Abstract

Coupled in situ investigations were conducted on a Fe–Mn–Al–Ni–Ti single crystal deformed in compression and two Fe–Mn–Al–Ni–Ti oligo-crystals deformed in tension. Acoustic emission measurements were employed to monitor the degradation of superelasticity and the stabilization of martensite due to dislocation processes. These observations were corroborated by the application of digital image correlation and infrared thermography measurements. A poor strain reversibility and a premature plastification of the parent phase were observed in case of the single crystal due to an unfavourable crystal orientation. A contradictory transformation behaviour of the two oligo-crystals was observed, with one specimen showing a promising strain reversibility and characterisitic signs of degradation, and the other specimen exhibiting a limited strain reversibility due to an unusual confinement of the martensitic phase transformation to an unfavourably oriented grain. In the former case, an increase in the dislocation density within five cycles was detected through a shift of the acoustic signals’ median frequencies. In the latter case, a strong coupling between martensite nucleation and dislocation generation led to a pronounced martensite stabilization after one loading cycle. For all specimens, temporal sequence effects related to the coupling of martensite nucleation and dislocation generation were detected by means of acoustic emission.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During the last decade, renewed interest in iron-based shape memory alloys (SMAs) was sparked by the discovery of the two alloys (i) Fe–28%Ni–17%Co–11.5%Al–2.5%Ta [1] and (ii) Fe-34%Mn-15%Al-7.5%Ni [2], both exhibiting a thermoelastic martensitic transformation allowing for large reversible strains. In particular, the Fe–Mn-Al-Ni alloy shows a high potential for material-intensive applications in the sector of civil engineering due to its comparatively low-cost alloying components and its exceptionally low Clausius-Clapeyron slope of ~ 0.5 MPa K−1, enabling applications in a wide temperature range [2,3,4,5,6]. Fe–Mn-Al-Ni exhibits a stress-induced martensitic phase transformation (SIMPT) from a high-temperature body-centred cubic (bcc) austenitic α phase to a low-temperature face-centred cubic (fcc) martensitic γ’ phase [2]. The occuring superelasticity (SE), however, is prone to a pronounced functional degradation after only a few loading cycles, thereby still hindering an industrial application requiring a high repeatability of the SE [7,8,9,10,11,12]. Furthermore, the SE and its cyclic stability show a strong dependence on the crystal orientation [10, 11, 13, 14], the grain size [15, 16], the ageing process and the corresponding properties of the precipitates [17,18,19], as well as the prevailing loading condition (tension/compression) [20].

Of particular importance for achieving a stable superelastic effect in Fe–Mn-Al-Ni is the specimen’s grain size and microstructure. The alloy is characterized by an anisotropic transformation strain, which is calculable using the energy minimization theory (EMT) [21] or the lattice deformation theory (LDT) [22]. Consequently, pronounced strain constraints from neighbouring grains arise in a randomly oriented polycrystalline grain structure leading to a supressed SIMPT as well as a severe defect generation in the vicinity of grain boundaries [15, 16, 23]. Omori et al. [24] introduced a crystal growth technique based on the cyclic heat treatment (CHT) between a high-temperature single-phase region and a lower-temperature two-phase region that promotes the process of an abnormal grain growth (AGG). The AGG arises from the spontaneous growth of a few grains at the expense of their smaller neighbouring grains, ultimately resulting in a bimodal, oligo-crystalline or even single-crystalline grain structure [24,25,26,27,28]. In this process, cooling to the two-phase region leads to a nucleation of subgrain structures in the parent phase, which is associated with a loss of coherency stemming from the precipitation of the second phase. It is assumed that the subgrain boundaries provide a crucial part of the required energy for an AGG [26, 29]. Vollmer et al. [30] demonstrated that substituting 1.5 at-% Al by Ti significantly increases the rate of the AGG. The underlying reason for the increased grain boundary migration rate in the Ti-alloyed composition presumably lies in the decreased size of the subgrains and the resultant higher driving force for the AGG [29].

After the grain size has been adjusted via CHT, the established procedure for Fe–Mn-Al-Ni consists of a final solution treatment in the α region, followed by an ageing process at 200–300 °C in order to tailor the volume fraction and the size of the coherently dispersed β precipitates [11, 15, 17, 31]. It was, however, observed that comparatively small β precipitates are already present after quenching from the α region [17], and that quenched, un-aged Fe–Mn-Al-Ni single crystals exhibit a reasonable SE both in tension and compression [17, 32]. In the case of Fe–Mn–Al–Ni–Ti, coherently dispersed β precipitates with sizes ranging from 8 to 16 nm were observed after quenching in 80 °C warm water as well, indicating that precipitation of the β phase occurred during the quenching process and that an additional ageing step might be unnecessary. A subsequent incremental strain test of a near 〈127〉 oriented single crystal indicated a high transformation stress (approximately 900 MPa) and a pronounced superelastic recovery up to an applied compressive strain of 8% [29].

The degradation of the SE in Fe-based SMAs has been the subject of numerous investigations [8, 10,11,12,13, 20, 33] and has been closely linked to the formation of dislocations due to (i) a lattice misfit between α and γ’ phase, (ii) an interaction of multiple martensite variants, (iii) a stabilization of martensite in the vicinity of precipitates, and (iv) the formation of unfavourable variants in the vicinity of HAGBs [11, 12, 23, 33]. In situ observations of the functional degradation in Fe–Mn–Al–Ni-based alloys revealed a transformation resistance in previously transformed specimen areas and a successive activation of previously untransformed areas [10,11,12, 34]. In a recent investigation of the degradation of a tensile oligo-crystal, some of the authors of the present study correlated large stress drops in the course of the initial SIMPT with a strong localized heating measured via in situ thermography. It was observed that the magnitude of the heating strongly decreased with an increase in the number of loading cycles, so that almost no measureable temperature change occurred during the fifth loading cycle [10]. Weidner et al. [8] studied the functional degradation of a near 〈001〉 oriented Fe–Mn–Al–Ni single crystal loaded up to an applied compressive strain of 7.5% using acoustic emission (AE) measurements coupled with microstructural investigations. They were able to distinguish between two different types of acoustic signals: (i) signals associated with SIMPT, twinning, detwinning and (ii) signals associated with the lateral movement of the α/γʹ interface and dislocation processes. With an increasing number of cycles, the detection rate of type (i) signals decreased significantly during the loading phase, thereby reflecting the stabilization of martensite upon progressive cycling. In contrast, acoustic signals recorded during the unloading regime remained at a comparatively constant level throughout all 25 cycles. The authors argued that the reverse transformation occured simultaneously at numerous sites, thereby fissuring the formerly large martensitic plates into various small fragments which then transform back to the parent phase individually [8]. In general, in situ AE measurements enable the detection of acoustic signals caused by microstructural processes within the entire specimen volume with a high temporal resolution [35]. However, the AE measurement is an indirect method of a random multiscale process and localized sources such as the martensitic phase transformation or an avalanche movement of dislocations can occur anywhere within the stressed volume of the specimen. Therefore, additional complementary imaging techniques need to be employed for a robust interpretation of the AE data. Both digital image correlation (DIC) [7, 10, 23, 34, 36] and infrared thermography (IR-TG) [37, 38] are established characterization techniques suited for imaging deformation processes in shape memory alloys. With a lower temporal resolution, these full-field measurement methods provide information about the spatial distribution of strain and temperature fields on the specimen surface [39].

In the present study, coupled in situ investigations on (i) a Fe–Mn–Al–Ni–Ti single crystal deformed in compression and (ii) two Fe–Mn–Al–Ni–Ti oligo-crystals loaded in tension were conducted. The different superelastic behaviours were characterized by utilizing the methods of AE, DIC and IR-TG, complemented with microstructural investigations using a scanning electron microscope (SEM) and transmission electron microscope (TEM). This coupled experimental setup aims to combine the volume integrative AE method with two-dimensional surface observations of local imaging characterization techniques (DIC, IR-TG). Thus, the acoustic signals detected upon loading and unloading can be assigned to local deformation processes.

Experimental Details

Materials and Preparation

Ingots with a chemical composition of Fe-34%Mn-15%Al-7.5%Ni-1.5%Ti (at-%) were produced via vacuum induction melting. During the following hot-forging in a temperature range of 1000–1250 °C, the final ingot size of 40 mm × 40 mm was obtained. By means of a subsequent hot-rolling process at temperatures of 1000–1250 °C, sheets with a width of 12 mm and a height of 2 mm were manufactured. Miniature tensile specimens with a total length of 28 mm, a gauge length of 15 mm and a gauge width of 1.5 mm were cut out of the sheets using electro-discharge machining. The specimens’ final thickness was 1 mm. Furthermore, a rod with a diameter of 6.5 mm was produced via the hot-rolling procedure. A cuboid compression specimen with a height of 6 mm and a cross section of 3 mm × 3 mm was machined out of the rod. After sealing the specimens in quartz tubes under argon atmosphere, a cyclic heat treatment consisting of three cycles was conducted in order to promote AGG [29]. The cycles consisted of heating to the α single-phase region at 1225 °C (heating rate 10 K/min), holding for 30 min, cooling to the α + γ two-phase region at 900 °C (cooling rate: 10 K/min) and holding for 15 min. After a final one-hour solution treatment at 1225 °C, the specimens were quenched in 80 °C tempered water. No further ageing treatment was conducted afterwards.

Mechanical Testing

Quasi-static tension and compression experiments were conducted using a miniature push–pull loading device (Kammrath & Weiss, Germany) with a constant crosshead displacement rate of 15 µm/s (tension) and 6 µm/s (compression) corresponding to a nominal strain rate of 1 × 10–3 s−1, respectively. While the tensile specimens were mounted using a custom-built form-fit specimen holder, the cuboid specimen was fitted between two compression plates made of tungsten carbide. One side of the plates exhibited a spherical profile enabling the self-centring of the setup and the specimen. A preload of 10–20 MPa was applied on all investigated specimens. During loading and unloading in compression and tension, respectively, the front surfaces were monitored using an infrared thermography camera, while the opposite sides of the specimens were recorded with a videocamera for subsequent DIC analyses. To ensure a high emission coefficient of εTG ~ 0.96, the front surfaces of the specimens were sprayed with a black thermal laquer. The opposite surfaces were carefully ground using emery paper of grade 800 in order to receive a satisfactory grey value distribution suitable for digital image correlation (DIC). In case of the tensile specimens, the front side was metallographically ground, polished and vibration-polished (colloidal silica), so that electron backscattered diffraction (EBSD) measurements could be taken prior to the application of the thermal laquer. In case of the compression specimen, the vibration-polished surface prepared for EBSD measurements was neither the frontside (thermography) nor the back side (DIC) but a third surface perpendicular to the aforementioned sides. Schematic illustrations of the experimental setup and the specimen geometries are displayed in reference [10]. It must be noted that all DIC images of the tensile specimens were mirrored along the loading axis so that a proper comparability with the recorded thermograms and the EBSD orientation scans is ensured.

Digital Image Correlation

The back side of the specimens was monitored with a video camera Manta G-505 (Allied Vision, Germany) yielding 8-bit grey scale images with a resolution of 2452 × 2056 pixels. The camera was mounted with either a × 1.0 tele centric optic (pixel resolution of 12.48 µm/pixel) or a × 0.28 tele centric optic (pixel resolution of 3.45 µm/pixel) for the tensile and compression specimens, respectively. The video extensometer system microDAC® (Chemnitzer Werkzeugmechanik, Germany) was used to measure the macroscopic strains parallel and perpendicular to the loading axis using two horizontal lines parallel to the loading axis (50 and 30 measuring points for tensile and compression specimens, respectively) as well as two lines perpendicular to the loading axis (10 and 15 measuring points for tensile and compression specimens, respectively). Images of the gauge section were taken with a frequency of 10 Hz. DIC analysis was then performed using the software package VEDDAC v.62 (Chemnitzer Werkzeugmechanik, Germany). A subset size of 15 × 15 pixels was selected while the distance between the individual subsets amounted to 10 × 10 pixels. The calculated displacement vectors were smoothed by applying a Gauss filter. The calculated local strain fields are displayed in terms of normal strains along the compressive εyy and tensile εxx axes, respectively, using false colour codes.

Infrared Thermography

The black-coated front side of the specimens was monitored using an infrared thermography camera VarioCam hr head 600 (InfraTec, Germany) which operates with a temperature resolution of 0.03 K at 30 °C. Thermograms were captured with an acquisition frequency of 25 Hz. The microbolometer plane focal array detector operated in a spectral range of 7.5–14 µm yielding images with a resolution of 640 × 480 pixel. Thermograms of the tensile specimens were recorded using a Germanium macro lens objective (Zeiss, Germany) with a spatial resolution of 50 µm. The compression specimen was recorded using a microscopic lens objective (Jenoptik, Germany) with a spatial resolution of 25 µm. Both objectives contained an aperture of f/1.0. Prior to each loading cycle, an automatic recalibration of the camera was performed.

Acoustic Emission

The acoustic signals generated during deformation were recorded using a wide band piezoelectric sensor with a flat frequency response between 150 and 750 kHz (Micro-F30 Physical Acoustic Corporation, USA) and a diameter of 9.5 mm. Due to the dimensions, the sensor was not mounted directly onto the specimens and was, therefore, clamped onto the miniature push–pull loading device. To improve the transfer of the AE signals, the sensor was coupled with machine oil to the loading device. The AE signals were recorded continuously during loading–unloading with a sampling rate of 2 million datapoints per second. Prior to acquisition, the signals were amplified by 60 dB with a 2/4/6 low-noise preamplifier (Physical Acoustic Corporation, USA). The signals were aditionally filtered by a built in 30–1000 kHz bandpass filter prior to storage via an 18-bit PCI-2 board (Physical Acoustic). Schematic illustrations of the AE recording system for the (a) compression specimen and (b) tensile specimens are given in Fig. 1. Prior to each mechanical test, the laboratory background noise was recorded for at least 3 s. The acoustic data streams were analysed both in the time domain as well as in the frequency domain. For transferring into the frequency domain, each data stream was divided into equal-sized blocks of 4096 samples with an overlap of 16 samples to avoid data loss. Subsequently, a Fast-Fourier-Transformation (FFT) was applied resulting in a power spectral density function (PSDF). This procedure was conducted for the pre-recorded laboratory background noise as well as for each block of the data stream. From this, the noise-corrected PSDFs were calculated and evaluated further with respect to their energy and their median frequency, which were calculated according to [40]. To identify signals of the same origin, the noise-corrected PSDFs were classified using an adaptive sequential k-means (ASK) cluster algorithm developed by Pomponi and Vinogradov [41]. The main goal of the clustering process is to group signals with the same origin and, therefore, similar PSDF by minimizing the dissimilarities within a cluster and maximizing the dissimilarities between different clusters.

Microstructural Investigations

The ex situ microstructural analyses were conducted using a field-emission scanning electron microscope (SEM) Mira 3 XMU (Tescan, Czech Republic). The vibration-polished front surface of the tensile specimens and the side surface of the compression specimen were characterized via secondary electron contrast and backscattered electron (BSE) contrast prior to mechanical testing. Furthermore, EBSD scans were performed using an acceleration voltage of 20 kV (tensile specimens) or 25 kV (compression specimen). After mechanical testing, an additional EBSD scan of the opposite surface of the tensile specimens (i.e. of the surface previously used for DIC) was performed. Thus, it was confirmed that the grains extend through the complete volume of the specimen. Orientation data for the EBSD scans were recorded using the OIM Data Collection software (version 6, EDAX/TSL, USA), while analysis of the EBSD data was performed with the MATLAB toolbox MTEX [42]. After specific loading cycles, the specimens were dismounted in order to investigate microstructural changes via secondary electron and BSE contrast. For this purpose, the thermal laquer on the front surface of the tensile specimens was carefully removed with aceton and ethanol using an ultrasonic bath.

After mechanical testing, microstructural investigations of the two tensile specimens were conducted using a JEM 2200 FS (JEOL, Japan) transmission electron microscope (TEM) operating at 200 kV. Two TEM lamellae were cut and lifted out of the specimens using the focussed ion beam device Helios Nanolab 600i (FEI, USA). Investigations via bright-field (BF) and dark-field (DF) imaging were coupled with selected area electron diffraction (SAED) measurements. Furthermore, scanning transmission electron microscopy (STEM) examinations were performed.

Results

Initial Microstructure

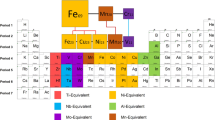

Both tensile specimens as well as the compression specimen exhibited a fully austenitic microstructure prior to mechanical loading. The crystallographic orientation of the investigated specimens according to the respective loading axes is shown in Fig. 2. If not specified otherwise, remarks about the crystallographic orientation of a specimen or a specimen’s grain always refer to the respective loading axis. The compression specimen exhibited a single-crystalline microstructure with an orientation of 〈122〉, see Fig. 2a. In the following, this specimen will be referred to as 〈122〉 single crystal. Both tensile specimens possessed an oligo-crystalline microstructure with a gauge section comprised of two large grains. The first tensile specimen’s gauge section was characterized by two grains with an orientation of 〈012〉 and 〈112〉, respectively (Fig. 2b). The high-angle grain boundary (HAGB) exhibited a misorientation angle of 45°. A further HAGB with a misorientation angle of 18° was located at the right end of the gauge section. This specimen will be referred to as 〈012〉-〈112〉 oligo-crystal in the following. The gauge section of the second tensile specimen (Fig. 2c) was characterized by two grains with an orientation of 〈012〉 and 〈124〉, respectively. In this case, the misorientation angle was 57°. This specimen will be referred to as 〈012〉-〈124〉 oligo-crystal.

EBSD orientation map of the a 〈122〉 single crystal, b 〈012〉-〈112〉 oligo-crystal, c 〈012〉-〈124〉 oligo-crystal. Plotting convention according to the inverse pole figure’s colour code and with respect to the horizontal loading axes. d Exact crystallographic orientations with respect to the loading axes of the grains I–V as marked in (a–c) displayed in the stereographic standard triangle

Superelastic Material Behaviour

〈122〉 single crystal. Figure 3a shows two compressive engineering stress vs. engineering strain curves of the 〈122〉 single crystal. In the first loading cycle, the plateau region of the SIMPT was not reached, so that the specimen was loaded predominantly elastically. Nevertheless, loading up to a maximum strain of 0.9% led to an irreversible strain of 0.1%. In the second loading cycle, the maximum strain was 6% and an irreversible residual strain of 3.1% remained after unloading. A Young’s modulus of 85 GPa was determined by measuring Hooke’s slope in the loading stage. A critical stress σcrit of 910 MPa was determined via the 0.2% strain offset method. After σcrit for the SIMPT was reached in the second loading cycle, a pronounced stress plateau was not observed, but rather a linear strain hardening up to 1210 MPa at maximum strain. The irregular strain drops in the unloading slope stem from a tilting of the specimen and do not represent the actual material behaviour. No further loading cycles were conducted due to the poor strain reversibility.

a Compressive engineering stress vs. engineering strain curves of the 〈122〉 single crystal. b Tensile engineering stress vs. engineering strain curve of the 〈012〉-〈112〉 oligo-crystal. c Tensile engineering stress vs. engineering strain curves of the 〈012〉-〈124〉 oligo-crystal. The specimens’ orientations with respect to the loading axes are marked in the stereographic standard triangles. d Evolution of σcrit, εirr and maximum ΔσH of the 〈012〉-〈124〉 oligo-crystal

〈012〉-〈112〉 oligo-crystal. Figure 3b displays the engineering stress vs. engineering strain curve of the 〈012〉-〈112〉 oligo-crystal. The tensile loading was carried out up to a maximum strain of εmax = 2% and an irreversible strain of εirr = 0.5% remained after unloading. A Young’s modulus of 164 GPa and a critical stress σcrit of 875 MPa at 0.2% plastic strain were measured from the loading path. No stress drop was recorded upon reaching the critical stress σcrit. No further loading cycles were conducted due to the poor strain reversibility.

〈012〉-〈124〉 oligo-crystal. Figure 3c displays the five tensile engineering stress vs. engineering strain hysteresis curves of the 〈012〉-〈124〉 oligo-crystal. In each loading cycle, the maximum elongation was increased successively in order to evaluate the subsequent reversibility of the applied strain. Figure 3d shows the change of the parameters σcrit, εirr, and the maximum hysteresis width ΔσH plotted versus the applied maximum strain of each cycle. After the first loading cycle to a maximum strain of εmax = 1.4%, a negligible irreversible strain of εirr = 0.04% was recorded. The fifth loading cycle with a maximum strain of εmax = 3.4% resulted in an irreversible strain of εirr = 0.2%. With an increasing number of cycles, the critical stress σcrit for the SIMPT decreased slightly from 615 MPa in the first cycle to 555 MPa in the fifth cycle. Upon reaching σcrit, a characteristic stress drop was not observed. The Young’s modulus of the austentic phase was determined from the elastic loading path and remained comparatively constant at a value of 92 GPa. For each cycle, the maximum width of the stress hysteresis ΔσH was measured, see Fig. 3c. These values increased from 205 MPa in the first cycle to 370 MPa in the fifth cycle, see Fig. 3d. In the first four loading cycles, a distinctive stress increment was observed upon the transition from the γʹ → α reverse transformation to the elastic unloading of the α-phase, see Fig. 3c. These stress increments amounted to 4 MPa (1st cycle), 40 MPa (2nd cycle), 16 MPa (3rd cycle) and 4 MPa (4th cycle).

Results of Digital Image Correlation

〈122〉 single crystal. The εyy strain contour plots of the first and second compressive loading cycle of the 〈122〉 single crystal at maximum load and after complete unloading, respectively, were determined by DIC. Figure 4a shows that loading up to εmax = 0.9% in the first cycle induced a homogeneous strain distribution with local strain values of εyy = 1–4%. A considerable amount of these strain fields remained in the sample even after complete unloading (Fig. 4b). In the second cycle, compressive loading of the specimen was conducted up to εmax = 6% resulting in an extensive deformation of the specimen. Besides strain fields with maximum measured strains of εyy = 15%, a buckling of the specimen was observed as well, see Fig. 4c. Unloading led to a partial reversibility of the measured strain fields. However, particularly the lower and upper end of the specimen were characterized by large amounts of irreversible strains of up to εyy = 15%. A permanent bending after unloading of the specimen was also observed, explaining the high amount of irreversible residual strain at the right side of the specimen, see Fig. 4d.

〈012〉-〈112〉 oligo-crystal. Figure 5 displays the local εxx strain contour plots from the tensile loading of the 〈012〉-〈112〉 oligo-crystal. For the state of maximum load, the majority of strain is accommodated in a band located in the 〈112〉 oriented grain (εxx = 6–8%), while some minor strain fields (εxx = 1–2%) were observed in the 〈012〉 oriented grain, see Fig. 5b. Unloading resulted in a partial reversibilty of the major strain band, although an irreversible strain field of εxx = 1–4% remained in the specimen (Fig. 5c).

Local εxx strain contour plots with respect to the horizontal loading axis from the tensile loading of the 〈012〉-〈112〉 oligo-crystal. a EBSD orientation map with respect to the loading axis. b Strain contour plot at maximum load, c strain contour plot after complete unloading. HAGBs are marked with dashed lines

〈012〉-〈124〉 oligo-crystal. For all five tensile loading cycles of the 〈012〉-〈124〉 oligo-crystal, the εxx strain distribution plots with respect to the horizontal loading axis are shown at maximum load and after complete unloading (F = 0 N) in Fig. 6. In the first cycle, loading up to a maximum strain of εmax = 1.4% induced the formation of a strain band (εxx = 6–8%) in the 〈012〉 oriented grain. Smaller areas of increased strain (εxx = 1–2%) are distributed along the complete gauge length (see Fig. 6b). After unloading, isolated strain fields (εxx = 1%) remained in the specimen, see Fig. 6c. As the maximum strain εmax was increased in each consecutive loading cycle, the strain band recorded at each state of maximum load broadened as well (cf. Figure 6b, d, f, h, j). From the second cycle onwards, increased local strains of up to εxx = 10% were measured, see Fig. 6d. In all loading cycles, the major strain band was, however, restricted within the 〈012〉 oriented grain. In the fifth cycle, during the state of maximum load, the strain band spanned almost the entire 〈012〉 oriented grain, while smaller strain fields of up to εxx = 2% accumulated in the vicinity of the HAGB as well as in the 〈124〉 oriented grain (Fig. 6j). Upon unloading, the specimen retained several irreversible strain fields (εxx = 1%) in the 〈012〉 oriented grain, see Fig. 6k. Nevertheless, the majority of the εxx strain was still reversible upon unloading.

Local εxx strain contour plots with respect to the tensile loading axis of the cycles 1–5 of the 〈012〉-〈124〉 oligo-crystal. a EBSD orientation map with respect to the loading axis. Images (b, d, f, h, j) display the state of maximum load for each cycle, and images (c, e, g, i, k) display the state after complete unloading in the respective cycle. HAGB is marked with a dashed line

Infrared Thermography

In the following, results of the in situ thermography measurements are presented. The phase transformation in the Fe–Mn–Al–Ni (+ Ti) alloy system induces a comparatively small change of entropy (ΔS = − 0.43 J mol−1 K−1 [2]). Therefore, local temperature changes due to the α → γʹ SIMPT or the γʹ → α reverse transformation are comparatively small as well. Using thermograms that depict relative temperature changes based on a defined reference thermogram, rather than absolute temperature distributions, allows for a significantly improved temperature resolution. Furthermore, thermograms with relative temperature distributions ensure a comparability between different cycles and specimens. Therefore, the thermography results are presented in terms of local temperature changes with respect to defined reference thermograms.

〈122〉 single crystal. No significant temperature changes were measured during the compressive loading of the 〈122〉 single crystal.

〈012〉-〈112〉 oligo-crystal. Figure 7 displays the results of the thermography measurements for the tensile loading of the 〈012〉-〈112〉 oligo-crystal. The thermogram in Fig. 7c was recorded in the region of the stress plateau (label 2 in Fig. 7a). In comparison to the reference state prior to the onset of the SIMPT (label 1 in Fig. 7a), a minor temperature increase of approximately 0.3 K was observed in the 〈112〉 oriented grain, while no temperature change was detected in the remaining portion of the gauge length. Figure 7d depicts the thermogram taken at maximum load (label 3 in Fig. 7a). In relation to the reference thermogram (label 1 in Fig. 7a), a widespread heating of up to 0.8 K occurred in a large area of the 〈112〉 oriented grain. The thermogram in Fig. 7e was recorded during the beginning of the unloading phase (label 4 in Fig. 7a). No significant change in temperature with respect to the state of maximum load was measured during this elastic unloading step. Figure 7f is recorded at a later stage in the unloading regime (label 5 in Fig. 7a). In relation to the state of maximum load, a cooling of up to 0.5 K was observed in the 〈112〉 oriented grain, while no temperature change occurred in the other grain. The thermogram in Fig. 7g was recorded during the final stage of unloading (label 6 in Fig. 7a). The measured temperature distribution in the 〈112〉 oriented grain was up to 1 K lower compared to the state of maximum load.

Relative temperature distribution during tensile loading/unloading of the 〈012〉-〈112〉 oligo-crystal. b EBSD orientation map with respect to the loading axis. For each thermogram (c–g) the moment it was recorded (‘pos’) is indicated, as well as the respective reference thermogram (‘ref’) to which it refers and the elapsed time with respect to the beginning of the test. The numbers 1–6 refer to the markings in the stress–strain hysteresis (a). HAGBs are marked in the thermograms

〈012〉-〈124〉 oligo-crystal. The six thermograms displayed in Fig. 8c–h were recorded during the second tensile loading cycle of the 〈012〉-〈124〉 oligo-crystal. Figure 8c gives a thermogram recorded halfway through the α → γʹ SIMPT (label 2 in Fig. 8a) and is based on a reference thermogram which was taken shortly before the onset of the SIMPT (label 1 in Fig. 8a). The 〈012〉 oriented grain is characterized by a homogeneous temperature increase of approximately 1 K, while the 〈124〉 oriented grain did not show any temperature changes compared to the reference thermogram. Figure 8d depicts the thermogram taken at maximum load (label 3 in Fig. 8a). A temperature increase of 2 K with respect to the reference thermogram was determined. Furthermore, a large part of the 〈124〉 oriented grain was characterized by an increased temperature, which can be ascribed to heat transfer effects inside the specimen. Figure 8e shows a thermogram recorded during the γʹ → α reverse transformation (label 4 in Fig. 8a). In comparison to the state of maximum load, a cooling of approximately 0.5 K was determined in case of the 〈012〉 oriented grain, while no temperature change occurred in the other grain. Figure 8f displays a thermogram recorded shortly before the distinctive stress increment (label 5 in Fig. 8a). In comparison to the state of maximum load, the temperature of the 〈012〉 oriented grain decreased approximately 1.5 K, while no notable cooling was recorded in case of the 〈124〉 oriented grain. Figure 8g gives a thermogram which was recorded during the stress increment (label 6 in Fig. 8a). No significant difference can be observed between the temperature distributions in Fig. 8f and g. The thermogram in Fig. 8h was recorded during the elastic unloading of the austenitic phase (label 7 in Fig. 8a). The 〈012〉 oriented grain is still characterized by a distinctive cooling of approximately 1 K, although the extent of the cooling declined compared to the thermograms shown in Fig. 8f and g.

Relative temperature distribution during the second tensile loading cycle of the 〈012〉-〈124〉 oligo-crystal. b EBSD orientation map with respect to the loading axis. For each thermogram (c–h) the moment it was recorded (‘pos’) is indicated, as well as the respective reference thermogram (‘ref’) to which it refers and the elapsed time with respect to the beginning of the test. The numbers 1–7 refer to the markings in the stress–strain hysteresis (a). HAGB is marked in the thermograms

In order to investigate the temperature development in the course of the stress increment during the unloading phase of the second tensile loading cycle in more detail, Fig. 9 presents five thermograms which are all based on the same reference thermogram (labelled ‘ref’ in Fig. 9a). The thermogram in Fig. 9c was taken 1 s after the reference thermogram and immediately before the beginning of the steep stress increment (label 1 in Fig. 9a). No significant temperature change was observed in the region of the gauge length. Figure 9d depicts a thermogram which was recorded shortly after the sudden stress increment (label 2 in Fig. 9a). A distinctive band of cooling (ΔT ~ − 0.3 K) is now observable in the 〈012〉 oriented grain. The rest of the gauge length experienced a less pronounced but homogeneous decrease in temperature as well. Figure 9e (label 3 in Fig. 9a) shows that during the increase of stress further cooling of the complete gauge length took place. Specifically, in the area of the 〈012〉 oriented grain, temperature changes up to − 0.5 K were recorded in a clearly localized manner. Figure 9f is recorded shortly after the maximum of the stress increment, see label 4 in Fig. 9a. Still, a cooling of the complete gauge length was observed even though the extent of cooling is lower compared to the preceding thermogram. No localization of the cooling effect can be identified since heat transfer effects now prevail in the specimen. The thermogram in Fig. 9g was taken 4.5 s after the initial reference thermogram, see label 5 in Fig. 9a. The temperature distribution was not characterized by a cooling anymore. Rather, a temperature level similar to that of the reference thermogram prevailed.

Detailed temperature evolution during the second tensile loading cycle of the 〈012〉-〈124〉 oligo-crystal. b EBSD orientation map with respect to the loading axis. For each thermogram (c–g) the moment it was recorded (‘pos’) is indicated, as well as the elapsed time with respect to the reference thermogram (‘ref’ in the hysteresis). The numbers 1–5 refer to the markings in the partial stress–strain hysteresis (a). HAGB is marked in the thermograms

Acoustic Emission

After transforming the measured acoustic signals of each cycle from the time domain into the frequency domain using FFT, the signals were seperated by an unsupervised clustering procedure into distinct groups using the ASK-cluster algorithm [39]. For each loading–unloading cycle of the investigated specimens, two distinct clusters of signals with similar acoustic profiles were identified, see Fig. 10. Hereafter, we designate these clusters as Cluster 1 (red colouring) and Cluster 2 (blue colouring), respectively.

Acoustic signals belonging to (a, b) the first compressive loading/unloading cycle of the 〈122〉 single crystal, (c, d) the second compressive loading/unloading cycle of the 〈122〉 single crystal, (e, f) the tensile loading/unloading cycle of the 〈012〉-〈112〉 oligo-crystal, (g, h) the second tensile loading/unloading cycle of the 〈012〉-〈124〉 oligo-crystal. Images (a, c, e, g) show bi-variant scatter plots of AE energy vs. median frequency displaying signals belonging to (i) Cluster 1 (red colouring) and (ii) Cluster 2 (blue colouring). Images (b, d, f, h) show the evolution of engineering stress (black curve), positive components of measured AE amplitude stream (green curve), cumulative AE energy of Cluster 1 (red curve) and cumulative AE energy of Cluster 2 (blue curve) vs. time (Color figure online)

〈122〉 single crystal. Figure 10a shows the results of the clustering for the first compressive loading cycle of the 〈122〉 single crystal in a bi-variant scatter plot of acoustic energy versus median frequency. Two different types of signals were identified: a rather low energy signal type with lower median frequencies (Cluster 1) and a rather high energy signal type with higher median frequencies (Cluster 2). In Fig. 10b, the cumulative cluster energy of both clusters as well as the engineering stress (black curve) and the AE signals’ positive components of the measured amplitude (green curve) are plotted. It is important to note the different scales of the cumulative energies which differ by one order of magnitude. During loading, the cumulative AE energy of Cluster 1 increased abruptly after 12 s (i.e. at approximately 50 MPa) and then more continuously between 60 and 70 s. During unloading, the cluster’s cumulative AE energy increased only slightly until a third rise of energy was observed at the end of the test. In case of Cluster 2, signals exhibiting a high AE energy were recorded after 40 s, see the blue curve in Fig. 10b. During loading, numerous transient signals with amplitudes of up to 3 V contributed to the stepwise increase of this cluster’s cumulative AE energy. Upon unloading, a high amount of transient signals was recorded between 75 and 90 s. These signals exhibited a high median frequency leading to a significant increase of the cumulative AE energy of Cluster 2. After 90 s, no further increase of this cluster’s cumulative AE energy was recorded.

Figure 10c displays the bi-variant scatter plot of acoustic energy versus median frequency for the second compressive loading cycle. Again, a low energy signal type (Cluster 1) and a high energy signal type (Cluster 2) were identified by the ASK-cluster algorithm. Figure 10d shows that the cumulated AE energy of Cluster 1 exhibited an early rise well before the onset of the SIMPT. Noticeable are individual high energy signals belonging to this cluster which contributed to the majority of the cumulated energy and were recorded at a stress of approximately 600 MPa (i.e. during the macroscopically elastic loading of the austenite). Shortly afterwards, upon reaching a stress of approximately 700 MPa, the cumulated energy of Cluster 2 began to increase as well, see the blue curve in Fig. 10d. Thus, signals belonging to both clusters were recorded even before the defined critical stress for the onset of SIMPT σcrit = 910 MPa was reached. The majority of the transient signals recorded during subsequent loading can be assigned to Cluster 2, so that a strong increase of this cluster’s cumulative energy was observed during the SIMPT. Both clusters experienced the strongest gain in cumulative AE energy during loading of the specimen. Upon unloading, Cluster 1 showed only a slight increase in cumulative AE energy, whereas a pronounced secondary increase in AE energy was recorded for Cluster 2 between 115 and 135 s, see Fig. 10d.

〈012〉-〈112〉 oligo-crystal. In Fig. 10e, the scatter plot of the AE energy vs. median frequency is shown for the 〈012〉-〈112〉 oligo-crystal. The first identified signal type was characterized by comparatively low median frequencies in the range between 60 kHz and approximately 175 kHz (Cluster 1). The second signal type was defined by a wider median frequency spectrum between 100 and 350 kHz (Cluster 2). These two clusters hardly differed in their maximum AE energy. As is visible in Fig. 10f, signals belonging to both clusters were detected after 11 s (i.e. at approximately 300 MPa), well before the defined critical stress for SIMPT σcrit = 875 MPa was reached. The highest increase in the cumulative AE energy of Cluster 1 was recorded up to approximately 25 s and, thus, falls into the period when σcrit was reached. During the period of the stress plateau between 25 and 38 s, only a minor increase in this cluster’s cumulative AE energy was observed. Likewise, only few high energy signals belonging to this cluster were detected during unloading. The cumulative AE energy of Cluster 2 increased significantly between 18 and 25 s as well. Upon reaching the plateau regime of the stress, the rate of the cumulative energy’s growth decreased, albeit to a smaller extent compared to Cluster 1. Upon unloading, no distinct change in the evolution of the cumulative energy of Cluster 2 was observed. Rather, an almost linear increase was registered up to 55 s.

〈012〉-〈124〉 oligo-crystal. Using the ASK-cluster algorithm to evaluate the acoustic signals of the 〈012〉-〈124〉 oligo-crystal, two different signal types were again identified: a low AE energy and low median frequency cluster with a median frequency range between 25 and 125 kHz (Cluster 1), as well as a high AE energy and high median frequency cluster with a median frequency ranging from 100 to 325 kHz (Cluster 2), see Fig. 10g. The positive components of the measured AE amplitude stream (green curve), the engineering stress (black curve) as well as the cumulative energy of the individual signals within the two clusters (red and blue curves) are plotted in Fig. 10h and 11 for the second and the fifth tensile loading cycle, respectively. In both cycles, only a few high energy signals were registered in the period of elastic loading of the α phase (approximately 0–15 s). With the onset of the SIMPT, large numbers of high energy transient signals were detected, whose quantity decreased significantly from the second to the fifth cycle. While 43 transient signals exceeding an amplitude of 6 V were recorded during loading in the second cycle, only 23 transient signals exceeded an amplitude of 6 V during loading in the fifth cycle. Furthermore, for both cycles, a strong asymmetry with respect to the detection of AE signals was observed between loading and unloading. While the forward SIMPT induced a large amount of high energy transient signals, the reverse transformation was characterized by a lower number of transient signals. A notable exception was registered in the second cycle between 50 and 55 s, see Fig. 10h. During this time intervall, a pronounced acoustic activity was recorded which can be correlated with the distinct stress increment and the heterogeneous local cooling displayed in Fig. 9. This abrupt phenomenon during the transition between γʹ → α reverse transformation and elastic unloading of the α phase was observed up to the fourth loading cycle, even though the intensity of the AE signals recorded during this stress increment decreased considerably after the second loading cycle.

Acoustic signals for the fifth tensile loading cycle of the 〈012〉-〈124〉 oligo-crystal. Evolution of engineering stress (black curve), positive components of measured AE amplitude stream (green curve), cumulative AE energy of Cluster 1 (red curve) and cumulative AE energy of Cluster 2 (blue curve) vs. time

During the second tensile loading cycle, the cumulative AE energy of Cluster 1 rose noticeably after approximately 12 s (i.e. at approximately 500 MPa), see Fig. 10h. During the period of the SIMPT, an almost linear increase of this cluster’s cumulative energy was registered. Importantly, no burst-like increments of the cumulative energy were detected as was done for the 〈122〉 single crystal and the 〈012〉-〈112〉 oriented tensile specimen. During unloading, virtually no high energy signals were added to Cluster 1 leading to a stagnation of its cumulative energy. The cumulative energy of the Cluster 2 increased stepwise when the defined critical stress σcrit was reached after approximately 15 s. During the reverse transformation, no significant AE energy was registered for this cluster until the stress increment between 50 and 55 s. Practically, all transient signals recorded during this time period were associated with Cluster 2 leading to a sharp increase in its cumulative AE energy, see Fig. 10h. For the fifth loading cycle, the cumulative AE energy of Cluster 1 and Cluster 2 is plotted in Fig. 11. The first acoustic events that occured belong to Cluster 1 and started after 12 s (450 MPa). After approximately 15 s (550 MPa), the high median frequency type signals of Cluster 2 were observed as well. Subsequently, with the onset of the SIMPT at approximately 560 MPa, the cumulative energies of both clusters started to increase rapidly. While the cumulative energy of Cluster 1 increased rather continuously during loading of the specimen, only a few isolated events in Cluster 2 contributed to its cumulative AE energy (whereby the highest increase was registered shortly before the point of maximum load). Upon unloading, barely any acoustic signals were detected that could be assigned to Cluster 1. The increase in the cumulative energy of Cluster 2 was low during the unloading phase as well. The small stress increment noticable in the unloading slope had no significant impact in terms of the emitted AE signals.

Microstructural Investigations in the SEM

The following section presents representative SEM micrographs, recorded in BSE contrast after unloading, showing slip lines as well as residual martensite. With the help of the MATLAB toolbox MTEX, an analysis of the primary and secondary bcc slip system of the oligo-crystals’ iron α-phase was conducted. The traces of the oligo-crystals’ primary and secondary slip planes are indicated with a solid and dashed line, respectively.

〈122〉 single crystal. After the first compressive loading cycle of the 〈122〉 single crystal, no remnant martensite was observed by BSE contrast, although fine parallel slip lines extending over multiple subgrains were detected, see Fig. 12a. An overview of the microstructure observed after the second loading cycle is shown in Fig. 12b. Stabilized martensite needles lying almost parallel to the horizontal loading axis were observed, as well as pronounced slip lines nearly prependicular to the martensite needles. Interestingly, selected slip lines seemed to extend over considerable distances of up to 500 µm through the single crystal (see arrows in Fig. 12b).

〈012〉-〈112〉 oligo-crystal. Figure 13a shows a BSE contrast overview from the 〈112〉 oriented grain of the 〈012〉-〈112〉 oligo-crystal as indicated in the inserted EBSD orientation map. An advanced martensite nucleation and stabilization took place after one loading cycle. Figure 13b highlights remnant martensite lamellae (light grey contrast) found in the middle of the 〈112〉 oriented grain. Furthermore, pronounced slip lines (marked by arrow) running through the α parent phase (dark grey contrast) and the martensite lamellae were observed. It was found that these slip lines coincide reasonably well with the trace of the slip plane belonging to the secondary slip system (\(\overline{1 }0\overline{1 }\)) [\(\overline{1 }\overline{1 }\)1] of the bcc iron phase (Schmid factor of µ = 0.36), see dotted line in Fig. 13b. For the primary slip system, a Schmid factor of µ = 0.37 was calculated. A magnified view of the area marked in Fig. 13b is shown in Fig. 13c. Additional line defects inside the martensite lamella which lie perpendicular to its alignment can be seen. Interestingly, these line defects did not extend into the parent phase but were limited to the remnant martensite lamella. Diffused cloud-like areas of brighter contrast extend into the α phase at points where the line defects impinged the α/γ’ interface (see arrows in Fig. 13c). These areas of increased dislocation densities in the α phase indicate the presence of high local stresses generated at the α/γʹ interface resulting in a pinning of the martensite lamella. Notably, in case of the 〈012〉 oriented grain, Schmid factors of µ = 0.49 and µ = 0.45 were calculated for the primary and secondary slip system, respectively. Despite the significantly higher Schmid factors, no remnants of martensite or slip were found in the 〈012〉 oriented grain or near the HAGB separating the two grains (see Supplementary Fig. A.1b).

Representative BSE contrast images of the 〈012〉-〈112〉 oligo-crystal taken after unloading. a Overview of the 〈112〉 oriented grain. The EBSD orientation map inset marks the position where the micrograph was recorded. b Detail of the rectangular area marked in (a) with pronounced slip lines marked by an arrow. The traces of the primary and secondary slip plane (bcc iron phase) are marked with a solid and dashed line, respectively. c Detail of the rectangular area marked in (b) with diffused cloud-like areas at α/γ’ interface marked by arrows

〈012〉-〈124〉 oligo-crystal. Figure 14 displays the microstructure of the 〈012〉-〈124〉 oligo-crystal after the fifth tensile loading cycle. Figure 14a gives an overview of retained martensite lamellae in the 〈012〉 oriented grain as indicated in the inserted EBSD orientation map. A thorough interaction of multiple variants and an advanced accumulation of irreversible martensite can be seen. This kind of retained martensite lamellae was prevalent in a major fraction of the 〈012〉 oriented grain. Schmid factors µ of 0.47 and 0.46 were calculated for the primary and secondary slip system of that grain, respectively. As visible in Fig. 14a, the traces of the remnant martensite lamellae coinside reasonably well with the slip planes of either the primary slip system (110) [1\(\overline{1 }\overline{1 }\)] (solid line) or the secondary slip system (\(\overline{1 }10\)) [\(\overline{1 }\overline{1 }\overline{1 }\)] (dashed line). Figure 14b highlights the specimen’s HAGB in the middle of the gauge section and depicts the accumulation of irreversible martensite in the immediate vicinity of the grain boundary. Retained martensite in a particularly high density was observed in the 〈124〉 oriented grain, albeit only within approximately 300 µm of the grain boundary. Apart from this region, no traces of martensite or slip were found in the 〈124〉 oriented grain. Martensite lamellae parallel to the slip plane of the primary system ((01\(\overline{1 }\)) [1\(\overline{1 }\overline{1 }\)], µ = 0.49, see solid line in Fig. 14b), as well as remnant martensite variants of multiple other orientations were observed.

Representative BSE contrast images of the 〈012〉-〈124〉 oligo-crystal taken after the 5th cycle in the unloaded state. a Overview of retained martensite lamellae in the 〈012〉 oriented grain. b Section of the HAGB with retained martensite lamellae in both grains. The HAGB is marked with a dashed line. The traces of the primary and secondary slip planes (bcc iron phase) are marked with a solid and dashed line, respectively

Discussion

Correlation Between AE Signals and Microstructural Deformation Processes

Numerous studies have already indicated the correlation between the formation and movement of dislocations, the stabilization of martensite and the degradation of the SE in Fe-based SMAs [8, 10, 12, 13]. Just as the interactions between martensite or austenite and the dislocations occur versatilely, the mechanisms leading to the formation of dislocations during loading of Fe-based SMAs are likewise manifold. Besides the extended formation of detwinned martensite, the interaction of different martensite variants can be a crucial cause for the nucleation of dislocations in Fe-based SMAs [10, 33]. Furthermore, finely dispersed precipitates were proven to exert a pinning effect on the evolving martensite variants, and thus, to cause the local stabilization of martensite, as well as the nucleation of dislocations [33, 43]. A separation of the individual mechanisms that lead to an increase in the dislocation density is very challenging since a combination of all mechanisms will most likely occur. From previous investigations on austenitic TRIP/TWIP (transformation/twinning induced plasticity) steels, which were accompanied by detailed microstructural investigations, it is known that clusters of signal waveforms with lower median frequencies can be attributed to the movement of dislocations, whereas clusters of signals with higher median frequencies correspond to the SIMPT [40, 44,45,46]. Similarly, Weidner et al. [8] associated clusters of signals exhibiting higher AE energies with the SIMPT, twinning and detwinning, while clustered signals of lower AE energies and a broader range of median frequencies were associated with accommodation proccesses due to the lateral movement of the α/γ’ interface and dislocation processes. Thus, the low AE energy, low median frequency signals identified in this study (Cluster 1) will be assigned to dislocation processes and accomodation processes due to the movement of the α/γ’ interfaces. The high AE energy, high median frequency signals (Cluster 2) are correlated with the nucleation and reverse transformation of martensite.

〈122〉 single crystal. Although the cumulated energy of the signals belonging to Cluster 1 was comparatively low during the first compressive cycle (order of magnitude: 103 arb. units), fine parallel slip lines were detected by means of BSE contrast after unloading (Fig. 12a). Furthermore, irreversible strain fields observed via DIC (Fig. 4b) point towards an incipient plastification of the specimen, even though the stress–strain curve (Fig. 3a) displayed a predominantly elastic loading. The high amount of detected AE signals associated with Cluster 2 points towards the nucleation of martensite during this cycle. It appears, however, that the transient signals recorded between 75 and 90 s (see Fig. 10b) are correlated with the reverse transformation of the martensite, explaining why no traces of residual martensite were found in subsequent microstructural investigations. This assumption agrees well with the partial reversibility of strain observed via DIC (Fig. 4b). In the specimen’s second loading cycle, a significantly higher cumulated energy (order of magnitude: 104 arb. units) of Cluster 1 (i.e. signals associated with dislocation processes) was detected, see Fig. 10d. Interestingly, these signals showed a significantly broader range of the median frequency compared to the same cluster in the first cycle. The larger spread of the signals’ median frequency can be associated with a reduction of the mean free path after a strong increase in the dislocation density during loading [8, 47]. Remarkedly, virtually all of these signals were recorded before the high critical stress σcrit of 910 MPa was reached, see Fig. 10d. Since the rise of these signals’ cumulative energy also preceded the rise of Cluster 2 (i.e. signals associated with the SIMPT), it can be assumed that widespread plasticity preceded the SIMPT. It is known that Fe–Mn–Al–Ni–Ti single crystals with a high density of subgrain boundaries suffer from a lower strain recoverability and exhibit a higher critical stress σcrit compared to single crystals with lower densities of subgrain boundaries [29]. Indeed, Fig. 12a shows that the 〈122〉 single crystal was characterized by a small subgrain size. In addition, it is known that σcrit of the Fe–Mn–Al–Ni alloy system exhibits a distinct dependency on the crystallographic orientation, with orientations close to 〈111〉 showing the highest transformation stresses [10, 14]. The premature plastification of the austenite in the second cycle seems, therefore, to stem from the combination of a high density of subgrain boundaries, a high critical transformation stress (due to an unfavourable orientation) and an increased dislocation density already present after the first cycle. The absence of measureable temperature changes during loading/unloading of the 〈122〉 single crystal was anticipated, given its low length-to-thickness ratio of 2 (as opposed to 15 in case of the tensile specimens). This low ratio leads to an efficient heat dissipation within the specimen.

〈012〉-〈112〉 oligo-crystal. In case of the 〈012〉-〈112〉 oligo-crystal’s tensile loading, an even higher cumulative AE energy of signals belonging to Cluster 1 was observed (order of magnitude: 105 arb. units). The largest part of those signals was detected upon reaching the critical stress σcrit (875 MPa) or immediately afterwards, see Fig. 10f. The initial nucleation of martensite and the subsequent movement of the α/γʹ interface were, therefore, accompanied by a widespread and strong nucleation and movement of dislocations. Due to the similar acoustic profile of the (i) accomodation processes resulting from the movement of the α/γʹ interface and (ii) dislocation slip, no concise distinction can be made between these cluster elements in terms of their acoustic emission [8]. However, since a high density of pronounced slip lines was observed after unloading (see Fig. 13b), it stands to reason that a widespread movement of dislocations did indeed accompany the SIMPT. This is linked to the 〈112〉 oriented grain’s detrimentally high transformation stress and the subsequent premature plasitification of the austenite. The cumulative energy of Cluster 1 rose simultaneously with the cumulative energy of Cluster 2, suggesting a direct coupling of dislocation processes and martensite nucleation events during the SIMPT. Although the specimen showed a macroscopically poor reversibility of strain (due to the widespread nucleation of dislocations and the pinning of martensite lamellae, see Fig. 13c), the high amount of AE signals detected during unloading which were associated with Cluster 2 indicates a multitude of local reverse transformation processes. This assumption can be affirmed by the DIC (Fig. 5c), as well as the distinct cooling of the 〈112〉 oriented grain upon unloading (Fig. 7f). A particularly striking feature of the signals belonging to Cluster 1 is their high cumulative AE energy, since the nucleation and movement of dislocations are normally described as a rather low energy processes when compared to the SIMPT [40, 44, 48]. Although the majority of the dislocations were generated simultaneously with the martensite, the large grain size of the previously undeformed 〈112〉 oriented grain resulted in an initially large mean free path for the dislocations in multiple slip systems [47, 49, 50]. Consequently, a high amount of slip lines extending through a major part of the specimen’s cross section was observed in the 〈112〉 oriented grain, see Fig. 13b. A few similarly dominant slip lines were also observed after the 〈122〉 single crystal’s second compressive loading cycle, since in that case the newly activated slip systems were characterized by large mean free paths as well (see Fig. 12b). These kinds of far-reaching slip lines which were formed prior to the widespread SIMPT contributed greatly to the 〈012〉-〈112〉 oligo-crystal’s high AE energy of Cluster 1.

To the best of the authors’ knowledge, no decisive reason can be given as to why no martensite or signs of slip were observed in the 〈012〉 oriented grain. Investigations on Cu-based SMAs revealed a sequential SIMPT—initiating in the most favourably oriented grain—as a characteristic deformation behaviour for oligo-crystals [51]. This was also observed in a recent study on Fe–Mn–Al–Ni, where an oligo-crystal with very similar grain orientations compared to the 〈012〉-〈112〉 oligo-crystal of the present study exhibited an excellent SE up to an applied strain of 4.5% [10]. In that study’s case, the SIMPT was initiated in the bulk of a near 〈011〉 oriented grain, while for a near 〈111〉 oriented grain remnants of martensite and dislocation glide were only observable in the immediate vicinity of a HAGB. Thus, when considering experimental references [10, 13, 14], theoretical approaches [22], as well as the significantly higher Schmid factors of the 〈012〉 oriented grain, one would expect the SIMPT to be initiated in the more favourably oriented 〈012〉 grain rather than in the 〈112〉 oriented grain. It is furthermore remarkable that no signs of slip or martensite were observed at the HAGB (cf. Supplementary Fig. A.1b), since such grain boundaries are known to present stress concentrations susceptible to slip initiation or martensite nucleation [10, 23, 36]. It is known that the density of subgrain boundaries can have an influence on the transformation behaviour of Fe–Mn–Al–Ni–Ti [29]. However, no significant differences between the investigated specimens’ subgrain sizes—which would explain the favoured transformation in the 〈012〉 oriented grain—were apparent. This is also exemplified in Supplementary Fig. A.1 and detailed in the Supplementary discussion. In addition, comparative TEM investigations using FIB lamellae lifed out from the 〈012〉 oriented grains of both investigated oligo-crystals were conducted in order to determine differences in the B2 precipitates’ volume fraction and/or size distribution which might be reasons for the different transformation behaviours of the two specimens. These precipitates are known to affect the SE of Fe-based SMAs [17, 31, 52, 53]. The results of the TEM investigations are shown in Supplementary Fig. A.2 and Supplementary Fig. A.3 and are detailed in the Supplementary discussion. A comparable volume fraction and size distribution of the precipitates in the 〈012〉 oriented grains of both oligo-crystals were found. An indication for a stronger incoherence between α-matrix and β-precipitates in case of the 〈012〉-〈124〉 oligo-crystal was observed by means of selected area electron diffraction (SAED) investigations. Further examinations which would allow for a conclusive interpretation of these results are, however, outside of this study’s scope. Therefore, it has to be concluded that neither significant differences in the subgrain density nor differing volume fractions and/or size distributions of the β-particles can offer an explanation for the abnormal transformation behaviour of the 〈012〉-〈112〉 oligo-crystal.

〈012〉-〈124〉 oligo-crystal. Figure 15a shows the evolution of the AE energy vs. median frequency plot of Cluster 1 for all tensile loading cycles of the 〈012〉-〈124〉 oligo-crystal. As already discussed, these signal waveforms can be attributed to the nucleation and motion of dislocations as well as the accommodation processes due to the movement of the α/γ’ interfaces [8, 40, 44,45,46, 49]. Figure 15a reveals that these signals show a shift towards higher median frequencies with an increasing number of loading cycles. This phenomenon is already documented in the literature for a variety of materials and reflects the increase in dislocation density and the concomitant decrease of the dislocations’ mean free path upon progressive cycling [47, 54,55,56]. Hence, the increase in dislocation density in a progressively cycled Fe–Mn–Al–Ni–Ti SMA is indirectly detectable via the shift of the median frequency of the AE signals. Figure 15b displays the evolution of Cluster 2 (i.e. signals associated with SIMPT) for all tensile loading cycles of the 〈012〉-〈124〉 oligo-crystal. The median frequency of those signals remains nearly constant, although the energy decreases with an increasing number of loading cycles. The decrease in AE energy can be explained by the ongoing martensite stabilization. With an increasing amount of stabilized martensite, the martensitic bands nucleating between the stabilized martensitic regions become successively smaller, whereby their emitted acoustic energy decreases as well [8]. This is also reflected in the significantly lower amount of high energy transient signals recorded during loading of the fifth cycle as compared to the second cycle.

Similar conclusions have been drawn by Weidner et al. [8] who studied the compressive deformation of a 〈001〉 oriented Fe–Mn–Al–Ni single crystal using AE investigations. These examinations revealed that the median frequencies of signals which were associated with dislocation processes shifted towards higher frequencies with an increasing number of loading cycles, thereby indicating the advancing functional degradation. In contrast, the median frequency of signals associated with the SIMPT remained almost constant, while the energy of these signals decreased with an increasing number of cycles. As already mentioned, it is difficult to differentiate the reasons that cause the increase in dislocation density during the cyclic loading of Fe-based SMAs. While the early onset of plasticity in the austenite contributed to the high dislocation density in case of the poorly reversible 〈122〉 single crystal and the 〈012〉-〈112〉 oligo-crystal, no evidence for such extensive premature plasticity was found for the superiorly reversible 〈012〉-〈124〉 oligo-crystal. This is because the SIMPT was initiated in the 〈012〉 oriented grain of the 〈012〉-〈124〉 oligo-crystal, which is characterized by a significantly lower critical stress σcrit. Thus, the majority of the signals associated with dislocation activites were measured after reaching σcrit, illustrating the higher significance of acommodation processes at the evolving α/γʹ interfaces and dislocation nucleation events due to martensite–martensite interactions. Furthermore, it should be noted that the cumulative AE energy of Cluster 1 (order of magnitude: 104 arb. units) rose continuously without any transient increments. This agrees well with the fact that no pronounced slip lines covering large areas of the entire gauge length were observed in case of the 〈012〉-〈124〉 oligo-crystal. Due to a lower σcrit, no premature plasticity ocurred in the austenite and favourable martensite variants nucleated in a comparatively undeformed microstructure in slip systems exhibiting the highest Schmid factors. However, the pronounced asymmetry of high energy transient signals during loading/unloading of the fifth cycle highlights the advanced stabilization of those variants. The progressive increase in the dislocation density of this specimen can, thus, be ascribed to the increasingly frequent variant–variant interactions and a progressive splitting of the martensite structures. This stabilization by means of variant–variant interactions, local dislocation generation in regions surrounding those interaction sites and a resulting fragmentation of formerly large martensite plates into numerous smaller ribbons is a known degradation mechanism in Fe-based SMAs [8, 10, 33]. Thus, the observed deterioration mechanism of the 〈012〉-〈124〉 oligo-crystal’s SE falls in line with previous investigations and appears to be characteristic for favourably oriented Fe–Mn–Al–Ni-based SMAs [8, 10].

Complementary In Situ Observation of the Degrading SE in the 〈012〉-〈124〉 Oligo-Crystal

Besides an increase in the cumulative irreversible strain, a broadening of the maximum hysteresis width ΔσH and a minor decrease of σcrit were measured upon the cycling of the 〈012〉-〈124〉 oligo-crystal, see Fig. 3d. The continuous broadening of the hysteresis width is mainly due to the increasing load. However, it can also be associated with an increasing dislocation activity and ensuing functional degradation [11, 57]. Similarly, a decrease in σcrit points towards a progressive stabilization of certain martensite variants due to dislocation generation at the α/γʹ interfaces [8, 33]. The strain distributions obtained via DIC (Fig. 6) reveal that the majority of the SIMPT was limited to the 〈012〉 oriented grain and that an increase in applied strain led to a broadening of the strain band caused by the SIMPT. Microstructural investigations in the SEM confirmed that the SIMPT was almost entirely confined to the 〈012〉 oriented grain, see Fig. 14a. Nevertheless, due to strain constraints at the HAGB stemming from the high misorientation angle between the grains (57°), stress concentrations seemed to cause the nucleation of diversely oriented martensitic lamellae on both sides of the HAGB, see Fig. 14b. This observation is known from other publications as well [23, 36, 51]. While the remnant martensite lamellae from the interior of the 〈012〉 oriented grain coincided well with the slip planes calculated for the primary and secondary slip systems of a bcc iron phase, a multitude of differently oriented variants were nucleated in the vicinity of the HAGB, which points towards the presence of complex local stress states.

In situ thermographic measurements of the specimen revealed a characterisitic evolution of the temperature distribution upon loading and unloading during all five tensile cycles. The exemplary thermograms shown in Fig. 8 highlight the local temperature increase in the left part of the gauge section as a consequence of the exothermic SIMPT. Due to the low change in entropy (ΔS ~ − 0.4 J mol−1 K−1 [2]) caused by the martensitic transformation, Fe–Mn–Al–Ni-based SMAs exhibit a comparatively low transformation-induced temperature change. Futhermore, due to the lack of pronounced stress drops caused by the initial transformation of a large martensitic volume, no sudden temperature increase was measured as was done in reference [10]. Instead, the temperature rose gradually up to a maximum increase of 2 K at maximum load, see Fig. 8d. Upon unloading, a distinct cooling in relation to the state of maximum load was measured due to the endothermic reverse transformation in this grain. Similar thermography results have been obtained for the SMAs Ni–Ti [37] and Cu-Al-Be [38], although the transformation-induced temperature changes were significantly larger due to the higher underlying entropy changes [58, 59]. In the present study, a characteristic stress increment was observed during the transition period from the γʹ → α reverse transformation to the elastic unloading regime of the α phase. Figure 9 displays the temperature evolution in the course of the second loading cycle’s stress increment. The distinct change in the unloading slope is correlated with the nucleation of a band of lower temperatures indicating a sudden cooling event in the middle of the 〈012〉 oriented grain. While the local cooling increased in intensity and lateral size, the stress increased as well. As soon as the maximum of the stress increment was reached, the local cooling decreased during the elastic unloading of the austenite. Similar stress increments have been observed upon unloading of Ni–Ti SMAs [60, 61]. In these studies, the increase in stress was associated with local energy barriers which have to be overcome in order to complete the reverse transformation. While some preferential martensite variants underwent a reverse transformation to the austenite directly at the beginning of the unloading step, local stress fields might hinder other variants from transforming back into the parent phase. With the macroscopic stress decreasing continuously, a stress increment at the end of the reverse transformation phase might become necessary in order to overcome local stresses around specific martensite variants or at specific austenite/martensite interfaces [60]. This hypothesis coincides well with the temperature distributions measured during the stress increment. Furthermore, the large number of high voltage acoustic signals observed in this regime confirms a high microstructural activity during this short period, see Fig. 10h. All of these recorded AE signals were assigned to Cluster 2, indicating pronounced microstructural processes related to the reverse transformation of martensite. The sudden decrease in temperature at the very beginning of the stress increment (Fig. 9d–f) was, therefore, caused by the reverse transformation of large martensitic plates. The continuously rising stress points towards an increasing resistance against the reverse transformation of further martensitic lamellae until all the martensitic volume fraction which is capable of a reverse transformation has transformed, leaving behind the residual, stabilized martensite observable after unloading. The intensity of this stress increment was most distinct in the second loading cycle, see Fig. 3c. It can be assumed that certain martensite variants which strongly resisted a reverse transformation in the second cycle were not formed in the first cycle due to the lower maximum appplied strain. After the second cycle, these variants’ resistance against a reverse transformation seemed to decline rapidly, suggesting a fast stabilization of martensite due to the interaction of different variants and concomitant dislocation generation (see Fig. 14a). As a result, the transient signals recorded during the stress increments in subsequent cycles decreased significantly to a point, where no distinctive stress increment occurred at all, see the fifth cycle (see Fig. 11).

Summary

The superelastic material behaviour of selected Fe–Mn–Al–Ni–Ti specimens—i.e. a 〈122〉 single crystal, a 〈012〉-〈112〉 oligo-crystal and a 〈012〉-〈124〉 oligo-crystal—was characterized by a combination of in situ measurement techniques such as acoustic emission, digital image correlation and infrared thermography. The central findings are summarized as follows:

-

Due to a high critical transformation stress of 910 MPa, the 〈122〉 single crystal experienced a premature plastification of the austenite before a martensitic phase transformation was initiated. Consequently, the specimen suffered from a limited strain reversibility with an applied strain of 6% leading to an irreversible strain of 3.1%.

-

The 〈012〉-〈112〉 oligo-crystal was characterized by an unusual transformation behaviour with the martensitic phase transformation being initiated in the 〈112〉 oriented grain—which is considered to be less favourably oriented than the 〈012〉 oriented grain. No conclusive explanation can be given for this anomaly. Due to the high critical transformation stress of the 〈112〉 oriented grain (875 MPa), the AE analysis displayed a pronounced dislocation nucleation concomitant with the nucleation of martensite. Loading up to an applied strain of 2% resulted in an irreversible strain of 0.5%.

-

The 〈012〉-〈124〉 oligo-crystal displayed a pronounced superelastic behaviour up to an applied strain of 3.4%. Due to the significantly lower critical stress of 615 MPa, no premature plastification of the austenite was observed and dislocation movement was restricted to accommodation processes at the α/γ’ interface or at martensite-martensite interaction sites.

-

For both oligo-crystals, a local heating and a local cooling were observed via thermography due to the exothermic martensitic transformation and the endothermic reverse transformation, respectively.

-

Two clusters of AE signals were identified for all investigated specimens, similar to previous studies [8, 44]: (i) Cluster 1, comprising low AE energy / low median frequency signals associated with dislocation motion; (ii) Cluster 2, comprising high AE energy / high median frequency signals associated with processes of martensite nucleation and reverse transformation.

-

The degradation of the 〈012〉-〈124〉 oligo-crystal’s superelasticity was correlated with a shift of signals belonging to Cluster 1 towards higher median frequencies, thereby indicating a decrease in the dislocations’ mean free path. In contrast, signals belonging to Cluster 2 showed a decrease in the emitted acoustic energy caused by an advancing stabilization of martensite upon cycling.

References

Tanaka Y, Himuro Y, Kainuma R et al (2010) Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 327:1488–1490. https://doi.org/10.1126/science.1183169

Omori T, Ando K, Okano M et al (2011) Superelastic effect in polycrystalline ferrous alloys. Science 333:68–71. https://doi.org/10.1126/science.1202232

Janke L (2005) Applications of shape memory alloys in civil engineering structures—overview, limits and new ideas. Mater Struct 38:578–592. https://doi.org/10.1617/14323

Cladera A, Weber B, Leinenbach C et al (2014) Iron-based shape memory alloys for civil engineering structures: an overview. Constr Build Mater 63:281–293. https://doi.org/10.1016/j.conbuildmat.2014.04.032

Czaderski C, Shahverdi M, Brönnimann R et al (2014) Feasibility of iron-based shape memory alloy strips for prestressed strengthening of concrete structures. Constr Build Mater 56:94–105. https://doi.org/10.1016/j.conbuildmat.2014.01.069

Fang C, Wang W, Ji Y et al (2021) Superior low-cycle fatigue performance of iron-based SMA for seismic damping application. J Constr Steel Res 184:106817. https://doi.org/10.1016/j.jcsr.2021.106817

Sidharth R, Wu Y, Brenne F et al (2020) Relationship between functional fatigue and structural fatigue of iron-based shape memory alloy FeMnNiAl. Shape Mem Superelasticity 6:256–272. https://doi.org/10.1007/s40830-020-00283-1

Weidner A, Vinogradov A, Vollmer M et al (2021) In situ characterization of the functional degradation of a [00-1] oriented Fe–Mn–Al–Ni single crystal under compression using acoustic emission measurements. Acta Mater 220:11733. https://doi.org/10.1016/j.actamat.2021.117333

Poklonov V, Kuksgauzen IV, Chumlyakov Y et al (2020) Superelasticity and its cyclic stability in [001]-oriented single crystals and oligocrystals of FeMnAlNi alloy in compression. Lett Mater 10:78–82. https://doi.org/10.22226/2410-3535-2020-1-78-82

Lehnert R, Müller M, Vollmer M et al (2023) On the influence of crystallographic orientation on superelasticity—Fe–Mn–Al–Ni shape memory alloys studied by advanced in situ characterization techniques. Mater Sci Eng A 871:144830. https://doi.org/10.1016/j.msea.2023.144830

Vollmer M, Krooß P, Kriegel MJ et al (2016) Cyclic degradation in bamboo-like Fe–Mn–Al–Ni shape memory alloys—the role of grain orientation. Scripta Mater 114:156–160. https://doi.org/10.1016/j.scriptamat.2015.12.007

Vollmer M, Kriegel MJ, Krooß P et al (2017) Cyclic degradation behavior of <001>-oriented Fe–Mn–Al–Ni single crystals in tension. Shape Mem Superelasticity 3:335–346. https://doi.org/10.1007/s40830-017-0117-0

Tseng LW, Ma J, Wang SJ et al (2016) Effects of crystallographic orientation on the superelastic response of FeMnAlNi single crystals. Scripta Mater 116:147–151. https://doi.org/10.1016/j.scriptamat.2016.01.032