Abstract

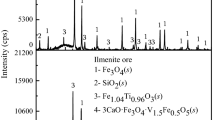

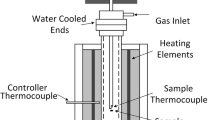

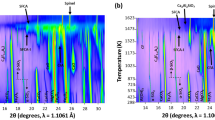

In the sintering of Ti-containing iron ores, the formation of perovskite was reported to harmfully affect the formation of silico-ferrite of calcium and aluminum. The formation of perovskite in ore blend of hematite and ilmenite ores in an Ar atmosphere was investigated in the temperature range of 1373 to 1523 K employing high-temperature in situ X-ray diffraction. The temperatures of melt formation in the ore blends were estimated employing thermal analysis in terms of thermogravimetric-differential scanning calorimetry. The hematite ore was thermally decomposed to magnetite at high temperatures accompanied by the release of oxygen combined with iron. Addition of ilmenite ore to hematite ore increased the temperature of melt formation in the sintering of the ore blend. Ilmenite, FeO·TiO2(s), in the ore was oxidized to a metastable phase of Fe2O3·2TiO2(s) and was acerbated by oxygen released from thermal decomposition of hematite at about 1423 K. Then the Fe2O3·2TiO2(s) decomposed to release TiO2(s) which reacted with CaO(s) to form perovskite-containing compound, CaO·TiO2· SiO2(s). MgO(s) interfered with the release of TiO2(s) by forming some stable or metastable magnesium titanium oxides such as Mg0.6Fe0.4O·Fe0.2Ti1.8O3(s), Mg0.9Ti0.1O·2TiO2(s), MgO·Fe2O3·3TiO2(s), MgO·2TiO2(s), and MgO·TiO2·Mg0.2Ti0.8O2(s) during the sintering of the hematite–ilmenite ore sinter blend. These compounds might have some potential of decreasing the available amounts of free TiO2 for formation of CaO·TiO2·SiO2(s) in this system.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- SFCA:

-

Silico-ferrite of calcium and aluminum

- RDI:

-

Reduction degradation index

- LOI:

-

Loss on ignition

References

Manshadi D, Manuel J, Hapugoda S, Ware N (2014) Sintering properties of titanium containing iron ores. ISIJ Int 54(10):2189–2195

Bristow NJ, Loo CE (1992) Sintering properties of iron ore mixes containing titanium. ISIJ Int 32(7):819–828

Bai YQ, Cheng SS, Bai YM (2011) Analysis of vanadium bearing titanomagnetite sintering process by dissection and sintering bed. J Iron Steel Res Int 18(6):8–15

Zhou M, Jiang T, Yang S, Xue X (2015) Sintering behaviors and consolidated mechanism of high-chromium vanadium and titanium magnetite fines. Int J Miner Process 22(9):917–925

Ding C, Lv X, Li G, Bai C, Xuan S, Tang K, Xu Y (2018) In: Proceedings of the 9th International Symposium on High Temperature Metallurgical Processing, pp 159–164. https://doi.org/10.1007/978-3-319-72138-5_16

Wang Z, Pinson D, Chew S, Monaghan BJ, Pownceby MI, Webster NAS, Rodgers H, Zhang G (2016) Effects of sintering materials and gas conditions on formation of silico-ferrites of calcium and aluminium during iron ore sintering. ISIJ Int 56(7):1138–1147

Cheng G, Gao Z, Yang H, Xue X (2017) Effect of calcium oxide on the crushing strength, reduction and smelting performance of high-chromium vanadium-titanium magnetite pellets. Metals 7:181. https://doi.org/10.3390/met7050181

Budzik R (2005) Behavior of titanium compounds in the process of sintering titanium-magnetite concentrates. Metalurgija 44:179–182

Zhang G, Ostrovski O (2002) Effect of preoxidation and sintering on properties of ilmenite concentrates. Int J Miner Process 64:201–218

Chiwandika EK, Jung SM (2020) Effects of ilmenite ore on phase development of hematite ore sinter. Metall Mater Trans B 51B:1469–1484

Lee H (1999) Chemical Thermodynamics for metals and materials. Imperial College Press, London, p 283

Qu Y, Yang Y, Zou Z, Zeilstra C, Meijer K, Boom R (2015) Melting and reduction behavior of individual fine hematite ore particles. ISIJ Int 55(1):149–157

Cheng Z, Qu Y, Zeilstra C, Stel J, Sietsma J, Yang Y (2020) Thermodynamic evaluation for reduction of iron oxide ore particles in a high temperature drop tube furnace. Ironmaking Steelmaking 47:173–177. https://doi.org/10.1080/03019233.2018.1498762

Gupta SK, Rajakumar V, Grieveson P (1991) Phase trensformations during heating of ilmenite concentrates. Metall Trans B 22B:711–716

Powncerby MI, Fisher-White MJ (1999) Phase equilibria in the system Fe2O3–MgO–TiO2 and FeO–MgO–TiO2 between 1173 and 1473 K, and Fe2+–Mg mixing properties of ilmenite, ferrous-psuedobrookite and ulvospinel solid solutions. Contrib Miner Petrol 135:198–211

Sitefane M, Masipa M, Maphutha P, Goso XC (2017) The effect of CaO to MgO ratio on the smelting characteristics of vanadium-bearing titaniferous magnetite. In: Proceedings of the 3rd Young Professional Conference Innovation Hub, Pretoria, The Southern African Institute of Mining and Metallurgy, pp 467–480.

Gao Q, Wei G, Shen Y, Jiang X, Zheng H, Shen F, Liu C (2017) Influence and mechanism of Indonesia vanadium titano-magnetite on metallurgical properties of iron ore sinter. J Cent South Univ 24:2805–2812

Verdeja LF, Ferreira SG, Bustinza IR, Javier IM (2013) Iron ore sintering. Part1. Theory and practice of the sintering process. Dyna 180:152–171

Zhang J, Guo X, Huang X (2012) Effects of temperature and atmosphere on sintering process of iron ores. J Iron Steel Res Int 19(10):1–6

Chiwandika EK, Cho S-K, Jung S-M (2020) Phase development in the sintering of a hematite–ilmenite ore blend. Minerals 10(9):800

Chiwandika EK, Bok J, Jung S-M (2021) Effect of MgO on phase development in hematite–ilmenite ore sinter. ISIJ Int 61(1):513–515

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Veena Sahajwalla.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chiwandika, E.K., Jung, SM. Perovskite Formation in Hematite–Ilmenite Ores Sintered in Argon. J. Sustain. Metall. 8, 310–320 (2022). https://doi.org/10.1007/s40831-021-00471-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-021-00471-y