1016/j.msea.2005.01.001

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farahani, M.R., Rezaei Ashtiani, H.R. & Elahi, S.H. Effect of Zinc Content on the Mechanical Properties of Closed-Cell Aluminum Foams. Inter Metalcast 16, 713–722 (2022). https://doi.org/10.1007/s40962-021-00635-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00635-2