Highlights

-

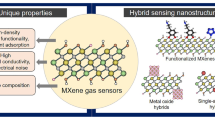

With its layered structure, abundant functional groups, and excellent electrical conductivity, MXene is of great research interest in the field of gas sensing.

-

The preparation technology of gas sensors is constantly being optimized, opening up avenues for the development of gas sensing.

-

MXene-based composite materials (MXene/graphene, MXene/metal oxides, MXene/MOF, and MXene/polymer) are applied in various gas sensors.

Abstract

With the development of science and technology, the scale of industrial production continues to grow, and the types and quantities of gas raw materials used in industrial production and produced during the production process are also constantly increasing. These gases include flammable and explosive gases, and even contain toxic gases. Therefore, it is very important and necessary for gas sensors to detect and monitor these gases quickly and accurately. In recent years, a new two-dimensional material called MXene has attracted widespread attention in various applications. Their abundant surface functional groups and sites, excellent current conductivity, tunable surface chemistry, and outstanding stability make them promising for gas sensor applications. Since the birth of MXene materials, researchers have utilized the efficient and convenient solution etching preparation, high flexibility, and easily functionalize MXene with other materials to prepare composites for gas sensing. This has opened a new chapter in high-performance gas sensing materials and provided a new approach for advanced sensor research. However, previous reviews on MXene-based composite materials in gas sensing only focused on the performance of gas sensing, without systematically explaining the gas sensing mechanisms generated by different gases, as well as summarizing and predicting the advantages and disadvantages of MXene-based composite materials. This article reviews the latest progress in the application of MXene-based composite materials in gas sensing. Firstly, a brief summary was given of the commonly used methods for preparing gas sensing device structures, followed by an introduction to the key attributes of MXene related to gas sensing performance. This article focuses on the performance of MXene-based composite materials used for gas sensing, such as MXene/graphene, MXene/Metal oxide, MXene/Transition metal sulfides (TMDs), MXene/Metal–organic framework (MOF), MXene/Polymer. It summarizes the advantages and disadvantages of MXene composite materials with different composites and discusses the possible gas sensing mechanisms of MXene-based composite materials for different gases. Finally, future directions and inroads of MXenes-based composites in gas sensing are presented and discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As a key component in information acquisition and signal conversion, sensors play an irreplaceable role in Internet of Things technology [1,2,3,4]. Among them, gas sensing can convert gas molecular signals over optical signals, electrical signals, etc., widely applicable to aerospace, industrial production, agricultural planting, and human health monitoring, to realize monitoring, forecasting, and automatic control of toxic and harmful gases, as well as prediction of human respiratory system diseases [5]. Sensors are mainly classified into electrical (resistive/capacitive), electrochemical, mass-sensitive, and optical types [6]. Electrical gas sensors are widely studied due to their simple structure and easy processing of output signals. Gas sensing materials in electrical sensor components can adsorb gas molecules through physical/chemical interactions and undergo charge transfer, thereby causing changes in the electrical signal of the device. Currently, electrical gas-sensitive materials include metal oxide semiconductors (MOSs), precious metals, carbon materials, organic materials, and two-dimensional materials. Since the discovery of graphene, two-dimensional materials, such as transition metal chalcogenides (TMDs) [7], boron nitride (BN) [8], layered double hydroxides (LDHs) [9], black phosphorus (BP) [10], and transition metal carbon/nitrides (MXenes) [11], have also been applied in the field of gas sensing. MXenes have become an emerging gas sensing material due to their unique layered structure, significant physical, optical, and electrical properties, as well as active surfaces [12, 13].

MXenes was proposed in 2011 by the Gogotsi group at Drexel University, USA [14]. Within the passed-century, MXenes and its composites have been receiving quite a lot of attraction in the field of energy storage and conversion [15, 16], electromagnetic shielding [17], and sensitive electronics [18]. Two-dimensional MXenes present a promising class on sensitive properties and a wide variety of structures, tunable structures, and controllable surface terminations [19]. In 2017, Lee et al. [20] found for the first time experimentally that Ti3C2 MXene has good gas-sensitive properties and exhibits gas-sensitive properties at room temperature [21,22,23,24,25,26,27,28]. Because common semiconductor gas-sensitive materials operate at high temperatures of 200–400 °C [29,30,31,32], MXene with room temperature gas-sensitive properties has the following advantages as a gas-sensitive material: (1) energy saving and simplification of the gas sensor structure [33, 34]; (2) painted on suitable matrix materials to develop portable and flexible gas sensors [35,36,37,38,39,40,41].

In recent years, the rapid development of MXenes has led to their rapid application in the field of gas sensing (Fig. 1) [1, 35, 38]. MXenes-based gas sensors are expected to achieve efficient and rapid detection of gases such as ammonia (NH3), nitrogen dioxide (NO2), and volatile organic compounds (VOCs) at room temperature [42,43,44]. However, due to its excellent electron transfer performance, two-dimensional layered structure, and abundant terminal groups, MXenes are not only sensitive to inorganic gases prone to electron loss or capture, but also highly sensitive to volatile organic compounds such as alcohols, ketones, and aldehydes [45]. This results in poor selectivity and specificity of MXenes in gas detection. Therefore, researchers often use surface modification, doping, and composite methods to enhance the gas sensing characteristics of MXenes [46,47,48,49,50,51,52]. Among them, compounding is an important strategy [53, 54]. The gas-sensitive composite phases of MXenes mainly include graphene and its derivatives, metal oxides, TMDs, MOFs, and polymers [55,56,57].

The current paper reviews the recent research progress of MXenes-based composites for gas sensors. Figure 2 shows an overview of the review article, highlighting the preparation of gas sensors, with a focus on the synthesis, advanced performance, and gas sensing behavior of MXenes composite materials (MXene/graphene, MXene/metal oxides, MXene/transition metal sulfides (TMDs), MXene/metal–organic framework (MOF), MXene/polymer). Finally, the (potential) advantages and challenges related to the development of MXenes were systematically discussed.

2 Preparation of Gas Sensors

Electrical gas sensors are sensors that convert gas composition and concentration into electrical signals [58,59,60,61]. In today's highly digitized and intelligent world, the increasingly deteriorating environmental and personal health issues have attracted widespread attention [27, 62,63,64,65,66]. In this regard, the development and design of gas sensors have received attention and favor from researchers [67, 68]. Gas sensors can detect various gases, such as gas composition detection in chemical production, coal mine gas concentration detection and alarm, environmental pollution monitoring, gas leakage, fire alarm, combustion detection, etc. With the continuous development of social technology, the types of substrates continue to increase. However, traditional methods for preparing gas sensing devices are not suitable for many substrates, and traditional methods require high preparation conditions, low production efficiency, and extremely high preparation costs [69,70,71,72,73,74]. Therefore, innovative manufacturing technologies for gas sensors are very important [75]. Appropriate manufacturing methods for gas sensors have provided strong support for the wide application of gas sensors by not only improving the performance of the sensors, effectively simplifying the process steps and reducing the cost of production [76,77,78].

At present, the existing technologies for preparing sensors include: coating technology [77,78,79,80,81,82], printing technology [83,84,85,86,87], rotating technology [88,89,90,91,92,93], transfer technology [94,95,96] (Fig. 3). These technologies have led to enormous efforts in manufacturing optimization, resulting in impressive advances in gas sensors [97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113]. Table 1 summarizes the advantages and limitations of these specific technologies [114].

Preparation methods for gas sensors: application of coating technology (trickle coating, spinner coating, sprays, soap coating); imprinting technology (inkjet printing, silk screen printing, writing printing, nano-imprinting (NL)); transfer technology (electrospinning, other spinning); assignment technology (drying transfer, humid transfer, support layer-assisted transfer)

Coating technology is a simple and efficient way to prepare sensitive soluble materials into thin-film structures at the surface of a substrate [115, 116]. The preparation process of this technique is not demanding in terms of equipment and fabrication conditions, making it suitable for many substrates, including many flexible substrates, especially if the boundary range of the sensitive material film is not strictly required [76, 117]. Therefore, the coating technique is also one of the most prevalent methods for the fabrication of gas sensors today. Specific methods of coating technology include trickle coating, spin coating, spray coating, and dip coating. Trickle-coating method is one of the simplest ways to prepare gas sensors by selecting a soluble sensitive material and applying the material solution dropwise onto the substrate via a pipette, which is simple to operate; spin-coating is an alternative and convenient method of making sensitive films, in which a soluble material is dripped onto a rotating substrate, which is then dried so that the substrate vaporizes the solvent and a sample of the substrate containing a thin film of the sensitive material is obtained; spray-coating method can be assisted by ultrasound and combines the hydrophilic and hydrophobic properties of the materials adhered to prepare a homogeneous and sensitive film, and it is a cost-effective method [79, 80, 118]. However, its shortcoming is that for films with specific needs (e.g., specific requirements for shape and location), a concealment procedure had to be applied to the areas that did the coating not need to be applied; dip coating is a versatile and cost-effective method of preparing gas-sensitive sensors, which proceeds by dipping the substrate into a solution of sensitive material, then adjusting the speed to lift the substrate out of suspension, and finally drying to eliminate any residual solvent on the substrate surface.

Printing technology is an innovative and modern manufacturing technology that enables the preparation of functional material suspensions based on substrates using the appropriate printers and finds its application in a wide range of electronic manufacturing applications [81, 119, 120]. Pre-designed gas sensors, such as specific patterns, film thicknesses, and boundary ranges, can be prepared on a massive scale by printing technology. Printing technologies can be categorized into four main types, which are inkjet printing, screen printing, writing printing, and nano-imprinting. Inkjet printing is an intriguing digital method for contactless spraying of ink and functional materials onto a variety of substrates through micron-sized nozzles; screen printing is recognized as a highly attractive and competitive manufacturing technology compared to inkjet printing for the rapid mass fabrication of microelectronic devices due to its pre-designed grid pattern and ease of manufacturing process; writing printing on a substrate is a familiar and practical printing technique in which a combination of a functional material solution is deposited on the substrate to form a structure by combining it with a pen or any other writing instrument; nanoimprint lithography (NIL) is a lithographic technique that offers the advantages of high productivity, low cost, and simplicity of the process to fabricate nanostructures in high volume, high resolution (< 5 nm), and lower cost. Simply put, NIL technology uses high-resolution electron beams and other methods to pattern complex nanostructures on a stamp, and then deforms the sensitive material with the patterned stamp to form the patterned material. Unlike traditional photolithography (where the direction or energy of the ions of the sensitive material is altered by photons or electrons to achieve pattern production), NIL technology mechanically deforms the sensitive material through direct contact, thus avoiding the resolution limitations of traditional techniques such as light diffraction or beam scattering.

Spinning is the process of extracting a precursor functional solution (e.g., polymer solution or melt) from a nozzle and depositing it on a collector to create long, continuous, one-dimensional fibers with micron/nanometer diameters [121,122,123]. Textiles can be coated with sensitive materials to form gas sensors. In addition, electronic devices based on sensitive optical fibers can be directly fabricated for gas detection via incorporating gas-sensitive materials into the precursor solution, which is a straightforward and effective method. Of the various spinning technologies, the electrospinning technology is of great interest and is widely utilized for the preparation of a wearable device.

Many substrates are incompatible given that in particular conventional fabrication techniques (e.g., chemical vapor deposition (CVD)), certain substrates cannot withstand drastic fabrication conditions (e.g., high temperatures, chemical etching reagents). The optimum way to resolve these incompatibilities lies in the transfer of nanostructures or thin films on rigid/donor substrates (e.g., silicon, glass) prepared by conventional fabrication techniques to acceptor substrates (e.g., PET, PMDS), which is defined as a transfer technique [124, 125]. Effective transfer techniques are critical to the fabrication of flexible gas sensors, which will enable many traditional fabrication processes that are only applicable to hard substrates to be used in the manufacture of wearable/flexible sensors [114]. Transfer techniques consist of dry transfers, wet transfers, and support coatings-assisted transfers. Dry transfer utilizes the adhesion gap between the film layer and the underlying substrate to transfer the film from the primary substrate to the intended substrate; wet transfer is available for transferring a mono sensitive layer to a variety of substrates in service media; and support layer-assisted transfer is a prominent transfer technique that utilizes an elastomeric impression as a support layer to retrieve a material with micro/nanostructures back from the supplier substrate and attach it to a non-natural substrate [126].

However, most of the aforementioned widely practiced techniques (e.g., coating, printing, and spinning) rely on the sensing material being in the liquid phase, this restricts the amount of gas sensing materials available because some types of materials with excellent sensing capabilities are harder to realize in the bulk of the liquid phase. Spin-coating and screen-printing methods result in ink waste due to the use of solution-phase materials, while inkjet printing and electrospinning processes both require the use of nozzle devices, with the risk of nozzle clogging. Moreover, technology of transfer, particularly transfer with the assistance of a supporting layer where at least two etching cycles are involved, is partly complex and time-consuming. Hence, a long way lies ahead in commercializing the product for the exploitation of gas sensors with enhanced performance and large-scale production.

3 Structure and Properties of MXene

3.1 Structure of MXene

MXene material is a type of metal carbide or metal nitride material with a two-dimensional layered structure. It is a two-dimensional transition metal group carbon/nitride obtained by selectively etching the A atomic layer in the ternary conductive ceramic MAX phase. The phase structure of MXene is shown in Fig. 4a, and the general formula of MXene structure is Mn+1XnTx, where M is a transition metal (such as Ti, V, and Mo), X represents C or N, n = 1, 2, or 3, Tx represents surface terminal groups (-OH, = O, and/or -F) [127]. Due to the hexagonal crystal structure formed by the interlacing of the M layer and X layer with the A layer in the precursor MAX phase of MXenes, the MXene phase also has a similarly symmetrical hexagonal lattice (Fig. 4b). The M atoms in MXenes are arranged in a tight structure, while the X atoms fill the gap positions of the octahedron. There are three arrangements in the MXenes structure: BγA-AγB (M2X-M2X), BγAβC-CβAγB (M3X2-M3X2) and BαCβAγB-BγAβCαB (M4X3-M4X3) [128]. As shown in Fig. 4c, the two-dimensional MXene consists of a thin sheet that has hexagonal cells, with an X layer sandwiched between two M transmission metal layers.

a Explain the "M," "A," and "X" elements of MAX phase through the periodic table, as well as the schematic diagram of MXenes structure and the currently reported MXenes. Reproduced with permission from Ref. [127]. b Crystal structure of MXene generated from MAX phase. c Side views of pristine M3X2, M4X3, M’2M”X2, and M’2M”2X MXenes, where M, M’, and M” denote transition metals, and X represents C or N. Reproduced with permission from Ref. [128]

3.2 MXene Characteristics for Gas Sensing

In the aqueous environment of chemical etching solutions, the outer surface of the detached MX layer is usually functionalized by -F, -OH or = O functional groups. These surface rich functional groups (-F, -OH or = O) can become attachment sites for the direct growth of other nanostructured materials or functional molecules [129, 130], which can be modified to provide feasibility for improving the selectivity of gas sensors. In addition, this surface functionalization has a significant impact on the electronic and ion transport properties of MXenes, namely, the conductivity of MXenes is directly related to the electron transfer process that occurs on their surface [131]. MXenes have certain metal properties and narrow bandgap semiconductor properties, which give them the inherent advantage of good conductivity. For example, Ti3C2Tx has a room temperature conductivity of up to 10,000 S cm−1 [132, 133].

Many theoretical calculations have shown that the ideal MXene is located near the Fermi level, with a considerable electron density and a cash property [128, 130]. Lane et al. calculated the ideal single-layer defect free MXene nanosheets using density functional theory, and the results showed that MXene exhibits metal conductivity, with Fermi levels higher than its precursor MAX phase [131]. However, when its surface is functionalized, some MXenes exhibit semiconductor properties. In addition, due to the different number of electrons received by different surface groups (-F, -OH, or = O) in equilibrium states, different surface groups have different effects on the electronic properties of MXene, and the orientation of the end groups also affects the electronic properties of MXene [132]. Table 2 lists the bandgap widths of some MXenes. MXenes with different bandgap widths can be used to prepare gas sensing arrays, achieving specific recognition of industrial raw gas, exhaust gas, and human exhaled gas. In summary, using MXenes as a gas sensing material has certain inherent advantages.

4 MXenes Composite in Gas Sensing Applications

In recent years, MXene composite materials containing graphene, semiconductor metal oxides, transition metal sulfides, organic metal frameworks, polymers, and other materials have received increasing research in gas sensing applications. Due to the more metallized nature and narrow band gap of MXenes, the addition of metal oxides, graphene derivatives, and chalcogenides provides more activated adsorption sites, defects, and modulation of working functions, thereby improving gas sensing performance. Table 3 summarizes the performance of gas/VOC/humidity sensors for MXene-based composites.

4.1 MXene/Graphene

Graphene is widely used in various fields because of its excellent thermal conductivity, high specific surface area, and easily modified structure [139,140,141,142,143]. MXenes are an excellent sensing material with a very narrow bandgap, but when pure MXenes are used in gas sensing devices, critical potential barriers are generated during the gas reaction process, which hinders their further sensitive response. Subsequently, researchers found that combining the two can effectively overcome this problem. For example, Liu et al. prepared three-dimensional (3D) hybrid aerogel [140] (Fig. 5a) from MXene (Ti3C2Tx), reduced graphite oxide (rGO) nanosheets, and ultrafine CuO nanoparticles. From the obtained 3D MXene/rGO/CuO aerogel, high pyruvic sensing performance was demonstrated at ambient temperature (Fig. 5b). Response of the sensor to 100 ppm of acetone was 52.09% (RT) (Fig. 5b), with a response time of ~ 6.5 s and a recovery time of ~ 7.5 s (Fig. 5c), demonstrating excellent reproducibility and selectivity. In 2020, Lee et al. [139] developed a Ti3C2Tx MXene/graphene hybrid fiber wearable gas sensor without a metal binder through a wet spinning process (Fig. 5d). The bandwidth capacity of the composite material has increased from 1.05 to 1.57 eV, while the fiber properties of the composite material enhance flexibility and response to NH3. A moderate response (6.8% at 50 ppm NH3) was displayed by the composites (Fig. 5e), with this being 7.9 and 4.7 times more responsive than that of pure MXenes and rGO, respectively (Fig. 5f).

a Schematic illustration of fabrication process of 3D MXene/rGO/CuO aerogel. b The selectivity for 3D MXene/rGO/CuO aerogel-based sensor to different gases of 100 ppm at RT. c Resistance changes of 3D MXene/rGO/CuO aerogel when exposed to 100 ppm acetone at RT. Reproduced with permission from Ref. [140]. d Schematic illustration of the spinning process for MXene/GO hybrid fiber. e Comparison of the gas response of MXene film, rGO fiber, and MXene/rGO hybrid fiber (40 wt% MXene). f Gas selectivity comparison of rGO fiber and MXene/rGO hybrid fiber (40 wt% MXene) to various testing gases at concentrations of 50 ppm. Reproduced with permission from Ref. [139]. g Schematic images of IDEs sensor. h Sensing performance of the ternary sensor toward HCHO vapor under 54%RH at 20 °C. i Selectivity investigation among a series of interference gases under 54%RH at 20 °C. Reproduced with permission from Ref. [141]

Wang et al. [141] proposed an ionic conductive composite film, which is composed of reduced graphite oxide (rGO), nitrogen doped MXene Ti3C2Tx (N-MXene), and titanium oxide (TiO2) (Fig. 5g), and detects 4–40 ppm formaldehyde HCHO vapor at room temperature (20 °C) and humidity. In various humidity conditions toward 4 ppm HCHO, the ternary sensor achieved an average reversible response of 26% at 54% RH (Fig. 5h). In addition, it also shows good repeatability, long-term stability, and selectivity (Fig. 5i). The excellent gas sensing performance of rGO nanosheets can be attributed to three aspects: firstly, in humid environments, rGO nanosheets serve as a good conductive platform for transporting and collecting charge carriers; second, the layered N-MXene facilitates the co-sorption and spreading of HCHO and water moieties; third, the TiO2 nanoparticles provide abundant resorption sites, which promote decomposition of the sorbed water.

In the wet CO2 sensing process of composite materials, few rGO nanosheets serve as a good conductive platform for transferring and collecting load carrier. The layered N-MXene provides further reactive sites to co-adsorb carbon dioxide and water, thus facilitating reactions involving water. The abundant amino groups in PEI polymers facilitate the binding of CO2 molecules, leading to significant changes in charge carrier density through proton conduction behavior [98, 168,169,170,171,172,173]. However, MXene composite material sensors with graphene or graphene derivatives are mostly subjected to multi gas testing, with no targeted detection of a single gas, and there is little research on humidity sensing [128, 174,175,176,177,178,179,180,181,182,183,184].

4.2 MXene/Metal Oxide

Metal oxides represent the oldest and most widely used sensing material and can be used in a variety of applications due to the high specific surface area, ease of fabrication, ease of functionalization, and extremely high sensitivity to a broad range of gases/volatile organic compounds. The sensing mechanism of metal oxides is mainly due to the changes in resistance caused by pre adsorbed oxygen species (oxygen molecules (O2), lattice oxygen < including surface lattice oxygen and bulk lattice oxygen > (O2−), atomic adsorption of oxygen (O−), molecular adsorption of oxygen (O2−)), and surface reactions of gas molecules [185]. Due to the high dependence of oxygen ionization on operating temperature, this mechanism typically requires metal oxide gas sensors to operate at relatively high temperatures, which is also the main drawback of metal oxide gas sensors [53, 145,146,147, 186]. However, research data suggests that the mixture of metal oxides with 2D MXenes has a more robust gas/volatile organic compound sensing response, and the emergence of this complex greatly overcomes the low selectivity and high operating temperature limitations of pure metal oxide sensing (Fig. 6).

Titanium dioxide (TiO2) is an ideal material for gas sensor preparation due to its pollution-free properties, ability to generate photogenerated electrons when stimulated, and simple preparation process. However, TiO2-based gas sensors also have some drawbacks, such as poor sensing performance, long response time, and recovery time. In 2019, Tai [144] designed a gas sensing element based on a TiO2/Ti3C2Tx bilayer film (Fig. 7a). According to the results, when compared with the pure Ti3C2Tx sensor, this TiO2/Ti3C2TX sensor exhibited a larger recognition value (1.63 times) with shorter response/recovery time (0.65/0.52 times) compared to the pure Ti3C2TX sensor for 10 ppm NH3 at room temperature of 25 °C (60.8% relative humidity) (Fig. 7b, c). Choiet et al. [44] covered the amplification and inductive properties against NO2 by Ti3C2 through the modulation of the introduction of the Schottky barrier (SB) (Fig. 7d), which combines TiO2 into conducting MXenes to form a heterogeneous structure. The TiO2/Ti3C2 composite sensor shows a NO2 sensitivity 13.7 times higher than the original Ti3C2 MXene (Fig. 7e), while the response of the reducing gas is almost unchanged, the reason for this is the highest charge density of NO2 in other interfering VOCs due to the formation and movement of SB inside caused by the adsorption of NO2 molecules, together with other interfering VOCs, and as explained in the mechanisms of sensing (Fig. 7f, g). Kuang et al. [154] successfully prepared Ti3C2Tx-TiO2 nanocomposites with regular morphology using Ti3C2Tx as the titanium source through a simple one-step hydrothermal synthesis method (Fig. 7h). Due to the formation of interface heterojunctions and modulation of carrier density, the detection response of Ti3C2Tx-TiO2 sensors to various VOCs at room temperature is enhanced by about 1.5–12.6 times compared to pure MXene sensors. In addition, this nanocomposite sensor has a better response to hexanal (the Ti3C2Tx-TiO2 sensor has a gas response of approximately 3.4% to 10 ppm hexanal).

a Structure of TiO2/Ti3C2Tx Gas Sensor. b Normalized response recovery curves of the TiO2/Ti3C2Tx, Ti3C2Tx and TiO2 gas sensors to 10 ppm NH3. c Response/recovery times of the Ti3C2Tx and TiO2/Ti3C2Tx gas sensors. Reproduced with permission from Ref. [144]. d A diagram of the composition process of TiO2/Ti3C2 MXene sensor. e Experimental real-time gas response curve of TiO2/Ti3C2 depending on NO2 concentration. f and g Suspension regime of NO2 gas by Ti3C2 and TiO2/TiO2/Ti3C2 thin films. Reproduced with permission from Ref. [44]. h Schematic diagram illustrating the process of the Ti3C2Tx-TiO2 nanocomposites preparation and gas sensing device fabrication. Reproduced with permission from Ref. [154]

In addition to the hydrothermal partial oxidation of Ti3C2Tx mentioned above, researchers have also prepared partially oxidized Ti3C2Tx by heat treatment at 350 °C [148] (Fig. 8a–g) and microwave-activated oxygen plasma [149] treatment (Fig. 8h). Sun et al. [150] investigated the processing-dependent sensing behavior of Ti2CTx (LiF/HCl), Ti2CTx (HF), and TiO2/Ti2CTx (LiF/HCl) at room temperature under 365 nm ultraviolet light (Fig. 9a, b). In addition, the results indicate that TiO2/Ti2CTx (LiF/HCl) exhibits better sensing performance than other samples (Fig. 9c). Since it contains abundant oxygen functional groups (-Ox, -(OH)x and Ti–O-Ti), providing more NH3 molecular interactions. Li et al. [159] developed a humidity sensor by in situ growth of TiO2 nanowires on two-dimensional (2D) Ti3C2 MXene using alkaline oxidation method (Fig. 9d). They found that the sea urchin-like Ti3C2/TiO2 composites have an order of magnitude larger surface area when compared to pure Ti3C2 or TiO2 materials (Fig. 9e) and exhibit documented high sensitivity at environments with low thermal relative humidity (RH) (from 7% RH to 33% RH, approximately 280 pF/% RH) (Fig. 9f).

Reproduced with permission from Ref. [148]. h Schematic diagram of the possible gas sensing mechanism of Ti3C2Tx MXene. Reproduced with permission from Ref [149]

Characterization of gas sensing in partially aluminized Ti3C2Tx MXene films on a multisensor chip. a Stabilization of the aqueous solution of layered MXene in photographic form. b Diagram of the construction of a single-layer Ti3C2Tx MXene sheet. c Photographs of an AFM image of a Ti3C2Tx MXene flake on Si/SiO2, the scale bar is 1 μm m. d Multi-electrode chip scheme for MXene sheet membrane produced by drop-in casting method. e SEM image of the MXene films overlaying the area in contact between the platinum alloy electrode and the Si/SiO2 backing. Scale bar is 1 μm. f MXene partial conductivity G(t) variation, relative to conductivity in air (in dry air at 350 °C with acetone, isopropyl alcohol (IPA), ethanol and methanol dosed sequentially at 2–10 ppm). g Illustration: dependence of chemical reactions, S = ΔG/Gair, average of all MXene sensor elements for organic vapor focus on a chip; error bands indicate the fluctuation of resistance of the entire multisensor array.

a Preparation process of Ti2CTx (LiF/HCl) nanosheets (Route 1) and Ti2CTx (HF) nanosheets (Route 2) is schematically shown. b Diagram of the fabrication of the TiO2/Ti2CTx (LiF/HCl) blend nanosheets. c Regularized resistance changes of each sensor at various NH3 levels. Reproduced with permission from Ref. [150]. d Ti3C2/TiO2-nanowires material preparation process: HF etching, liquid-phase exfoliation, alkali oxidation, and other methods. e BET surface area of Ti3C2 and Ti3C2/TiO2. f Complex impedance plots of Ti3C2/TiO2 composite film at 7%-23% RH. Reproduced with permission from Ref. [159]

CuO exhibits the advantage of wide range response to VOCs, but has the drawbacks of small response values, slow response/recovery speed, and low durability. For this reason, Angga Hermawan et al. [145] reported a simple method to prepare CuO-Ti3C2Tx MXene hybrid by self-assembling electrostatically (Fig. 10a). CuO-Ti3C2Tx MXene showed a better methane gas sensing response (Rg/Ra) of 11.4 than pristine CuO nanoparticles at 250°C for 50 ppm toluene gas sensing response nearly five times higher than that of pristine CuO particles for 50 ppm toluene at 250 °C. (Fig. 10b). In addition, due to the high conductivity of the metal phase in Ti3C2Tx MXene, the hybridization of CuO with Ti3C2Tx MXene not only improves the response time, but also improves selectivity, response (270 s), and recovery time (10 s) (Fig. 10c, d).

a Schematic Representation of a Facile Preparation of CuO nanoparticles/Ti3C2Tx Hybrid Heterostructures and Gas Sensor Device Fabrication. b Gas sensing response of CuO, Ti3C2Tx MXene, and CuO/Ti3C2Tx MXene tested at different working temperatures. c Response/recovery times. d Selectivity of CuO/Ti3C2Tx-30 wt% to 50 ppm of tested gas. Reproduced with permission from Ref. [145]. e Schematic illustration of the Co3O4@PEI/Ti3C2Tx MXene composites. f CoPM-24 sensor selectivity study under the influence of the presence of various gases at 100 ppm. g Momentary feedback of CoPM-24 (Co3O4@PEI/Ti3C2Tx) sensor to 100–0.03 ppm NOx. Reproduced with permission from Ref. [146]

Sun et al. [146] used simple noncovalent chemical methods and hydrothermal methods to effectively rivet Co3O4 nanocrystals onto functionalized Ti3C2Tx MXene sheets of branched polyethylene imine (PEI), and prepared Co3O4@PEI/Ti3C2Tx MXene composite material (Fig. 10e). Sun et al. examined the sensing performance of nitrogen oxides (consisting of NO2 and NO) using Co3O4@PEI/Ti3C2Tx (CoPM) complexes and found that CoPM-24 complexes exhibited 27.9% response when added at 2.4 mg Ti3C2Tx along with high selectivity and very weak detection limits (30 ppb-NOx) (Fig. 10f, g). In 2021, Zhang et al. [147] as a high-performance self-powered formaldehyde (HCHO) sensor based on MXene/Co3O4 composite was prepared. Electricity was supplied through piezoelectric nanogenerators (PENGs) of ZnO/MXene nanowire arrays. p-type metal oxide Co3O4 provided more active sites for formaldehyde interactions, thus the MXene/Co3O4 composite exhibited good response at room temperature with 9.2% response at 10 ppm HCOH and low detection limit—0.01 ppm.

In 2019, Sun et al. [187] used a simple solvothermal method to grow one-dimensional W18O49 nanorods in situ on the Ti3C2Tx surface. The W18O49/Ti3C2Tx composites exhibited a high response to low concentrations of acetone (11.6–20 ppm) (Fig. 11a), as well as high selectivity, long-term stability, and also a fast response and recovery response to very low of acetone (170 ppb) can also be detected (Fig. 11b). Physical properties of NH3 sensing were improved by forming heterojunctions and enhancing the number of active sites, relative surface area, and pore size of pristine Ti3C2Tx by functionalizing Ti3C2Tx with WO3 nanoparticles by a simple ultrasonic method, as shown in Fig. 11c. The resulting Ti3C2Tx/WO3-50% (weight percent of WO3) sensor exhibited excellent response to NH3 (22.3% at 1 ppm), which was 15.4 times that of the pristine Ti3C2Tx sensor (1.54% at 1 ppm) with no electrical resistance drift (Fig. 11d) [151].

a Image demonstrating the mechanism of acetone sensing by W18O49/Ti3C2Tx nanocomposites. b Image of instantaneous response curves of W18O49/Ti3C2Tx-based sensors in the range of acetone concentrations from 0.17 to 500 ppm. Reproduced with permission from Ref. [187]. c Mechanisms of sensing of NH3 by Ti3C2Tx/WO3-50% of composites. d Different amounts of WO3 of the composite sensor in response behavior to 1 ppm NH3 at room temperature. Reproduced with permission from Ref. [151]

In addition to this, He et al. [152] successfully synthesized two-dimensional (2D) MXene modified by tin dioxide nanoparticles for gas sensing detection as well by hydrothermal method. Wang et al. [153] successfully synthesized SnO-SnO2 (p–n junction) and Ti3C2Tx MXene nanocomposites for gas sensing by a one-step hydrothermal method. Zinc oxide (ZnO) has long been used as a gas detector. Although it has good response to various gases, high operating temperature limits the widespread application as a gas sensing material. Qui et al. [157] ZnO/Ti3C2Tx MXene nanocomposite composed of 2D multilayer MXene and 1D ZnO nanoparticles prepared a room temperature toxic gas sensor (Fig. 12a). The nanocomposite material exhibits enhanced response and recovery behavior to toxic gases, superior to pure Ti3C2Tx MXene and pure ZnO. Its gas sensing principle is shown in Fig. 12b. Under the irradiation of the sun, ZnSO3 nanocube and layered Ti3C2Tx MXene were synthesized by simple static self-assembly to synthesize ZnSO3/Ti3C2Tx MXene nanocomposites (Fig. 12c). Sima et al. [158] found that the ZnSO3/Ti3C2Tx MXene nanocomposite-based sensor displayed significant selectivity for formaldehyde, with high response (194.7% to 100 ppm and 62.4% to 5 ppm) (Fig. 12d), and rapid response/recovery times (6.2/5.1 s at 100 ppm formaldehyde) (Fig. 12e), and these tests were conducted at RT. Figure 12f shows the gas sensing scheme of the ZnSO3/Ti3C2Tx MXene laminate.

a Schematic synthesis procedure of ZnO/Ti3C2Tx heterostructure. b Schematic NO2-sensing reaction mechanism of ZnO/Ti3C2Tx nanocomposite. Reproduced with permission from Ref. [157]. c Schematic of fabrication process of (c1) ZnSnO3 nanocube, (c2) layered Ti3C2Tx MXene and (c3) ZnSnO3/Ti3C2Tx MXene composites. d Selective curve of ZnSnO3/Ti3C2Tx MXene composites to 100 ppm different gas at room temperature. e Response performance of ZnSnO3/Ti3C2Tx MXene composites to 100 ppm form aldehyde at room temperature. f Schematic of gas sensing mechanism of ZnSnO3/Ti3C2Tx MXene composites. Reproduced with permission from Ref. [158]

Different research groups have conducted extensive research on gas sensing performance using pure Ti3C2Tx and its complexes with different metal oxides, such as V2O5 [45], \(\alpha\)-Fe2O3 [155], In2O3 [156], and K2Ti4O9 [160]. Liu [155] successfully prepared heterogeneous composite materials of \(\alpha\)-Fe2O3 and Ti3C2Tx MXene using a simple hydrothermal method (Fig, 13a-c), and characterized their morphology and microstructure through various characterization methods (Fig. 13b–f). The results indicate that a size of approximately 250 nm wide was prepared \(\alpha\)-Fe2O3 nanocube and uniformly distributed on the surface of Ti3C2Tx MXene nanosheets. The results indicate that a size of approximately 250 nm wide was prepared \(\alpha\)-Fe2O3 nanocube and uniformly distributed on the surface of Ti3C2Tx MXene nanosheets. The gas sensitivity test results show that compared with other typical gases, the sensor based on \(\alpha\)-Fe2O3/Ti3C2Tx MXene composite material exhibits excellent selectivity toward acetone, and very favorable response to 5 ppm acetone: 16.6% (Fig. 13g), high rate of response and recovery: 5/5 s (Fig. 13h), excellent linearity, and significant repeatability at room temperature (RT) (Fig. 13i) [160].

Illustration of the preparation process of a positively charged α-Fe2O3 nanocubes, b Sheet-like Ti3C2Tx MXene and c α-Fe2O3/Ti3C2Tx MXene composites. d SEM images of α-Fe2O3/Ti3C2Tx MXene composites. e TEM image. f HRTEM image of the α-Fe2O3/Ti3C2Tx MXene composites. Reproduced with permission from Ref. [155]. g Selective property of the sensor based on α-Fe2O3/Ti3C2Tx MXene composites to 5 ppm of various target gases at room temperature. h The real-time resistance measurement of α-Fe2O3/Ti3C2Tx MXene composite sensor toward acetone vapor at RT. i Long-term stability of the α-Fe2O3/Ti3C2Tx MXene-based sensor for 5 ppm acetone. Reproduced with permission from Ref. [160]

Taken together, as shown in Table 3, TiO2 is the most commonly used metal oxide composition to assist MXenes in detecting reducing gases at room temperature. For the response of NH3 gas, MXenes, and tungsten tin oxides showed the best response values, but the lower response limit did not change significantly, and the response recovery time needs further investigation [164, 192]. On the other hand, we found that Co3O4 and ZnO are suitable support materials for the detection of oxidizing gases using MXenes. In the presence of In2O3 and \(\alpha\)-Fe2O3, other reducing volatile organic compounds, such as methanol and acetone, were better perceived, respectively.

4.3 MXene/TMDs

Two-dimensional chalcogenides are two-dimensional materials with unique structures, excellent mechanical, electrical, optical properties, and low energy consumption. It is a well-explored sensing application material. However, for gas/VOC sensing, the research on the composite materials of 2D chalcogenides and MXene is still a rarely explored field. So far, there are only two reports on the combination of MXene and sulfides for gas sensing. Firstly, Qui et al. [161] prepared MoS2/Ti3C2Tx heterostructures with interconnected network nanostructures through a simple hydrothermal method (Fig. 14a). The synthesized MoS2/Ti3C2Tx heterostructure exhibits significant lattice matching (Fig. 14b), where vertically arranged MoS2 nanosheets grow on Ti3C2Tx MXene and have a large specific surface area. The obtained gas sensor exhibits very high sensitivity and selectivity to NO2 gas exposure, reaching up to 25% at 10 ppm, as well as rapid recovery and long-term stability (Fig. 14c, d). Due to the large number of Mo active sites and the conductivity of Ti3C2Tx MXene, which can accelerate electron movement and excellent heterojunction interface contact, the presented structure exhibits enhanced NO2 sensing activity. Secondly, Chen et al. [162] reported on the Ti3C2TX/WSe2 nanohybrid material, which was prepared through simple surface treatment and peel-based process (Fig. 14e), and combined as a sensing material into inkjet printing and wireless operation sensors (Fig. 14f). The sensing measurement has excellent repeatability and reproducibility. The energy band diagram of the Ti3C2Tx/WSe2 sensor in the presence of ethanol shows n-type sensing behavior and Schottky barrier modulation (Fig. 14g). Compared with sensors made from raw Ti3C2Tx and raw WSe2, the Ti3C2Tx/WSe2 hybrid sensor exhibits a 12-fold improvement in ethanol sensitivity, low electrical noise, sound selectivity, and ultra-fast response/recovery characteristics (Fig. 14h). Table 3 summarizes a detailed overview of sensors for MXene and TMDs composite materials.

a Schematic illustrating the synthesis process of the MoS2/Ti3C2Tx heterostructure from the Ti3AlC2 MAX phase. b HRTEM images of the MoS2/Ti3C2Tx heterostructure. c Comparison of responses of MT2 sample to various gases at 10 ppm concentration. d Cyclic responses of MT2 to 10 and 20 ppm NO2 gas. Reproduced with permission from Ref. [161]. e Schematic illustration of preparation processes for Ti3C2Tx/WSe2 nanohybrids. f Schematic illustration of inkjet-printed gas sensors in detection of volatile organic compounds with a wireless monitoring system. g Comparison of gas response as a function of ethanol gas concentrations for Ti3C2Tx and Ti3C2Tx/WSe2 sensors. h Selectivity test of the Ti3C2Tx and Ti3C2Tx/WSe2 sensors upon exposure to various VOCs at 40 ppm. Reproduced with permission from Ref. [162]

4.4 MXene/MOF

In recent decades, metal organic frameworks (MOFs) have developed rapidly and their popularity has not decreased, making them a hot topic in the field of materials. However, the conductive MOF obtained by combining MOF and MXene breaks the shackles of MOF materials that are almost non-conductive, perfectly combines the controllable structure of organic materials and the long-term order of inorganic materials, plus the unique high electron mobility, conductive MOF can be described as a favorite, and is also one of the most potential materials in gas sensing applications [163], such as Chang et al. [164] designing and preparing a rod-shaped porphyrin based metal oxide (Co TCP (Fe)) and MXene (Ti3C2Tx) through hydrogen bonding to form a chemically resistant NO sensing hybrid (Co-TCPP (Fe)/Ti3C2Tx) (Fig. 15a). The sensor based on Co TCP (Fe)/Ti3C2Tx shows excellent NO sensing performance at room temperature (Fig. 15b), including high response (= 2.0, 10 ppm) (Fig. 15c), reliable repeatability, high selectivity, low actual detection limit (pLOD, 200 ppb), and rapid room temperature NO sensing response/recovery speed (95/15 s, 10 ppm) (Fig. 15d).

Reproduced with permission from Ref. [164]

a Synthesis process of Co-TCPP(Fe), Ti3C2Tx, and Co-TCPP(Fe)/Ti3C2Tx. b Schematic diagram of the sensing mechanism of the Co-TCPP(Fe)/Ti3C2Tx-20 toward NO. c Selectivity of the sensor to various gases at concentrations of 10 and 20 ppm. d Real-time response–recovery curve of the Co-TCPP(Fe)/Ti3C2Tx-20 based sensor toward 10 ppm NO at room temperature.

4.5 MXene/Polymer

Polymers have excellent flexibility, favorable sensitivity, appropriate electrical conductivity, low cost, a large number of organic groups to interact with the gas on the surface, light weight, and low reaction temperature, making them suitable for gaseous/VOC sensing applications when mixed with MXenes. MXene/polymer composite sensors are used to identify ammonia [101, 103, 165, 166], ethanol [32, 105], methanol [33, 104], acetone [31, 102], and humidity [99, 100, 112, 113] for wear and tear [189,190,191,192,193,194]. With respect to ammonia identification, the original MXene-based sensor shows excellent NH3 sensing characteristics, but ammonia has very high adsorption energy and NH3 is difficult to partition from the MXene screen during recovery, and demonstrates extended recognition time as well as wandering of the baseline resistance. To surmount these limitations, Li et al. [165] developed in situ a flexible chemorepulsive gas sensor based on a hybrid polyaniline (PANI)/Ti3C2Tx sensitive layer for tracking ammonia volatilization out of agriculture using self-assembled method in situ (Fig. 16a). The sensor exhibits excellent NH3 sensing performance over a temperature range of 10–40°C at 20%–80% relative humidity (RH) (sensing response to 10 ppm ammonia peaks at 4.7 at 40% RH, which is almost three times higher than in dry air (~ 1.6)) (Fig. 16b–d). Zhao et al. [105] also used over-PANI, via a low-temperature in situ polymerization method to rationally modified PANI particles coated with Ti3C2Tx nanosheets (Fig. 17a, b). This evoked remarkable detection sensitivity, a rapid response/recovery rate and mechanistic stability as well at room temperature. A year later, Zhao et al. [166] also developed room temperature nanocomposites based on 2D MXenes materials and cationic polyacrylamide (CPAM) (Fig. 17c) with high gas responsiveness and flexibility aimed at building high-performance ammonia sensors.

Reproduced with permission from Ref. [165]

a Application scenarios of PANI/Ti3C2Tx hybrid sensitive film-based flexible NH3 sensor for ammonia volatilization monitoring in agriculture. b Selectivity of the hybrid sensor to NH3 and other interference gases in agricultural fields at room temperature. c Moisture dynamic response of the NH3 sensing performance of PANI/Ti3C2Tx hybrid sensitive films. d Dynamic sensing response of the hybrid sensor toward 10 ppm NH3 in the range of 10–40 °C at dry air and 60% RH.

a A diagram of the composite synthesis of PANI/Ti3C2Tx nanocomposite, which includes the peeling process of Ti3AlC2 and the consolidation process of ANI. b Sketch of the Inter-digital polarization of the electrodes shown before and after plating PANI/Ti3C2Tx nanocomposites. Reproduced with permission from Ref. [105]. c Synthesis scheme of CPAM/Ti3C2Tx nanocomposites, including the etching process for Ti3AlC2 and composite process of CPAM and Ti3C2Tx. Reproduced with permission from Ref. [166]

Conductive polymers-3,4-ethylenedioxythiophene (EDOT) and poly(4-styrenesulfonate) (PSS) are also commonly used to composite with MXene. Jin et al. [103] used a dip coating technique to make a gas sensor from the resulting PEDOT:PSS/MXene composite (Fig. 18a). NH3 at room temperature demonstrated a strong gas response of 36.6% to 100 ppm NH3 with recovery and response times of 116 and 40 s. Furthermore, the hybrid sensor presented stronger sensitivity performance compared to pure PEDOT:PSS and Ti3C2Tx MXene-based sensors, evidencing that the PEDOT:PSS copolymer and Ti3C2Tx MXene two-dimensional ingredients have a synergistic effect on each other. In addition to showing a high response to ammonia gas, it also responded well to other gases, e.g., Wang et al. [104] used a 4:1 mixture of PEDOT:PSS and Ti3C2Tx to prepare a methanol gas sensor (Fig. 18b, c), where the reaction rate of 5.54 was high for the largest reaction and the second largest reaction tested at room temperature when compared to pure PEDOT:PSS and pure Ti3C2Tx.

a Schematic Illustration for the Synthesis of PEDOT:PSS/MXene Composites and the Fabrication Process of the Composite-Based Gas Sensor. Reproduced with permission from Ref. [103]. b Ti3C2Tx/PEDOT:PSS profile of material and gas sensor manufacturing. c The diagram of the experimental setup. Reproduced with permission from Ref. [104]

For humidity sensing, composites of polymers with MXene are excellent materials. The synergistic effect of chitosan-modified Ti3C2Tx exhibited remarkable performance, enhancing the electrical response to H2O molecules. Inspired by the structure of onions (Fig. 19a), Li and colleagues [112] synthesized ion-excited MXene/chitosan–quercetin multilayer membranes (MCQMs) using a layering-by-layer assembly approach (Fig, 19b, c) for which strong interactions to the molecules were found (Fig. 19d). The monolayer pair exhibited the highest resistance in MCQMs, with improved conductivity and reproducibility as the number of layers increased, and the sensor exhibited an ultra-high responsiveness (317% at 90% RH), a wide field of detection, and praiseworthy response and recovery speeds (0.75 and 1.6 s at 90% RH) (Fig. 19e–g). For true breathing studies, An et al. [110] described the mechanism of aqueous adsorption of a multilayer component made of MXene microsheets with polyelectrolytes (Fig. 19h) intended for super-fast humidity sensing (Fig. 19i–k), and they showed that MXene/polyelectrolyte multilayers prepared using layer-by-layer (LbL) components exhibited response and recovery times exceeding those of most humidity sensors (Fig. 19l, m).

a Photograph of purple onion scale leaves and schematic diagram of the scale leaves. b Schematic diagram of the MCQMs composed of MXene flakes and chitosan–quercetin membranes. c The humidity sensor based on laser-induced interdigitated electrode upon PI substrate. Inset shows the photograph of the flexible humidity sensor. d Chitosan and H2O intercalation induced by MCQMs. e 4-Layer induction response to MCQMs. f and g A study of the reaction/recovery time of four layers to MCQM under diverse humidity conditions. Reproduced with permission from Ref. [112]. h Schematic of the PDAC/MXene assembly. i Schematic illustrations showing the proposed humidity response mechanism of the MXene/polyelectrolyte multilayers. Schematic diagrams of MXene/polyelectrolyte multilayers and the corresponding electrical circuit models for j low and k high humidity. l and m Comparison of recovery and response times between the MXene/polyelectrolyte multilayers from this study and other humidity sensors reported in the literature. Reproduced with permission from Ref. [110]

In addition, comparing all MXene/polymer gas sensing materials in Table 3, it was found that among all reported polymers, PEDOT: PSS and polyaniline were the most suitable for improving NH3 sensing at room temperature together with MXenes. The biopolymer cellulose composite with MXenes (Ti3C2Tx/PANI/bacterial cellulose) was the most suitable for humidity sensing [195,196,197,198,199,200,201,202,203,204,205,206,207,208]. The main advantages of polymer doping with MXene are the improved selectivity and sensitivity of MXene, the disadvantages of which are poor stability and more stringent environmental requirements during measurements [148, 209,210,211,212,213,214,215].

4.6 Other Materials

Li et al. [111] fabricated a transparent mobile hygrometer using an inkjet printing technique, using a Ti3C2/Ag blend as a humidity-sensitive membrane and polydiallyldimethylammonium chloride-based (PDDA) as an adhesive barrier (Fig. 20a). The sensor has ultra-high sensitivity (106 ± 800%) (Fig. 20d), fast responsiveness (80 ms), and excellent resistance to bending (Fig. 20c, d). Liu et al. [105] reported a vacuum-assisted layer-by-layer assembly technique (Fig. 20e) for conformal deposition of conductive materials on textiles (Fig. 20f, g), resulting in a leaf like nanostructure composed of silver nanowires (AgNWs) as high conductivity skeletons (veins) and transition metal carbide/carbon nitride (MXene) nanosheets as thin layers. Having a highly sensitive humidity response (57% RH) (Fig. 20h), Zhu et al. [97] demonstrated a new paper thin-film H2 sensor using Ti3C2Tx MXene nanosheets and palladium colloidal nanoclusters (Pb CNC) as activators. The MXene@Pd CNC paper film is easily prepared through a vacuum filtration process based on a fully colloidal solution (Fig. 21a). The paper film is flexible, lightweight, and has a dense, shiny surface. The obtained MXene@Pd CNC thin-film sensor exhibits moderate H2 response at room temperature in a flat or curved state (Fig. 21b). Specifically, MXene@Pd CNC thin-film sensor provides a response time of (32 ± 7)s and a sensitivity of S = (23.0 ± 4.0)% ± 4% H2 (Fig. 21c). In addition, the MXene@Pd CNC sensor can perform "in situ mode" H2 detection directly along a paper film of the required size. Intense H2 entrapment in the ultrafine palladium carbon nanotube lattice alters the work function and leads to MXene's electron codoping, explaining the underlying regime of gas induction (Fig. 21d). Muckleyet et al. [110] reported on ion intercalated MXenes (Ti3C2-K and Ti3C2-Mg) for humidity sensing (RT). Ion embedding increases the spacing between MXene layers and absorbs H2O molecules between the layers (Fig. 21e). The conclusion drawn from neutron scattering combined with theoretical calculations is that K+and Mg2+ ions cause each ion to embed 2 and 5 H2O molecules, respectively, indicating an increase in lattice parameters. They also found that the weight response of MXene to water is 10 times faster than their electrical response, indicating that the expansion/contraction of channels between MXene layers caused by H2O leads to the capture of H2O molecules as depletion charge dopants (Fig. 21f–i).

a Flowsheet for the fabrication of Ti3C2/Ag-based moisture sensor by inkjet publishing method. b Characteristics of the TA2 response and recovery of the sensor exposed to varying relative humidity (RH) conditions. c Duration of response and recovery of sensor TA2. d Application of sensor TA2 to various curvature measurement performance. (TA2: Ti3C2/Ag = 2wt%). Reproduced with permission from Ref. [111]. e Schematic illustrating the fabrication of hydrophobic, permeable, and conductive silk textile with a vacuum-assisted layer-by-layer assembly approach. f Schematic of the MAF silk detecting sweating humidity. g Humidity response of (MA)nF silk for monitoring human sweating. h Sensitivities of electrical resistance change at 57% RH for MAF silk. (MAF: MXene/Ag NWs/POTs). Reproduced with permission from Ref. [108]

a Diagrams of the manufacturing of MXene and MXene@Pd CNC films and photographs of the completed Pd CNC and MXene suspending solutions. b Sensitivities and response times of MXene@Pd CNC film sensor to 4% H2 (left) and the corresponding flexibility show (right) under different bending angles. Sensitivities and response times of MXene@Pd CNC film sensor to 4% H2 after n-time bending cycles (left) and one bending cycle show from \(\theta\)=0° to 180° and back to 0°. c MXene@Pd CNC film real-time response/recovery profiles for a wide range of high H2 compositions (0.5 ~ 40 v/v%). d Band diagrams of Pd and MXene before and after being exposed to H2, and electronic transfer between the surface H2 sorbed and Pd CNC and MXene. Reproduced with permission from Ref. [97]. e Design the structure of MXenes interaction between water vapor and ion insertion. f The normalized elastic strength of mature MXene samples measured at 2 K increments over a temperature interval of 20 to 300 K. g A representative normalized QENS spectrum was measured at 300 K from the same sample with a representative Q = 0.51 Å−1. h Dependence of half-width at half-maximum extracted from the model fit on Q2 Solids lines are jump diffusion model fits. The extracted water diffusion coefficient values are shown. i Elastic time constants for the reactions of \(\Delta\) R and \(\Delta\) M during H2O desorption (\(\tau\)). Reproduced with permission from Ref. [110]

Within other studies, the investigators tried to improve the sampling performance by doping iron molybdate (Fe2(MoO4)3) [107], Ni(OH)2 [106] and Ti3C2Tx MXene for H2 (in room temperature), n-butanol (in 120 ℃), and NH3 (in room temperature) sensing, respectively. In another study, transition metal fluoride oxide (TiOF2) was surface modified on Ti3C2Tx and subsequently used as a humidity sensor (Fig. 22a–f). By stabilizing the surface end groups, the MXene films showed improved reaction area, flexibility, and catalytic oxidation (Fig. 22j). In addition, the manufactured sensors exhibit good sensitivity and selectivity when exposed to humid environments [98] (Fig. 22h, i). Table 3 provides a detailed overview of sensors based on MXene nanocomposites. In conclusion, insertion of metallic ions and precious metals is also an effective way to improve the gas sensing performance of the original MXenes [109].

a Scheme for the fabrication of TiOF2@Ti3C2Tx. b and c The cross section of the monolayer of the TiOF2@Ti3C2Tx sheet and the rainbow map to show the composition distribution in situ. d TEM image of TiOF2 nanospheres growing on the Ti3C2Tx substrate. e HRTEM image of TiOF2 nanospheres. f HRTEM image of Ti3C2 substrate. g Scheme for the hydrolysis and adsorption to synthesize TiOF2@Ti3C2Tx. h Complex impedance property of TiOF2@Ti3C2Tx at the different RH. i Response and recovery properties of sensors with TiOF2, Ti3C2Tx and TiOF2@Ti3C2Tx. j Three samples tested for extended stability at variable humidity. Reproduced with permission from Ref. [98]

The new MXene gas sensor will be the next generation of universal sensors for future wearable electronic devices, with performance comparable to other 2D material sensors. Through Table 3, it can be clearly found that most of the reported 2D MXenes-based composites are suitable for sensing at room temperature. Secondly, MXenes-based composite materials have been tested for sensing different gases/VOCs and have been found to be highly sensitive to ammonia, acetone, ethanol, nitrogen dioxide, methane, and humidity. On the other hand, the application of MXene-based composites in gas sensors has advantages and disadvantages, as shown in Table 4.

5 Gas Sensing Mechanism of MXenes

5.1 MXenes Surface Adsorption Calculation

It has been theoretically proven that MXenes with semiconductor properties (M2CO2, M = Sc, Ti, Zr, Hf) are highly sensitive to NH3, as shown in Fig. 23a. Xiao et al. [216] calculated and found that after NH3 was adsorbed as an electron donor on M2CO2, charge transfer mainly occurred between the M atom of M2CO2 and the N atom of NH3. When MXene adsorbed NH3, the charge of NH3 molecules was transferred to the transition metal atom on the surface of MXene, and the conductivity of Ti2CO2 was significantly improved. They also found that desorption of NH3 can be easily achieved by adjusting the electrons injected into M2CO2, making the NH3 sensor reversible [217]. For example, the lowest unoccupied electronic state (LUES) of Zr2CO2 mainly comes from Zr atoms, which means that when an additional electron is introduced into Zr2CO2, the electrons will fill the unoccupied electronic orbitals of Zr atoms. Therefore, the injected electrons are mainly distributed on the transition metal, leading to an increase in the metal bond length and adsorption energy of NH3-M, resulting in a decrease in the energy of NH3 adsorption on the MXene surface. The research team [218] also found that the single-molecule layer Sc2CO2 has good adsorption strength and obvious charge transfer for SO2. The transfer of charge from SO2 to Sc2CO2 increases the DOS at the Fermi level of Sc2CO2 and the conductivity of Sc2CO2. By applying external tensile strain or electric field, high selectivity, high sensitivity, controllable capture, or reversible desorption can be achieved, which predicts that Sc2CO2 has good sensing performance for toxic SO2 gas, as shown in Fig. 23b, c. The surface functional groups of MXenes have an undeniable contribution or impact on gas sensing performance. Junkaew et al. [219] used density functional theory (DFT) calculations to investigate the reactivity and selectivity of four O-functionalized MXenes, namely M2CO2 (M = Ti, V, Nb, Mo), toward gas molecules. According to the calculated adsorption energy results, among the 11 gas molecules, Ti2CO2 and Nb2CO2 have stronger adsorption capacity for NH3, while Mo2CO2 and V2CO2 are more sensitive to NO. The surface functional groups of Ti3C2Tx MXene material are a combination of -F, = O, and -OH. The presence and content changes of these functional groups can achieve selective sensing of gas molecules. For example, Pourfath et al. [220] studied through charge difference calculations that the contribution of surface functional groups to charge transfer is different. Fluorine atoms have a smaller contribution to charge transfer than oxygen atoms. Therefore, there is a strong electrostatic attraction between the lone pair electrons of the O atom in the = O functional group on MXenes and the positively charged part of the exposed hydrogen atom in NH3 molecules. Therefore, controlling the content of the = O functional group on the MXenes surface can improve the selectivity toward NH3 molecules. Recently, Naqvi et al. [221] explored several gases (such as CH4) through DFT calculations.

a Side and top views of the most stable configurations of different gas molecules adsorbed on the Ti3C2O2 surface. Reproduced with permission from Ref. [216]. b Two-probe model of monolayer Sc2CO2 sensor for detecting SO2 molecule. c Predicted I-V characteristics of Sc2 CO2 with SO2 molecules. Reproduced with permission from Ref. [218]. d Density functional theory (DFT) simulation results for gas molecules adsorbed on various 2D materials. Side and top views of the minimum energy configurations for acetone and ammonia on Ti3C2(OH)2. Minimum binding energies of acetone and ammonia on Ti3C2(OH)2, Ti3C2O2, Ti3C2F2, graphene, MoS2, and BP. Reproduced with permission from Ref. [42]. e The (002) peak shift of Ti3C2T2 film during N2 purging for 200 min. The (002) peak shift of Ti3C2Tx film during introduction of CO2 (1%) or ethanol (0.1%) for 70 min, followed by N2 purging for 120 min to purge out target gases. Reproduced with permission from Ref. [222].

5.2 First Principles Exploration of MXenes Gas-Sensitive Mechanisms

Maleski et al. [42] used DFT to simulate and calculate the binding energies of acetone and ammonia on Ti3C2Tx, MoS2, RGO, and BP to study the sensing mechanism of Ti3C2Tx on acetone and NH3 gases, as shown in Fig. 23d. For the two gases of acetone and ammonia, Ti3C2(OH)2 exhibits the strongest binding energy more than twice that of other two-dimensional materials. It is speculated that the superior gas adsorption performance of hydroxyl groups in Ti3C2Tx is the main reason for its high sensitivity to acetone and ammonia. This work demonstrates the presence of charge transfer induced by gas adsorption in the gas sensing mechanism of MXenes. In addition, Zhou et al. [216] used Ti3C2Tx as a gas sensing material to test CH4, H2S, H2O, NH3, NO, ethanol, methanol, and acetone gases at room temperature, and found that Ti3C2Tx had very high selectivity for NH3. In order to understand the reason for this high selectivity, they also studied the adsorption behavior, adsorption energy, adsorption geometry, charge transfer, and other aspects using first principles calculation methods. They also confirmed that the charge transfer caused by NH3 adsorption on Ti3C2Tx is the main reason for the change in resistance of Ti3C2Tx. However, MXenes have metal conductivity and contain interlayer water molecules, which means that gas molecules may interact in a more complex manner than typical charge transfer. Koh et al. [222] demonstrated the swelling effect of gas on Ti3C2Tx MXene materials by intercalating Ti3C2Tx with Na+ ions and using in situ XRD technology. After 70 min of ethanol blowing, the (002) peak of Ti3C2Tx shifted toward a smaller angle and the interlayer spacing increased by 0.82 Å. After 120 min of N2 blowing, the adsorbed ethanol was desorbed and the (002) peak of Ti3C2Tx recovered toward a larger angle. The interlayer spacing of Ti3C2Tx membrane decreased by 0.51 Å compared to that after ethanol swelling, as shown in Fig. 23e. Therefore, regulating the interlayer distance of Ti3C2Tx MXene is also very important for improving the selectivity of gas sensing.

6 Summary and Outlook

Starting from the application of new MXene-based composites in the field of gas sensing, this article briefly introduces the preparation methods of gas sensing devices, the structure of MXene, and the properties related to gas sensing. It focuses on the research progress of MXene and graphene, metal oxides, TMDs, MOFs, and polymers in the field of gas sensing, and summarizes the gas sensing mechanism of MXene. However, the development of practical gas sensors based on MXene still faces many challenges:

-

1.

It is necessary to develop green and safe macro preparation methods and surface functional group oriented regulation technologies for MXene. At present, the most mature preparation method for Mn+1Xn is liquid-phase chemical etching, usually using ternary Mn+1AXn precursors as starting materials. In fluorinated solutions such as hydrofluoric acid (HF) and fluoride salts (LiF + HCl, NH4HF2), chemical etching selectively removes the A-layer elements in ternary Mn+1AXn, achieving good selective etching effect and obtaining functional group-rich multilayer Mn+1XnTx materials. On the one hand, MAX phase is usually formed through high-temperature processing of titanium and aluminum, and requires several grinding processes to obtain fine MAX powder. On the other hand, using hydrofluoric acid or fluorinated salts as etching solvents, the highly toxic gases generated during the preparation process seriously endanger human and environmental safety. In addition, the etching capabilities of different solution systems vary, resulting in low two-dimensional yield and difficulty in optimizing the preparation process. This will result in high preparation costs for MXene materials and limit their large-scale application in the gas sensing field. More importantly, the fluorine containing solution reaction system inevitably leads to the random coexistence of three functional groups (= O, -F, -OH) on the surface of Mn+1XnTx, making accurate control extremely difficult. The regulation of functional group states (types and quantities) by changing experimental conditions faces enormous challenges in experiments, and mature and feasible experimental methods for precise regulation of functional groups have not yet been formed, making it difficult to improve selectivity for specific gases through the design of surface functional groups.

-

2.

The variety of MXene material systems still needs to be greatly expanded. Since the discovery of MXene materials in 2011, people's understanding of their structure is still in the initial stage, especially the lack of effective preparation techniques for the types of MXene materials predicted by theory. As a result, MXene currently used in the gas sensing field mainly focuses on two-dimensional Ti3C2Tx and its composite materials. For the large number of MXene material families, more innovative preparation methods have been developed to synthesize pure MXene materials with more diverse types. The combination of surface modification, element doping, heterogeneous recombination and other means to design the composition of the material is a technical bottleneck in expanding the application of MXene in the gas sensing field.

-

3.

The interaction mechanism between MXene and gas molecules needs to be further studied. Due to the richer atomic species and combination types of MXene compared to traditional two-dimensional materials such as graphene, the surface adsorption and charge transfer mechanisms in gas-sensitive processes will be more complex. Whether it is oxidizing or reducing, it is observed that all adsorbed gas molecules will cause an increase or decrease in resistance with a high signal-to-noise ratio. At the same time, interlayer expansion also has a significant impact on the conductivity changes and gas response of the material.

At present, research on MXene is still in its infancy, providing a basic building block for gas-sensitive materials. Experimental data and computational predictions indicate that by selecting over 60 sets of available layered ternary carbides and nitrides, stable structures of different types of MXene can be obtained. It is expected that MXene and its composites will have unlimited potential in the field of gas sensing.

References

H. Wang, X. Yuan, G. Zeng, Y. Wu, Y. Liu et al., Three dimensional graphene based materials: Synthesis and applications from energy storage and conversion to electrochemical sensor and environmental remediation. Adv. Colloid Interface Sci. 221, 41–59 (2015). https://doi.org/10.1016/j.cis.2015.04.005

L. Qin, Q. Tao, X. Liu, M. Fahlman, J. Halim et al., Polymer-MXene composite films formed by MXene-facilitated electrochemical polymerization for flexible solid-state microsupercapacitors. Nano Energy 60, 734–742 (2019). https://doi.org/10.1016/j.nanoen.2019.04.002

Y. Zhang, S. Yu, G. Lou, Y. Shen, H. Chen, Review of macroporous materials as electrochemical supercapacitor electrodes. J. Mater. Sci. 52, 11201–11228 (2017). https://doi.org/10.1007/s10853-017-0955-3

L. Zhu, D. Zheng, Z. Wang, X. Zheng, P. Fang et al., A confinement strategy for stabilizing ZIF-derived bifunctional catalysts as a benchmark cathode of flexible all-solid-state zinc-air batteries. Adv. Mater. 30, e1805268 (2018). https://doi.org/10.1002/adma.201805268

H. Tai, Z. Duan, Y. Wang, S. Wang, Y. Jiang, Paper-based sensors for gas, humidity, and strain detections: a review. ACS Appl. Mater. Interfaces 12, 31037–31053 (2020). https://doi.org/10.1021/acsami.0c06435

H. Tai, S. Wang, Z. Duan, Y. Jiang, Evolution of breath analysis based on humidity and gas sensors: Potential and challenges. Sens. Actuat. B Chem. 318, 128104 (2020). https://doi.org/10.1016/j.snb.2020.128104

P. Geng, S. Zheng, H. Tang, R. Zhu, L. Zhang et al., Transition metal sulfides based on graphene for electrochemical energy storage. Adv. Energy Mater. 8, 1703259 (2018). https://doi.org/10.1002/aenm.201703259

V. Sharma, H.L. Kagdada, P.K. Jha, P. Śpiewak, K.J. Kurzydłowski, Thermal transport properties of boron nitride based materials: a review. Renew. Sustain. Energy Rev. 120, 109622 (2020). https://doi.org/10.1016/j.rser.2019.109622

A.C. Bouali, M. Serdechnova, C. Blawert, J. Tedim, M.G.S. Ferreira et al., Layered double hydroxides (LDHs) as functional materials for the corrosion protection of aluminum alloys: a review. Appl. Mater. Today 21, 100857 (2020). https://doi.org/10.1016/j.apmt.2020.100857

A.M. Kuchkaev, S. Lavate, A.M. Kuchkaev, A.V. Sukhov, R. Srivastava et al., Chemical functionalization of 2D black phosphorus toward its applications in energy devices and catalysis: a review. Energy Technol. 9, 2100581 (2021). https://doi.org/10.1002/ente.202100581

D.H. Ho, Y.Y. Choi, S.B. Jo, J.-M. Myoung, J.H. Cho, Sensing with MXenes: progress and prospects. Adv. Mater. 33, 2005846 (2021). https://doi.org/10.1002/adma.202005846

K. Nataf, T.H. Bradley, An economic comparison of battery energy storage to conventional energy efficiency technologies in Colorado manufacturing facilities. Appl. Energy 164, 133–139 (2016). https://doi.org/10.1016/j.apenergy.2015.11.102

H. Zheng, Y. Zeng, H. Zhang, X. Zhao, M. Chen et al., Oxygen vacancy activated Bi2O3 nanoflowers as a high-performance anode for rechargeable alkaline battery. J. Power. Sources 433, 126684 (2019). https://doi.org/10.1016/j.jpowsour.2019.05.090

A. Feng, Y. Yu, Y. Wang, F. Jiang, Y. Yu et al., Two-dimensional MXene Ti3C2 produced by exfoliation of Ti3AlC2. Mater. Des. 114, 161–166 (2017). https://doi.org/10.1016/j.matdes.2016.10.053

T. Bashir, S. Zhou, S. Yang, S.A. Ismail, T. Ali et al., Progress in 3D-MXene electrodes for lithium/sodium/potassium/magnesium/zinc/aluminum-ion batteries. Electrochem. Energy Rev. 6, 5 (2023). https://doi.org/10.1007/s41918-022-00174-2

X. Hui, X. Ge, R. Zhao, Z. Li, L. Yin, Interface chemistry on MXene-based materials for enhanced energy storage and conversion performance. Adv. Funct. Mater. 30, 2005190 (2020). https://doi.org/10.1002/adfm.202005190

A. Iqbal, P. Sambyal, C.M. Koo, 2D MXenes for electromagnetic shielding: a review. Adv. Funct. Mater. 30, 2000883 (2020). https://doi.org/10.1002/adfm.202000883

Q.-N. Zhao, Y.-J. Zhang, Z.-H. Duan, S. Wang, C. Liu et al., A review on Ti3C2Tx-based nanomaterials: synthesis and applications in gas and humidity sensors. Rare Met. 40, 1459–1476 (2021). https://doi.org/10.1007/s12598-020-01602-2

A. Hermawan, T. Amrillah, A. Riapanitra, W.-J. Ong, S. Yin, Prospects and challenges of MXenes as emerging sensing materials for flexible and wearable breath-based biomarker diagnosis. Adv. Healthc. Mater. 10, e2100970 (2021). https://doi.org/10.1002/adhm.202100970

E. Lee, A. VahidMohammadi, B.C. Prorok, Y.S. Yoon, M. Beidaghi et al., Room temperature gas sensing of two-dimensional titanium carbide (MXene). ACS Appl. Mater. Interfaces 9, 37184–37190 (2017). https://doi.org/10.1021/acsami.7b11055

H. Shi, P. Zhang, Z. Liu, S. Park, M.R. Lohe et al., Ambient-stable two-dimensional titanium carbide (MXene) enabled by iodine etching. Angew. Chem. Int. Ed. 60, 8689–8693 (2021). https://doi.org/10.1002/anie.202015627

Z. Yang, W. Li, G. Zhang, J. Wang, J. Zuo et al., Constructing SbOC bond to improve the alloying reaction reversibility of free-standing Sb2Se3 nanorods for potassium-ion batteries. Nano Energy 93, 106764 (2022). https://doi.org/10.1016/j.nanoen.2021.106764

C. Zhang, L. McKeon, M.P. Kremer, S.-H. Park, O. Ronan et al., Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 10, 1795 (2019). https://doi.org/10.1038/s41467-019-09398-1

Y. Liang, X. Luo, W. Weng, Z. Hu, Y. Zhang et al., Activated carbon nanotube fiber fabric as a high-performance flexible electrode for solid-state supercapacitors. ACS Appl. Mater. Interfaces 13, 28433–28441 (2021). https://doi.org/10.1021/acsami.1c02758

H. Shan, J. Qin, Y. Ding, H.M.K. Sari, X. Song et al., Controllable heterojunctions with a semicoherent phase boundary boosting the potassium storage of CoSe2/FeSe2. Adv. Mater. 33, e2102471 (2021). https://doi.org/10.1002/adma.202102471

H. Hwang, S. Byun, S. Yuk, S. Kim, S.H. Song et al., High-rate electrospun Ti3C2Tx MXene/carbon nanofiber electrodes for flexible supercapacitors. Appl. Surf. Sci. 556, 149710 (2021). https://doi.org/10.1016/j.apsusc.2021.149710

M. Li, J. Lu, K. Luo, Y. Li, K. Chang et al., Element replacement approach by reaction with lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. J. Am. Chem. Soc. 141, 4730–4737 (2019). https://doi.org/10.1021/jacs.9b00574

K. Li, X. Wang, X. Wang, M. Liang, V. Nicolosi et al., All-pseudocapacitive asymmetric MXene-carbon-conducting polymer supercapacitors. Nano Energy 75, 104971 (2020). https://doi.org/10.1016/j.nanoen.2020.104971

H.T.M. Hoa, K.J. Lee, H.P. Pham, T.A. Doan, H.H. Nguyen et al., Ammonia gas sensing behavior of hybridization between reduced graphene oxide and gold nanoparticles. J. Nanomater. 2020, 7680508 (2020). https://doi.org/10.1155/2020/7680508

X. Li, Y. Zhao, X. Wang, J. Wang, A.M. Gaskov et al., Reduced graphene oxide (rGO) decorated TiO2 microspheres for selective room-temperature gas sensors. Sens. Actuat. B Chem. 230, 330–336 (2016). https://doi.org/10.1016/j.snb.2016.02.069

W. Zhang, M. Gong, J. Yang, J. Gu, Zr-MOFs integrated with a guest capturer and a photosensitizer for the simultaneous adsorption and degradation of 4-chlorophenol. Langmuir 37, 8157–8166 (2021). https://doi.org/10.1021/acs.langmuir.1c00823

P. Guo, H. Pan, Selectivity of Ti-doped In2O3 ceramics as an ammonia sensor. Sens. Actuat. B Chem. 114, 762–767 (2006). https://doi.org/10.1016/j.snb.2005.07.040

J. Li, Y. Wang, H. Song, Y. Guo, S. Hu et al., Photocatalytic hydrogen under visible light by nitrogen-doped rutile titania graphitic carbon nitride composites: an experimental and theoretical study. Adv. Compos. Hybrid Mater. 6, 83 (2023). https://doi.org/10.1007/s42114-023-00659-8

Y. Wang, T. Guo, Z. Tian, K. Bibi, Y.-Z. Zhang et al., MXenes for energy harvesting. Adv. Mater. 34, 2108560 (2022). https://doi.org/10.1002/adma.202108560

X. He, H. Zhang, X. Zhao, P. Zhang, M. Chen et al., Stabilized molybdenum trioxide nanowires as novel ultrahigh-capacity cathode for rechargeable zinc ion battery. Adv. Sci. 6, 1900151 (2019). https://doi.org/10.1002/advs.201900151

K.C. Divya, J. Østergaard, Battery energy storage technology for power systems—An overview. Electr. Power Syst. Res. 79, 511–520 (2009). https://doi.org/10.1016/j.epsr.2008.09.017

C.J. Zhang, Y. Ma, X. Zhang, S. Abdolhosseinzadeh, H. Sheng et al., Two-dimensional transition metal carbides and nitrides (MXenes): synthesis, properties, and electrochemical energy storage applications. Energy Environ. Mater. 3, 29–55 (2020). https://doi.org/10.1002/eem2.12058

Y. Wang, X. Wang, X. Li, Y. Bai, H. Xiao et al., Scalable fabrication of polyaniline nanodots decorated MXene film electrodes enabled by viscous functional inks for high-energy-density asymmetric supercapacitors. Chem. Eng. J. 405, 126664 (2021). https://doi.org/10.1016/j.cej.2020.126664

X. Xu, Y. Zhang, H. Sun, J. Zhou, F. Yang et al., Progress and perspective: MXene and MXene-based nanomaterials for high-performance energy storage devices. Adv. Electron. Mater. 7, 2000967 (2021). https://doi.org/10.1002/aelm.202000967

F. Wang, X. Wu, X. Yuan, Z. Liu, Y. Zhang et al., Latest advances in supercapacitors: from new electrode materials to novel device designs. Chem. Soc. Rev. 46, 6816–6854 (2017). https://doi.org/10.1039/C7CS00205J