Abstract

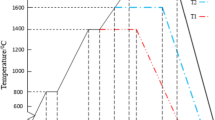

Antimony is often used as a hardener for alloys. There are few studies on the preparation of antimony from Sb2O3 by microwave carbothermal reduction. In this study, Sb2O3 was used as the raw material, and the resonant cavity perturbation method was used to select anthracite as the reducing agent according to the microwave absorption of the material mixture. The single-factor experiment of reduction temperature, reduction time, and reducing agent ratio was carried out in a microwave tube furnace. The process parameters were optimized by response surface methodology (RSM). Under the optimized conditions, the reduction temperature was 758 °C, the reduction time was 56 min, the reducing agent addition ratio was 0.123, and the molten salt addition ratio was 0.1. An antimony ingot with a yield of 92.19% and a purity of 99.45% was obtained. The products and residue of the antimony ingot were analyzed by X-ray diffraction analysis (XRD), X-ray fluorescence (XRF), thermogravimetric (TG) analysis, scanning electron microscopy (SEM), and the mechanism of carbothermal reduction of antimony oxide powder in a microwave field was studied. The results showed that the microwave carbothermal reduction process of Sb2O3 under a microwave field had three stages: 25~655 °C, 655~850 °C, and >850 °C. Different stages changed with temperature. This green and energy-saving microwave heating technology can provide a feasible method for the efficient preparation of antimony.

Graphical Abstract

Similar content being viewed by others

References

Dheyaa BM, Jassim WH, Hameed, NA (2017) Evaluation of the epoxy/antimony trioxide nanocomposites as flame retardant. In: Ibn Al-Haitham 1st International Scientific Conference on biology, chemistry, computer science, mathematics, and physics (IHSCICONF), Baghdad, Iraq. https://doi.org/10.1088/1742-6596/1003/1/012078

Ilyas RA, Sapuan SM, Asyraf MRM et al (2021) Polymer composites filled with metal derivatives: a review of flame retardants. Polymers. https://doi.org/10.3390/polym13111701

van Velzen D, Langenkamp H, Herb G (1998) Antimony, its sources, applications and flow paths into urban and industrial waste: a review. Waste Manage Res. 16:32–40. https://doi.org/10.1177/0734242x9801600105

Liu C, Shin J, Son S et al (2021) Pnictogens in medicinal chemistry: evolution from erstwhile drugs to emerging layered photonic nanomedicine. Chemical Society Reviews. 50:2260–2279. https://doi.org/10.1039/d0cs01175d

Yang N, Sun HZ (2009) Application of arsenic, antimony and bismuth in medicine. Progress Chem 21:856–865

Li HM, Wang KL, Zhou M et al (2019) Facile tailoring of multidimensional nanostructured Sb for sodium storage applications. Acs Nano 13:9533–9540. https://doi.org/10.1021/acsnano.9b04520

Watanabe H, Imoto H, Tanaka H (1998) Preparation, crystal structure, and electrical resistivity of SbRe2O6 with a Re-Re bond. J Solid State Chem 138:245–249. https://doi.org/10.1006/jssc.1998.7776

Xiong PX, Wu JX, Zhou MF et al (2020) Bismuth-antimony alloy nanoparticle@porous carbon nanosheet composite anode for high-performance potassium-ion batteries. Acs Nano 14:1018–1026. https://doi.org/10.1021/acsnano.9b08526

Yang T, Zhong JS, Liu JW et al (2021) A general strategy for antimony-based alloy nanocomposite embedded in Swiss-cheese-like nitrogen-doped porous carbon for energy storage. Adv Mater. https://doi.org/10.1002/adfm.202009433

Liu W, Luo H, Qing W et al (2014) Investigation into oxygen-enriched bottom-blown stibnite and direct reduction. Metall Mater Trans 45:1281–1290. https://doi.org/10.1007/S11663-014-0055-6

Li XY, Qu JK, Xie HW et al (2020) An electro-deoxidation approach to co-converting antimony oxide/graphene oxide to antimony/graphene composite for sodium-ion battery anode. Electrochim Acta. https://doi.org/10.1016/j.electacta.2019.135501

Zheng XM, You JH, Fan JJ et al (2020) Electrodeposited binder-free Sb/NiSb anode of sodium-ion batteries with excellent cycle stability and rate capability and new insights into its reaction mechanism by operando XRD analysis. Nano Energy. https://doi.org/10.1016/j.nanoen.2020.105123

Geng, A. H., L. H. Cao, C. M. Wan, et al., 2010. High-pressure Raman investigation of the semiconductor antimony oxide. In: 3rd International Symposium on Growth of III-Nitrides (ISGN), Montpellier, France. https://doi.org/10.1002/pssc.201000786

He GX, Chen YG, Yang N et al (2016) KSbI6O18: An antimony iodate semiconductor material with cyclic chiral S-6-symmetric hexaiodate. Inorg Chem Commun. 65:13–15. https://doi.org/10.1016/j.inoche.2016.01.006

Janowska G, Slusarski L, Koch M et al (1997) Thermal stability and combustibility of butyl and halogenated butyl rubbers. J Thermal Anal Calorimetry 50:889–896. https://doi.org/10.1007/bf01979219

Li Y, Chen Y, Xue H et al (2016) One-step extraction of antimony in low temperature from stibnite concentrate using iron oxide as sulfur-fixing agent. Metals. https://doi.org/10.3390/met6070153

Padilla R, Chambi LC, Ruiz MC (2014) Antimony production by carbothermic reduction of stibnite in the presence of lime. J Min Metall Sect B: Metall 50:5–13. https://doi.org/10.2298/jmmb130604003p

Kartal L, Daryal MB, Şireli GK, Timur S (2019) One-step electrochemical reduction of stibnite concentrate in molten borax. Int J Miner Metall Mater. 26(10):1258–1265. https://doi.org/10.1007/s12613-019-1867-9

Anderson CG (2012) The metallurgy of antimony. Chemie Der Erde-Geochemistry 72:3–8. https://doi.org/10.1016/j.chemer.2012.04.001

Dubrovin AS, KuznetsoVl (1965) Role of gas pressure and heat transfer in thermometallurgy. Russian Metall 53

Xiao HP, Ge JL, Chen Y et al (2019) Arsenic migration during co-processing of secondary residues from ammonium paratungstate production in cement kiln. Environ Sci Pollut Res 26:16105–16114. https://doi.org/10.1007/s11356-019-04821-y

Ouyang Z, Liu SF, Tang CB et al (2019) Kinetic studies for sulfur-fixing and roasting reduction of antimony sulfide for direct antimony extraction. Vacuum 159:358–366. https://doi.org/10.1016/j.vacuum.2018.10.062

Ting Lei CZ, Zhang Hanping (2009) Modern non-ferrous metal metallurgy science and technology series antimony metallurgy. Metallurgical Industry Press, Beijing

Ye LG, Ouyang Z, Chen YM et al (2019) Selective separation of antimony from a Sb-Fe mixed solution by hydrolysis and application in the hydrometallurgical process of antimony extraction. Separation and Purification Technology. https://doi.org/10.1016/j.seppur.2019.115753

Xiao X, Zhang SF, Zhang H et al (2020) Extraction of rare and high-valued metals from blast furnace dust. Rare Metal Technol 2020:305–315. https://doi.org/10.1007/978-3-030-36785-9_29

Trisnawati EW, Andriyah, L, Wahyuningsih S et al. (2018) Purification of Cassiterite mineral Bangka Indonesia by pyrometallurgy and hydrometallurgy methods. In: 3rd International Conference on Advanced Materials for Better Future (ICAMBF), Surakarta, Indonesia. https://doi.org/10.1088/1757-899X/578/1/012062

Zhang X, Liu ZC, Deng BW et al (2021) Honeycomb-like NiCo2O4@MnO2 nanosheets array/3D porous expanded graphite hybrids for high-performance microwave absorber with hydrophobic and flame-retardant functions. Chem Eng J. https://doi.org/10.1016/j.cej.2021.129547

Li KQ, Jiang Q, Chen G et al (2021) Kinetics characteristics and microwave reduction behavior of walnut shell-pyrolusite blends. Bioresour Technol. https://doi.org/10.1016/j.biortech.2020.124172

Veronesi P, Colombini E, Rosa R et al (2017) Microwave processing of high entropy alloys: a powder metallurgy approach. Chem Eng Process—Process Intensification 122:397–403. https://doi.org/10.1016/j.cep.2017.02.016

Manohar G, Maity SR, Pandey KM (2022) Microstructural and Mechanical properties of microwave sintered AA7075/Graphite/SiC hybrid composite fabricated by powder metallurgy techniques. Silicon 14:5179–5189. https://doi.org/10.1007/s12633-021-01299-7

Manohar G, Pandey KM, Maity SR (2022) Effect of variations in microwave processing temperatures on microstructural and mechanical properties of AA7075/SiC/graphite hybrid composite fabricated by powder metallurgy techniques. Silicon 14:7831–7847. https://doi.org/10.1007/s12633-021-01554-x

Zhang, Y. H., Y. F. Xu, Y. N. Sun, et al., 2022. Surface quality optimization of laser cladding based on surface response and genetic neural network model. Surface Topography-Metrology and Properties. 10, https://doi.org/10.1088/2051-672X/aca3bd

Liu CH, Zhao PF, Zhu XJ et al (2021) A novel production method of antimony trioxide from stibnite concentrate and the dielectric properties of antimony sulfide with different desulfurizer. Miner Eng. https://doi.org/10.1016/j.mineng.2021.107097

Liu CH, Zhang LB, Peng JH et al (2013) Effect of temperature on dielectric property and microwave heating behavior of low grade Panzhihua ilmenite ore. Trans Nonferrous Metals Soc China 23:3462–3469. https://doi.org/10.1016/s1003-6326(13)62889-7

Liu C, Peng J, Li X et al (2014) Dielectric properties and microwave heating characteristics of ilmenite for welding electrode. J Nonferrous Metal Sci Eng. 5:1–7. https://doi.org/10.13264/j.cnki.ysjskx.2014.06.001

Liu SY, Li QJ, Wang ZY et al (2020) Metals droplet assembling mechanism during carbon reduction of stainless steel pickling sludge. J Clean Product. https://doi.org/10.1016/j.jclepro.2019.119580

Funding

This work was supported by the National Natural Science Foundation of China [grant number 52264040], the Applied Basic Research Foundation of Yunnan Province 202401AT070038, and Ten Thousand Talent Plans for Young Top-notch Talents of Yunnan Province [grant number YNWR-QNBJ-2019-066].

Author information

Authors and Affiliations

Contributions

LL: Writing—review and editing and Data curation. LZ: Formal analysis, Investigation, and Conceptualization. CL: Supervision, Project administration, and Resources. YL: Conceptualization, Validation, and Resources. JG: Formal analysis and Validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was M. Akbar Rhamdhani.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, L., Zhou, L., Liu, C. et al. Preparation of Antimony Metal by Carbothermal Reduction of Antimony Oxide Powder in a Microwave Field: Mechanism and Process. J. Sustain. Metall. (2024). https://doi.org/10.1007/s40831-024-00809-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40831-024-00809-2