Abstract

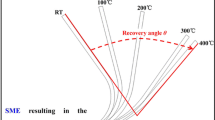

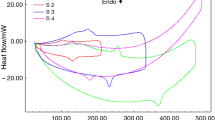

The solvus temperature of face-centered cubic (FCC) phase in Fe–34Mn–xAl–4Cr–7.5Ni (x = 13, 14, and 15) shape memory alloys with different Al contents, and their abnormal grain growth and superelasticity at various temperatures were evaluated. With increasing Al content, the solvus temperature of the FCC phase decreased and the FCC precipitates became finer. Whereas cyclic heat treatment induced abnormal grain growth (AGG) in all samples, large grains were obtained more easily in the alloys with higher Al content. The critical stress for martensitic transformation increased with increasing Al content. The x = 14 alloy is the optimal composition considering grain growth and superelasticity. The newly developed Fe–34Mn–14Al–4Cr–7.5Ni alloy, in which single-crystal can easily be fabricated by AGG, exhibited superelasticity at temperatures ranging from − 263 °C (10 K) to 27 °C (300 K), with a very small temperature-dependence of the critical stress, comparable to that of conventional Fe–34Mn–13.5Al–3Cr–7.5Ni alloy.

Similar content being viewed by others

References

Dunne DP, Wayman CM (1973) The effect of austenite ordering on the martensite transformation in Fe-Pt alloys near the composition Fe3Pt: I. Morphology and transformation characteristics Metall Trans 4:137–145

Sohmura T, Oshima R, Fujita FE (1980) Thermoelastic FCC-FCT martensitic transformation in Fe-Pd alloy. Scr Metall 14:855–856

Maki T, Kobayashi K, Minato M, Tamura I (1984) Thermoelastic martensite in an ausaged Fe-Ni-Ti-Co alloy. Scr Metall 18:1105–1109

Tanaka Y, Himuro Y, Kainuma R et al (2010) Ferrous polycrystalline shape-memory alloys showing huge superelasticity. Science 327:1488–1490

Omori T, Abe S, Tanaka Y et al (2013) Thermoelastic martensitic transformation and superelasticity in Fe–Ni–Co–Al–Nb–B polycrystalline alloy. Scr Mater 69:812–815

Lee D, Omori T, Kainuma R (2014) Ductility enhancement and superelasticity in Fe–Ni–Co–Al–Ti–B polycrystalline alloy. J Alloys Compd 617:120–123

Sato A, Chishima E, Soma K, Mori T (1982) Shape memory effect in γ⇄ϵ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall 30:1177–1183

Sawaguchi T, Maruyama T, Otsuka H et al (2016) Design concept and applications of Fe-Mn-Si-based alloys-from shape-memory to seismic response control. Mater Trans 57:283–293

La Roca P, Baruj A, Sade M (2017) Shape-memory effect and pseudoelasticity in Fe–Mn-based alloys. Shape Mem Superelasticity 3:37–48

Omori T, Watanabe K, Umetsu RY et al (2009) Martensitic transformation and magnetic field-induced strain in Fe-Mn-Ga shape memory alloy. Appl Phys Lett 95:27–30

Zhu W, Liu EK, Feng L et al (2009) Magnetic-field-induced transformation in FeMnGa alloys. Appl Phys Lett 95:e222512

Omori T, Ando K, Okano M et al (2011) Superelastic effect in polycrystalline ferrous alloys. Science 333:68–71

Lee D, Omori T, Han K et al (2018) Effect of thermomechanical processing on texture and superelasticity in Fe–Ni-Co-Al–Ti-B alloy. Shape Mem Superelasticity 4:102–111

Zhang C, Zhu C, Shin S, Vecchio K (2018) Enhancement of <001> recrystallization texture in non-equiatomic Fe-Ni-Co-Al-based high entropy alloys by combination of annealing and Cr addition. J Alloys Compd 768:277–286

Lee D, Omori T, Han K et al (2020) Texture formation in a polycrystalline Fe–Ni–Co–Al–Ti–B shape memory alloy. ISIJ Int 60:2973–2982

Sobrero CE, Lauhoff C, Wegener T et al (2020) On the impact of texture and grain size on the pseudoelastic properties of polycrystalline Fe–Ni–Co–Al–Ti alloy. Shape Mem Superelasticity 6:191–201

Ma J, Hornbuckle BC, Karaman I et al (2013) The effect of nanoprecipitates on the superelastic properties of FeNiCoAlTa shape memory alloy single crystals. Acta Mater 61:3445–3455

Tseng LW, Ma J, Karaman I et al (2015) Superelastic response of the FeNiCoAlTi single crystals under tension and compression. Scr Mater 101:1–4

Chumlyakov YI, Kireeva IV, Kuts OA et al (2015) Shape memory effect and superelasticity in [001] single crystals of Fe–Ni–Co–Al–Nb(B) ferromagnetic alloy. Russ Phys J 58:889–897

Ando K, Omori T, Ohnuma I et al (2009) Ferromagnetic to weak-magnetic transition accompanied by bcc to fcc transformation in Fe-Mn-Al alloy. Appl Phys Lett 95:e212504

Omori T, Nagasako M, Okano M et al (2012) Microstructure and martensitic transformation in the Fe-Mn-Al-Ni shape memory alloy with B2-type coherent fine particles. Appl Phys Lett 101:e231907

Tseng LW, Ma J, Wang SJ et al (2015) Superelastic response of a single crystalline FeMnAlNi shape memory alloy under tension and compression. Acta Mater 89:374–383

Xia J, Xu X, Miyake A et al (2017) Stress- and magnetic field-induced martensitic transformation at cryogenic temperatures in Fe–Mn–Al–Ni shape memory alloys. Shape Mem Superelasticity 3:467–475

Omori T, Okano M, Kainuma R (2013) Effect of grain size on superelasticity in Fe-Mn-Al-Ni shape memory alloy wire. APL Mater 1:e032103

Tseng LW, Ma J, Vollmer M et al (2016) Effect of grain size on the superelastic response of a FeMnAlNi polycrystalline shape memory alloy. Scr Mater 125:68–72

Tseng LW, Ma J, Hornbuckle BC et al (2015) The effect of precipitates on the superelastic response of [100] oriented FeMnAlNi single crystals under compression. Acta Mater 97:234–244

La Roca P, Baruj A, Sobrero CE et al (2017) Nanoprecipitation effects on phase stability of Fe-Mn-Al-Ni alloys. J Alloys Compd 708:422–427

Ozcan H, Ma J, Wang SJ et al (2017) Effects of cyclic heat treatment and aging on superelasticity in oligocrystalline Fe-Mn-Al-Ni shape memory alloy wires. Scr Mater 134:66–70

Tseng LW, Ma J, Wang SJ et al (2016) Effects of crystallographic orientation on the superelastic response of FeMnAlNi single crystals. Scr Mater 116:147–151

Poklonov VV, Chumlyakov YI, Kireeva IV, Kirillov VA (2018) Superelastic response in <1 2 2>-oriented single crystals of FeMnAlNi shape memory alloy in tension and compression. Mater Lett 233:195–198

Tseng LW, Ma J, Chumlyakov YI, Karaman I (2019) Orientation dependence of superelasticity in FeMnAlNi single crystals under compression. Scr Mater 166:48–52

Omori T, Kusama T, Kawata S et al (2013) Abnormal grain growth induced by cyclic heat treatment. Science 341:1500–1502

Kusama T, Omori T, Saito T et al (2017) Ultra-large single crystals by abnormal grain growth. Nat Commun 8:354

Omori T, Iwaizako H, Kainuma R (2016) Abnormal grain growth induced by cyclic heat treatment in Fe-Mn-Al-Ni superelastic alloy. Mater Des 101:263–269

Vollmer M, Arold T, Kriegel MJ et al (2019) Promoting abnormal grain growth in Fe-based shape memory alloys through compositional adjustments. Nat Commun 10:2337

Vollmer M, Bauer A, Frenck J-M et al (2021) Novel prestressing applications in civil engineering structures enabled by Fe-Mn-Al-Ni shape memory alloys. Eng Struct 241:e112430

Vollmer M, Krooß P, Karaman I, Niendorf T (2017) On the effect of titanium on quenching sensitivity and pseudoelastic response in Fe-Mn-Al-Ni-base shape memory alloy. Scr Mater 126:20–23

Xia J, Omori T, Kainuma R (2020) Abnormal grain growth in Fe–Mn–Al–Ni shape memory alloy with higher Al content. Scr Mater 187:355–359

Vallejos JM, Giordana MF, Sobrero CE, Malarria JA (2020) Excellent pseudoelasticity of Al-rich Fe–33Mn–17Al–6Ni–0.15C (at%) shape memory single crystals obtained without an aging conditioning stage. Scr Mater 179:25–29

Walnsch A, Kriegel MJ, Motylenko M et al (2021) Thermodynamics of martensite formation in Fe–Mn–Al–Ni shape memory alloys. Scr Mater 192:26–31

Walnsch A, Kriegel MJ, Fischer PDB et al (2021) Nanoscale twinning and superstructures of martensite in the Fe–Mn–Al–Ni system. Materialia 16:e101062

Umino R, Liu XJ, Sutou Y et al (2006) Experimental determination and thermodynamic calculation of phase equilibria in the Fe-Mn-Al system. J Phase Equilibria Diffus 27:54–62

Villars. P, Prince. A, Okamoto. H (eds) 1995 Handbook of ternary alloy phase diagrams, Materials Park (Ohio), American Society for Metals, 7:8777

Noguchi Y, Omori T, Kainuma R (2017) Effects of Cr on martensitic transformation and oxidation resistance in Fe-Mn-Al-Ni alloys. In: International conference on martensitic transformations (ICOMAT-2017)

Xia J, Noguchi Y, Xu X et al (2020) Iron-based superelastic alloys with near-constant critical stress temperature dependence. Science 369:855–858

Ozcan H (2018) Private Communication

Xia J (2021) Development of novel Fe-Mn-Al-Ni based superelastic alloy system with tunable temperature-dependence on transformation stress. Doctor Thesis, Tohoku University.

Hao SM, Takayama T, Ishida K, Nishizawa T (1984) Miscibility gap in Fe-Ni-Al and Fe-Ni-Al-Co systems. Metall Trans A 15:1819–1828

Hao SM, Ishida K, Nishizawa T (1985) Role of alloying elements in phase decomposition in alnico magnet alloys. Metall Trans A 16:179–185

Kainuma R, Ise M, Ishikawa K et al (1998) Phase equilibria and stability of the B2 phase in the Ni-Mn-Al and Co-Mn-Al systems. J Alloys Compd 269:173–180

Niitsu K, Xu X, Umetsu RY, Kainuma R (2013) Stress-induced transformations at low temperatures in a Ni45Co5Mn36In14 metamagnetic shape memory alloy. Appl Phys Lett 103:e242406

Ozcan H, Ma J, Karaman I et al (2018) Microstructural design considerations in Fe-Mn-Al-Ni shape memory alloy wires: Effects of natural aging. Scr Mater 142:153–157

Abuzaid W, Wu Y, Sidharth R, Brenne F, Alkan S, Vollmer M, Krooß P, Niendorf T, Sehitoglu H (2019) Shape Mem Superelasticity 5:263–277

Frenck JM, Vollmer M, Mandel M et al (2021) On the Influence of Microstructure on the Corrosion Behavior of Fe–Mn–Al–Ni Shape Memory Alloy in 5.0 wt% NaCl Solution. Adv Eng Mater 23:1–9

Mandel M, Kietov V, Hornig R et al (2021) On the polarisation and Mott-Schottky characteristics of an Fe-Mn-Al-Ni shape-memory alloy and pure Fe in NaCl-free and NaCl-contaminated Ca(OH)2, sat solution—A comparative study. Corros Sci 179:e109172

Yuan X, Zhao Y, Li X, Chen L (2017) Effect of Cr on mechanical properties and corrosion behaviors of Fe-Mn-C-Al-Cr-N TWIP steels. J Mater Sci Technol 33:1555–1560

Acknowledgements

This study was supported by JSPS KAKENHI grant 15H05766. JX appreciates the experimental support provided by Dr. K. Kobayashi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in Shape Memory and Superelasticity on Fe-Based Shape Memory Alloys. This issue was organized by Dr. Toshihiro Omori and Dr. Ryosuke Kainuma, Tohoku University.

Rights and permissions

About this article

Cite this article

Xia, J., Hoshi, T., Xu, X. et al. Effect of Al Content on Abnormal Grain Growth and Superelasticity in Fe–Mn–Al–Cr–Ni Shape Memory Alloys with Near-Zero Temperature-Dependence of Transformation Stress. Shap. Mem. Superelasticity 7, 402–413 (2021). https://doi.org/10.1007/s40830-021-00349-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-021-00349-8