Abstract

The fundamentals of the widest-spread methods of thermal analysis including a short excursion into differential scanning calorimetry are presented. Five practical examples illustrate the experimental approach for the measurement design and explain their chemical interpretation.

Similar content being viewed by others

Introduction

If a reaction between two substances shall be started or accelerated, the chemist’s first choice is increasing the temperature of the carefully mixed reactants. This is true as well both for liquids or solutions of solids (where a good contact between the reactants is made by stirring) and for mixtures of solids. In each case, a precondition for understanding the processes occurring in the mixed system is knowing the behaviour of the participating individual compounds under heating. These substance or system properties are summarized under the term thermal behaviour; they are investigated and described by the various methods of thermal analysis (TA). As an up-to-date definition of this multitude of physico-chemical measuring methods can serve the following: TA means to follow the changes of one or more physical parameters of a sample subjected to a controlled temperature program as a function of temperature or time [1, 2].

This definition acknowledges that in many (not in all!) cases the temperature-dependent property changes can characterize a phase as unequivocally as its chemical formula or structure [3].

TA methods determine properties—they do not represent a kind of structure analysis, even if knowing the structure (mostly the crystal structure) practically always favours or enables the interpretation of thermal processes.

History

Regarding the history of natural sciences, it seems not exaggerated to notate that “TA is the late fruit of the love of researchers to analyze matter” [4]. Since the time of Aristotle (384–322 B.C.) the dogma “Fire is the general analysator of matter” predominated. It was Robert Boyle (1626–1691) in his famous book The Sceptical Chymist (1661) who contradicted by the statement that fire cannot be the general analysator of matter as fire is destructive [5].

Hundred years later, in 1763, Joseph Black (1728–1799) was the first to distinguish between latent and sensible (to be felt!) heat and between temperature (quality of heat) and heat (quantity of heat).

Regarding the substances investigated, the origin of modern TA methods are the clay minerals. Antoine Laurent de Lavoisier (1743–1794) was probably the first who performed a TA study that would correspond to today’s requirements: during his studies of mass changes upon oxidation, he also investigated a clay mineral under heating; it was named Montmorillonite by Cronstedt in 1788 [6].

Lavoisier’s main aspect was the mass change, but decades later it was rather the aspect of temperature or heat that led Henri Le Chatelier (1850–1936) to publish his important work on clays (1887) [7, 8]. Also the introduction of the Pt–PtRh10 thermocouple for measuring high temperatures can be traced back to Le Chatelier. Further crucial contributions to today’s TA are the difference measuring principle of thermocouples, the use of an inert reference substance (cf. Fig. 3), and the phase rule of Josiah Willard Gibbs (1839–1903).

Methods of thermal analysis

Three groups of physical parameters to be measured (mass, temperature or heat flux, mechanical and other parameters) allow for a classification of the TA methods (Fig. 1).Footnote 1

The scheme does not mention the reaction calorimetry for which, on the other hand, a large variety of apparative solutions has been developed [9]. Undoubtedly, it belongs to the thermal methods of analysis. Reaction calorimetry is performed in much larger reaction vessels (e.g. glass reactors establishing adiabatic conditions) than usual TA or calorimetry. It contributes primarily to the up-scaling of chemical processes to be practised in industry [10].

Finally, the thermometric titration and its potential for the study of biochemical systems have to be mentioned here [11, 12].

Conventional TA and simultaneous thermal analysis (STA)

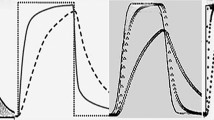

Previously, doing classical or conventional TA meant to follow the temperature of a sample upon heating and/or cooling, i.e. to record dependencies T = f(T) or T = f(t). In the field of heterogeneous equilibria, mostly of inorganic systems, this was rather easy to practise in the student’s lab classes first for single-phase (Fig. 2), then for binary systems. As an example, the system Sn–Pb was comparably easy to record: mixtures of various compositions are prepared in porcelain crucibles, a thermometer or a thermocouple is positioned into the mixture, which is then heated up to complete melting, carefully homogenized and then left for free cooling. Measuring the temperature decrease allows to detect transition or stop points which reflect the solidification behaviour of the given mixture. This simple setup allows to establish not too complicated phase diagrams containing eutectic and/or dystectic points. Similar experimental setups were utilized by the mineralogists working in the nineteenth century when studying the phase behaviour of minerals.

Application of Gibbs’phase rule to melting and solidification of a solid. On the left hand a heating up with constant linear heating rate over the melting point (m.p.); on the right hand “free” cooling (dashed line) according to Newton’s cooling law and the temperature evolution for the solidification passing through an invariant plateau (F = 0). For constant pressure one obtains the so-called reduced phase rule. It determines the number of freedom degrees F of the system depending on the number of coexisting phases P and the number of components K in the system

Later on, TA transformed into difference thermal analysis (DTA), primarily, after introduction of a thermally inert reference substance subjected to the same heating or cooling program as the sample and, secondarily, by the development of the difference measuring setup (W. C. Roberts-Austen 1899 [13]).Footnote 2 Instead of T = f(T) one followed now ΔT = f(T) (Fig. 3).

Difference measuring setup of two Pt–PtRh10 thermocouples for the simultaneous registration of the sample temperature T S, the reference temperature T R, and the temperature difference ΔT existing between sample S and reference R. On the right hand schematically the generation of a DTA signal for an endothermal first-order phase transition, e.g. a melting process. At the transition temperature (m.p.) the supplied heat is not used any more for increasing the temperature of the sample, but for carrying out the transition. Consequently, for equal heating power ΔT becomes the larger, the greater the sample mass is. DTA effects are sample mass-dependent and necessarily asymmetric. On the left hand, a commercially available sample holder head with Pt beakers is shown; the crucibles are set onto the thermocouple welding pearls and establish a good thermal contact

Other than in the schematic representation in Fig. 3, the experimental DTA curves exhibit fluent changes which strongly depend on outer experimental conditions; this is limiting the record of reproducible data. Therefore, extrapolation procedures are recommended being especially important for the determination of the beginning of thermal effects (Fig. 4). The labelling of the characteristic temperatures is laid down in international conventions [14].

Information content of a DTA signal with the extrapolation lines (dashed bold) for determining the characteristic temperatures (Onset~; extrapolated onset~, peak~, and extrapolated end temperatures). The peak area A can be used for enthalpimetric estimations after determination of an apparatus-dependent calibration factor Fcal. This is based on the fact that the isobarically exchanged heat dq P represents the enthalpy change ΔH. It is a conclusion deduced from the first basic law of thermodynamics (right). The different thermophysical properties prior to and after the effect cause the base line shift (~ΔC P). The signal asymmetry is primarily influenced by the heating rate and can be described by the shape factor a/b. It can be utilized for kinetic evaluations

An interpretation of DTA effects has to acknowledge that for first-order phase transitions, e.g. a melting process, only the onset temperature T exon is relevant, but not the peak temperature T P. It is, from a physical point of view, only the point where heat supply and heat consumption are equal. Moreover, T P is sample mass-dependent (cf. explanations to Fig. 3).Footnote 3 In case of “real” chemical reactions, also the peak maximum is significant as it represents the maximal heat exchange of the reaction.

If more than one parameter is followed in one measuring device, we are dealing with simultaneous thermal analysis which is mostly realized in the combination DTA-TG. Simply spoken, a DTA measuring cell is assembled onto a sensitive balance which was realized at first with the Derivatograph Footnote 4 by the Hungarian Optical Works MOM [15]. In the meantime, a large variety of differently conceived devices only for the combination DTA-TG is commercially available (Fig. 5). The differences in the apparatus design can have both advantages and disadvantages; it is the operator’s task to evaluate them and to make an appropriate choice (e.g. upward or downward flow of the carrier gas, horizontal or vertical position of the sample holder, suspension or top-loading sample crucibles).

Presumably each introductory text dealing with the practice of TA presents at least one of these two substances with a measuring curve’s plot: calcium oxalate monohydrate, CaC2O4·H2O, or copper(II)-sulphate pentahydrate, CuSO4·5 H2O. Indeed, these substances are very appropriate examples and, moreover, are the most-recommended testing substances for the daily laboratory practice: their thermal behaviour is well known, they practically do not change upon storage,Footnote 5 and the TA curves exhibit thermal effects with unequivocal shape and position. Therefore, further information about these substances should be taken from well-introduced textbooks [3, 16, 17], whereas two less-known compounds, being, on the other hand, not less-informative, will be elucidated here. Additionally, these two examples illustrate well the benefit of case-dependently designed measuring programs [cyclic heating and cooling (Fig. 6) or gas changes (Fig. 7) and others] which allow for the determination of important sample properties by measuring a single sample only.

Setup of a simple STA device with a mechanical balance (adapted from [17]). The balance parts are thermostated at constant temperature, whereas the crucibles containing sample and reference are at the measuring temperature. This leads to buoyancy differences and falsifies the TG evaluation which can be avoided by correction curves (mostly sample-free heating runs)

STA curves of NaClO4·H2O and its dehydration product NaClO4 as a result of cyclic heating and cooling under nitrogen. It is followed by an isothermal program step at humid air for checking a possible rehydration of NaClO4. The TG and DTA traces for the first heating up to 350 °C and the first cooling are shown (upper section). Below, TG and DTA for the second heating again up to 350 °C (T values at the DTA curve in °C). The second cooling curves were omitted as they are identical with the first cooling. Afterwards, the measurement was continued with an up-lifted oven for 2 h at humid air; consequently, the TG curve is more noisy due to air convection. Instead of an y axis’ scaling for TG (in mg or %) and DTG (in mg/min or %/min), a schematic scaling for TG in mole crystal water, n H2O, is given. The following findings can be deduced: (1) after a two-stage dehydration, the water-free NaClO4 melts with T exon 303 °C; (2) the following program change from heating to cooling causes a DTA base line jump (dotted); (3) upon cooling, the crystallization peak is recorded without under-cooling; (4) repeated heating yields re-melting of NaClO4 at the same temperature. As expected, mass losses do not appear prior to melting; (5) after the melting peak, a DTA base line shift appears (C P difference between solid and liquid phases); and (6) at humid air, no mass gain is observed within 2 h

The starting point for the measurement depicted in Fig. 6 was a literature recommendation about the usage of NaClO4 pre-dried at 130 °C as a drying agent in a reaction mixture, but all syntheses failed. As a result of our investigation by applying a cyclic heating and cooling followed by an additional measuring step, it turned out (a) that the reported drying temperature of 130 °C was too low because a hemihydrate, NaClO4·0,5 H2O, exists (which means that a “defined water entry” of 0.5 mol H2O per mole “drying agent” took place); (b) that a single heating-up to 160 °C yields completely dehydrated NaClO4 which (c) does not rehydrate upon exposure to humid air.

Figure 7 shows the influence of an atmosphere change on the shape of TA curves. Two separate measuring runs are compared, but the gas change can be carried out also during a running temperature program. This applies, e.g. to organic material after an anaerobe decomposition (pyrolysis) when the residue of this treatment shall be completely burned out until the formation of the ash. Based on phantasy and skills, the experienced operator can gain an unexpectedly broad information about sample properties by measuring a single sample if appropriately chosen temperature programs are designed.

Figures 6 and 7 clearly demonstrate the variety of possible conclusions that can be drawn about practically significant sample properties. The information gain is yet higher if, additionally, the released gases are characterized qualitatively or even quantitatively. This is possible utilizing the various forms of coupling TA to spectroscopic methods; they are summarized under the term EGA techniques (Evolved Gas Analysis) [18–20]. Today, these techniques, commercially available approximately since 1975, are not only used for studying decompositions, but generally for the investigation of reactions under different gas atmospheres; an especially promising variation of it represents the pulse thermal analysis, PulseTA® [21–23] (see below).

Influences on shape and quality of thermoanalytical curves

The discussion of the thermoanalytical findings deducable from Figs. 6 and 7 made unequivocally clear that not only the numeric values, e.g. for mass losses or selected temperatures, are significant, but that also the signal shape, interpreted in the context of all experimental conditions, has to be taken into consideration for obtaining further important information. To a certain extent, most of these outer conditions (and requirements) can be influenced and governed by the operator. Table 1 gives an overview about the main tendencies and some personal experimental experience.

Differential scanning calorimetry (DSC), thermooptical analysis (TOA), and the study of mechanical properties (TMA, DMA, µTA)

It turned out from Fig. 4 that, by means of DTA, enthalpimetric measurements are possible as well. Their precision, however, is limited due to the strong dependence of the DTA signals from experimental conditions (deviations 10–15 %). This disadvantage has been overcome by the differential scanning calorimetry (DSC) [24]. An experimental setup deduced from DTA, but much less-dependent on outer influences, allows for measurements of a greater precision especially for determining C P. Today, the employment of DSC largely predominates that of DTA which primarily applies to the huge field of organic polymers [25], of pharmaceuticals [26], and of the industrial process analysis, in particular that of a risk assessment by calorimetry [27]. The apparative variety covers a broad spectrum reaching from small table devicesFootnote 6 until weighing systems (DSC-TG).

Figure 8 shows the principal setup of two variants of DSC. In case of the historically older heat flux DSC, both crucibles (i.e. pans with a flat bottom, possibly with a lid) are connected via a heat-conducting metal band which leads to a rapid compensation of the temperature differences. The heat flux establishing this compensation is the measuring signal.

STA curves of shredded, air-dried straw in air (15.10 mg) and in nitrogen (16.94 mg) in Pt crucibles. The real moisture content is given by the measurement in air, whereas for N2 a defined gas atmosphere is established by threefold evacuation of the recipient and flushing with N2. This leads to a pre-dehydration of the material (Δm only 1.92 %). Knowing the evolution of the DTA base line (not shown here, the “thermal asymmetry” of the system), one can state that the reaction under N2 (pyrolysis, corresponds to the “dry heating” known from organic chemistry) practically does not exhibit any heat exchange. This is unexpected, but might be explained by an unfavourable sample geometry (cut fibres) resulting in a bad thermal contact with the crucible. The strong exothermicity, on the other hand, of the two-step straw burning is obvious; it is surprisingly early accomplished (~500 °C)

It is obvious that such a kind of measuring setup is less dependent on outer influences, e.g. from the thermal asymmetry or from the carrier gas flow.

Sample and reference can also be heated separately. In this case, the measuring signal is the different heating power required for keeping both at the same temperature. Power-compensated DSC became undoubtedly State-of-the-art of modern scanning calorimetry which is certainly also a consequence of the enormous progress made in measurement and evaluation software during the last two decades.Footnote 7

Due to its higher caloric sensitivity, DSC rather than DTA is the appropriate tool for investigating structure transitions in polymers. Figure 9 depicts a measurement of polyethylene terephthalate, PET, with the characteristic sequence of: (1) the glass transition with T g (a complex relaxation process exhibiting an endothermal base line shift); (2) the cold crystallization (partial or entire ordering processes in the polymer matrix); and (3) the melting of the crystalline parts (endothermal). All three stages are strongly dependent on the thermal history of the material. It explains the extraordinary importance of these measurements for the materials science.

Another field of today’s calorimetric methods, the modulated-temperature techniques, have been developed thanks to the extraordinary performance of electronics for program control and data evaluation: in Modulated-Temperature DSC, MTDSC [29] a sinus-shaped modulation is superimposed onto the linear temperature ascent so that alternating over- and retarded heating results. Together with a fascinating miniaturization of measuring heads and calorimeters (Chip calorimetry), an extraordinary progress in polymer characterization was achieved [30]. Furthermore, the chiral discrimination by chip calorimetry [31] or the so-called electronic nose [32, 33] should be mentioned here.

Thermooptical analysis (TOA), also named thermomicroscopy, in its simplest variant is realized in the form of the heating microscope (e.g. according to Kofler) which is utilized in the laboratory for decades for the determination of melting points. Besides a simple microscopic inspection of the temperature-depending changes (e.g. the beginning transparency of melting crystals), one can follow structure transitions in the solid state in polarized light upon heating or cooling. Today, TOA is predominantly applied in pharmaceutical chemistry, especially for the detection of polymorphs [34]. A recent development of TOA utilizes LED light conductors and a video camera for detecting melting points via the light transmission of melting solids [35] (Fig. 10).

DSC curve of the second heating (20 K/min) of polyethylene terephthalate (3.003 mg) in Al pans under N2 (from [28]). In order to distinguish between substance and sample properties, a preceding first heating including the melting is recommended. Provided the cooling rate (here 20 K/min) is sufficiently high to allow for a solidification in the glassy state, the second heating run more clearly expresses the substance properties rather than the sample properties. Additionally, the thermal contact between sample and crucible or pan is better when measuring a sample after solidification from a melt

It should be mentioned here that despite all fascinating measurement improvements during the last decades one very significant point is lacking, which is considered as a great obstacle especially in the inorganic solid-state chemistry: the possibility of a visual inspection of a sample at very high temperatures (i.e. practically a variation of TOA). The question, whether liquid phases appear upon sintering or not, for example, is extremely important, but it can be answered in most of the cases only indirectly [36]. The usage of high-temperature-resistant windows is principally possible: polished sapphire plates are used in crystal growth devices for a long time [37]. Excepted the case of laboratory devices, this (admittedly extreme) challenge did not lead to any progress until now. This might be explained by probably two reasons: on the one hand, the number of potential users is too low for an economically balanced development and, on the other hand, it is difficult to imagine how a DTA oven with a homogeneous temperature field (!) could be designed which would allow a visual inspection of the inside of a crucible from the top.

A wide field of activities for materials scientists opens with studying the temperature-dependent changes of mechanical properties. The thermomechanical analysis (TMA) follows dimensional changes of a sample under a constant outer force. It is used for the determination of length changes,Footnote 8 e.g. during sintering processes, or of the weakening and shrinking of polymers. The dynamic mechanical analysis (DMA) as well regards the flow behaviour and the viscoelastic (rheological) properties of samples, but under a periodic (and, possibly, increasing) force impact. Time- and frequency-dependent property changes are followed which are important for the determination of glass transitions, of the bending–breaking behaviour and other parameters such as deadening, shock resistance, stress relaxation, etc.

Figure 11 explains the deduction of the most important parameters to be determined by DMA. The parameters E′ and E″ describe the observation that solid materials can “store” an outer force impact, but can “forget” it as well. This is an extraordinarily significant property which has to be known, i.e. to be measured and quantified, when one is dealing with development, testing, life time estimation, etc., of materials. Large data collections and symposium series are dedicated exclusively to these methods TMA, DMA, and others [38, 39].

Video-supported investigation of phase transitions: the light intensity behind the sample tubelets increases drastically at the melting point (points B and C). The utilizable temperature range is limited, of course (figure adapted from [35])

The microthermic analysis (µTA) is a combination of high-resolution force microscopy with TA. Other than in the case of usual force microscopy, the utilized wire top is made from a Wollaston wire the core of which is a 5-µm Pt wire. It is uncovered over a short distance and acts as a temperature probe. The thermal conductivity of the sample surface is determined and, based on this, a surface topography is monitored [38]. This is a valuable method for studying thin films, color layers (ageing behaviour, irradiation resistance) and of composites.

Coupling techniques: evolved gas analysis (EGA)

Coupling to mass spectrometry (TA-MS)

Based on the statements related to Figs. 6 and 7, it is incontestable that the qualitative and quantitative characterization of gaseous products released from a reacting solid are of crucial importance for a complete and correct description of the occurring processes. Approximately since 1975, EGA instrumentation is commercially available in a large variety. The widest-spread coupling techniques are TA-MS (mass spectrometry) and TA-FTIR (Fourier transform infrared spectroscopy). It has become today’s State-of-the-art to perform investigations of the thermal behaviour of substances exclusively by employing this kind of (admittedly expensive) analytical method.

Figure 5 has to be completed by a coupling adaptor to a gas-analysing device replacing the simple gas outlet. Thus, one obtains the principal setup of an EGA apparatus. Their large variety follows from the various apparative solutions for this coupling, i.e. for an unfalsified gas transfer from the TA crucible into the spectrometer (or, alternatively, into a GC assembled between spectrometer and TA cell for separating the gases prior to analyse them [40]). Experimental and apparative details should be avoided here; excellent overviews presented at symposia or specialized publications can be found in literature [41–43].

The considerable information gain by TA-MS shall be demonstrated by the example in Fig. 12; it shows a completion of the data presented in Fig. 7 by the ion current (IC) curves recorded in the Multiple Ion Detection (MID) mode. At a first glance, a chemical interpretation is based on the presence or absence of the corresponding fragments. It should be completed by an evaluation of the qualitative curve shape of the relevant mass numbers. This can answer the question whether a given fragment originates from the same or from different molecules. Overlaying processes can be recognized in the same way. Furthermore, intensity contributions to a given mass number can occur by different chemical reasons which, on the one hand, renders things more complicated, but, on the other hand, it represents an important source for a correct chemical interpretation. Thus, for the temperature range between 200 and 400 °C, the qualitative intensity evolution of m16,Footnote 9 m18, m44, and m48 is practically identical, but is not around 100 °C, where only m18 exhibits an IC maximum. Therefore, the water release around 100 °C is a drying step, whereas the water release around 300 °C represents “reaction water” formed together with other pyrolysis products (CH4, CO2, SO2, etc.) in the complicated mid-temperature stage with strongly structured IC signals.

TA-MS curves of shredded air-dried straw in nitrogen (16.94 mg) in Pt crucibles. In addition to the DTA and TG curves in Fig. 7, the ion current (IC) curves for the mass numbers m/z = 16(CH4 +), 18(H2O+), 44(CO2 +, …), and 48(SO+) are monitored

Pulse thermal analysis, PulseTA®

Pulse techniques, i.e. the injection of defined, mostly small volumes of gaseous reactants into a reaction system are well-established in heterogeneous catalysis research since many decades. Preferring, however, information about the gas phase composition, conversion rates, or selectivities, the changes occurring in the solid catalyst during the catalytic reaction are often neglected. This has been overcome by the development of PulseTA® (PTA), i.e. a measuring technique adapted to the situation of TA-MS or TA-FTIR devices [21]. Modern coupling instrumentation practically always measure TG, of course, so that important data including the sample mass can be recorded in one (!) simultaneous measuring run.

PTA is an extension of usual EGA devices by a gas dosing unit for one or two permanent gases and is based on quantitative signal evaluation both for educt and product mixtures after a preceding calibration of the corresponding mass or wave number that is characteristic for the released (or injected) substance. This calibration can be performed ex situ in a preceding separate TA experiment with an appropriate calibration substance exhibiting a defined behaviour. It can also be performed in situ, e.g. by injecting the calibration substance prior to or after the reaction step during which the regarded substance is liberated.

An interesting variation of quantitative PTA is the “tailor-made synthesis” of step-wise reduced metal oxides by hydrogen pulses which can be governed via the mass loss (H2O) per pulse and the integral peak area of the corresponding mass numbers [21].

The qualitative aspect of PTA comes into the game if quantitative signal evaluation is not possible or not sufficiently precise. In this case, a TA-MS device equipped with a commercially available PTA box can be employed simply as a “reactor” and one focuses only on qualitative signal interpretation. Despite this limitation, qualitative PTA successfully contributed to the comprehension of reaction mechanisms [44] or of adsorption processes [23]. By using hand-made septum-tightened injectors such as utilized in GC not only the pulsing of gases, but of liquids as well is possible (H2O, MeOH, even 40 % HF [45]). The small volumes (2–5 µL) rapidly evaporate, are transported with the carrier gas along the sample crucibles (dead times ~50 s) and interact with the solid.

Figure 13 elucidates this kind of measurement. It is an especially informative example for the deep insight in fine details of the reaction behaviour that can be obtained via PTA experiments. It makes understandable all essentials of the measurement design and the approach for a chemical interpretation. Based on this, one is enabled to understand the comparably unusual experiment which is demonstrated in Fig. 14. It comprises two isothermal segments (145 und 350 °C), which were deduced from the chemical questions to be answered: (a) is it possible to simulate in a PTA measurement the forming reaction of a MIVO2 catalyst by gaseous HF as practised in industry? and (b) can one obtain additional, probably quantitative information? Finally, (c) can one detect an interaction of the catalyst at reaction temperature (350 °C) with HF?Footnote 10

Isothermal PTA measurement of a pre-treated (2 h 250 °C; vacuum) sample of β-AlF3 (43.81 mg) in N2 with the IC curve for m/z = m31 (CH3O+). (1) Four injections of 3 µL each of liquid CH3OH, evaporating in the injector (110 °C), are pulsed onto the sample; (2) the first pulse causes a persistent mass gain of 70 µg being due to the methanol adsorption. Therefore, (3) the related DTA signal is exothermic. The second pulse already yields another signal shape (4) for TG and (5) for DTA: the slight overswing of the TG step is removed in the carrier gas flow reaching a constant level; a lower persistent mass gain as before results (50 µg). The reason for this decrease is the desorption of only physisorbed methanol which causes the endothermal post-effect of the main DTA peak. Due to the continuing surface saturation (6) the persistent mass gain gets smaller with each injection, (7) the DTA signal shape does not change any more. For a complete surface coverage one, perhaps two further methanol pulses would be required; the actual surface coverage by the four TG steps (Δm = +150 µg) amounts to 0.107 mmol/g (0.9 mol %) CH3OH. This high value is due to the large surface area (~200 m2/g) [22]

PTA curves of MIVO2 (37.07 mg) in N2 with injections of 1 mL HF(g) during two isothermal segments at 145 and 350 °C. The sample was pre-treated at 170 °C (Δm = 0.32 %) for preparing a fresh surface. A necessary precondition for a meaningful interpretation of the sample behaviour is a preceding sample-free measuring run (blank, TG and DTA blue). The injections are performed in the same way as with sample; for legibility reasons only the IC curve (m20; HF+) for the sample measurement (TG and DTA red) are monitored. (1) Neither a TG nor a DTA effect are observed for three sample-free pulses of 1 mL HF each; (2) the first pulse onto MIVO2 has a lower IC intensity than the following ones; (3) the first two pulses cause slight mass gains, then the surface is saturated; (4) the exothermal DTA effects do not show endothermal post-effects; accordingly pure chemisorption occurs; (5) the curve shifts during the setting of the next isothermal segment are omitted; (6) at 350 °C again three injections of 1 mL HF are performed; (7) the DTA effects are sharper, but (8) no TG steps are recorded, because (9) comparably strong post-effects indicate immediate desorption of HF which was only weakly physisorbed. The total mass gain of 0.018 mg yields a coverage of 0.2 mol-% HF which is in line with the idea of a slightly fluorinated F-MIVO2

As a result of this measurement one can summarize: (a) the forming reaction of the catalyst could be simulated sufficiently; (b) the surface coverage with HF yields a meaningful value; (c) as expected, no chemical interaction of the catalyst with HF occurs at 350 °C, but there are hints for a very weak physisorption; (d) surprisingly, the injection of HF(g) into the empty recipient did not yield neither a TG nor a DTA signal (which, on the other hand, proved clearly that the sample-free PTA run could be considered as a real blank experiment).

A further and comparably illustrative example for the potential of PTA represents an iron(III)-doped cerium(IV) oxide, Ce0.9Fe0.1O2−x, which was pulsed with CO2 at 50 and 135 °C; it is comprehensively elucidated in [46].

Notes

Principally, one has to distinguish between Analysis (consisting of measuring method (or procedure), evaluation, and interpretation) and, on the other hand, Method. Unfortunately, this is inconsistently applied even in governmental standards (e.g. TG vs. TGA or DTA vs. Difference thermometry [1]). We prefer here the use of terms being well-established in science and laboratory practice such as TG together with DTA (instead of DTM) or TMA instead of thermomechanometry.

Not only in English (Differential Thermal Analysis), in German as well the term Differentialthermoanalyse is in use. Taking into account that differences shall be measured (hopefully large ones for sensitivity reasons), one should avoid this term. On the other hand, it is justified to speak about Differential Thermal Gravimetry (DTG) as in fact it represents the first time derivative.

It is, therefore, recommended to avoid formulations such as “The reaction or transition at the temperature × °C”when discussing T p. It is much more correct to formulate “The reaction starting at T exon °C…”or “The reaction occurring between T exon and …”.

Derivatograph was the trade mark of a measuring device, not the name of a method. It is a hint to the first time derivative of the TG curve (differential thermal gravimetry, DTG) which was also delivered by this device; it survived by the term “Derivatogram” being (incorrectly) used in the daily lab speech. One should use, however, terms like diagram, thermogram, TA measurement, etc.

Sometimes one observes, however, somewhat lower mass losses exclusively for the first dehydration step of CuSO4·5 H2O. Especially powdered samples of the pentahydrate slightly dehydrate, whereas CaC2O4·H2O does not dehydrate at all. Moreover, it is a good indicator for oxygen impurities in the carrier gas: the second of three endothermal steps will be superimposed by a certain exothermicity due to the formation of CO2 from CO.

For example on board of tankers: prior to loading the freight, a comparably rapid heating run in air can be performed. The DSC peak area yields a measure for the exothermicity of the burning process which approximates the fuel value of the raw oil, i.e. an important quality criterion.

One should bear in mind that the introduction of the scanning methods into calorimetry (early 1970s) was vigorously disputed amongst the calorimetrists. Scanning was discredited as an inappropriate approach having nothing to do with real calorimetry. Remember that a classical calorimetric experiment required extremely long times for reaching the temperature equilibrium, but the novel scanning methods preferred rapid measuring runs with heating rates between 5 and 20 K/min. Nevertheless, for a reliable interpretation, the fundamental difference between equilibrium and non-equilibrium methods has to be taken into consideration.

With thermodilatometry (TD; dilatare, to expand) as well, but with negligible force impact.

To be formulated correctly as m/z = 16 (CH4 +), but abbreviated here in this shortened form, correspondingly for other mass numbers in the text and in the figures.

Gaseous HF was injected in the following way: from the vapour phase above 100 % HF stored in a septum-tightened PE vial we took samples of HF(g) by using a normal PE syringe; it was flushed three times with HF(g) prior to injecting a volume into the recipient. As already observed in preceding investigations, the volume error for these manual injections is unexpectedly low—it can be estimated in sample-free measurements and amounted to ca. 3–5 % for tests with H2O. In the present case, the small peak area for the first pulse seems to be due to a handling error.

References

DIN 51005:2005-08 (2005) Thermische Analyse (TA)—Begriffe. Beuth Verlag, Berlin

ASTM E 473-00 (2000) Standard definition of terms relating to thermal analysis

Heide K (1982) Dynamische Thermische Analysenmethoden, Deutscher Verlag für Grundstoffindustrie, Leipzig, 2. Aufl. S. 15

Linke D (1984) unpublished

http://www.gutenberg.org/files/22914/22914-h/22914-h.html (chapter 24)

LeChatelier H (1887) Bull Soc Fr Minéral Cristallogr 10 (1887) 204-11

LeChatelier H (1887) Z Phys Chem 1:396–402

Rémi A, Giordano M, Mathonat C, Naumann R (2003) Thermochim Acta 405:43–50

Moritz HU, Reichert KH (eds.) (2001) Proc. 7th Intern. Workshop on Polymer Reaction Engineering, DECHEMA Monographien 137. Wiley-VCH, Weinheim

Stäudel L, Stille A, Wöhrmann H (1979) GIT Laborfachzeitschrift 23:291–293

http://www.food.metrohm.com/de/Titration/Thermometric/Applications.html

Roberts-Austen WC (1899) Metallographist 2:186

Hill JO (1981) For better thermal analysis, special edn. of the International Confederation for Thermal Analysis and Calorimetry, ICTAC. University of Rome

Paulik J, Paulik F (1981) Simultaneous thermoanalytical examination by means of the Derivatograph. In: Svehla g (ed) Compr. Anal. Chem., vol. XII. Elsevier

Schultze D (1971) Differentialthermoanalyse, 2nd edn. Deutscher Verlag der Wissenschaften, Berlin

Hemminger WF, Cammenga HK (1989) Methoden der Thermischen Analyse. Springer, Berlin, Heidelberg

Wiedemann HG, Bayer G (1978) Trends and Applications of Thermogravimetry. In: Topics in Current Chemistry, vol. 77. Springer, Berlin

Emmerich W-D, Post E (1997) J Therm Anal 49:1007–1012

Fischer M, Wohlfahrt S, Saraji-Bozorgzad M, Matuschek G, Post E, Denner T, Streibel T, Zimmermann R (2013) J Therm Anal Calor 113:1667–1673

Maciejewski M, Baiker A (2008) Pulse Thermal Analysis. In: Brown ME, Gallagher PK (eds) Handbook of Thermal Analysis and Calorimetry, vol. 5, ch. 4. Elsevier, pp 93–132

Feist M, König R, Bässler S, Kemnitz E (2010) Thermochim Acta 498:100–105

Feist M, Teinz K, Robles Manuel S, Kemnitz E (2011) Thermochim Acta 524:170–178

Höhne G, Hemminger W, Flammersheim HJ (1995) Differential scanning calorimetry—an introduction for practitioners. Springer, Berlin, Heidelberg

Ehrenstein GW, Riedel G, Trawiel P (2004) Thermal analysis of plastics: theory and practice. Carl Hanser Verlag, München

Marti E (ed) Pharmacy and thermal analysis (PhandTA). Symposium proceedings at http://www.eurostar-science.org/index.html

Stoessel F (2008) Thermal safety of chemical processes: risk assessment and process design. Wiley-VCH, Weinheim

Füglein E (2013) Thermische Analyse und Rheologie, Vorlesungsskript WS 2013/14, Fachbereich Angewandte Chemie. TH Georg-Simon-Ohm, Nürnberg

Reading M, Hourston DJ (eds) (2006) Modulated-temperature differential scanning calorimetry. Springer, Berlin, Heidelberg

Schick C (2010) Eur Phys J Special Topics 189:3–36

Kirchner R, Seidel J, Wolf G, Wulff G (2001) Proc. 14th Ulm-Freiberger Kalorimetrietage, TU Bergakademie Freiberg, 21–23.03.2001. http://www.gefta.org/gefta_ufk2001.html

Lerchner J, Maskow T, Wolf G (2008) Chem Eng Process 47:991–999

Lerchner J, Caspary D, Wolf G (2000) Sensors Actuators B70:57–66

Carlton RA (2011) Pharmaceutical Microscopy. Springer, Berlin, Heidelberg

Wagner M (2009) TA UserCom 29. http://www.mt.com/TA-webinars

Neher R, Gestrich T, Herrmann M (2012) Proc. GEFTA-STK-Symposium, Universität des Saarlandes, Saarbrücken. http://www.gefta.org/gefta_jt2012.html

Uecker R, Reiche P, Ganschow S, Wilde P-M, Uecker D-C, Worzala H, Schultze D (1997) J Cryst Growth 174:320–323

Häßler R, Kunze W (2007) Thermische Eigenschaften polymerer Werkstoffe, Stoffsammlung DMA-DSC-TGA-TMA-µTA, Eschborn. ISBN: 978-3-940184-00-9-01-6

Kunze W (ed) (2004) Charakterisierung von Polymeren mit Hilfe von Thermischer Analyse und Rheologie, Proc. Würzburger Tage TAInstruments GmbH, Alzenau

Füglein E, Hanss J, Post E (2013) Proc. Central & Eastern Eur. Conf. Therm. Anal. Calorim. Vilnius, Lithuania, OP4.09. http://www.ceec-tac.org/conf2/welcome.html

Kaisersberger E, Post E (1997) Thermochim Acta 295:73–93

Hanss J, Kalytta A, Reller A (2003) Hyphenated Techniques in Thermal Analysis, Proc. In: Kapsch E, Hollering M (eds) 5th Selber Kopplungstage. Bad Orb, Germany, pp 151–163

Kettrup A (1984) Thermogravimetrie—Differenzthermoanalyse. In: Analytiker-Taschenbuch, Bd. 4. Springer, Berlin, Heidelberg, S. 85–106

Feist M, Murwani IK, Kemnitz E (2003) J Therm Anal Calor 72:75

Feist M, Kemnitz E (2006) Thermochim Acta 446:84

Feist M (2014) GIT Laborfachzeitschrift 58(4):31–34

Acknowledgments

The valuable advice obtained from Dr. Ekkehard Füglein (Netzsch Gerätebau, Germany) during the final editing of the manuscript is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

The German version of this article is available as electronic supplementary material.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Feist, M. Thermal analysis: basics, applications, and benefit. ChemTexts 1, 8 (2015). https://doi.org/10.1007/s40828-015-0008-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40828-015-0008-y