Abstract

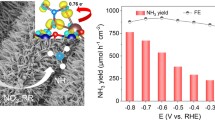

The removal of nitric oxide (NO) is deemed essential due to its environmental detrimental effects, and electrocatalytic NO reduction reaction (NORR) for ammonia synthesis presents a sustainable approach. In this work, we synthesized copper oxide (CuO) nanosheet catalyst with a high specific surface area and abundant defects. This catalyst exhibited a remarkable 92.1% ammonia Faradaic efficiency (FE) in a flow cell, accompanied by a current density of 1.1 A cm−2 and an ammonia production rate of 7356 µmol cm−2 h−1 at −0.26 V vs. reversible hydrogen electrode. The FE of ammonia remained above 80% during stability test for 50 h at a current density of more than 400 mA cm−2. Quasi in situ X-ray photoelectron spectroscopy and in situ X-ray absorption spectroscopy revealed that the CuO nanosheets were electrochemically reduced to monomeric copper during NORR. Compared with Cu nanoparticles, the CuO nanosheets showed a high electrochemical surface area and high intrinsic activity for NORR.

摘要

一氧化氮电还原反应将工业废气转化为有价值的氨, 表现出极 具潜力的应用前景. 在本工作中, 我们合成了具有高比表面积和丰富缺 陷的氧化铜纳米片催化剂, 在流动池中氨法拉第效率达到92.1%, 在 −0.2 V vs. RHE时, 一氧化氮电还原电流密度和氨的生产速率分别达到 1.1 A cm−2和7356 µmol cm−2 h−1. 在电流密度超过400 m A cm−2 时, 氨 法拉第效率在50 小时保持在80%以上. 准原位X 射线光电子能谱和原 位X 射线吸收光谱结果表明氧化铜纳米片在一氧化氮电还原过程中被 电化学还原成单质铜. 与铜纳米颗粒相比, 氧化铜纳米片展现出较高的 电化学表面积和一氧化氮电还原的内在活性.

Similar content being viewed by others

References

Zhang X, Davidson EA, Mauzerall DL, et al. Managing nitrogen for sustainable development. Nature, 2015, 528: 51–59

Soloveichik G. Electrochemical synthesis of ammonia as a potential alternative to the Haber-Bosch process. Nat Catal, 2019, 2: 377–380

Daiyan R, Tran-Phu T, Kumar P, et al. Nitrate reduction to ammonium: From CuO defect engineering to waste NOx-to-NH3 economic feasibility. Energy Environ Sci, 2021, 14: 3588–3598

Kyriakou V, Garagounis I, Vourros A, et al. An electrochemical Haber-Bosch process. Joule, 2020, 4: 142–158

Smith C, Hill AK, Torrente-Murciano L. Current and future role of Haber-Bosch ammonia in a carbon-free energy landscape. Energy Environ Sci, 2020, 13: 331–344

Lan R, Irvine JTS, Tao S. Ammonia and related chemicals as potential indirect hydrogen storage materials. Int J Hydrogen Energy, 2012, 37: 1482–1494

Cui X, Tang C, Zhang Q. A review of electrocatalytic reduction of dinitrogen to ammonia under ambient conditions. Adv Energy Mater, 2018, 8: 1800369

Suryanto BHR, Du HL, Wang D, et al. Challenges and prospects in the catalysis of electroreduction of nitrogen to ammonia. Nat Catal, 2019, 2: 290–296

Wang J, Yu L, Hu L, et al. Ambient ammonia synthesis via palladium-catalyzed electrohydrogenation of dinitrogen at low overpotential. Nat Commun, 2018, 9: 1795

Yu J, Yong X, Cao A, et al. Bi-layer single atom catalysts boosted nitrate-to-ammonia electroreduction with high activity and selectivity. Acta Physico Chim Sin, 2023, 0: 2307015

Liu H, Li J, Du F, et al. A core-shell copper oxides-cobalt oxides heterostructure nanowire arrays for nitrate reduction to ammonia with high yield rate. Green Energy Environ, 2023, 8: 1619–1629

Kato M, Araki A, Hara Y, et al. Cathodic arc-plasma deposition of platinum nanoparticles on fluorine-doped tin oxide for electrocatalytic nitrate reduction reaction. Electrochemistry, 2018, 86: 220–222

Wang D, Chen Z, Gu K, et al. Hexagonal cobalt nanosheets for high-performance electrocatalytic NO reduction to NH3. J Am Chem Soc, 2023, 145: 6899–6904

Long J, Chen S, Zhang Y, et al. Direct electrochemical ammonia synthesis from nitric oxide. Angew Chem Int Ed, 2020, 59: 9711–9718

Ko BH, Hasa B, Shin H, et al. Electrochemical reduction of gaseous nitrogen oxides on transition metals at ambient conditions. J Am Chem Soc, 2022, 144: 1258–1266

Wang K, Liu D, Liu L, et al. Tuning the local electronic structure of oxygen vacancies over copper-doped zinc oxide for efficient CO2 electroreduction. eScience, 2022, 2: 518–528

Zhang L, Cong M, Ding X, et al. A Janus Fe-SnO2 catalyst that enables bifunctional electrochemical nitrogen fixation. Angew Chem Int Ed, 2020, 59: 10888–10893

Ma Y, Yang T, Zou H, et al. Synergizing Mo single atoms and Mo2C nanoparticles on CNTs synchronizes selectivity and activity of electrocatalytic N2 reduction to ammonia. Adv Mater, 2020, 32: 2002177

Serapinienė B, Gudavičiūtė L, Tutlienė S, et al. On the electrochemically active surface area determination of electrodeposited porous Cu 3D nanostructures. Coatings, 2023, 13: 1335

Kim DY, Shin D, Heo J, et al. Unveiling electrode-electrolyte design-based NO reduction for NH3 synthesis. ACS Energy Lett, 2020, 5: 3647–3656

Liang J, Hu W, Song B, et al. Efficient nitric oxide electroreduction toward ambient ammonia synthesis catalyzed by a CoP nanoarray. Inorg Chem Front, 2022, 9: 1366–1372

Zhou J, Han S, Yang R, et al. Linear adsorption enables NO selective electroreduction to hydroxylamine on single co sites. Angew Chem Int Ed, 2023, 62: e202305184

Wu Z, Liu Y, Wang D, et al. Cu@Co with dilatation strain for high-performance electrocatalytic reduction of low-concentration nitric oxide. Adv Mater, 2024, 36: 2309470

Guo X, Wang P, Wu T, et al. Aqueous electroreduction of nitric oxide to ammonia at low concentration via vacancy engineered FeOCl. Angew Chem Int Ed, 2024, 63: e202318792

Dhanabal D, Markandaraj SS, Shanmugam S. Transition metal nanoparticle-embedded nitrogen-doped carbon nanorods as an efficient electrocatalyst for selective electroreduction of nitric oxide to ammonia. ACS Catal, 2023, 13: 9136–9149

Cheon S, Kim WJ, Kim DY, et al. Electro-synthesis of ammonia from dilute nitric oxide on a gas diffusion electrode. ACS Energy Lett, 2022, 7: 958–965

Zhang H, Li Y, Cheng C, et al. Isolated electron-rich ruthenium atoms in intermetallic compounds for boosting electrochemical nitric oxide reduction to ammonia. Angew Chem Int Ed, 2023, 62: e202213351

Chen K, Zhang Y, Xiang J, et al. p-Block antimony single-atom catalysts for nitric oxide electroreduction to ammonia. ACS Energy Lett, 2023, 8: 1281–1288

Shao J, Jing H, Wei P, et al. Electrochemical synthesis of ammonia from nitric oxide using a copper-tin alloy catalyst. Nat Energy, 2023, 8: 1273–1283

Li H, Liu T, Wei P, et al. High-rate CO2 electroreduction to C2+ products over a copper-copper iodide catalyst. Angew Chem Int Ed, 2021, 60: 14329–14333

Acknowledgements

This work was supported by the National Key R&D Program of China (2023YFA1508002), the National Natural Science Foundation of China (22125205 and 92015302), the Fundamental Research Funds for the Central Universities (20720220008), Dalian National Laboratory for Clean Energy (DNL201923), and the Photon Science Center for Carbon Neutrality. We thank staff at the BL14W1 beamline of Shanghai Synchrotron Radiation Facility for their technical assistance during the XAS measurements.

Author information

Authors and Affiliations

Contributions

Author contributions Shao J synthesized the catalysts and performed the electrochemical measurements and characterizations. Wei P conducted the XAFS experiments. Wang S, Song Y, Fu Y and Zhang X contributed to the data analysis. Li R helped with the XPS study. Wang G designed the work and revised the manuscript. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest The authors declare that they have no conflict of interest.

Additional information

Supplementary information Supporting data are available in the online version of the paper.

Jiaqi Shao is a PhD candidate in materials physics and chemistry at Dalian Institute of Chemical Physics, Chinese Academy of Sciences. He is dedicated to the design of advanced nanomaterials for electrochemical ammonia production from nitric oxide.

Guoxiong Wang is a professor in physical chemistry at Dalian Institute of Chemical Physics, Chinese Academy of Sciences. His research is electrocatalysis fundamentals and electrolysis technologies for fuels and chemicals production.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Shao, J., Wei, P., Wang, S. et al. Copper oxide nanosheets for efficient electrochemical reduction of nitric oxide. Sci. China Mater. (2024). https://doi.org/10.1007/s40843-024-2830-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40843-024-2830-5