Abstract

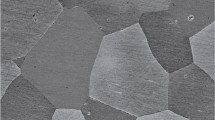

The use of shape memory alloys for micro-actuators constitutes a field of application in which copper–aluminum-based alloys find their usefulness because they can reach higher activation temperatures and are easier to produce than titanium-based alloys, particularly by the method proposed in this work. SMA tapes are a two-dimensional structure that offers many design options such as stamping, punching, and deep drawing, but they are also suitable for laser cutting, engraving, stamping, and EDM machining. This work has been made to study the manufacture of copper-based shape memory alloys (SMAs) using the cold co-rolling process also called the cold-roll bonding (CRB) process. In this process, a thin metal sandwich can be produced with a rolling machine. This sandwich consists of layers of CuNiBe master alloy and Al. During the rolling phase, the sandwich has no shape memory effect (SME) or superelastic effect (SE), so thin strips can be easily produced. After the rolling phase, the sandwich is subjected to a complex heat treatment to gain the SME. To validate this process to produce Cu-based SMAs, several alloys with different CuAlNiBe compositions have been tested. The SMAs obtained were characterized by optical microscopy, scanning electron microscopy (SEM) and X-ray diffraction (XRD) techniques. The martensitic transformation was studied by Differential Scanning Calorimetry (DSC) and SME and SE were studied by three-point bending tests. This work shows that the CRB is a good process for making a wide variety of Cu-based SMA ribbons.

Similar content being viewed by others

References

Pattor E, Berveiller M (1994) Technologie des Alliages à Mémoire de Forme. Hermès

Elmay W, Patoor E, Gloriant T et al (2014) Improvement of superelastic performance of Ti-Nb binary alloys for biomedical applications. J Mater Eng Perform 23:2471–2476. https://doi.org/10.1007/s11665-014-0876-0

Reis R, Gonzalez CH (2008) Fabrication of shape memory alloys using the plasma skull push/pull process. J Mater Process Technol 9:3657–3664. https://doi.org/10.1016/j.jmatprotec.2008.08.025

Vajpai SK, Dube RK, Chatterjee P et al (2012) A novel powder metallurgy processing approach to prepare fine-grained Cu-Al-Ni shape memory alloy strips from elemental powders. Metall Mater Trans A. https://doi.org/10.1007/s11661-012-1081-0

Agrawal A, Dube RK (2018) Methods of fabricating Cu-Al-Ni shape memory alloys. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2018.03.390

Fischer M, Joguet D, Robin G et al (2016) In situ elaboration of a binary Ti-26Nb alloy by selective laser melting of elemental titanium and niobium mixed powders. Mater Sci Eng C. https://doi.org/10.1016/j.msec.2016.02.033

Fischer M, Laheurte P, Acquier P et al (2017) Synthesis and characterization of Ti-27.5Nb alloy made by CLAD® additive manufacturing process for biomedical applications. Mater Sci Eng C. https://doi.org/10.1016/j.msec.2017.02.060

Lojen G, Anzel I, Kneissl A et al (2005) Microstructure of rapidly solidified Cu–Al–Ni shape memory alloy ribbons. J Mater Process Technol 163:220–229. https://doi.org/10.1016/j.jmatprotec.2005.02.196

Frémond M (1996) Shape memory alloy. In: Shape Memory Alloys. International Centre for Mechanical Sciences (Courses and Lectures), vol 351. Springer, Vienna. https://doi.org/10.1007/978-3-7091-4348-3_1

Cuniberti A, Montecinos S, Lovey FC (2009) Effect of γ2-phase precipitates on the martensitic transformation of a β-CuAlBe shape memory alloy. Intermetallics 17:435–440. https://doi.org/10.1016/j.intermet.2008.12.001

Mukunthan K, Brown LC (1988) Preparation and properties of fine grain β-CuAlNi strain-memory alloys. Metall Trans A 19:2921–2929. https://doi.org/10.1007/BF02647718

Kenji ADACHl, (1989) Formation of X phases and origin of grain refinement effect in Cu-Al-Ni shapememoryalloys added with titanium. ISIJ Int 29:378–387

Kim JW, Roh DW, Lee ES, Kim YG (1990) Effects on microstructure and tensile properties of a zirconium addition to a Cu-Al-Ni shape memory alloy. Metall Trans A 21:741–744. https://doi.org/10.1007/BF02671945

Vajpai SK, Dube RK, Sangal S (2011) Processing and characterization of Cu-Al-Ni shape memory alloy strips prepared from prealloyed powder by hot densification rolling of powder preforms. Metall Mater Trans A. https://doi.org/10.1007/s11661-011-0728-6

Xu H, Song G, Mao X (2011) Influence of Be and Ni to Cu-Al alloy shape memory performance. Adv Mater Res 198:1258–1262. https://doi.org/10.4028/www.scientific.net/AMR.197-198.1258

Zhu M, Ye X, Li C et al (2009) Preparation of single crystal CuAlNiBe SMA and its performances. J Alloy Compd 478:404–410. https://doi.org/10.1016/j.jallcom.2008.11.051

Recarte V, Pérez-Sáeza R, Bocanegra E et al (1999) Dependence of the martensitic transformation characteristics on concentration in Cu–Al–Ni shape memory alloys. Mater Sci Eng A 275:380–384. https://doi.org/10.1016/S0921-5093(99)00302-0

Recarte V, Pérez-Sáeza R, Bocanegra E et al (2001) Influence of Al and Ni concentration on the martensitic transformation in Cu-Al-Ni shape-memory alloys. Metall Mater Trans A. https://doi.org/10.1007/s11661-002-0379-8

Delaey N, Mwamba N (1982) The influence on Ni-content on the Ms-temperature OF Cu-Zn-Al-Ni alloys. J Phys Colloques. https://doi.org/10.1051/jphyscol:19824102

Belkahla S, Zufiiga HF, G G, (1993) Elaboration and characterization of new low temperature shape memory Cu-Al-Be alloys. Mater Sci Eng A 169:119–124

Izadinia M, Dehghani K (2011) Structure and properties of nanostructured Cu-13.2Al-5.1Ni shape memory alloy produced by melt spinning. Trans Nonferrous Met Soc China 21:2037–2043. https://doi.org/10.1016/S1003-6326(11)60969-2

Ergen S, Uzun O, Yilmaz F, Kiliçaslan MF (2013) Shape memory properties and microstructural evolution of rapidly solidified CuAlBe alloys. Mater Charact 80:3–8. https://doi.org/10.1016/j.matchar.2013.03.010

Bay N (1985) Bond strength in cold roll bonding. Ann CIRP 34:221–224

Bay N (1983) Mechanisms producing metallic bonds in cold welding. Weld Res Suppl 62:137–142

Jamaati R, Toroghinejad MR (2011) Cold roll bonding bond strengths: review. Mater Sci Technol 27:1101–1108. https://doi.org/10.1179/026708310X12815992418256

Ghalehbandi SM, Malaki M (2019) Accumulative roll bonding—a review. Appl Sci. https://doi.org/10.3390/app9173627

Scarsbrookt G (1987) The martensitic transformation behaviour and stabilisation Cu-Zn-Al ribbons. Acta-Metallurgica 35:47–56

Alizadeh M, Avazzadeh M (2019) Evaluation of Cu-26Zn-5Al shape memory alloy fabricated by accumulative roll bonding process. Mater Sci Eng A 757:88–94. https://doi.org/10.1016/j.msea.2019.04.092

Alizadeh M, Dashtestaninejad MK (2016) Fabrication of manganese-aluminum bronze as a shape memory alloy by accumulative roll bonding process. JMADE 111:263–270. https://doi.org/10.1016/j.matdes.2016.08.074

Moghaddam AO, Ketabchi M, Afrasiabi Y (2014) Accumulative roll bonding and post-deformation annealing of Cu-Al-Mn shape memory alloy. J Mater Eng Perform 23:4429–4435. https://doi.org/10.1007/s11665-014-1228-9

Inoue H, Ishio M, Takasugi T (2003) Texture of TiNi shape memory alloy sheets produced by roll-bonding and solid phase reaction from elementary metals. Acta Materialia 51:6373–6383. https://doi.org/10.1016/j.actamat.2003.08.009

Ye N, Ren X, Liang J (2020) Microstructure and mechanical properties of Ni/Ti/Al/Cu composite produced by accumulative roll bonding (ARB) at room temperature. Integr Med Res. https://doi.org/10.1016/j.jmrt.2020.03.077

Funamizu Y, Watanabe K (1971) Interdiffusion in the Al–Cu System. Trans Jpn Inst Met 12(3):147–152. https://doi.org/10.2320/matertrans1960.12.147

Bowles CQ (1992) Diffusion bonding of beryllium-copper alloys. J Mater Sc 27:49–54

Schwarz SM, Kempshall BW, Giannuzzi LA (2003) Effects of diffusion induced recrystallization on volume diffusion in the copper-nickel system. Acta Materialia. https://doi.org/10.1016/S1359-6454(03)00082-X

ASTM F 2004 (2008) Standard test method for transformation temperature of nickel-titanium alloys by thermal analysis

ASTM F 2082 (2008) Standard Test Method for Determination of Transformation Temperature of Nickel- Titanium Shape Memory Alloys by Bend and Free Recovery

Paul A, Van Dal MJH, Kodentsov AA, Van Loo FJJ (2004) The Kirkendall effect in multiphase diffusion. Acta Mater 52:623–630. https://doi.org/10.1016/j.actamat.2003.10.007

Paul A (2004) The Kirkendall effect in solid state diffusion. Tech Univ Eindhoven. https://doi.org/10.6100/IR579448

De Oliveira DF, de Lima JSG, Brito ICA et al (2010) Mechanical strength evaluation of a CuAlBe shape memory alloy under different thermal conditions. Mater Sci Forum 643:105–111. https://doi.org/10.4028/www.scientific.net/MSF.643.105

Paper O, Soliman HN, Habib N (2014) Effect of ageing treatment on hardness of Cu-12.5 wt% Al shape memory alloy. Indian J Phys. https://doi.org/10.1007/s12648-014-0480-z

Moreau F, Tidu A, Eberhardt A, Heizmann JJ (1995) Study of CuAlBe shape memory alloy by X-ray diffraction. J Phys IV 5:1–6

Malard B, Sittner P, Berveiller S, Patoor E (2012) Advances in martensitic transformations in Cu-based shape memory alloys achieved by in situ neutron and synchrotron X-ray diffraction methods. Comptes Rendus Phys 13:280–292. https://doi.org/10.1016/j.crhy.2011.12.003

Sharma M, Vajpai SK, Dube RK (2010) Processing and characterization of Cu-Al-Ni shape memory alloy strips prepared from elemental powders via a novel powder metallurgy route. Metall and Mat Trans A. https://doi.org/10.1007/s11661-010-0351-y

Zeifert BH, Salmones J, Cabanas-moreno JG, Calderon HA (2008) Raney-nickel catalysts produced by mechanical alloying. Rev Adv Mater Sci 18:633

Das N, Dey GK, Murty BS, Pabi SK (2005) On amorphization and nanocomposite formation in Al–Ni–Ti system by mechanical alloying. Pramana 65:831–840

Cheniti H, Bouabdallah M, Patoor E (2009) High temperature decomposition of the B1 phase in a Cu–Al–Ni shape memory alloy. J Alloys Compd 476:420–424. https://doi.org/10.1016/j.jallcom.2008.09.003

Al-humairi SSN (2019) Cu-based shape memory alloys: modified structures and their related properties. Recent Adv Metall Eng Electrodepos. https://doi.org/10.5772/intechopen.86193

Acknowledgments

This research was supported by the SMART team of the LEM3 laboratory and Nimesis Technology. The authors want to thank sincerely our colleagues Stephane Boulard and Kévin Musseleck, Quentin and Nathan Peltier who provided help that strongly assisted this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Peltier, L., Perroud, O., Moll, P. et al. Production and Mechanical Properties of Cu-Al-Ni-Be Shape Memory Alloy Thin Ribbons Using a Cold Co-Rolled Process. Shap. Mem. Superelasticity 7, 344–352 (2021). https://doi.org/10.1007/s40830-021-00336-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-021-00336-z