Abstract

With the presence of internal interfaces such as the austenite–martensite interface and the internal twin boundaries in the martensite, shape memory alloys (SMAs) can be employed in passive/active damping applications. Due to the latent heat of transformation, a temperature rise/drop during a load/unload cycle is expected to dynamically couple with the mechanical response of the SMA and influence the stress levels of forward/reverse transformation and thus the hysteretic area (i.e. the dissipated energy). Additionally, the temperature change per cycle is a function of loading frequency due to momentary heat transfer effects. To this end, for the first time, we demonstrate a rate insensitive shape memory alloy system, Fe43.5Mn34Al15Ni7.5 which also exhibits near-zero temperature dependent stress–strain response. Contrastingly, we show that Ni50.8Ti, which is widely used commercially, is highly rate sensitive. With straightforward in situ experiments, complemented with thermomechanical modelling, we pinpoint the key material parameter which dictates frequency sensitivity. The corresponding results are then discussed in the light of different mechanisms contributing to the damping capacity of SMAs.

Similar content being viewed by others

References

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Hartl DJ, Lagoudas DC (2007) Aerospace applications of shape memory alloys. Proc Ins Mech Eng G 221(4):535–552

Janke L, Czaderski C, Motavalli M, Ruth J (2005) Applications of shape memory alloys in civil engineering structures—overview, limits and new ideas. Mater Struct 38(5):578–592

Safranski D, Dupont K, Gall K (2020) Pseudoelastic NiTiNOL in Orthopaedic Applications. Shape Memory and Superelasticity 6(3):332–341

Song S-H, Lee J-Y, Rodrigue H, Choi I-S, Kang YJ, Ahn S-H (2016) 35 Hz shape memory alloy actuator with bending-twisting mode. Sci Rep 6:21118

Duerig TW (2002) The use of superelasticity in modern medicine. MRS Bull 27(2):101–104

Torra V, Martorell F, Lovey FC, Sade ML (2017) Civil engineering applications: specific properties of NiTi thick wires and their damping capabilities. a review. Shap Mem Superelasticity 3(4):403–413

Williams EA, Shaw G, Elahinia M (2010) Control of an automotive shape memory alloy mirror actuator. Mechatronics 20(5):527–534

Karaman I, Basaran B, Karaca HE, Karsilayan AI, Chumlyakov YI (2007) Energy harvesting using martensite variant reorientation mechanism in a NiMnGa magnetic shape memory alloy. Appl Phys Lett 90(17):172505

Pagounis E, Muellner P (2018) materials and actuator solutions for advanced magnetic shape memory devices, ACTUATOR 2018; 16th International Conference on New Actuators, pp. 1–7

Bucsek AN, Nunn W, Jalan B, James RD (2020) energy conversion by phase transformation in the small-temperature-difference regime. Annu Rev Mater Res 50:283–318

Müller I, Xu H (1991) On the pseudo-elastic hysteresis. Acta Metall Mater 39(3):263–271

Blanter MS, Golovin IS, Neuhäuser H, Sinning H-R (2007) Other mechanisms of internal friction, internal friction in metallic materials: a handbook. Springer, Berlin Heidelberg, pp 121–155

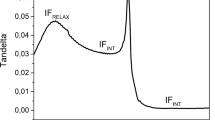

San Juan J, Nó M (2003) Damping behavior during martensitic transformation in shape memory alloys. J alloys compds 355(1–2):65–71

Van Humbeeck J (2001) 5.3 the martensitic transformation. Mater Sci Forum 366–368:382–415

Kumar PK, Lagoudas DC (2008) Introduction to shape memory alloys, shape memory alloys: modeling and engineering applications. Springer, Boston, pp 1–51

Juan JS, Nó ML, Schuh CA (2009) Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat Nanotechnol 4(7):415–419

Bidaux J-E, Schaller R, Benoit W (1989) Study of the hcp-fcc phase transition in cobalt by acoustic measurements. Acta Metall 37(3):803–811

San Juan J, Perez-Saez RB (2001) 5.4 transitory effects. Mater Sci Forum 366–368:416–436

Van Humbeeck J (2003) Damping capacity of thermoelastic martensite in shape memory alloys. J Alloy Compd 355(1):58–64

Segui C, Cesari E, Pons J, Chernenko V (2004) Internal friction behaviour of Ni–Mn–Ga. Mater Sci Eng A 370(1):481–484

Chen Y, Jiang HC, Liu SW, Rong LJ, Zhao XQ (2009) Damping capacity of TiNi-based shape memory alloys. J Alloy Compd 482(1):151–154

He Y, Yin H, Zhou R, Sun Q (2010) Ambient effect on damping peak of NiTi shape memory alloy. Mater Lett 64(13):1483–1486

Dayananda GN, Rao MS (2008) Effect of strain rate on properties of superelastic NiTi thin wires. Mater Sci Eng A 486(1):96–103

Dolce M, Cardone D (2001) Mechanical behaviour of shape memory alloys for seismic applications 2. Austenite NiTi wires subjected to tension. int J Mech Sci 43(11):2657–2677

DesRoches R, McCormick J, Delemont M (2004) Cyclic properties of superelastic shape memory alloy wires and bars. J Struct Eng 130(1):38–46

Nemat-Nasser S, Yong Choi J, Guo W-G, Isaacs JB, Taya M (2005) High strain-rate, small strain response of a NiTi shape-memory alloy. J Eng Mater Technol 127(1):83–89

Malécot P, Lexcellent C, Foltête E, Collet M (2006) Shape memory alloys cyclic behavior: experimental study and modeling. J Eng Mater Technol 128(3):335–345

Tobushi H, Shimeno Y, Hachisuka T, Tanaka K (1998) Influence of strain rate on superelastic properties of TiNi shape memory alloy. Mech Mater 30(2):141–150

Heller L, Šittner P, Pilch J, Landa M (2009) Factors controlling superelastic damping capacity of SMAs. J Mater Eng Perform 18(5):603–611

Yin H, He Y, Sun Q (2014) Effect of deformation frequency on temperature and stress oscillations in cyclic phase transition of NiTi shape memory alloy. J Mech Phys Solids 67:100–128

Zhang X, Feng P, He Y, Yu T, Sun Q (2010) Experimental study on rate dependence of macroscopic domain and stress hysteresis in NiTi shape memory alloy strips. Int J Mech Sci 52(12):1660–1670

Van Humbeeck J, Delaey L (1981) THE influence of strain-rate, amplitude and temperature on the hysteresis of a pseudoelastic Cu-Zn-Al single crystal. J Phys Colloques 42(C5):C5-1007-C5-1011

Hartl DJ, Lagoudas DC (2008) Thermomechanical characterization of shape memory alloy materials, shape memory alloys: modeling and engineering applications. Springer, Boston, pp 53–119

Leo PH, Shield TW, Bruno OP (1993) Transient heat transfer effects on the pseudoelastic behavior of shape-memory wires. Acta Metall Mater 41(8):2477–2485

Shaw JA, Kyriakides S (1995) Thermomechanical aspects of NiTi. J Mech Phys Solids 43(8):1243–1281

Yin H, Yan Y, Huo Y, Sun Q (2013) Rate dependent damping of single crystal CuAlNi shape memory alloy. Mater Lett 109:287–290

Zener C (1938) Internal friction in solids II. General theory of thermoelastic internal friction. Phys Rev 53(1):90

Moumni Z, Herpen AV, Riberty P (2005) Fatigue analysis of shape memory alloys: energy approach. Smart Mater Struct 14(5):S287–S292

Sateesh VL, Senthilkumar P, Satisha, Dayananda GN (2014) Low Cycle fatigue evaluation of NiTi SESMA thin wires. J Mater Eng Perform 23(7):2429–2436

Zhang Y, You Y, Moumni Z, Anlas G, Zhu J, Zhang W (2017) Experimental and theoretical investigation of the frequency effect on low cycle fatigue of shape memory alloys. Int J Plast 90:1–30

Dejonghe W, Batist D (1976) Factors affecting the internal friction peak due to thermoelastic martensitic transformation. Scripta Metallurgica 10:1125–1128

Perez-Saez R, Recarte V, Nó M, San Juan J (1998) Anelastic contributions and transformed volume fraction during thermoelastic martensitic transformations. Phys Rev B 57(10):5684

Mercier O, Melton K (1976) The influence of an anisotrophic elastic medium on the motion of dislocations: application to the martensitic transformation. Scr Metall 10(12):1075–1080

Hornbogen E (1985) The effect of variables on martensitic transformation temperatures. Acta Metall 33(4):595–601

Hornbogen E (2004) Review thermo-mechanical fatigue of shape memory alloys. J Mater Sci 39(2):385–399

Olson G, Cohen M (1975) Thermoelastic behavior in martensitic transformations. Scr Metall 9(11):1247–1254

Roitburd A, Kurdjumov G (1979) The nature of martensitic transformations. Mater Sci Eng 39(2):141–167

Bhattacharya K (2003) Microstructure of martensite: why it forms and how it gives rise to the shape-memory effect. Oxford University Press, Oxford

Bhattacharya K, Conti S, Zanzotto G, Zimmer J (2004) Crystal symmetry and the reversibility of martensitic transformations. Nature 428(6978):55

Kajiwara S (1999) Characteristic features of shape memory effect and related transformation behavior in Fe-based alloys. Mater Sci Eng A 273–275:67–88

Kajiwara S, Owen WS (1977) The martensite-austenite interface and the thickness of twins in martensite in Fe3Pt. Scr Metall 11(2):137–142

Mohammed ASK, Sehitoglu H (2020) Martensitic twin boundary migration as a source of irreversible slip in shape memory alloys. Acta Mater 186:50–67

Simon T, Kröger A, Somsen C, Dlouhy A, Eggeler G (2010) On the multiplication of dislocations during martensitic transformations in NiTi shape memory alloys. Acta Mater 58(5):1850–1860

Humbeeck JV, Kustov S (2005) Active and passive damping of noise and vibrations through shape memory alloys: applications and mechanisms. Smart Mater Struct 14(5):S171–S185

Vollmer M, Krooß P, Karaman I, Niendorf T (2017) On the effect of titanium on quenching sensitivity and pseudoelastic response in Fe-Mn-Al-Ni-base shape memory alloy. Scripta Mater 126:20–23

Abuzaid W, Wu Y, Sidharth R, Brenne F, Alkan S, Vollmer M, Krooß P, Niendorf T, Sehitoglu H (2019) FeMnNiAl iron-based shape memory alloy: promises and challenges. Shap Mem Superelasticity 5:263–277

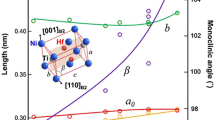

Xia J, Noguchi Y, Xu X, Odaira T, Kimura Y, Nagasako M, Omori T, Kainuma R (2020) Iron-based superelastic alloys with near-constant critical stress temperature dependence. Science 369(6505):855–858

Omori T, Ando K, Okano M, Xu X, Tanaka Y, Ohnuma I, Kainuma R, Ishida K (2011) Superelastic effect in polycrystalline ferrous alloys. Science 333(6038):68–71

Vollmer M, Baunack D, Janoschka D, Niendorf T (2020) Induction butt welding followed by abnormal grain growth: a promising route for joining of Fe–Mn–Al–Ni tubes. Shap Mem Superelasticity. 6:131–138

Sidharth R, Wu Y, Brenne F, Abuzaid W, Sehitoglu H (2020) Relationship between functional fatigue and structural fatigue of iron-based shape memory alloy FeMnNiAl. Shap Mem Superelasticity. 6:256–272

Van Humbeeck J (2001) Shape memory alloys: a material and a technology. Adv Eng Mater 3(11):837–850

Otsuka K, Ren X (2005) Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci 50(5):511–678

Calvi A (2011) Spacecraft loads analysis. ESA/ESTEC, Noordwijk, The Netherlands

Torra V, Isalgue A, Lovey FC, Sade M (2015) Shape memory alloys as an effective tool to damp oscillations. J Therm Anal Calorim 119(3):1475–1533

Ahadi A, Sun Q (2013) Stress hysteresis and temperature dependence of phase transition stress in nanostructured NiTi—effects of grain size. Appl Phys Lett 103(2):021902

He YJ, Sun QP (2011) On non-monotonic rate dependence of stress hysteresis of superelastic shape memory alloy bars. Int J Solids Struct 48(11):1688–1695

He YJ, Sun QP (2011) Rate-dependent damping capacity of NiTi shape memory alloy. Solid State Phenom 172–174:37–42

Sun S, Rajapakse RKND (2003) Simulation of pseudoelastic behaviour of SMA under cyclic loading. Comput Mater Sci 28(3):663–674

Ikeda TJ (2015) Analytical investigation of strain loading frequency effect on stress-strain-temperature relationship of shape-memory alloy. Archiv Mech 67(4):275–291

Yu C, Kang G, Kan Q, Zhu Y (2015) Rate-dependent cyclic deformation of super-elastic NiTi shape memory alloy: thermo-mechanical coupled and physical mechanism-based constitutive model. Int J Plast 72:60–90

Huang M, Brinson LC (1998) A multivariant model for single crystal shape memory alloy behavior. J Mech Phys Solids 46(8):1379–1409

Gall K, Sehitoglu H (1999) The role of texture in tension–compression asymmetry in polycrystalline NiTi. Int J Plast 15(1):69–92

Hamilton RF, Sehitoglu H, Chumlyakov Y, Maier H (2004) Stress dependence of the hysteresis in single crystal NiTi alloys. Acta Mater 52(11):3383–3402

Omori T, Nagasako M, Okano M, Endo K, Kainuma R (2012) Microstructure and martensitic transformation in the Fe-Mn-Al-Ni shape memory alloy with B2-type coherent fine particles. Appl Phys Lett 101(23):231907

Mura T (1987) Isotropic inclusions. In: Mura T (ed) Micromechanics of defects in solids. Springer, Dordrecht, pp 74–128

Ren G, Sehitoglu H (2016) Interatomic potential for the NiTi alloy and its application. Comput Mater Sci 123:19–25

Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications. Springer, Berlin

Duerig TW, Melton K, Stöckel D (2013) Engineering aspects of shape memory alloys. Butterworth-heinemann, Oxford

Tanaka K, Kobayashi S, Sato Y (1986) Thermomechanics of transformation pseudoelasticity and shape memory effect in alloys. Int J Plast 2(1):59–72

Liu Y, Galvin S (1997) Criteria for pseudoelasticity in near-equiatomic NiTi shape memory alloys. Acta Mater 45(11):4431–4439

Patoor E, El Amrani M, Eberhardt A, Berveiller M (1995) Determination of the origin for the dissymmetry observed between tensile and compression tests on shape memory alloys. Le Journal de Physique IV 5(C2):C2-495-C2-500

Hirth J, Wang J, Tomé C (2016) Disconnections and other defects associated with twin interfaces. Prog Mater Sci 83:417–471

Mohammed ASK, Sehitoglu H (2020) Modeling the interface structure of type II twin boundary in B19′ NiTi from an atomistic and topological standpoint. Acta Mater 183:93–109

Mohammed ASK, Sehitoglu H (2021) Strain-sensitive Topological Evolution of Twin Interfaces. Acta Materialia 208:116716

Kajiwara S, Kikuchi T (1982) Dislocation structures produced by reverse martensitic transformation in a Cu Zn alloy. Acta Metall 30(2):589–598

Kajiwara S, Kikuchi T (1983) Reversible movement of the austenite-martensite interface and dislocation structures in reverse-transformed austenite in Fe-Ni-C alloys. Philos Mag A 48(4):509–526

Sehitoglu H, Wu Y, Alkan S, Ertekin E (2017) Plastic deformation of B2-NiTi–is it slip or twinning? Philos Mag Lett 97(6):217–228

Tseng L, Ma J, Hornbuckle B, Karaman I, Thompson G, Luo Z, Chumlyakov Y (2015) The effect of precipitates on the superelastic response of [1 0 0] oriented FeMnAlNi single crystals under compression. Acta Mater 97:234–244

Tseng L, Ma J, Wang S, Karaman I, Kaya M, Luo Z, Chumlyakov Y (2015) Superelastic response of a single crystalline FeMnAlNi shape memory alloy under tension and compression. Acta Mater 89:374–383

Wu Y, Ertekin E, Sehitoglu H (2017) Elastocaloric cooling capacity of shape memory alloys–Role of deformation temperatures, mechanical cycling, stress hysteresis and inhomogeneity of transformation. Acta Mater 135:158–176

Bonnot E, Romero R, Mañosa L, Vives E, Planes A (2008) Elastocaloric effect associated with the martensitic transition in shape-memory alloys. Phys Rev Lett 100(12):125901

Ojha A, Sehitoglu H (2016) Transformation stress modeling in new FeMnAlNi shape memory alloy. Int J Plast 86:93–111

Liu Y, Xie Z, Van Humbeeck J, Delaey L (1998) Asymmetry of stress–strain curves under tension and compression for NiTi shape memory alloys. Acta Mater 46(12):4325–4338

Sidharth R, Abuzaid W, Vollmer M, Niendorf T, Sehitoglu H (2020) Fatigue crack initiation in the iron-based shape memory alloy FeMnAlNiTi. Shap Mem Superelasticity 6(3):323–331

Sehitoglu H, Karaman I, Anderson R, Zhang X, Gall K, Maier H, Chumlyakov Y (2000) Compressive response of NiTi single crystals. Acta Mater 48(13):3311–3326

Vollmer M, Bauer A, Kriegel MJ, Motylenko M, Niendorf T (2021) Functionally graded structures realized based on Fe–Mn–Al–Ni shape memory alloys. Scripta Materialia 194:113619

Acknowledgements

This work is supported by the National Science Foundation DMR Grant 1709515 Metallic Materials and Nanomaterials Program which is gratefully acknowledged. We would like to thank Prof. Yuri Chumlyakov of Tomsk State University, Russia for providing the single crystals. SEM and EBSD were carried out in part in the Frederick Seitz Materials Research Laboratory Central Research Facilities, University of Illinois Urbana-Champaign.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in Shape Memory and Superelasticity on the Mechanics and Physics of Active Materials and Systems. This issue was organized by Dr. Theocharis Baxevanis, University of Houston; Dr. Dimitris Lagoudas, Texas A&M University; and Dr. Ibrahim Karaman, Texas A&M University.

Appendices

Appendix

Specific Damping Capacity, Sample Variability and Clausius-Clapeyron Slope

The specific damping capacity, which is the ratio of area under the hysteresis loop and the total applied strain energy, of FeMnAlNi and NiTi is shown in Fig. 9 below. Figure 10 depicts the stress strain curves of two different FeMnAlNi samples with near < 123 > orientation and different initial microstructure, note the variability in the stress–strain behavior and the specific damping capacity. Figure 11 depicts the stress strain curves of two different NiTi samples with < 011 > loading orientation and same initial microstructure having nearly the same specific damping capacity.

Variation of transformation stress with loading temperature for FeMnAlNi and NiTi are shown in Fig. 12. The data were collected from prior studies. Note the wide range of superelastic functionality for FeMnAlNi, all the way from −196 °C to at least 240 °C. The Clausius-Clapeyron slope ranges from 0.2 to 0.6 MPa/°C. The wide range of variability in the transformation stresses can be attributed to different ageing times resulting in different precipitate sizes. The FeMnAlNi shown in Fig. 12 were aged at 200 °C for 3 h [57], 24 h [59] and 10 h [89]. Whereas, for Ni50.8Ti with an ageing time of 1.5 h at 550 °C, the superelastic functionality is limited to a temperature range of about 0–90 °C [97]. The Clausius-Clapeyron slope ranges from 7 to 10 MPa/°C.

Stress–Strain behavior of two FeMnAlNi samples with near < 123 > orientation and different initial microstructure. Note the values of specific damping capacity. DIC insets depict only one dominant variant is active for both the samples. Just by visual inspection, AA’ seems to have higher initial martensite volume fraction

Rights and permissions

About this article

Cite this article

Sidharth, R., Mohammed, A.S.K., Abuzaid, W. et al. Unraveling Frequency Effects in Shape Memory Alloys: NiTi and FeMnAlNi. Shap. Mem. Superelasticity 7, 235–249 (2021). https://doi.org/10.1007/s40830-021-00335-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40830-021-00335-0