Abstract

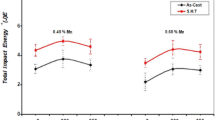

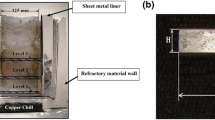

This study focused on investigating the effects of Sr-modification and solidification rate as well as the aging treatment conditions on the impact toughness behavior of Al–11%Si near-eutectic alloys with the objective of fully evaluating its behavior under high rates of loading. The Al–11%Si-based alloys, however, display lower impact energy values than those obtained for hypoeutectic 356 and 319 alloys. The impact behavior of aged Al–11%Si-based alloys is similar under both low and high solidification rate conditions; the air-cooled alloys (high solidification rate), however, display higher impact energy values than do furnace-cooled alloys (low solidification rate). Artificial aging at 240 °C for 44 h produces a significant improvement in the impact energy values as a result of softening effect, regardless of alloy composition. The presence of undissolved intermetallic phases, mainly Al2Cu and α-Al15(Mn,Fe)3Si2, increases alloy brittleness and thus also reduces alloy toughness. The segregation of Al2Cu caused by Sr addition is a further parameter to be considered, especially for furnace-cooled alloys. The impact energy values of air-cooled alloys are significantly higher than those obtained for furnace-cooled alloys based on the microstructural differences between the two categories of alloys, regardless of alloy conditions. Crack propagation occurs mainly in the near-eutectic alloys by passing through the Al2Cu and/or α-iron intermetallic phases, shattering them into fragments. In numerous cases, the morphology of the intermetallic phase is retained, indicating that the fracture is of the transverse type rather than a particle/matrix fracture.

Similar content being viewed by others

References

Z. Ma, E. Samuel, A.M.A. Mohamed, A.M. Samuel, F.H. Samuel, H.W. Doty, Parameters Controlling the Microstructure of Al–11Si–2.5Cu–Mg Alloys. Mater. Des. 31(2), 902–912 (2010)

S.G. Shabestari, F. Shahri, Influence of Modification, Solidification Conditions and Heat Treatment on the Microstructure and Mechanical Treatment of A356 Aluminum Alloy. J. Mater. Sci. 39, 2023–2032 (2004)

D. Apelian, S. Shivkumar, G. Sigworth, Fundamental Aspects of Heat Treatment of Cast Al–Si–Mg Alloys. AFS Trans. 97, 727–742 (1989)

F. Paray, J.E. Gruzleski, Microstructure-Mechanical Property Relationship in a 356 Alloy. Part1: Microstructure. Cast Met. 7(1), 29–40 (1994)

E. Tillová, M. Panušková, Effect of Solution Treatment on Intermetallic Phases Morphology in AlSi9Cu3 Cast Alloy. Metalurgija 47(3), 207–210 (2008)

F. Paray, B. Kulunk, J.E. Gruzleski, Impact Properties of Al–Si Foundry Alloys. Int. J. Cast Met. Res. 13, 17–37 (2000)

O. Elsebaie, A.M.A. Mohamed, A.M. Samuel, F.H. Samuel, A.M.A. Al-Ahmari, The Role of Alloying Additives and Aging Treatment in the Impact Behavior of 319 Cast Alloy. Mater. Des. 32(10), 3205–3220 (2011)

O. Elsebaie, A.M. Samuel, F.M. Samuel, Effects of Sr-Modification, Iron-Based Intermetallics and Aging Conditions on the Impact Toughness of 356 Cast Alloy. J. Mater. Sci. 46(9), 3027–3045 (2011)

Z. Ma, E. Samuel, A.M.A. Mohamed, A.M. Samuel, F.H. Samuel, H.W. Doty, Influence of Aging Treatments and Alloying Additives on the Hardness of Al–11Si–2.5Cu–Mg Alloys. Mater. Des. 31(4), 3791–3803 (2010)

J.E. Gruzleski, B.M. Closset, The Treatment of Liquid Aluminum–Silicon Alloys (American Foundrymen’s Society, Des Plaines, 1990)

A.M. Samuel, F.H. Samuel, H.W. Doty, Observations on the Formation of β-Al5FeSi Phase in 319 Type Al–Si Alloys. J. Mater. Sci. 31, 5529–5539 (1996)

L. Bäckerud, G. Chai, J. Tamminen, Solidification Characteristics of Aluminum Alloys, Vol. 2: Foundry Alloys (AFS/Skanaluminium, Des Plaines, 1990), pp. 71–229

F.H. Samuel, A.M. Samuel, H.W. Doty, Factors Controlling the Type and Morphology of Copper-Containing Phases in 319 Aluminum Alloy. AFS Trans. 104, 893–901 (1996)

K.G. Basavakumar, P.G. Mukunda, M. Chakraborty, Impact Toughness in Al–12Si and Al–12Si–3Cu Cast Alloys—Part 1: Effect of Process Variables and Microstructure. Int. J. Impact Eng. 35, 199–205 (2008)

J.L. Jorstad, “Understanding Sludge”, Proceedings of the 14th SDCE International Die Casting Congress and Exposition, Toronto, ON, Canada, paper No. G-T87-011 (May 11–14, 1987)

G. Pucella, A.M. Samuel, F.H. Samuel, H.W. Doty, S. Valtierra, Sludge Formation in Sr-Modified Al–11.5%Si Diecasting Alloys. AFS Trans. 107, 398–405 (1999)

M.F. Hafiz, T. Kobayashi, N. Fat-Halla, Role of Microstructure in Relation to the Toughness of Hypoeutectic Al–Si Casting Alloy. Cast Met. 7, 103–111 (1994)

A.M.A. Mohamed, F.H. Samuel, A.M. Samuel, H.W. Doty, Influence of Additives on the Impact Toughness of Al–10.8% Si Near-Eutectic Cast Alloys. Mater. Des. 30(10), 4218–4229 (2009)

J.E. Hatch, Aluminum: Properties and Physical Metallurgy, 2nd edn. (American Society for Metals, Metals Park, 1984)

Acknowledgements

The authors would like to thank Amal Samuel for enhancing the quality of the images presented in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elsebaie, O., Samuel, A.M., Doty, H.W. et al. On the Impact Properties and Fractography of Al–11%Si Casting Alloy. Inter Metalcast 12, 36–54 (2018). https://doi.org/10.1007/s40962-017-0138-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0138-7