Abstract

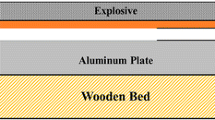

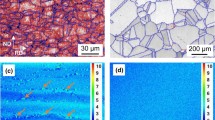

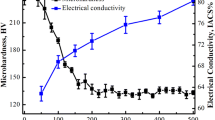

In metallurgical theory, the generation of new phases requires high temperature diffusion over a long period of time. Here, we report an experimental study of the generation of new phases using large mechanical deformations and high pressure, rather than heat. A 4.83-mm-thick 23-layered Cu/Al sandwich strip was formed by cold rolling. When the Cu/Al sandwich was further rolled to a 0.13-mm-thick foil on a four-high micro-foil mini mill at room temperature, some rectangular-shaped phases appeared at the Cu/Al interfaces. The scanning electron microscopy, transmission electron microscopy, and X-ray diffraction analyses reveal that the phases are a mixture of Al2Cu/AlCu/Al4Cu9, which indicates that chemical reactions occur at the Cu/Al interfaces during cold deformation. This study provides new insights into the design and development of composite materials for various applications.

中文摘要

金属学理论认为新相的形成需要高温且长时间. 然而, 本研究发现, 在没有热作用的前提下, 大的机械变形和大的压力也可以使一些新相产生. 实验中首先采用冷轧方法制备出4.83 mm厚的三明治Cu/Al复合带(23层), 然后在四辊微成型轧机上(3M轧机)进行冷轧. 当Cu/Al复合带被轧到厚度为0.13 mm时, 发现在Cu/Al界面处有矩形状的相出现. 采用SEM、 TEM和XRD分析得出, 这些相是由三种不同的金属间化合物Al2Cu/AlCu/Al4Cu9所组成, 这表明冷变形过程中Cu/Al界面之间发生了化学反应. 这一发现为设计和研制具有特殊性能的复合材料提供了新思路.

Similar content being viewed by others

References

Fang TH, Li WL, Tao NR, et al. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science, 2011, 331:1857–1859

Lu K. The future of metals. Science, 2010, 328:319–320

Mirab S, Nili-Ahmadabadi M. On the flow and mechanical behavior of Al matrix composite reinforced by nickel based (90% Ni-10% Cr) wires during equal channel angular pressing. Mater Sci Eng A, 2013, 583:43–51

Jin YG, Baek HM, Hwang SK, et al. Continuous high strength aluminum bolt manufacturing by the spring-loaded ECAP system. J Mater Process Technol, 2012, 212:848–855

Wang L, Wang YC, Zhilyaev AP, et al. Microstructure and texture evolution in ultrafine-grained pure Ti processed by equal-channel angular pressing with subsequent dynamic compression. Scr Mater, 2014, 77:33–36

Bachmaier A, Kerber M, Setman D, et al. The formation of supersaturated solid solutions in Fe-Cu alloys deformed by high-pressure torsion. Acta Mater, 2012, 60:860–871

Loucif A, Figueiredo RB, Baudin T, et al. Microstructural evolution in an Al-6061 alloy processed by high-pressure torsion. Mater Sci Eng A, 2010, 527:4864–4869

Pirgazi H, Akbarzadeh A, Petrov R, et al. Microstructure evolution and mechanical properties of AA1100 aluminum sheet processed by accumulative roll bonding. Mater Sci Eng A, 2008, 497:132–138

Rezaei MR, Toroghinejad MR, Ashrafizadeh F. Effects of ARB and ageing processes on mechanical properties and microstructure of 6061 aluminum alloy. J Mater Process Technol, 2011, 211:1184–1190

Gao XH, Qi KM, Qiu CL. Magnetic properties of grain oriented ultra-thin silicon steel sheets processed by conventional rolling and cross shear rolling. Mater Sci Eng A, 2006, 430:138–141

Lu AQ, Zhang Y, Li Y, et al. Effect of cross shear rolling on microstructure and properties of surface nanocrystallized 316l stainless steel. Acta Metall Sin, 2005, 41:3–8

Yu HL, Lu C, Tieu K, et al. Asymmetric cryorolling for fabrication of nanostructural aluminum sheets. Sci Rep, 2012, 2:772

Lu L, Sui ML, Lu K. Superplastic extensibility of nanocrystalline copper at room temperature. Science, 2000, 287:1463–1466

Liu XC, Zhang HW, Lu K. Strain-induced ultrahard and ultrastable nanolaminated structure in nickel. Science, 2013, 342:337–340

Liu G, Liu JY, Wang XL, et al. Formation of nanocrystallines in the surface layer of commercial pure titanium thin sheet during asymmetric rolling. Acta Metall Sin, 2013, 49:599–604

Wu K, Chang H, Maawad E, et al. Microstructure and mechanical properties of the Mg/Al laminated composite fabricated by accumulative roll bonding (ARB). Mater Sci Eng A, 2010, 527:3073–3078

Chang H, Zheng MY, Gan WM, et al. Texture evolution of the Mg/Al laminated composite fabricated by the accumulative roll bonding. Scr Mater, 2009, 61:717–720

Chang H, Zheng MY, Xu C, et al. Microstructure and mechanical properties of the Mg/Al multilayer fabricated by accumulative roll bonding (ARB) at ambient temperature. Mater Sci Eng A, 2012, 543:249–256

Chang H, Zheng MY, Ganc WM, et al. Texture evolution of the Mg/Al laminated composite by accumulative roll bonding at ambient temperature. Rare Metal Mater Eng, 2013, 42:441–446, in Chinese

Nasiri Dehsorkhi R, Qods F, Tajally M. Investigation on microstructure and mechanical properties of Al-Zn composite during accumulative roll bonding (ARB) process. Mater Sci Eng A, 2011, 530:63–72

Tayyebi M, Eghbali B. Processing of Al/304 stainless steel composite by roll bonding. Sci Technol, 2012, 28:1414–1419

Stover AK, Krywopusk NM, Fritz GM, et al. An analysis of the microstructure and properties of cold-rolled Ni, Al laminate foils. J Mater Sci, 2013, 48:5917–5929

Hansen BL, Carpenter JS, Sintay SD, et al. Modeling the texture evolution of Cu/Nb layered composites during rolling. Int J Plasticity, 2013, 49:71–84

Carpentera JS, Vogela SC, LeDonneb JE, et al. Modeling the texture evolution of Cu/Nb layered composites during rolling. Acta Mater, 2012, 60:1576–1586

Eslami AH, Mojtaba Zebarjad S, Moshksar MM. Study on mechanical and magnetic properties of Cu/Ni multilayer composite fabricated by accumulative roll bonding process. Mater Sci Technol, 2013, 29:1000–1005

Tohidi AA, Ketabchi M, Hasannia A. Nanograined Ti-Nb microalloy steel achieved by accumulative roll bonding (ARB) process. Mater Sci Eng A, 2013, 577:43–47

Ali S, Mohammad Reza T. Fabrication of Al/Ni/Cu composite by accumulative roll bonding and electroplating processes and investigation of its microstructure and mechanical properties. Mater Sci Eng A, 2012, 558:386–393

Zhang RG, Acoff VL. Processing sheet materials by accumulative roll bonding and reaction annealing from Ti/Al/Nb elemental foils. Mater Sci Eng A, 2007, 463:67–73

Yu QB, Liu XH, Tang DL. Extreme extensibility of copper foil under compound forming conditions. Sci Rep, 2013, 3:3556

Yu YN. Principles of Metallography. 2nd ed. Beijing: Metallurgical Industry Press, 2013. 273–274

Eizadjou M, Kazemi Talachi A, Danesh Manesh H, et al. Investigation of structure and mechanical properties of multi-layered Al/Cu composite produced by accumulative roll bonding (ARB) process. Compos Sci Technol, 2008, 68:2003–2009

Min GH, Lee JM, Kang SB, et al. Evolution of microstructure for multilayered Al/Ni composites by accumulative roll bonding process. Mater Lett, 2006, 60:3255–3259

Author information

Authors and Affiliations

Corresponding author

Additional information

Qingbo Yu was born in 1970. In 2004, he got his PhD degree in materials processing engineering at the State Key Laboratory of Rolling and Automation, Northeastern University. Currently, he is a professor, and his research interests include rolling technology and theory, quality control of rolled steel in production, and heat treatment of metal materials.

Xianghua Liu is currently a professor at the Research Institute of Science and Technology, Northeastern University. He got his PhD degree majored in metal pressure machining at Northeastern University (China) in 1987. His research focused on rolling technology and theory, modelling and simulation in metal forming, and asymmetric rolling. To date, he has published more than 300 peer-reviewed research papers, and held more than 20 patents.

Ying Sun earned her BSc and MSc degrees at the College of Materials Science and Engineering, Qiqihar University, in 1997 and 2010, respectively. Her research focuses on the design and chemical synthesis of nanoparticles and graphene-based nanocomposites, and their biomedical and energy related applications.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Yu, Q., Liu, X. & Sun, Y. Formation of intermetallic compounds of Cu/Al multilayer foils during cold rolling. Sci. China Mater. 58, 574–583 (2015). https://doi.org/10.1007/s40843-015-0070-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-015-0070-1