Highlights

-

An overview of advanced materials for NH3 capture from the aspects of interaction sites and transport pathways is presented.

-

The classifications, working principles, design ideas and structure–property relationships on materials for NH3 capture are discussed in detail.

-

The challenges and encouraging outlooks with worthwhile directions for NH3 capture are proposed.

Abstract

Ammonia (NH3) is a carbon-free, hydrogen-rich chemical related to global food safety, clean energy, and environmental protection. As an essential technology for meeting the requirements raised by such issues, NH3 capture has been intensively explored by researchers in both fundamental and applied fields. The four typical methods used are (1) solvent absorption by ionic liquids and their derivatives, (2) adsorption by porous solids, (3) ab-adsorption by porous liquids, and (4) membrane separation. Rooted in the development of advanced materials for NH3 capture, we conducted a coherent review of the design of different materials, mainly in the past 5 years, their interactions with NH3 molecules and construction of transport pathways, as well as the structure–property relationship, with specific examples discussed. Finally, the challenges in current research and future worthwhile directions for NH3 capture materials are proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ammonia (NH3), an important basic chemical, is a feed stock for nitrogenous fertilizer production via the Haber process, which is important for global food safety [1,2,3]. It is also a promising clean energy source owing to its high hydrogen density and carbon-free nature, and it provides safer transport and storage compared with H2 due to its easy liquefaction and low penetration rate toward transport equipment [4,5,6,7,8]. However, NH3 is a toxic and irritating gas that is detrimental to human health. Specifically, it injures the human eyes, skin, respiratory tract, and liver when its concentration in the blood is higher than 25 ppm [9]. Meanwhile, the excessive emission of NH3 in the atmosphere will participate in chemical reactions to form 2.5-µm particulate matter (PM2.5), causing negative effects such as haze and soil acidification, etc. [10, 11].

NH3-containing gases come from a wide range of sources. For example, it is inevitable to generate a large amount of NH3-containing exhausted gas during urea manufacturing and ammonia synthesis processes. In addition to the mentioned chemical process, the direct NH3 emission from agriculture such as compost and animal breed place also causes serious negative effects [11, 12]. Therefore, NH3 capture and recovery from these sources benefit both resource utilization and environmental protection. The traditional technologies for capturing NH3 involve physical condensation and water/acid scrubbing. Physical condensation relies on a boiling point difference to achieve separation. In such a case, NH3-containing gas should be cooled to a lower temperature (e.g., − 15 °C) to liquify gaseous NH3, while other compounds remain gaseous, which always consumes more energy. Water/acid scrubbing depends on the different solubilities of gases in liquid solvents to achieve gas separation. However, the NH3 recovery from water is energy-intensive, and large quantities of NH3-containing wastewater are inevitably produced, causing serious secondary pollution. Inorganic acid solutions, such as H2SO4 and H3PO4 are highly corrosive, and the reaction of inorganic acids with NH3 is almost irreversible and generates the low-valued salts.

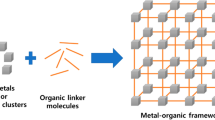

Based on the above analysis, it is necessary to develop novel green technologies for NH3 capture and recovery, in which the design and controllable fabrication of advanced materials are crucial. To date, many materials have been developed, including ionic liquids (ILs), crystalline porous materials (CPMs), porous organic polymers (POPs), and their composites. However, most reviews have focused on a single topic such as ILs for NH3 absorption [13,14,15] or metal–organic frameworks (MOFs) for NH3 adsorption [16,17,18,19]. Overall reviews of both developed and emerging NH3 capture materials are still limited. Rooted in the development of the advanced materials for NH3 capture, we aimed to provide a coherent review of the design of different materials mainly over the past 5 years, and their interactions with NH3 molecules, and the construction of transport pathways. This review first presents a summary of the categories of materials, including functional solvents, porous solids, porous liquids and emerging membranes, along with brief working principles and evaluated parameters. Then, the recent advancements in such materials are briefly reviewed in detail. Functional solvents including ILs and deep eutectic solvents (DESs), have been introduced due to their structural tunability, negligible vapor pressure, and lower energy consumption compared with traditional solvents. As for various NH3-containing gases separation system, balancing the absorption–desorption ability, costs, and variations in physical properties of functional solvents is challenging. As an alternative strategy, porous solids involving conventional inorganic porous materials (CIPMs), porous organic polymers (POPs), crystalline porous materials (CPMs), and composite adsorbents have been proposed, and their performances have been analyzed based on the pore properties and type of interaction sites. Such solids are difficult to be implemented in conventional flow processes, and their performance remains limited. And most of them faced with the problem of structural collapse. Based on the fluidity of liquid absorbents and the porosity of porous solids, an important direction for porous liquids (PLs) for NH3 ab-adsorption was proposed. However, this technology is on the rise and not yet mature and requires to further development. Emerging organic, inorganic and hybrid membranes for NH3 separation and their gas separation performance are discussed; however, it is difficult to meet the demands of industrialization, and the long-term stability of various membranes has still not been explored. In the conclusions and prospects of this review, challenges in current research and encouraging outlooks for the future application of such materials in advanced NH3 capture are analyzed and proposed.

2 Working Principles

The design and development of these materials are important for achieving efficient NH3 capture. Excellent NH3-capturing materials require two features. One is rich specific sites that can interact with NH3 molecules to attain high affinity. It should be noted that the interaction cannot be too strong; otherwise, it is not conducive to the release of captured NH3 from the materials. The other is the introduction of transport pathways, which are expected to provide modulable diffusion channels and rich accessible sites, thereby improving the NH3 capture performance and reducing regeneration consumption.

According to the material characteristics and capture principle, the NH3 capture materials can be divided into the following four types as shown in Fig. 1: absorbents (functional solvents, Sect. 3), adsorbents (porous solids, Sect. 4), ab-adsorbents (porous liquids, Sect. 5), and membrane materials (Sect. 6).

Functional solvents utilize gas with different solubilities in liquid solvents to achieve selective NH3 absorption. The interaction sites (hydroxyl groups, acidic protons, amino groups, metal ions, etc.) on functional solvents play an important role in enhancing the NH3 absorption performance. The NH3 absorption capacity of a given solvent, which is largely influenced by the pressure and temperature, can be determined by the gravimetric methods, vapor–liquid equilibrium apparatus, etc. [20, 21]. The regeneration ability of absorbents is another important evaluation parameter that is significantly related to the energy efficiency and economic benefits in practical applications.

The working principle of porous solids relies mainly on their confined micropores to accommodate gas molecules and the interaction sites in these pores to achieve selective NH3 adsorption. The pore structures and interaction site strengths of porous solids can be obtained using a physical adsorption apparatus, temperature-programmed desorption of ammonia, and other methods. The NH3 adsorption isotherm is normally measured using a gas adsorption instrument that monitors the change in pressure of a sample held at a given temperature when exposed to different ammonia pressures [22]. The NH3 adsorption dynamics of samples can be investigated either by breakthrough curves [16], which record the concentration curve of each component over time through a breakthrough column, or by dynamic mode measured on a gas adsorption instrument [23], which can provide the speed to reach equilibrium and the time-dependent adsorption capacity at a given pressure and temperature.

Although porous solids offer major benefits, such as lower energy penalties in adsorption–desorption cycles, they are difficult to implement in conventional flow processes. To address this limitation, ab-adsorbents, i.e., PLs, have been developed by introducing permanent porosity into liquid materials. The existence of intrinsic micropores in PLs allows for rapid NH3 adsorption–desorption (kinetics) while maintaining liquid fluidity and high adsorption capacity and selectivity (thermodynamics) resulting from both components. Such a combination is also beneficial for reducing the regeneration consumption and thus increasing the energy efficiency compared with liquid absorption, owing to the introduction of a pore structure on the feasible gas diffusion pathways [24]. The gas uptake of PLs can be measured by gas adsorption equipment [25] and column breakthrough tests [26]. Annihilation lifetime spectroscopy (PALS) and density measurements [27, 28] are usually used to confirm the permanent porosity of PLs.

Membrane separation uses different gas permeation rates through membranes to achieve NH3 selective separation. Gas permeation tests usually use the differential pressure method; specifically, they can be divided into the constant pressure-variable volume and constant volume-variable pressure methods. Permeance and selectivity are key parameters for gas separation membranes [29, 30]. The permeance (Pi) and separation selectivity (\(\alpha_{i/j}\)) can be calculated using the following equations:

where Pi and Pj represent the permeance of gases i and j, respectively (cm3 (STP)/(cm2 s cm Hg)); 1 GPU = 1 × 10–6 cm3 (STP)/(cm2 s cm Hg); Qi denotes permeate flow rate of gas i at the standard state (cm3 (STP) s−1); and A and Δpi represent the effective membrane area (cm2) and transmembrane pressure difference of gas i, respectively.

3 Functional Solvents for NH3 Absorption

As advanced solvents, ionic liquids (ILs) are prospective candidates for NH3 capture. ILs are entirely composed of organic cations and organic/inorganic anions, which make them designable according to application requirements [13,14,15]. In addition, the unique properties of ILs, including negligible vapor pressure, low specific heat capacity, and excellent recyclability, greatly reduce the regeneration energy consumption and solvent loss during the NH3 capture process compared to water scrubbing [15, 31]. Current research on NH3 capture using IL-based solvents involves the design and development of absorbents, mass-transfer investigation, process simulation and assessment, and industrial applications. The development of task-specific absorbents for efficient and reversible NH3 capture is fundamental and critical; thus, it has attracted the attention of many researchers. In this section, the NH3 absorption–desorption performance, physical property variation, and absorption mechanism of task-specific ILs and their analogous DESs are briefly discussed from the perspective of the types and numbers of interaction sites for NH3 absorption (Fig. 2).

3.1 Task-Specific Ionic Liquids

Considerable efforts have been devoted to designing novel task-specific ILs for efficient NH3 absorption. The interaction sites between ILs and NH3 molecules play an important role in efficient and reversible NH3 absorption. The introduction of hydroxyl groups, acidic protons, amino groups, sulfo-/carboxyl groups, and metal ions remarkably improves the NH3 absorption capacity of ILs. Table 1 lists the NH3 absorption capacities of representative ILs.

The dissolution behavior of NH3 in conventional ILs was firstly reported in 2007, and it was inferred that strong intermolecular complexes between NH3 and ILs are formed [32]. Subsequently, it was found that cations had a greater influence on NH3 solubility than anions and that the hydrogen bond between the acidic 2-H of the imidazole cation and N atom of NH3 played a crucial role in NH3 absorption [33]. Thus, a feasible strategy for designing task-specific ILs is to tune the hydrogen-donating ability of the cations by adjusting the type and number of functional groups.

A series of task-specific ILs based on the hydrogen bond interaction were developed by introducing single hydroxyl functional groups and acidic protons into cations of ILs, and these ILs usually have higher NH3 absorption capacity (0.83–4.2 mol NH3/mol IL) than that of conventional ILs (< 0.8 mol NH3/mol IL), simultaneously showing great regeneration ability. Palomar et al. [34, 35] adopted the COSMO-RS calculation method to screen potential NH3 absorbents from 272 ILs and found that hydroxyl-functionalized ILs [EtOHmim][BF4] and [choline][NTf2] are promising for NH3 absorption. As expected, a higher absorption capacity was achieved by hydroxyl-functionalized ILs compared with conventional ILs, and the separation mechanism of hydrogen bond interactions between ILs and NH3 was further proved by near-infrared spectroscopy (NIR) and nuclear magnetic resonance (NMR) spectroscopy [36, 37]. Shang et al. [38] proposed a new strategy for introducing an acidic proton onto a cation to improve the NH3 absorption capacity. The protic ionic liquid (PIL) [Bim][NTf2] (Fig. 3a) exhibited high NH3 absorption capacity with a value of 2.69 mol NH3/mol IL at 313 K and 100 kPa. There was no evident decline in the absorption ability of the recycled [Bim][NTf2] after being used four times. Notably, the viscosity of the IL–NH3 system during the NH3 absorption process first increased and then decreased sharply to a lower value [39], which is completely different from the increased viscosity caused by CO2 absorption. Furthermore, the NH3 absorption mechanism of ILs was revealed through molecular dynamics (MD) simulations [40]. The results indicated that the energy of strong N3–H···N(NH3) hydrogen bond between [Bim]+ and NH3 molecules is up to − 79.0 kJ mol−1, which is twice as strong as the hydrogen bond energy between C2-H of [Bmim]+ and NH3. This strong interaction induced the enrichment of cations at the PIL–gas interface, resulting in NH3 molecules penetrating deeply into the bulk of the PILs and achieving selective absorption of NH3 from gases containing N2 and H2. Besides, there are always other gases present, such as water in NH3-containing gases in industrial streams. Trace water was also found to enhance NH3 absorption owing to the cooperative absorption caused by [Bim][NTf2] and H2O.

Multiple hydrogen sites can be incorporated into the cations of ILs to improve their absorption performance through cooperative hydrogen bonding interactions. The NH3 absorption capacity of imidazole-based ILs ([2-Mim][NTf2] and [Im][NTf2]) (Fig. 3b) with two acidic protons on cations was up to 3.46 mol NH3/mol IL. The NH3 absorption capacity remained stable after five cycles of absorption and desorption [41]. Subsequently, Sun et al. [20] synthesized triazole cation-functionalized ionic liquids (TCFILs) containing three acidic protons (Fig. 3c). These TCFILs showed a rapid transition from the initial solid to liquid state during the NH3 absorption process. Moreover, [1, 2, 3-TrizH2][NO3]2 exhibited an ultrahigh NH3 absorption capacity of 4.187 mol NH3/mol IL (about 365 mg NH3/g IL) at 303.15 K and 101 kPa and great recyclability benefiting from multiple hydrogen bonds, which is comparable to that of traditional water absorbents used in industry (300 mg NH3/g H2O at 313 K and 101 kPa). Meanwhile, [1, 2, 3-TrizH2][CF3SO3]2 showed faster absorption kinetics than that of [1, 2, 3-TrizH2][NO3]2. At the same time, the effect of water molecules on NH3 absorption performance was studied. The results indicated that the addition of small amounts of water to [1, 2, 3-TrizH2][CF3SO3]2 had no obvious impact on the NH3 capacity and shortened the absorption equilibrium time from 20 to 15 min, owing to the reduced viscosity of the systems. Additionally, simultaneously embedding acidic protons and hydroxyl groups on the cations of ILs is an efficient strategy to further improve NH3 absorption capacity. Yuan et al. [21, 42] found that these imidazole- and pyridinium-based dual-functionalized PILs (DPILs) (Fig. 3d) possessed higher NH3 solubility than ILs functionalized only by a single hydroxyl group. Specifically, the NH3 solubility of [EtOHim][NTf2] was as high as 3.110 mol NH3/mol IL, which is approximately 30-fold greater than that of [Emim][NTf2] and four-fold greater than that of the functionalized IL [EtOHmim][NTf2]. These DPILs also exhibited outstanding recyclability, an excellent NH3/CO2 selectivity of 65, and NH3/ N2 selectivity of 104.

There have been a few reports on the application of amino-functionalized ILs for NH3 absorption. For example, Luo et al. [43, 44] designed a series of cation-functional PILs with single or multiple amidino groups (Fig. 4). Reversible cooperative hydrogen bond (CHB) networks were formed by hydrogen bond interactions between ammonia and amidino groups. The NH3 absorption–desorption process was accompanied by the breakage and reformation of CHBs in the ILs, which led to a sigmoidal NH3 absorption isotherm and energy-saving desorption. The [BzAm][NTf2] showed NH3 absorption with a threshold pressure of 0.28 kPa and capacity of 2.8 mol NH3/mol IL at 100 kPa. The absorbed NH3 could also be rapidly stripped at 323 K and 1 kPa within 30 min. In addition, the threshold pressure and NH3 ammonia production capacity could be tuned by varying the CHB interactions in the ILs. Similarly, Deng et al. [45] synthesized six protic ethanolamine-based ILs with multiple binding sites for efficient and reversible NH3 uptake. Among them, ethanolamine thiocyanate ([EtA][SCN]) had suitable viscosity of 78.18 mPa s and exhibited the best absorption ability of 2.538 mol NH3/mol IL at atmospheric pressure and 293.15 K due to multiple hydrogen-bonding interactions between acidic protons, hydroxyl groups, and thiocyanate with NH3. In addition, the outstanding NH3/CO2 ideal selectivity with a value of 365 was observed in [EtA][SCN], which provides a competitive way to selectively separate NH3 from CO2 in tail gas.

At the same time, NH3 is typically an alkaline gas. The introduction of Brønsted acidic groups to react with NH3 is expected to improve the absorption capacity of ILs. Recent studies have shown that imidazolium- and ammonium-based ILs with sulfo and carboxy groups exhibit higher NH3 solubilities than conventional and hydroxy-functionalized ILs. Moreover, the acidity of the Brønsted acidic group and the chemical structures of the acidic group and constituent ions also significantly affected the NH3 capacity [46]. Another effective approach for improving the NH3 absorption capacity is to develop metal ILs based on complexation with NH3. Pioneering work on metal ILs for NH3 absorption was reported in 2013, which used [Bmim][Zn2Cl5] as an NH3 absorbents and showed a superior absorption capacity of 8.0 mol NH3/mol IL at 323 K and 100 kPa, but the strong complex interaction between metal ILs and NH3 molecules led to irreversibility of the materials [47, 48]. To solve the above problems, Zeng et al. [49] designed a series of novel cobalt ILs, [Cnmim]2[Co(NCS)4] (n = 2, 4, or 6), for reversible NH3 absorption. The cobalt ILs exhibited a remarkable NH3 absorption capacity of 6.09 mol NH3/mol IL, which is more than 30 times higher than those of conventional ILs [Cnmim][SCN] without metals. This superior performance was attributed to the moderate Lewis acid–base interaction and cooperative hydrogen bonding between the MILs and NH3 confirmed by experimental characterizations and density functional theory (DFT) calculations. At the same time, these cobalt ILs exhibited excellent recyclability and maintained a stable NH3 capacity after five cycles. Wang et al. [50] further systematically studied the effects of various metal centers on the physicochemical properties and NH3 absorption capacity. Among the range of MILs, [Bmim]2[SnCl4] not only showed a high absorption capacity of 5.169 mol NH3/mol IL at 303.15 K and 100 kPa, which is much higher than that of conventional ILs, but also showed no obvious NH3 capacity loss after five absorption and desorption cycles.

In addition to the above high-valence MILs, alkali metal ions, especially lithium (Li), have also been introduced into PILs to increase NH3 absorption performance. Shang et al. [41] prepared novel sorbents that simultaneously incorporate acidic protons into cations and Li+ ions into anions. The solid ILs gradually became liquids after NH3 adsorption. An exceptional NH3 capacity of 7.01 mol NH3/mol IL was achieved using [2-Mim][Li(NTf2)2] at 313 K and atmospheric pressure, which is the highest NH3 capacity reported for an IL to date. This superior capacity is attributed to the synergistic effect of hydrogen bonding between acidic protons and NH3, as well as the Lewis acid–base interaction between the Li+-based anion and NH3. Inspired by this, Cai et al. [51] further synthesized liquid chelation-activated multi-site ILs for reversible chemical absorption of NH3, as shown in Fig. 5. The chelation of triethylene glycol (TEG) with Li+ activates the hydroxyl sites in TEG for strong interaction with NH3, resulting into an outstanding NH3 absorption capacity of 3.36 mol NH3/mol IL at 313 K and 102.5 kPa.

Reproduced with permission from Ref. [51], Copyright 2022, John Wiley and Sons

Structures and pictures of Li-TEG–chelated ILs.

3.2 Deep Eutectic Solvents

Given the lone-pair electrons and alkalinity of NH3, the DESs with strong hydrogen-bond donating ability or Brøn-sted acidity are usually useful for capturing NH3. DESs generally consist of two or three components capable of intermolecular interactions, particularly hydrogen bond interactions, which have lower melting points than those of each separate component [52]. They can be easily prepared by simply mixing hydrogen bond acceptors (HBAs) with hydrogen bond donors (HBDs). The introduction of a second or third component effectively reduces the viscosity and improves the mass transfer efficiency. Because of the diverse structures of HBAs and HBDs, many DESs have been synthesized for NH3 absorption. Table 2 lists the NH3 absorption capacities of representative DESs.

The current interest in DESs for NH3 absorption is rooted in the pioneering work on hybrid ternary DESs with flexible hydrogen-bonded supramolecular networks designed by Li et al. [53]. The reported DESs are composed of choline chloride (ChCl), resorcinol (Res), and glycerol (Gly), which break the trade-off between NH3-DES interaction strength and the stability of traditional DESs. The NH3 mass solubility of ChCl/Res/Gly (1:3:5) DESs reached 130 mg g−1 at 313 K and 101 kPa, which exceeds those of hydroxyl-functionalized ILs and ordinary DESs. More importantly, this excellent performance was retained after ten absorption–desorption cycles. Additionally, the presence of CO2 in melamine tail gases is unavoidable. Thus, the CO2 absorption of optimized DESs was investigated. The results showed that the solubility of CO2 was 0.91 mg g−1, which is far lower than NH3 solubility under the same conditions, showing great potential for the separation of NH3 and CO2.

Subsequently, a series of DESs using ChCl as the HBA were developed for NH3 capture owing to their excellent biodegradability and low price, including ChCl/Urea [54] and ChCl/dihydric alcohols [55]. Sun et al. [56] innovatively introduced metal chlorides, such as anhydrous MgCl2, NiCl2, MnCl2, and ZnCl2, into a binary Res/EG system to prepare ternary DESs, and the NH3 capacity notably increased owing to the cooperating hydrogen bonding and Lewis acid–base interactions. In particular, the NH3 absorption capacity of MgCl2/Res/EG (0.1:1:2) was 289 mg g−1 at 293 K and 100 kPa. In addition, the introduction of hydroxyl, amide, and carboxyl groups into the structure of HBDs in DESs was an effective method to obtain NH3 absorbents with excellent performance [57,58,59]. ChCl-based DESs containing hydroxyl groups on HBDs exhibited higher NH3 absorption capacity than DESs containing amide groups. The optimal NH3 capacity of ChCl/EG (1:2) reached 46 mg g−1 at 303.15 K and 546.1 kPa. Moreover, NH3 absorption in this system was thermodynamically spontaneous according to thermodynamic property calculations, including standard Gibbs energy, dissolution enthalpy, and dissolution entropy [60]. Huang et al. [61, 62] further proposed introducing an HBD component with weak acidity into a ChCl-based system, which not only improved the NH3 absorption capacity but also resulted in the reversible absorption of NH3.

Considering the potential risk that toxic components in DESs pose to human health and the environment, Li et al. [63] proposed “natural DESs” composed of ChCl and sugar. These DESs exhibited higher NH3 capacities at low pressure and increased temperature compared with other reported DESs, which is important for practical applications, especially for low-concentration NH3 capture. Most studies have focused on the rational design of HBD structures in DESs to regulate the NH3 absorption performance, whereas Kazarina et al. [64,65,66] considered the functional group modification of HBAs. The substitution of hydroxyl groups in ChCl, as shown in Fig. 6, remarkably decreased the toxicity and enhanced NH3 solubility via hydrogen bond interactions. The NH3 absorption capacity was enhanced by increasing the number of hydroxyl groups of the choline cation. The absorption capacities of [Me2COH2N]Cl/Urea with two hydroxyl groups and [MeCOH3N]Cl/Urea with three hydroxyl groups were 35.3 and 44.7 mg NH3/g DES at 313.2 K and 101.3 kPa, respectively, which is approximately twice that of ChCl/urea (2:3) under the same conditions.

Reproduced with permission from Ref. [66]. Copyright 2022, American Chemical Society

Structure of HBAs modified by hydroxyl groups on cation and NH3 absorption performance.

In addition to ChCl-based DESs, much less expensive ethylamine hydrochloride (EaCl)-based DESs have also been developed. Similarly, the EaCl-based DESs with different hydrogen-bond donating ability or Brønsted acidity such as EaCl/AA [67], EaCl/Gly [68], EaCl/PhOH [69], and EaCl/Res [70], were explored for NH3 capture. The effects of EaCl/HBD molar ratio, temperature, and pressure were investigated systematically. An appropriate EaCl/HBD molar ratio is beneficial for obtaining DESs with low viscosity and high NH3 absorption capacity. Decreased temperature and increased pressure contributed to enhanced NH3 absorption capacity.

However, the above-mentioned Cl-containing DESs have potential corrosivity hazards toward equipment in the practical applications. Zheng et al. [71] further proposed non-chloride DESs with multiple weak acidic sites (one carboxylic group and two phenolic hydroxyl groups) by dihydroxybenzoic acid (DHBA) and EG for selective NH3 absorption. The DHAB/EGs DESs provided multiple hydrogen bond sites with NH3 molecules, enabling exceptional and reversible NH3 absorption with the value of 199 mg g−1 at 100 kPa and 298.15 K. Additionally, imidazole-based ILs without chloride elements were prepared as DESs, such as [Bmim][MeSO3]/urea [72], and [Im][NO3]/EG [73]; protic imidazole IL-based [Im][NO3]/EG DES with a molar ratio of 1:3 exhibited the highest capacity of 211 mg NH3/g DES at 303 K and 100 kPa and great NH3/CO2 selectivity of 139.6 along with good recyclability. In addition, non-ILs binary DES systems have been developed for NH3 absorption, such as N-methylacetamide(MAA)/tetrazole [74], NH4SCN/Gly [75], and GI/AT [76], in which the optimal NH3 mass absorption capacity of NH4SCN/Gly (2:3) was as high as 223 mg/g DES at 303 K and 100 kPa because of the cooperative hydrogen bond interactions between NH4+, OH, and NH3 molecules.

4 Porous Solids for NH3 Adsorption

Compared with liquid absorption materials, porous solids for NH3 adsorption have been extensively studied [17, 77]. The abundant pores in solid materials provide the space for fast NH3 transport, which also avoids the problems of corrosion and low mass transfer efficiency resulting from acid scrubbing and the high viscosity of ILs. The reported porous solids can be roughly divided into four types: CIPMs, POPs, CPMs, and composite adsorbents, as shown in Fig. 7. Generally, CIPMs, such as activated carbon (AC), are low-cost and easy to fabricate, but the interaction between these materials and NH3 molecules is weak. As a potential solution, POPs have been exploited, by the disordered pores formed by polymer segments/ordered pores and acidic groups enhance the NH3 adsorption capacity. In addition, CPMs, such as MOFs, hydrogen-bonded organic frameworks (HOFs), and covalent organic frameworks (COFs, also belonging to POPs), usually exhibit high NH3 adsorption capacities and fast adsorption kinetics owing to their ordered pore structures and strong interactions with NH3. Furthermore, composite adsorbents, especially IL-based composites, which couple the high NH3 affinity of task-specific ILs with the porous properties of solid supports, are employed for NH3 capture. In this section, we focus on the novel adsorbents reported in the last 5 years, covering the design ideas of the corresponding materials, NH3 adsorption performance, and adsorption mechanism.

4.1 Conventional Inorganic Porous Materials

Conventional inorganic porous materials (CIPMs), including activated carbons (ACs) [78,79,80], zeolite [77], metal halides [81], and mesoporous silica/alumina [82], have been widely used for NH3 capture because of their favorable characteristics, such as diverse pore architectures, high stability, and low cost. However, the NH3 adsorption capacity of these materials is relatively low owing to their limited affinity toward NH3 molecules. Therefore, the modification of functional groups to these CIPMs has been proposed to improve the NH3 adsorption capacity. For instance, Zheng et al. [83] developed fiber-form AC modified by acidic oxygen groups, which exhibited a high NH3 adsorption capacity of 50 mg g−1. Li et al. [84] found that AC modified by HNO3 exhibited the best NH3 removal performance among three inorganic acid-modified ACs, with a maximum NH3 adsorption amount of 40 mg g−1, owing to the reduced adsorption energy caused by the co-adsorption of NH3 with residual HNO3 via a hydrogen bond network. More recently, Zhang et al. [85] demonstrated that ordered MS functionalized with a sulfonic group (OMS-SO3H) exhibited ultra-high precision for NH3 reversible adsorption and separation, benefiting from the high density of –SO3H superic acid sites in ordered mesochannels.

Zeolites are another popular material for NH3 adsorption, and its properties, including acidity/basicity and hydrophilicity/hydrophobicity, can be tuned by varying the Si/Al ratio. Therefore, through interaction between NH3 and zeolites, NH3 adsorption performance can be finely regulated. Martos et al. [86] revealed that hydrogen bonds play an important role in NH3 capture with pure or high-silica zeolites, as confirmed by experimental and molecular simulations. Ouyang et al. [87] further indicated that NH3 adsorption capacity was inversely proportional to the Si/Al ratio. Exchanging the counter cation from Na+ to Li+ led to a higher NH3 adsorption capacity owing to stronger interactions between Li+ and NH3. In addition, the Al distribution in the nanopores and synthetic materials also affected the NH3 adsorption performance [88, 89].

Metal halides can effectively capture NH3 molecules by forming metal–ammonia complexes; however, regeneration at low temperatures is difficult [81]. Recently, Shen et al. [90] further studied the effect of metal halide types with the same metal cation and number of cycles on NH3 adsorption capacity. The NH3 adsorption capacity followed the order CuCl2 > CuBr2 > CuI, and these materials underwent severe sintering during the high-temperature regeneration process, causing difficulty in recycling. Cao et al. [91] exploited a novel porous SrCl2 structure with 96 wt% loading scaffolded by reduced graphene oxide networks to avoid sintering, which showed superior NH3 adsorption capacity (50.5 mmol g−1) and rapid absorption–desorption kinetics and maintained a porous structure accommodating the volume without disintegration during cycling experiments.

4.2 Porous Organic Polymers

Porous organic polymers (POPs) are among the most widely studied materials for gas separation owing to their various monomer geometries and excellent thermal/chemical stabilities derived from the covalent nature of polymers [92, 93]. The functionalization of POPs with tunable and strong acid sites is an effective way to improve NH3 adsorption performance. In 2014, Van Humbeck et al. [94] firstly presented a series of diamondoid POPs densely functionalized with carbonylic acids for NH3 capture. Among various polymers, BPP-5 with a multiply interpenetrated structure dominated by pores smaller than 6 Å pores exhibits an NH3 uptake of 17.7 mmol g−1 at 1 bar, and BPP-7 with larger pore size shows improved NH3 absorption kinetics at low pressure (3.15 mmol g−1 at 480 ppm), but the recyclability of these POPs is not clear. Since then, various POPs modified by acid groups have been developed for NH3 adsorption, such as COOH-copolymer PDAB-AA [95], PIM-1-COOH [96], H3PO4 modified POPs [97], H2SO4-modified ethylene glycol dimethacrylate (EGDMA) polymers [98, 99] and sulfonated POPs [100], and the regeneration abilities of most materials have also been investigated systematically. Table 3 presents the NH3 adsorption performance and regeneration properties of representative POPs.

Recently, Kan et al. [101] further reported a sulfonated and ordered mesoporous polymer (SOMP). The strong affinity of the –HSO3 group with NH3 in sequential pore space of SOMPs, as shown in Fig. 8, not only enhances the molecular recognition ability but also facilitates NH3 fast diffusion inside SOMPs so that favorable NH3 adsorption capacity (15.09 mmol g−1 at 25 °C and 1 bar) and excellent reversibility could be achieved. Additionally, a multi-step post-modification strategy was proposed to further improve the NH3 adsorption performance of POPs. Kang et al. [102] found that a high NH3 adsorption capacity, especially at low pressures, and excellent recyclability were obtained owing to the formation of high-density acidic functional groups (–COOH and –HSO3) induced by post-oxidation and post-sulfonation processes on poly(dimethylsiloxane) (PDMS)-coated hyper-crosslinked POPs. Furthermore, sequential post-sulfonation and post-alkylation reactions were developed to modify POPs for NH3 capture. A record-high NH3 capacity (4.03 mmol g−1) at 500 ppm was achieved, and it adsorbed 0.48 mmol g−1 even at a concentration of 800 ppb. Simultaneously, the hydrophobic nature of alkyl chains offers rapid desorption kinetics and exceptional recyclability under dry and humid conditions at room temperature [103].

Reproduced with permission from Ref. [101]. Copyright 2022, Elsevier

NH3 adsorption mechanism of SOMPs.

In addition to their ability to interact with acidic groups, the hydrogen bond-forming properties of NH3 molecules are highly attractive for POPs. Lima et al. [104] demonstrated that hydrogen bonds play an important role in the NH3 uptake by poly(amic acid) (PAA) by combining TGA with neutron spectroscopy, supported by DFT calculations. Besides, the hydrogen bond sites with –COOH groups efficiently improved NH3 adsorption performance of PAA, but strong interaction also made complete regeneration difficult [105].

The incorporation of open metal sites and ionic units to prepare porous ionic polymers as NH3 adsorbents is also promising. As shown in Fig. 9, Luo et al. [106] reported porous cobaltous thiocyanate (Co(II)(SCN)42−, TA)-functionalized polyILs with an NH3 uptake capacity of 12.2–20.1 mmol g−1 owing to cooperative interactions containing NH3 coordinating with Co(II) instead of SCN− and hydrogen bonding of H at the C2 atom in the imidazolium ring (C2H···NH3). At the same time, the competitive interaction between NH3 and free SCN− promoted NH3 release, contributing to the good recyclability of the adsorbents. Moreover, the coordinative numbers of metal centers in polyILs with NH3 molecules have a significant effect on the NH3 capacity. For instance, high NH3 adsorption capacity was achieved when the coordination number increased from n = 4 (M = Cu/Zn) to n = 6 (M = Co). Increasing the moderate size of the cross-linking agent R enhances the NH3 capacity of PILs; however, oversizing R also reduces the porosity of polyILs [107]. Similarly, PIPs have also been explored, and multiple active sites containing charged skeletons, Lewis acid defects, and metal ions in Cu@PIP jointly promoted improved NH3 adsorption performance and outstanding recyclability without structural collapse [93].

Reproduced with permission from Ref. [106]. Copyright 2021, Elsevier

Proposed mechanism of NH3 adsorption with PIL-Tas.

4.3 Crystalline Porous Materials

MOFs, which are typical CPMs, are one of the most promising candidates for NH3 adsorption because their sorption selectivity is directly tunable as a function of the topology and chemical composition of the pores [19, 108,109,110,111,112]. Takahashi et al. [113] firstly demonstrated the possibility of historical pigment of Prussian blue and its analogs (CoHCC and CuHCF) for NH3 capture. The NH3 uptake capacity of Prussian blue is up to 12.5 mmol g−1 at 0.1 MPa owing to the NH3 transformation into NH4+ with H2O in air, which is much higher than that of standard NH3 adsorbents (5.08–11.3 mmol g−1). Subsequently, various MOFs for efficient NH3 adsorption have been developed, in which the incorporation of open metal sites, functional sites on the ligand, and defect sites are effective measures to improve NH3 adsorption performance. The NH3 adsorption performance and regeneration properties of representative MOFs are listed in Table 4.

The incorporation of open metal sites in MOFs provides high NH3 affinity, which is expected to remarkably improve NH3 adsorption performance. For example, Dinca’s group developed a series of triazole MOFs with open metal sites (Co, Ni, and Cu), in which Co2Cl2BBTA (BBTA = 1H,5H-benzo(1,2d), (4,5-d′)bistriazole) with smaller-pores exhibited greater capacities than their larger-pores BTDD-based counterparts (BTDD = bis(1H-1,2,3triazolo[4,5-b],[4′,5′-i])dibenzo[1,4]dioxin) benefiting from the higher density of open metal sites. The static uptake is up to 19.79 mmol NH3 g−1 at 1 bar and 298 K, which is more than twice the capacity of commercial activated carbon [114]. In contrast to the above-mentioned formation of NH3-binding sites triggered by high-quality clusters, Carne-Sanchez et al. [115] reported metal–organic polyhedrals (MOPs) with Rh(II) as open metal sites for NH3 capture. The low nuclear Rh(II) paddlewheel clusters in the synthesized MOFs firstly coordinated with NH3 molecules, which further induced the adsorption of additional NH3 molecules through H-bond interaction. This unique mechanism endows the prepared Rh-MOPs with a high NH3 adsorption capacity exceeding 10 mmol g−1, which can be easily regenerated via immersion in an acidic solution. The effect of open metal sites on NH3 adsorption behavior was also investigated systemically. For example, CuBTC exhibited a higher ammonia uptake of 23.88 mmol g−1 compared with others (ZnBTC, 11.33 mmol g−1; FeBTC, 9.5 mmol g−1) [116], and Al-PMOF showed greater NH3 adsorption reversibility compared to those of isoreticular Ga-PMOF and In-PMOF [117]. Likewise, Zr6-NU-907 exhibited the highest NH3 adsorption capacity at low pressure among the NU-907 family of MOFs, owing to the higher electronegativity of metal Zr ions. The in situ IR results further demonstrated that NH4+ and Lewis-bound NH3 species were formed during NH3 adsorption [118]. The Mg2(dodpdc) exhibited record-high NH3 capacity of 23.90 mmol g−1 at 1 bar and 8.25 mmol g−1 at a low pressure of 0.57 mbar in a series of M2(dodpdc) MOFs that were constructed from various divalent metal cations (M = Mg2+, Mn2+, Co2+, Ni2+, and Zn2+) and a tetradentate ligand dobpdc4− (Fig. 10a). At the same time, it was confirmed that Mg2(dodpdc) shows excellent structural stability even for wet NH3 owing to the higher affinity of Mg2+ for oxygen atoms than for nitrogen atoms, showing great potential for practical applications [119].

Reproduced with permission from Ref. [119]. Copyright 2020, John Wiley and Sons. b Structure of MFM-303(Al). Reproduced with permission from Ref. [121]. Copyright 2021, American Chemical Society. c Structure of UiO-66 material with defect site and Cu(II) Reproduced with permission from Ref. [125]. Copyright 2022, American Chemical Society

a Atomic structure of M2(dobpdc) (M2+ = Mg2+, Mn2+, Co2+, Ni2+,and Zn2+) and NH3 adsorption isotherms at 298 K.

Functionalization of the ligand is another effective strategy for improving the NH3 adsorption performance of MOFs. Nguyen et al. [120] functionalized ligands by incorporating electrophilic boron (B) centers, which electrophilized the pores and promoted the capture of electrostatic NH3 molecules. Moreover, the bulky duryl groups precluded strong acid–base B-N interactions to ensure the robustness of MOFs in the presence of NH3. Therefore, the prepared SION105-Eu MOF via this strategy is easily regenerated after NH3 adsorption by simple heating at 75 °C. In addition, a robust Al-based MOF, MFM-303(Al), functionalized with free carboxylic acid and hydroxyl groups, was developed for NH3 capture, as shown in Fig. 10b [121]. Two carboxylate groups from each tetracarboxylic ligand molecule were bound to the Al(III) centers, whereas the other two remained uncoordinated and formed intramolecular hydrogen bonds with neighboring ligands. These acidic sites in the pores not only make MFM-303(Al) show excellent adsorption performance for low concentrations of NH3 under both dry and wet conditions but also offer an exceptional packing density of NH3 at 293 K (0.801 g cm−3), comparable to that of solid NH3 at 193 K (0.817 g cm−3), which means that MFM-303(Al) could be used for NH3 storage in practical applications.

Defective MOF construction by missing ligands or metal nodes can tune the nanostructure and pore size [122,123,124], thereby affecting the NH3 adsorption performance. Ma et al. [125] simultaneously introduced defect sites and open Cu(I) and Cu(II) sites on a robust UiO-66 material, as shown in Fig. 10c, which exhibited high and reversible NH3 adsorption capacity, avoiding the issues that MOFs with multiple coordination Cu(II) sites suffer from irreversible NH3 sorption and structural degradation during adsorption. The excellent NH3 adsorption–desorption reversibility of these MOFs predominantly resulted from the reversible change in the near-linear coordination geometry of the Cu(II) sites as a function of NH3 binding.

Although MOFs possess high adsorption capacity and selectivity, most of them still face the challenge of structural degradation when in contact with NH3 [126, 127]. Thus, enhancing the strength of the coordination bonds and tuning the moderate interaction between metal centers and NH3 when designing MOFs should be emphatically considered. Yang et al. [128] designed a kind of ultra-stable MFM-300(Al), in which AlO4(OH)2 was bridged by 3,3′,5,5′-bipphenyl-tetracarboxylic acid to form a “wine-rack” framework, which could store ammonia for at least 183 weeks without decreasing in the apparent domain size of changes in the unit cell volumes. The NH3 adsorption capacity reached 15.7 mmol g−1 at 273 K and 1.0 bar, and there was no loss of NH3 adsorption capacity over 50 cycles owing to the reversible H/D site exchange between the MOF and NH3 molecules revealed by in situ neutron powder diffraction and synchrotron FTIR micro-spectroscopy [129]. O Other isostructural analogs of MFM-300(M) (M = Fe, Cr, V) have also been reported, among which MFM-300(M) (M = Cr, VIII) showed higher stability against humid NH3 than MFM-300(M) (M = Fe, VIV) [130]. Wang et al. [131] further synthesized super-stable CAU-10-based MOFs by choosing relatively inert Al3+ as metal nodes. Besides excellent long-term stability (more than 2 years), hydroxyl-functionalized CAU-10-O showed ultrahigh NH3 adsorption capacity (3.5 mmol g−1 at 25.0 °C) for low-concentration NH3 (5000 ppm), high selectivity of NH3 to N2 (up to 4850), and mild regeneration conditions (80 °C under vacuum for 6 h). Such great separation performance of CAU-10-OH was attributed to the multiple hydrogen bonding interactions (μ-OH···NH3 and –OH···NH3) between NH3 and CAU-10-OH.

Flexible MOFs with reversible structural transformations (topology, pore size or shape) usually exhibit a steep S-shaped adsorption curve, which can realize a high NH3 working capacity and facile regeneration [132, 133]. For example, Chen et al. [134] found that the dehydration of M(NA)2(H2O)4, (M = Zn, Co, Cu, Cd, NA = nicotinate) induces a structural transformation from zero-dimensional (0D) to two/three-dimensional (2D/3D), which is reversible after water adsorption. The layered 2D Zn(NA)2 exhibited a gate-opening effect at a pressure of 0.22 bar, leading to a two-step NH3 uptake with a capacity of 10.2 mmol g−1 at 1 bar, while 2D Co(NA)2 showed a continually increasing NH3 trend with an increase in pressure and an NH3 adsorption capacity up to 17.5 mmol g−1. For the transformed 3D Cu(NA)2 and Cd(NA)2, higher NH3 adsorption rates and shorter adsorption equilibrium times were achieved after three cycles. Meanwhile, both MOFs showed great recyclability and could be regenerated under vacuum and heating conditions of 150 °C for 70 min. Similarly, Kang et al. [135] developed a novel sorbent called flexible HOFs KUF-1 for NH3 adsorption, which showed unprecedented type IV adsorption behavior in the NH3 isotherm at 298 K, with a capacity of 6.67 mmol g−1 at 1 bar (Fig. 11). This material can be completely regenerated at room temperature under vacuum. In addition, FDU-HOF-3 with self-healing properties and excellent capture performance at low NH3 (8.13 mmol g−1 at 25 mbar) has also been developed [136]. Encouraged by reversible hydrogen network, Li et al. [137] further developed ionic frameworks [Ph3ImH][NTf2]2 constructed from protic imidazolium ILs units through ionic and hydrogen bonding interactions for NH3 capture, which presented selective NH3 capture of 15.65 mmol g−1 (25 °C and 1 bar) and mild regeneration conditions (80 °C and 1 mbar).

(Reproduced with permission from Ref. [135]. Copyright 2020, John Wiley and Sons

Type IV NH3 adsorption isotherm by HOF KUF-1a

Another emerging CPM, covalent organic frameworks (COFs), have also been explored for NH3 adsorption. In contrast to MOFs, COFs are formed by connecting light atoms (hydrogen, boron, carbon, nitrogen, etc.) via strong covalent bonds. Thus, COFs usually exhibit higher NH3 stability than MOFs based on the difference in bond strength. In addition, they have ordered pore structures that can effectively adsorb NH3 molecules and be regulated according to the specific separation conditions [138, 139]. Inspired by the functional design of MOFs, decorating the pore walls of COFs with various open metal sites has also been proposed to improve NH3 adsorption performance. For example, Yang et al. [140] adopted a surface pore engineering strategy to design multivariate COFs by decorating the pore walls with various functional units for NH3 adsorption (Fig. 12). Owing to the high NH3 affinity of synergistic multivariate and open metal sites, the COFs exhibited high NH3 adsorption capacities (14.3 and 19.8 mmol g−1 at 298 and 283 K, respectively). Zhao et al. [141] investigated the NH3 adsorption properties of COF-10 and its Li-doped derivatives using simulations. The NH3 adsorption capacity could be improved by introducing more charged lithium atoms; however, this was not proportional to the number of lithium atoms. In addition, the charge distribution also affected the NH3 adsorption behavior. In particular, a positive potential shield on the surface of COF-10-6Li protected NH3 from negative charge repulsion on the inner skeleton; thus, a remarkable enhancement in the NH3 adsorption capacity was observed when six lithium atoms were introduced.

(Reproduced with permission from Ref. [140]. Copyright 2018, American Chemical Society

a Scheme for surface pore engineering of COFs with various groups. b Possible pore structure of COFs with various groups (gray, C; blue, N; red, O; yellow, metal)

The actual performances of various materials under working conditions (containing H2O and impurity molecules in handling gases) are important for practical applications. Although several MOFs have been explored, the number of MOFs reported for NH3 capture from complex environments remains limited. Liu et al. [142] conducted a high-throughput computational screening (HTCS) of 2932 CoRe MOFs based on grand canonical Monte Carlo (GCMC) simulations to screen for the optimal MOF for NH3 capture from humid gas. They found that the key to a high NH3 capture performance was affinity or Henry’s constant of MOFs toward NH3 and water molecules. Previous research has indicated that NH3 uptake by MOFs mostly exhibits a solubilization-like mechanism in the presence of H2O molecules [143]. Hydrophobic MOFs possessed higher NH3 selectivity, while hydrophilic MOFs exhibited higher NH3 uptake despite strong adsorption competition from H2O molecules. In addition, the presence of H2O molecules could promote the enhancement of NH3 uptake in the MOFs with a coefficient (describing the effect of H2O adsorption on NH3 uptake) of ICH2O_NH3 < 0, but their ammonia uptake was still lower than that with ICH2O_NH3 > 0, which is important for the structural design of MOFs. In fact, in NH3-contaning gas from different NH3 emission sources, not only are H2O molecules present, but there are also other impurities such as SO2, which also greatly affect the NH3 adsorption behaviors. Chen et al. [144] combined adsorption isotherms with DFT calculations to investigate this effect at low pressure. It was found that NH3 is the most affinitive molecule to HKUST-1 among three molecules, while SO2 was the most affinitive molecule to UIO-66; therefore, NH3 is likely to displace pre-adsorbed SO2 or H2O on HKUST-1. Also, there is chemical adsorption on HKUST-1 and MIL-100(Fe) toward NH3, while NH3 adsorption to UIO-66 likely involves physisorption.

4.4 Composite Adsorbents

Composite adsorbents combine the advantages of different materials in terms of NH3 adsorption, such as metal chloride/carbon cubes, metal chloride/COFs, and IL-based composites, showing good development prospects for NH3 capture [145,146,147,148]. As a representative composite material, supported IL-phase (SILP) materials (Fig. 13a) have received more attention due to the cooperative effect of the porous support and functional ILs [48, 149, 150], which also solve the problems associated with the application of highly viscous or solid ILs for NH3 separation. Functional ILs in SILP materials mainly provide high NH3 affinity via interaction sites (see Sect. 3.1). Porous supports not only provide NH3 transport pathways but also effectively disperse ILs to expose more accessible sites of ILs to further improve the NH3 adsorption capacity.

Reproduced with permission from Ref. [156]. Copyright 2020, Elsevier

a Schematic diagram of supported ILs phase materials. b Schematic diagram of mechanism of [BOHmim][Zn2Cl5]@MIL-101(Cr).

Pioneering work on SILP for NH3 adsorption was reported in 2014, where an AC support material was coated with [C2C1Im]Cl/CuCl2. The superior NH3 adsorption capacity was predominantly attributed to strong interactions between Cu2+ and NH3 molecules [48]. However, regeneration was difficult under mild conditions. Therefore, subsequent studies have focused on the design of SILP materials for reversible NH3 adsorption, in which the appropriate selection and matching of supports and ILs are of great importance. Yu et al. [151] selected protic ILs with reversible NH3 absorption to be supported on AC with low cost and large surface area for NH3 adsorption. The results showed that 20 wt% [2-Mim][NTf2]@AC-980 exhibited a higher NH3 adsorption capacity of 68.61 mg g−1 NH3 at 303.15 K and 0.10 MPa (30% higher than that of pure AC) and excellent recyclability, benefiting from the synergistic interaction of hydrogen bonding between the ILs and NH3 and hierarchical pores. To further improve the NH3 adsorption performance, various task-specific ILs with multiple hydrogen-bond interaction sites/complexation sites and porous supports with different pore sizes were utilized to develop a variety of SILP materials, such as multiphoton ILs@HZSM-5 [152], hydroxyl ammonium protic ILs@MCM-41 [153], Zn-based ILs@FDU-12 [154], and MILs [Bmim]2[Co(NCS)4]@silica composites [155]. Enhanced NH3 adsorption capacity and excellent adsorption–desorption performance were achieved in these materials, presenting great potential for application.

Encouraged by their tunable pore structure and chemical composition, MOFs have also been exploited as porous supports for constructing versatile SILPs. Han et al. [156] fabricated a highly stable IL@MOF composite material for NH3 capture for the first time. [BOHmim][Zn2Cl5]@MIL-101(Cr) exhibited superior NH3 uptake of 24.12 mmol g−1 at 298 K and 1 bar, and such high NH3 adsorption capacity could be maintained under humid NH3 conditions. This excellent performance was related to the synergistic effect of multiple adsorption sites and the large free transport space provided by alkyl chains. Moreover, a small amount of adsorbed water provided additional NH3 uptake, as shown in Fig. 11b. Subsequently, a [CAM][Cl]@MIL-101(Cr) composite was developed, and high-purity NH3 was obtained in one step, as proven by a breakthrough experiment of an NH3/CO2 mixture showing superhigh NH3/CO2 separation factor of up to 1518 [157]. Shi et al. [158] anchored 43.4 wt% LiCl into the nanopores of MIL-53-(OH)2 by charge transfer and hydrogen bonding for NH3 capture. A record NH3 adsorption capacity (33.9 mmol g−1 at 1.0 bar and 25 °C) and superior selectivity of NH3/N2 (3571 at 25 °C), NH3/CO2 (30.3 at 80 °C) and NH3/H2O (15.6 at 50 °C) were achieved owing to synergistic action of NH3 coordination with the highly dispersed Li+ in the MOF nanopores and hydrogen bonding of NH3 with Cl−.

SILPs simultaneously improved the NH3 adsorption capacity and promoted NH3 transport, but the loading of ILs was always lower; therefore, the merits of liquid ILs were not fully displayed for the separation process [159,160,161]. A novel encapsulated ionic liquid (ENIL) was developed to achieve high IL loading and fully utilize the characteristics of ILs in confined spaces. Simultaneously, this material achieved the discretization of ILs from continuous to small drops, thereby increasing the surface contact area and improving the mass transfer rate. Palomar et al. [162, 163] prepared an ENIL by confining [EtOHmim][BF4] into hollow carbon submicron capsules. The unique core–shell structure as shown in Fig. 14 not only preserves the high NH3 affinity and fluidity properties of ILs but also accelerates the absorption–desorption process compared with the continuous ILs phase. High IL content (> 85 wt%), nearly identical sorption capacity to pure ILs, and excellent regeneration properties were achieved in ENILs, providing a pioneering strategy for designing novel IL composites with ultrahigh IL loading for efficient NH3 separation.

Reproduced with permission from Ref. [163], Copyright 2016, Royal Society of Chemistry

a SEM image, b TEM images of hollow carbonaceous submicrocapsules. c TEM image of ENIL prepared with [EtOHmim][BF4].

5 Porous Liquids for NH3 Ab-Adsorption

Porous liquids (PLs) are attractive materials that combine the permanent porosity of porous solids with liquid fluidity so that they can be easily coupled with existing process equipment, such as pumps and pipelines. Different from traditional liquids consisting of only random, transient cavities between the liquid molecules (here called “extrinsic” porosity), PLs are made of porous hosts possessing persistent empty cavities (called “intrinsic” porosity), which are able to work as a gas transport pathway to provide rapid adsorption and high capacity. The concept of PLs was first proposed by James and coworkers [164] and can be divided into three types according to the existing way of the porous hosts as shown in Fig. 15 [165,166,167]. Type I is a neat liquid composed of fluid hosts with empty cavities, whereas Type II and Type III are essentially dissolved empty hosts or homogeneously dispersed framework materials in sterically hindered solvents, respectively. To date, the application of PLs has focused on gas capture and storage [167,168,169,170], while the synthesis of stable PLs remains a significant challenge owing to intermolecular self-filling, collapse, or decomposition of the organic hosts and serious settling of solid particles.

Adapted from Ref. [164]

Schematic diagram of traditional liquids and three different types of PLs.

The synthesis of fluid hosts with empty cavities is the key to obtaining Type I PLs. Giri et al. [171] grafted medium-length alkyl tails onto the surfaces of rigid organic iminospherand cages to synthesize PLs. Alkylation obviously reduced the melting point of the cage from > 300 °C to as low as 50 °C, making it possible to obtain fluid cages with empty cavities at relatively low temperatures. The liquidation of reported porous materials is also an effective method for preparing PLs (PLs prepared by this method are also called Type IV PLs, in which porosity is offered by non-discrete molecular species [172]). For example, Gaillac et al. [173] studied the melting process and liquid nature of porous ZIF-4 using in situ variable temperature XRD, ex situ neutron pair distribution function (PDF), and first-principles molecular dynamics (FPMD). They verified that the porosity of ZIF-4 was retained after melting process. In addition, hollow carbon or silica spheres grafted with ILs is another facile strategy for preparing a new PL phase. Zhang et al. [167] grafted positively charged organsilane onto the surface of hollow silica spheres, followed by an anion exchange reaction to prepare HS-liquid at room temperature, as shown in Fig. 16. TEM images, N2-sorption isotherms, and small-angle X-ray scattering (SAXS) data revealed that well-defined hollow spheres were obtained. More importantly, the empty cavities significantly promoted CO2/N2 separation, showing attractive properties for target-specific applications, such as NH3 separation.

Reproduced with permission from Ref. [167]. Copyright 2014, John Wiley and Sons

Two-step synthetic strategy for porous liquid fabrication. HS, hollow silica, OS, organosilane.

In addition, the various MOFs and functional solvents used for NH3 capture, as reported above, offer more opportunities for preparing Type-III PLs. The combination of MOFs with specific sterically hindered solvents, such as ILs, is expected to form new PLs with high gas uptake and separation performance. For example, Type-III PLs, including ZIF-8-[Bpy][NTf2] [174] and ZIF-8-[DBU-PEG][NTf2]2 [168], were obtained by dispersing MOFs in ILs. Recently, Gomes et al. [27] also selected ZIF-8 and Mg-MOF-74 as porous hosts and dispersed them in [P66614][NTf2], as shown in Fig. 17. The results showed that PLs were obtained by ZIF-8 but not by Mg-OF-74 because of its small pore apertures (3.4 Å) preventing the penetration of large long-chain cations. As a result, remarkable gas uptake performance (up to 150% more nitrogen and 100% more methane than pure IL) was realized at 303 K and 5 bar.

Reproduced with permission from Ref. [27]. Copyright 2018, John Wiley and Sons

a Preparation of the porous liquids. b Molecular simulation of the porous liquids show empty pores in ZIF-8. c Dissolution of N2 in the PLs.

Overall, although examples of PLs for NH3 ab-adsorption have not been reported, the development of PLs for NH3 capture is attractive and promising from the perspective of fundamental research and practical applications. Importantly, the exciting results of CO2 capture realized by PLs reveal their promising application in efficient NH3 capture. At the same time, the aforementioned advanced ILs and various CPMs provide rich experience for designing novel PLs for NH3 capture.

6 Emerging Membranes for NH3 Separation

Membrane separation is another potential option for NH3 capture because of its easy operation, low device occupancy, and energy saving [175,176,177]. Membrane separation can directly yield gaseous ammonia components without regeneration and has become increasingly attractive. However, unlike the extensive research on membranes for classical gases such as CO2, studies on NH3 capture using membranes are limited. Current research has primarily focused on the design of membrane materials to improve NH3 permeability and selectivity. One effective measure is to introduce interaction sites to enhance NH3 adsorption on the surfaces of membranes. Accelerating the NH3 diffusivity in the membrane by constructing transport pathways is another effective strategy. Table 5 displays the NH3 separation performances of representative membrane materials.

Polymeric membranes are the most typically reported NH3 separation membranes because of their high processability, in which gas permeation basically obeys the solution-diffusion mechanism. The NH3 transport properties of commercial cellulose acetate (CA) membranes were reported in 2006, and the results showed that the sorption process, dominated by hydrogen bond interactions between the NH3 molecules and membranes, played an important role in NH3 permeation [178]. Afterward, various polymers were exploited as membranes for NH3 separation, such as fluorinated polymers [179, 180]. However, these polymeric membranes showed great permeability but little selectivity and still suffered a trade-off effect between permeability and selectivity (called the Robeson upper bound).

To overcome the above challenges, researchers have proposed the design of polymeric membranes with NH3-interacted sites, such as sulfonated copolymers, to enhance the selective adsorption and solubility coefficients of ammonia. Phillip et al. [181] regulated the domain size of sulfonated block copolymers and the degree of crosslinking to affect NH3 separation performance. The results confirmed that the membrane designed using this strategy could retain high selectivity (mixed NH3/N2 selectivity > 90) compared to a Nafion membrane. Ansaloni et al. [182] further adjusted the membrane morphology of midblock-sulfonated pentablock ionomers (SBI-26 and SBI-52) by changing the type of casting solvent used to construct micro-domains conducive to NH3 separation. Recently, fluorinated sulfonic acid polymer/ceramic composite membranes with high thermal stability were developed, in which the acidic sulfonic groups on the polymer chains acted as NH3 sites, exhibiting NH3 separation performance with NH3 permeance of > 2.31 × 10−6 mol m−2 s−1 Pa−1, NH3/H2 separation factor of 90, and NH3/N2 of 800 at 50 °C in a mixed system [183].

In addition, incorporating NH3-interacted small molecules, such as ILs, into the polymer matrix is expected to improve the NH3 permeability and selectivity. As expected, the NH3 permeability was remarkably enhanced with increasing IL content, benefiting from the enhanced NH3 solubility [184, 185]. It is worth mentioning that the moderating interaction between membranes and NH3 plays an important role in increasing NH3 solubility, while excessively strong interactions also restrict NH3 diffusivity. Therefore, the selection of appropriate ILs, such as hydroxyl task-specific ILs, is crucial for preparing membranes with high permeances. The optimum NH3 permeability reached 3729.3 barrer with an NH3/N2 ideal selectivity of 1110.8, which are increases of 265.3% and 163.7%, respectively, compared to neat Pebax membrane. In addition, ILs enrich the ionic domains of block polymers to construct effective gas transport channels. The self-assembled NH3 transport channels induced by ILs and high NH3 affinity (Fig. 18) cooperatively promoted an increase in the NH3 diffusion and solubility coefficients, resulting in superior NH3 separation performance with an NH3 permeability of 3565 barrer and NH3/N2 and NH3/H2 selectivity as high as 1865 and 364, respectively [186, 187].

(Reproduced with permission from Ref. [186]. Copyright 2021, Elsevier

Schematic diagram of IL/Nexar hybrid membranes for NH3 separation

Effective strategies include constructing a transport channel and increasing the free volume of the membrane to promote gas transport/diffusivity and enhance ammonia separation. Wang et al. [188] first adopted a simulation method to verify the NH3 separation possibility of 2D-polyphthalocyanine (PPc) membranes with intrinsic pores. A high (H2/N2)/NH3 selectivity of 107 was obtained at room temperature. Inspired by the above idea, Zaripov et al. [189] further prepared bulky agent octaglycidyl polyhedral oligomeric silsesquioxane (Gl-POSS) branched membranes, in which the disordered nanopores formed by the polymer segments greatly promoted NH3 transport. High ideal selectivity was achieved at Gl-POSS contents of 0.5–1 wt%. Subsequently, various membrane materials such as porous silica [190], ceramics [191], and zeolites [192], and other inorganic membranes, have been developed to achieve selective separation with the help of different pore sizes. However, unsatisfactory separation performance has encouraged researchers to further develop novel membranes to meet application requirements. Strategies combining porous properties and preferential adsorption have been proposed. For example, Petukhov et al. [193] prepared a 2D MXene membrane for NH3 separation in which acidic termination groups of interlayer galleries greatly promoted basic NH3 adsorption, and the increase of interlayer distance caused by vapor adsorption within MXene’s stacked structure also contributed to enhanced NH3 diffusivity. Similarly, ultra-thin Prussian blue (PB) analog membranes with high NH3 sorption capacity, pore channels (size of cavities < 0.3 nm), and high transformation ability of ammonia into NH4+ were prepared, achieving high NH3 permeance exceeding 0.3 m3 (STP) m−2 bar−1 h−1 and ultimate ideal NH3/H2 selectivity of 40 and NH3/N2 selectivity over 100 [194]. Furthermore, Wei et al. [195] coupled preferential adsorption and the seizing effect to prepare a ZIF-21 membrane with ~ 2.8 Å polar channel. Polar pores with limited apertures could efficiently seize NH3 molecules from gas mixtures. These two factors jointly promoted the ZIF-21 membrane to exhibit a high NH3 permeance of 1727 GPU with NH3/N2 and NH3/H2 ideal selectivities of 35 and 12, respectively. Considering the similarity between NH3 and H2O in terms of polarity and molecular size, Yu et al. [196, 197] developed an Na+-gated nanochannel membrane via a secondary growth method, which allowed small and polar NH3 molecules to permeate while blocking other non-polar and/or larger molecules, exhibiting remarkable selectivity (NH3/H2 > 4280 and NH3/N2 > 10,000 at 250 °C and 35 bar), excellent chemical stability, and long-term running stability.

Mixed matrix membranes (MMMs) have attracted increasing attention for NH3 separation in recent years because of the synergistic effect of both polymer and porous components [198,199,200]. Raza et al. [201] introduced carboxylic group-functionalized multiwall carbon nanotubes (COOH-MWCNTs) into a CA/PEG polymer matrix, which notably increased the permeability of NH3 and N2 owing to the enhanced voids and free volume. In addition, HKUST-1/PVDF MMMs were exploited by Cohen et al. [202] because HKUST-1 can bind with ammonia via Lewis acid–base interactions. Moreover, the HKUST-1 MMMs exhibited outstanding structural stability and maintained their ammonia capacity better than unstable powder under humid conditions. Our group [203] further combined HKUST-1 and protic IL [Bim][NTf2] to improve NH3 separation performance by employing hydrogen bond interactions. The optimal ternary MMM exhibited ideal NH3/N2 and NH3/H2 selectivities of 530.1 and 94.2, respectively. The optimal NH3 permeability reached up to 3680.0 barrer, which is 260% and 129% higher than those of the pristine Pebax membrane and Pebax/HKUST-1 MMM, respectively.

7 Conclusions and Prospects

To effectively capture such hydrogen-rich, carbon-free, but highly corrosive molecules with triple the properties of energy, environment, and resources, great strides have been made in the development of advanced materials in the last decade. In this review, recent advances in NH3 capture materials, particularly those over the past 5 years, were briefly summarized. Major obstacles for specific applications, such as absorbents (functional solvents), adsorbents (porous solids), and membranes, were identified based on extensive studies. The interaction sites and transport pathways play a crucial role in improving NH3 capture performance. The potential application of the emerging hybrid technology, ab-adsorbents, using porous liquids as key capture materials, was also discussed. This review answers the question of how to connect advanced materials and NH3 capture technology via modulation of interaction sites and transport pathways.

However, for these NH3 capture technologies to be accepted as green strategies, the structure–property relationships between the materials and special parameters need to be further clarified, for which many challenges must be faced. In other words, there are worthwhile directions for researchers to further develop single/hybrid material designs and applications from either experimental or theoretical perspectives. The following aspects could be considered:

-

1.

Intelligent design & rational prediction Designing novel materials and predicting their NH3 capture performance via a combination of theoretical calculations and experiments is highly desired. Various materials offer many possibilities for NH3 capture; however, relying solely on experimental methods normally requires a long time. An effective strategy for obtaining an optimal solution is to utilize computational artificial intelligence (AI)-assisted molecular design and high-throughput screening technologies. Specifically, the properties of existing ammonia capture materials can be analyzed and important structures for efficient NH3 capture can be extracted to build data- and mechanism-driven modes to further guide the development of high-performance materials. Furthermore, exploiting hybrid materials with complementary components, such as PLs, MOF@COF, and COF@MOFs, based on such recognition to further widen the variety of materials and obtain unforeseen structures has the potential to improve NH3 capture performance. Interfacial properties, such as compatibility, interaction synergy, and growth mechanism, of hybrid materials are also worth exploring for further development of novel materials. In addition, the determination of the synthesis conditions and process parameters with the assistance of mobile robotic chemists is the most promising method for shortening the research and development process.

-

2.

Excellent performance & high stability The development of NH3 capture materials with high capacity, fast transport, and good stability remains challenging. Various functional materials have been developed based on the unique Lewis/Brønsted base and hydrogen bond formation properties of NH3 molecules, while most of them still suffer from low capacity, slow kinetics, and structural collapse. In addition, although many NH3 capture materials have been reported, breathing materials with a flexible nature (energy-saving synergistic adsorption–desorption) and dynamic properties (kinetic-induced non-equilibrium separation) are relatively limited. Therefore, the design of a robust system with both a high NH3 capacity and soft porosity is a worthwhile direction to explore for practical applications.

-

3.

Scale-up The large-scale preparation of materials should be considered to meet the requirements of industrial applications. Although significant progress has been achieved, especially in advanced materials for NH3 capture, most current research is still limited to laboratories, and the yields of some materials are very small. Effective measures to boost scaled-up production and industrial applications need to be taken, such as screening inexpensive raw materials, simplifying synthesis steps, and using environmentally friendly synthetic methods. Specifically, expensive raw materials can be replaced with low-cost ones to synthesize various materials for NH3 capture using a one-step rather than multi-step method to synthesize materials to omit complex purification process, using green solvents, such as water, as much as possible such as water to avoid volatile organic solvents. In addition, optimizing flow diagrams for chemical processes, heat exchange networks, and performing energetic–environmental–economic assessments using process simulation software are expected to improve energy efficiency and reduce operating costs to accelerate the process of industrialization. In future, AI-assisted reaction simulations will be a powerful platform for exploring effective solutions to overcome the drawbacks of stepwise amplification and accelerate industrialization.

-

4.

Practical evaluation The practical utilization conditions of various materials should be considered. Most current studies have investigated capture performance under ambient pressure in pure gas. However, the composition, pressure, and NH3 concentration of handling gases in real life are different, such as in the NH3 synthesis process (NH3/H2/N2, > 10 MPa, 10%–20% NH3), personal protective equipment (NH3/air, NH3 < 5000 ppm), and NH3 decomposition process (NH3/H2, NH3 < 0.1ppm). Therefore, the data obtained in existing studies are far from reflecting realistic conditions. Based on the above analysis, it is necessary to upgrade existing equipment and perform operando characterizations to further evaluate the actual performance and reveal mechanisms in the future. Specifically, existing equipment must be improved to match the handling conditions (pressure and composition) of product gases to obtain a more realistic evaluation. The design of the internals should be optimized to meet fluid mechanics requirements, thereby achieving excellent mass and heat transfer in the equipment. Operando characterizations should be performed under practical working conditions to track the ab/adsorption and desorption of NH3 molecules from various materials and to study possible structural changes under actual conditions to further reveal separation mechanisms [110, 204, 205].

-

5.

Integration process Absorption–adsorption–membrane separation to develop an integrated technology to achieve self-adapting NH3 capture is a promising direction for future research. Because massive amounts of NH3-containing gases from various sources face different separation requirements, multi-process integration is more efficient and applicable than a single technology. A rational process design for integrated technology is expected to achieve material cost and energy consumption savings.

Overall, functional solvents, porous solids, porous liquids, and membranes are potential alternatives for NH3 capture. Although the road ahead is unknown, we firmly believe that various materials will become more competitive in the future through long-term and constant efforts.

Abbreviations

- AA:

-

Acetamide

- ACs:

-

Activated carbons

- [Bmim][SCN]:

-

1-Butyl-3-methylimidazolium thiocyanate

- [Bmim][NTf2]:

-

1-Butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide

- [Bmim][Zn2Cl5]:

-

1-Butyl-3-methylimidazolium chlorozincate

- [Bmim]2[Co(NCS)4]:

-

1-Butyl-3methylimidazolium tetraisothiocyanatocobaltate(II))

- [Bmim][MeSO3]:

-

1-Butyl-3-methylimidazolium methanesulfonate

- [Bmim]2[CuCl4]:

-

Bis(1-butyl-3methyl imidazolium) copper tetrachloride

- [Bmim]2[NiCl4]:

-

Bis(1-butyl-3methyl imidazolium) nickel tetrachloride

- [Bmim]2[SnCl4]:

-

Bis(1-butyl-3methyl imidazolium) stannum tetrachloride

- [Bpy][NTf2]:

-

N-butyl pyridinium bis(trifluoromethyl sulfonyl)imide

- [BOHmim][Zn2Cl5]:

-

1-(4-Hydroxy-butyl)-3-methylimidazolium chlorozincate

- [Bim][NTf2]:

-

1-Butylimidazolium bis(trifluoromethylsulfonyl)imide

- BBTA:

-

1H,5H-benzo(1,2d), (4,5-d′)bistriazole

- BTC:

-

1,3,5-Benzenetricarboxylic acid

- BTDD:

-

Bis(1H-1,2,3triazolo[4,5-b],[4′,5′-i])dibenzo[1,4]dioxin

- CPMs:

-

Crystalline porous materials

- COFs:

-

Covalent organic frameworks

- CIPMs:

-

Conventional inorganic porous materials

- CHBs:

-

Cooperative hydrogen bonds

- ChCl:

-

Choline chloride

- CA:

-

Cellulose acetate

- COOH-MWCNTs:

-

Carboxylic group functionalized multiple-wall carbon nanotubes

- [choline][NTf2]:

-

Choline bis(trifluoromethylsulfonyl)imide

- [CAM][Cl]:

-

Carbamide chloride

- DESs:

-

Deep eutectic solvents

- 2D/3D materials:

-

Two/three-dimensional materils

- dodpdc:

-

4,4'-Dihydroxybiphenyl-3,3'-dicarboxylic acid

- [DBU-PEG][NTf2]2 :

-

8,8′ (3,6Dioxaoctane1,8diyl)bis(1,8Diazabicyclo[5.4.0]undec7en8ium) bis(trifluoromethylsulfonyl)imide)

- [DMEA][Ac]:

-

N,N-dimethylethanolammonium acetate

- [EtOHim][NTf2]:

-

1-Hydroxyethyl-3-methyl bis(trifluoromethylsulfonyl)imide

- [EtOHim][BF4]:

-

1-Hydroxyethyl-3-methyl tetrafluoroborate

- [Emim][NTf2]:

-