Highlights

-

Recent progress in noble metal-decorated (NM-D) semiconducting metal oxides (SMOs) gas sensors are summarized.

-

Gas sensing mechanisms related to noble metal decoration are carefully discussed.

-

Crucial challenges facing the development of NM-D SMOs gas sensors are analyzed.

Abstract

Highly sensitive gas sensors with remarkably low detection limits are attractive for diverse practical application fields including real-time environmental monitoring, exhaled breath diagnosis, and food freshness analysis. Among various chemiresistive sensing materials, noble metal-decorated semiconducting metal oxides (SMOs) have currently aroused extensive attention by virtue of the unique electronic and catalytic properties of noble metals. This review highlights the research progress on the designs and applications of different noble metal-decorated SMOs with diverse nanostructures (e.g., nanoparticles, nanowires, nanorods, nanosheets, nanoflowers, and microspheres) for high-performance gas sensors with higher response, faster response/recovery speed, lower operating temperature, and ultra-low detection limits. The key topics include Pt, Pd, Au, other noble metals (e.g., Ag, Ru, and Rh.), and bimetals-decorated SMOs containing ZnO, SnO2, WO3, other SMOs (e.g., In2O3, Fe2O3, and CuO), and heterostructured SMOs. In addition to conventional devices, the innovative applications like photo-assisted room temperature gas sensors and mechanically flexible smart wearable devices are also discussed. Moreover, the relevant mechanisms for the sensing performance improvement caused by noble metal decoration, including the electronic sensitization effect and the chemical sensitization effect, have also been summarized in detail. Finally, major challenges and future perspectives towards noble metal-decorated SMOs-based chemiresistive gas sensors are proposed.

Similar content being viewed by others

1 Introduction

With the rapid development of Internet of Things (IoTs), highly sensitive and selective gas sensors with remarkably low limit of detection (LOD), fast response/recovery speed, and excellent long-term stability and reversibility are in ever increasing demand for smart cities, smart plants, and even smart healthcare [1,2,3,4]. On the one hand, ultra-sensitive gas sensors can monitor even trace level hazardous, toxic, or explosive gases like volatile organic compounds (VOCs), hydrogen sulfide (H2S), ammonia (NH3), formaldehyde (HCHO), nitrogen dioxide (NO2), methane (CH4), and hydrogen (H2), protecting human health from environmental pollutants or leakage accidents [5,6,7]. On the other hand, highly selective and reliable gas sensors with precise accuracy have shown great application potential in various emerging fields closely related to our daily life, such as food freshness monitoring [8], drunk driving inspecting [9], and non-invasive disease diagnosis through human exhaled breath analysis [10, 11], as shown in Fig. 1. For example, with the advance of modern medicine, endogenous ammonia in exhaled breath have been demonstrated to be important biomarkers for the non-invasive diagnosis of chronic kidney diseases [12].

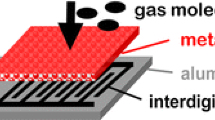

Among various types of gas sensors including electrochemical [13], optical [14], mass sensitive [15], thermoelectric [16], and magnetic [17] gas sensors, chemiresistive sensors have attracted tremendous research enthusiasm for owning unique advantages of higher sensitivity, smaller size, lower cost, easily manipulated, and even highly integrated for micro-electromechanical systems (MEMS)-based sensors [18, 19]. Generally, chemiresistive gas sensors are mainly comprised of highly sensitive materials, a pair of sensing electrodes, and a pair of heating electrodes providing a high enough operating temperature to active the sensing materials [20]. Since the sensitive material is regarded as the most crucial component of a chemeresistive gas sensor, many efforts have been devoted to develop satisfactory gas sensing materials. Ever since Seiyama invented the first oxide-based gas sensor around the world in 1962 [21], nanostructured semiconducting metal oxides (SMOs) have been considered as prospective gas sensing materials by virtue of their high specific surface area, abundant active adsorption sites, superior electrical properties, and low cost [22,23,24].

However, single SMO nanomaterial-based gas sensors suffer from low response, poor selectivity, and too high operating temperature, which cannot satisfy the requirements of practical applications. Therefore, diverse methods, mainly consisted of constructing heterostructures [25, 26], decorating catalysts [28], designing charge transfer hybrids [29], and introducing molecular probing and sieving effect [29, 30], have been widely explored for the improvement of gas sensing performance [31]. Among all these strategies, the noble metal decoration, which involves hybrid nanocomposites with synergistic effects and introduces highly active catalysts for gas chemisorption, exactly paves a new extraordinary road for gas sensing performance enhancement and has attracted widespread research attention [27, 32]. Recently, the widely used noble metals mainly include platinum (Pt), palladium (Pd), gold (Au), silver (Ag), ruthenium (Ru), rhodium (Rh), and their bimetal composites. The relevant mechanisms for the gas sensing performance improvement include the electronic sensitization effect of constructing a metal–semiconductor contact [33] and the chemical sensitization effect of the spillover effect [34]. As a result, the synergistic effects not only promote fast interaction between the noble metal decorated SMOs and target gases, but also effectively decrease the operating temperatures by lowering the gas sensing activation energy.

Actually, several reviews about noble metal-decorated SMOs-based gas sensors are focused more on either certain type of noble metals, such as Ag-modified SMOs-based gas sensors [35] and Pd-decorated nanostructures-based gas sensors [36], or certain type of SMOs, such as noble metal-decorated nanostructured ZnO-based H2 gas sensors [37]. However, few comprehensive reviews focusing on the recent advances in diverse noble metal-decorated SMOs for high-performance gas sensors have been reported. Herein, this review will comprehensively reflect and summarize recent progress in SMOs-based chemiresistive gas sensors decorated by not only common noble metals including Pt, Pd, and Au, but also other unusual noble metals like Ag, Ru, and Rh, and even well-structured bimetals containing alloy structures, core–shell structures, and heterostructures, as shown in Fig. 2. Meanwhile, the different effects of noble metal decoration on different SMOs containing common SMOs of ZnO, SnO2, WO3, other SMOs (e.g., In2O3, Fe2O3, TiO2, CuO, NiO, and Co3O4), and heterostructured SMOs will be comprehensively discussed and summarized as well. In addition to the detailed summarization on conventional gas sensing properties, the innovative applications like photo-assisted room temperature gas sensors and mechanically flexible smart wearable devices are discussed at the same time. Moreover, the relevant mechanisms for the sensing performance improvement caused by noble metal decoration, including the electronic sensitization and chemical sensitization effect will also be summarized in detail. Finally, crucial challenges facing the development of noble metal-decorated SMOs-based gas sensors are identified and feasible routes for effectively improving gas sensing performance like selectivity, power consumption, and long-term stability by constructing integrated sensor arrays, employing neural network algorithms, as well as developing MEMS and field effect transistor (FET)-type devices are carefully considered and proposed. Constructing long-term stable noble metals-decorated SMOs-based gas sensor arrays, combined with advanced neural computation, should allow real-life electronic olfactory sensing in the future (Fig. 1). Overall, the present topical review aims to provide a comprehensive perspective on noble metal-decorated SMOs-based gas sensors, including the material structure, gas sensing mechanisms, properties, applications, challenges, and prospects, hoping to be served as an important reference for newcomers as well as experienced researchers.

Copyright 2017, Royal Society of Chemistry. The gas sensor array figure is reproduced with permission from Ref. [39]. Copyright 2016, American Chemical Society. The electronic olfactory sensing figure is reproduced with permission from Ref. [40]. Copyright 2021, American Chemical Society

Process of electronic olfactory sensing realization for important applications based on gas sensor arrays. The disease diagnosis figure is reproduced with permission from Ref. [38].

Copyright 2017, Wiley–VCH. The Au NPs figure is reproduced with permission from Ref. [41]. Copyright 2022, Elsevier. The Ag NPs figure is reproduced with permission from Ref. [42]. Copyright 2011, American Chemical Society. The Ru NPs figure is reproduced with permission from Ref. [43]. Copyright 2020, Elsevier. The Rh NPs figure is reproduced with permission from Ref. [44]. Copyright 2019, American Chemical Society. The core–shell NPs figure is reproduced with permission from Ref. [45]. Copyright 2020, American Chemical Society. The heterostructure NPs figure is reproduced with permission from Ref. [46]. Copyright 2013, Elsevier. The alloy NPs figure is reproduced with permission from Ref. [47]. Copyright 2021, Elsevier. The Pd NPs figure is reproduced with permission from Ref. [48]. Copyright 2016, American Chemical Society

Overview schematic representation of various noble metal decorated SMOs for gas sensors. The Pt NPs figure is reproduced with permission from Ref. [32].

2 Gas Sensing Mechanisms of Noble Metal-Decorated SMOs

2.1 General Gas Sensing Mechanism of Chemiresistive SMOs

2.1.1 Basic Gas Sensing Mechanism of Chemiresistive SMOs

The basic sensing mechanism of chemiresistive SMOs-based gas sensors is based on the oxygen adsorption model [49]. Oxygen molecules in air will preferably accumulate on the surface of SMOs and capture electrons from SMOs, leading to the generation of chemisorbed oxygen species (O2−, O−, or O2−) [50] and an electron depletion layer (for n-type SMOs) or a hole accumulation layer (for p-type SMOs). As a result, the resistance of n-SMOs/p-SMOs will then be increased/reduced, respectively. The reaction processes are listed as following:

When SMOs are exposed to target gases, the adsorbed gas molecules would react with the chemisorbed oxygen intermediates, releasing the electrons back to SMOs (for reducing gas) or instead extracting more electrons from SMOs (for oxidizing gas), which depends on the redox characteristics of the target gases. Thus, the width of the electron depletion layer/hole accumulation layer and further the resistance of SMOs will be changed accordingly. As a result, the resistance variation indicates the sensitivity of SMOs-based gas sensors.

More specifically, for an n-SMO material, when a reducing gas is introduced, the width of the electron depletion layer will decrease, and thus the resistance of the n-SMO material will be reduced correspondingly. When an oxidizing gas is introduced, the width of the electron depletion layer and therefore the resistance of the n-SMO material will be both increased. For a p-SMO material, when facing a reducing gas, the width of the hole accumulation layer will be reduced due to the recombination of the re-injected electrons and holes, leading to an increase of the resistance. Conversely, when introducing an oxidizing gas, the width of the hole accumulation layer will be further increased because of the further extraction of electrons, thus resulting in a decrease of the p-SMOs resistance.

2.1.2 Mechanism of Heterojunction for Improved Gas Sensing Performance

The heterojunction is formed at the contact interface of two different SMO materials, including anisotype heterojunction (i.e., p–n or n–p) and isotype heterojunction (i.e., n–n or p–p) [51]. In order to balance the different Fermi levels at the interface, the charge transfer and depletion/barrier layers formation are introduced, which are positive factors for improving gas sensing performance [51, 52]. Actually, the additional depletion layers at the interface could also participate in the gas sensing behaviors and help increase the resistance variation of the sensing SMOs, leading to the improvement of gas sensing properties.

First considering anisotype heterojunction, take the p–n heterojunction as an example, depletion layers are created by electron–hole recombination on the both p-side and n-side. Thus, a potential conduction barrier is formed and resistance is increased. Exposure of a reducing gas will help consume surface oxygen species and inject electrons into the surface to shrink the depletion layer. It leads to a significant reduction in electrical resistance and achieves a higher gas sensing response.

As for isotype heterojunction, in the n–n heterojunction, for example, an additional electron depletion layer will be formed at the n–n interface causing an increase of the material resistance. After exposed to a reducing gas, the electron depletion layer will be further decreased, resulting in a sharp decrease of resistance and an enhancement of gas sensing response.

2.2 Mechanism of Noble Metal Decoration for Improved Gas Sensing Performance

2.2.1 Mechanism of Single Noble Metal Decoration for Enhanced Response

The remarkable improvement of gas sensing performance after noble metal decoration could be attributed to two main mechanisms, the electronic sensitization and the chemical sensitization. First, during the electronic sensitization process, the majority carriers will transfer between noble metals and SMOs due to the mismatch of work functions, leading to the generation of potential barriers. As representatively shown in Fig. 3a, due to the higher work function of noble metals, the electrons generated during the sensing process will be transferred from the conduction band of SMOs into noble metals until the Fermi level is equal [33, 48, 53]. This behavior leads to the formation of a Schottky barrier and an increase in the thickness of the electron depletion layer, which could inhibit the recombination of separated electron–hole pairs and cause a significant change of the resistance when exposure to target gases, resulting in a much higher response. Second, during the chemical sensitization process, the noble metals could facilitate the dissociation of oxygen molecules to produce more reactive chemisorbed oxygen ions which then spill over the surface of SMO to react with more target gas molecules [54,55,56]. Thus, the chemical sensitization is also known as the spillover effect. As exhibited in Fig. 3b, oxygen molecules will preferentially adsorb on the noble metal nanoparticles (NPs) and then be dissociated into O− which then spill over to the surface of SMOs. Taking the reducing gas as an example, the large amount of O− could react with more target reducing gas molecules and cause the release of electrons, resulting in the rapid resistance change and thus the significant improvement of the gas sensing performance. Besides, the decoration of noble metal NPs indeed increases the specific surface area of the sensing materials, providing more catalytic active sites for gas diffusion and adsorption [57].

2.2.2 Mechanism of Bimetal Decoration for Enhanced Response

The mechanisms of bimetallic decoration on SMOs for the gas sensing performance enhancement are also discussed here. Figure 3c–d exhibit the representative electronic sensitization and the chemical sensitization processes of bimetal-decorated SMOs [58,59,60], respectively, which are similar to monometallic decoration discussed before. More specifically, Fig. 3c exhibits the established Schottky barrier and the additional depletion layer caused by the much higher work function of bimetals than SMOs. Accordingly, the additional depletion layer promotes the transfer of electrons during the gas sensing process, thus improving the gas sensing properties of the bimetal-decorated SMOs [57]. In addition, as shown in Fig. 3d, the bimetals could also catalyze the dissociation of oxygen molecules and lead to the spill-over of reactive chemisorbed oxygen ions on the surface of SMO, facilitating the reaction between target gases and reactive oxygen ions and therefore enhancing the gas sensing performance [58]. Apart from the simple combination of two monometallic properties, the synergistic effects further improve the physical and chemical properties as well as promote the gas sensing performance [61]. Specifically, bimetal composites could introduce tunable electronic structure, morphology, and stoichiometry, thus providing designable energy band structures and catalytic characteristics [62]. Moreover, bimetallic decoration could further lower the activation energy of the sensing reaction via synergistic catalysis, which contributes to a decrease of the operating temperature and an acceleration of the response/recovery process [63, 64].

2.2.3 Mechanism of Noble Metal Decoration for Improved Selectivity

Based on various reported literatures, different noble metal decoration tends to promote the gas sensing performance towards different certain gases due to the special catalytic sensitization. Herein, some of the most important affecting mechanisms related to the catalytic sensitization are discussed. First, the selective reaction occurred between a specific noble metal and a certain gas greatly attributes to the enhanced selectivity. Most obviously, the Pd-decorated SMOs have a specific enhancement for H2 gas molecules, which could be ascribed to the reversible conversion of Pd to PdHx [65, 66]. Pd possesses the unique ability to adsorb and dissociate H2 molecules into H atoms. Particularly, by combing with dissociated H atoms, Pd can be converted into PdHx according to the reaction of 2Pd + xH2 \(\leftrightarrow \) 2PdHx [67]. Subsequently, due to the reduced work function of PdHx compared with Pd, more electrons will be injected into SMOs promoted by the lower Schottky barrier, leading to a further decrease of the material resistance [68]. Therefore, Pd is considered as the best emerging noble metal for the decoration of SMOs-based H2 sensors.

Second, the strength of the coupling effects between specific noble metals and certain gas molecules will greatly influence the improvement of selective detection. The strong electronic effect of gas molecules will form a coupling effect with specific noble metals and therefore significantly affect the molecule adsorption behaviors on metals, which will even surpass the steric effect of certain molecules. More specifically, the coupling effect originates from the interactions between the adsorbate valence states and the s- and d-states of a certain metal [69]. Since the influence of the coupling to the metal s-states is approximately the same for different noble metals, the strength of the coupling effect largely depends on the coupling to the d electrons. Moreover, since the d bands are recognized to be narrow, the coupling of molecules to the d electrons will cause a splitting of the molecule resonance and generate both bonding state and antibonding state above the d bands, leading to the strong interactions [69]. Therefore, the d-band model could effectively reflect the trends in the molecule coupling strengths on noble metal surfaces, which will help to guide the selection of noble metals for highly selective target gases detection. Meanwhile, the band center (εd) could well describe the characteristics of the d bands, which is commonly chosen as the representative parameter. For instance, as shown in Fig. 4a, both the theoretical calculations and experimental results reveal that, as εd relative to the Fermi level becomes more positive, the oxygen adsorption energy gets larger [69], which will greatly affect the gas sensing response. Similar theoretical calculation results were observed in the adsorption energies of a series of 4d transition metals to CO and NO exhibited in Fig. 4b.

Reproduced with permission from Ref. [69]. Copyright 2000, Elsevier

a Calculated, model estimates, and experimental results of the variation in the oxygen adsorption energy of a series of 4d transition metals, which exhibited a good correlation with εd. b Calculated and model estimates of the variation in the adsorption energy of a series of 4d transition metals to CO and NO.

Last but not least, since the adsorption of gas molecules on the noble metal surface is the primary condition for any possible catalytic reactions, the selective adsorption of gas molecules on a certain noble metal surface under different temperature will also affect the selectivity of noble metal decorated SMOs-based sensors. For example, Kim et al. [70] reported that Au decorated SnO2 NWs exhibited special enhancement of selectivity to carbon monoxide (CO) rather than benzene (C6H6) and toluene (C7H8) at 300 °C, which can be attributed to the desorption of all C6H6 molecules and their dissociated biphenyl groups from Au surfaces above 127 °C observed by the previous experimental result [71].

2.3 Recent Advanced Strategies for Further Understanding on the Gas Sensing Mechanism of Noble Metal-Decorated SMOs

2.3.1 Density Functional Theory Calculations

Recently, the first-principle calculations based on the density functional theory (DFT) have been widely employed for further exploration on the adsorption properties of various noble metal-decorated SMOs-based gas sensing materials [72,73,74]. Specifically, different parameters including the adsorption energy, adsorption distance, and charge transfer could all reflect the adsorption properties.

First, the adsorption energy (Eads) is defined as Eads = Esub-gas–(Esub + Egas), where Esub-gas represents the total energy of the gas molecule–substrate adsorption system, and Esub/Egas denotes the energy of the substrate and the isolated gas molecule, respectively. Accordingly, Eads < 0 implies that the adsorption process is exothermic and spontaneous, leading to an energetically stable adsorption system [19]. Meanwhile, the more negative adsorption energy indicates a much stronger adsorption reaction as well as a higher sensing response. For example, Liu et al. [75] constructed geometrically optimized Pd4 cluster-decorated SnO2 and intrinsic SnO2 models for H2 and acetylene (C2H2) adsorption and calculated the corresponding adsorption energies via the DFT method. As a result, the adsorption energies of H2/SnO2, H2/Pd4-SnO2, C2H2/SnO2, and C2H2/Pd4-SnO2 are − 0.205, − 0.574, − 0.974, and − 1.282 eV, respectively, indicating a better gas sensing performance of Pd decorated SnO2 than intrinsic SnO2. Their follow-up experimental measurements further demonstrate much higher responses of Pd decorated SnO2 than intrinsic SnO2 towards H2 and C2H2, which corresponds well with the theoretical calculation results.

Second, since the chemical adsorption takes place when the bonds between the target gas molecules and the exposed atoms on the substrate materials are formed, the specific adsorption distance therefore can help reveal the gas adsorption behaviors [76]. More specifically, the shorter the adsorption distance, the stronger the adsorption interaction. For instance, for the comparison of the gas adsorption performance between intrinsic ZnO and Pd decorated-ZnO, Liangruksa et al. [77] investigated the adsorption distances between the H2 molecule and the nearest atoms of the substrates after adsorption. In detail, the adsorption distances for dO(ZnO)−H(gas) and dPd(Pd2 cluster)−H(gas) are calculated to be 3.70 and 1.58 Å, respectively, implying the enhanced H2 gas adsorption interaction after Pd decoration on the ZnO surface. In addition, the H–H bond length of the H2 molecule stretches longer after the chemical adsorption, which benefits the dissociation of the H–H bond and in turn promotes the H2 adsorption reaction.

Third, the charge transfer (∆Q) refers to the quantity of electons transferred from gas molecules to substrate materials. Consequently, the greater value of ∆Q means the more electrons transferred, further indicating the higher gas sensing response [78]. For example, based on Barder charge analysis, Chen et al. [79] discovered that the charge transfer for the C6H6 molecule adsorbed on intrinsic, Pd-decorated, and Pt-decorated ZnO monolayers are calculated to be approximately 0.01798e, 0.0231e, and 0.0243e, respectively. Accordingly, the noble metal (Pd, Pt) decoration could enhance the charge transfer as well as the gas sensing performance.

2.3.2 In-situ Transmission Electron Microscopy Analysis

With the rapid progress of modern science and technology, increasingly advanced characterization techniques have been applied in the field of gas sensing to further reveal the morphology and composition changes before and after the gas sensing process. Significantly, the emerging in-situ transmission electron microscopy (TEM) technique can help to directly observe the solid–gas reaction process and record the morphological and compositional evolution of the sensing materials during the real-time gas sensing process at the desired temperature [80, 81], which is urgently deserved to be used in gas sensing mechanism investigation. For example, Wang et al. [82] revealed the failure mechanisms of bimetal Pd–Ag nanoparticles in ZnO-based H2 sensors under operation conditions with the help of gas-cell in-situ TEM, which further guided the optimized design of satisfactory H2 sensors with excellent long-term stability. In detail, the morphological evolution of bimetal Pd–Ag nanoparticles on the surface of ZnO nanowires at two characteristic operating temperatures of 300 and 500 °C was observed in real time on the in-situ TEM characterization platform. Based on the in-situ TEM analysis, two reasonable failure mechanisms of the bimetal Pd–Ag nanoparticles are proposed: particles coalescence at 300 °C and phase segregation at 500 °C. However, particles coalescence will lead to the formation of large nanoparticles with degraded catalytic activities, and phase segregation of Ag migrating from the Pd–Ag alloy nanoparticles will result in the decrease of the synergistic effect, both causing the degradation of gas sensing performance. In addition, Hui et al. [83] synthesized Au/WO2.7 nanocomposites and carefully investigated the changes in morphology and electronic structure under H2 atmosphere by in-situ TEM, which helped to analyze the intrinsic interaction between Au/WO2.7 nanocomposites and H2. As a result, both swing and sintering processes of Au NPs were observed at the heating environment, which could indicate the inner mechanism for the change rule of sensing performance with increasing operating temperature. Meanwhile, no injection of H atoms was observed in the surface of Au/WO2.7 nanocomposites after the introduction of H2 into the vacuum environment, which suggested that the H2 sensing mechanism for Au/WO2.7 nanocomposites under a vacuum are dominated by mass transport pathways.

3 Single Noble Metal-Decorated SMOs-Based Gas Sensors

3.1 Pt-Decorated SMOs-Based Gas Sensors

3.1.1 Pt-decorated ZnO Gas Sensors

Pt-decorated ZnO materials were synthesized with various morphologies including zero-dimensional (0D) nanoparticles [84], one-dimensional (1D) nanorods [85], nanotubes [86], two-dimensional (2D) nanosheets [87], and three-dimensional (3D) hierarchical structures [88]. Benefiting from high specific surface area and continuous electron transfer pathways, Pt-decorated 1D ZnO nanostructures exhibit enhanced sensing behaviors such as reduced working temperature, remarkable sensitivity and selectivity, and fast response/recovery process. For instance, Yu et al. [89] reported a Pt-decorated ZnO nanorods sensor through a facile immersion-calcination method, which was highly sensitive to target ppb-level H2S gas. As shown in Fig. 5a, the Pt-decorated ZnO-based sensor exhibited the highest response at each concentration (20–80 ppb) than that of other sensors. Owing to the excessive enhanced surface catalytic activity, when the concentration of the Pt NPs was increased, the response of the sensor was degraded. Moreover, the response of the Pt-decorated ZnO-based sensor was 23.1 towards at 260 °C at a low H2S concentration of 100 ppb, which was 5.8-fold higher than the pure ZnO sensor (3.4). Besides, the lowest H2S detection of the Pt-ZnO-based sensor could obtain as low as 1.1 ppb. In brief, the excellent H2S sensor can be achieved by combining the sensitization effect of Pt and the specific surface area of nanorods. Young et al. [85] prepared Pt NPs-decorated ZnO nanorods via a hydrothermal strategy. Due to the spillover effect of Pt, the response of Pt-decorated ZnO nanorods-based sensor to 1000 ppm methanol was significantly improved from 1.34 to 121.03 at 270 °C (Table 1).

Reproduced with permission from Ref. [89]. Copyright 2021, Elsevier. b Response and recovery behavior of 0.50 at% Pt-decorated ZnO to 50 ppm CO at 180 °C. Reproduced with permission from Ref. [34]. Copyright 2020, Elsevier. c Mechanism of Pt-decorated ZnO sensor toward NH3. Reproduced with permission from Ref. [90]. Copyright 2020, Elsevier. d Responses of pure ZnO, Pt-commercial ZnO, and Pt-decorated ZnO microspheres-based sensors to various gases. Reproduced with permission from Ref. [72]. Copyright 2021, Elsevier. e Fabrication process of Pt@ZnO polyhedrons. f SEM image of Pt@ZnO polyhedrons. Reproduced with permission from Ref. [91]. Copyright 2021, Elsevier. g Responses of 3DIO ZnO and 3DIO Pt-decorated ZnO@ZIF-8 based sensors to simulated H2S abnormal/healthy breath samples. Reproduced with permission from Ref. [92]. Copyright 2022, Elsevier

a Response of the pristine and Pt-decorated ZnO sensors towards different concentrations varying from 20 to 80 ppb.

Pt-decorated 2D ZnO structures have attracted much attention owing to their controllable morphology, exhibiting diverse sensing properties [90]. Wang et al. [34] fabricated the Pt-decorated ZnO nanosheets with various Pt concentration through a simple wet-chemical method. The 0.50 at% Pt-decorated ZnO displayed the most excellent sensing properties among 0.25, 0.75, and 1.00 at% Pt/ZnO, demonstrating that a reasonable Pt concentration was crucial to promote the gas sensing behavior. Specially, the working temperature of Pt-decorated ZnO senor was decreased from 210 to 180 °C because that the catalyst Pt could decrease the activation energy of gas chemisorption. As shown in Fig. 5b, the response/recovery speed of the as-prepared ZnO sensor was shortened from 108/285 to 6/19 s toward 50 ppm CO, which benefited from the addition of Pt decreasing the activation energy of gas reaction as well as accelerating the gas adsorption and desorption. Li et al. [90] prepared Pt/ZnO ordered porous monolayer films by a polystyrene sphere (PS) monolayer colloidal crystal template method. The Pt-decorated ZnO-based sensor showed an excellent response of 324 towards 100 ppm NH3, which was 200 times of the pure ZnO-based sensor. The mechanism of Pt-decorated ZnO toward NH3 is exhibited in Fig. 5c. When the as-prepared gas sensors were surrounded by air, the oxygen molecules were adsorbed on the material, extracting electrons, and thus forming the chemisorbed oxygen ions (O−, O2−). The spillover effect of Pt catalyzed the adsorbed oxygen molecules to produce more chemisorbed oxygen ions and reacts with more NH3 molecules, resulting in larger response. Another advantage of using Pt is the modulation of the electronic character of ZnO. The work function of Pt was 5.65 eV, which was higher than the ZnO (3.30 eV) Therefore, the electron transferred from ZnO to Pt NPs and then widened the depletion layers. Moreover, PtOx and ZnO could construct a p-n heterojunction to enhance sensing performance, which could enhance the oxygen adsorption and modulate the conduction channel. The mechanism agrees well with the experimental results.

Compared to 1D or 2D structures, Pt-ZnO with 3D structures demonstrate enhanced performance owing to their large effective specific surface area. Liu et al. [72] prepared a hierarchical Pt-decorated ZnO microspheres with porous nanosheets through a hydrothermal strategy, followed by a reduction method. The as-prepared sensor exhibited high response towards 100 ppm triethylamine (TEA) of 242 at 200 °C, which was 50-fold enhancement for the pristine ZnO sensor. Notably, it had excellent selectivity to react with TEA gas while repressing other VOC gases, shown in Fig. 5d. Moreover, the DFT calculation indicated the adsorption energy of TEA on Pt-ZnO (−3.16 eV) was lower than ZnO (−1.21 eV), proving Pt-ZnO was of great advantages to sense TEA gas. In recent years, metal organic framework (MOF) structures have been introduced to improve the capability of electron transference between the target gas and the noble metal. For instance, Qin et al. [91] reported a Pt-decorated ZnO polyhedrons via an in-situ reduction method using with a template of zeolitic imidazolate framework-8 (ZIF-8). The synthesis process and the scanning electron microscopy (SEM) image of Pt@ZnO polyhedrons were exhibited in Fig. 5e–f, respectively. In contrast to the pure ZnO sensor, the obtained Pt@ZnO polyhedrons could not only promote the response value but also lower the temperature owing to the catalytic effect of Pt. The 2% Pt@ZnO sensor displayed good response of 10 to 50 ppm CO at 100 °C, high selectivity, and long-term stability. Notably, the 2% Pt@ZnO sensor showed an ultra-low detection limit (100 ppb), which was ascribed to the highly dispersed Pt NPs, enhancing the utilization rate of active sites. Overall, the introduction of the MOF structure effectively improved the dispersity of Pt NPs on the ZnO, thus enhancing the gas sensing behavior especially for detecting ppb-level gas. Zhou et al. [92] synthesized a 3D inverse opal (3DIO) microporous ZnO, further coated a ZIF-8 molecular sieve membrane through in-situ growth from the ZnO skeleton, and then functionalized with small Pt NPs. The microporous ZnO structure and the ZIF-8 filter membrane provided more active adsorption sites and eliminated the VOC interference, facilitating the gas sensing behaviors. Thus, this 3DIO Pt-decorated ZnO@ZIF-8 sensor exhibited great sensing behaviors that the response of the sensor was 118 toward 5.5 ppm H2S and the lowest H2S detection of sensor was 40 ppb. Moreover, the 3DIO Pt-decorated ZnO@ZIF-8 sensor was widely used in various fields, such as food quality evaluation, diagnosis of halitosis, and environment monitoring. For instance, as shown in Fig. 5g, the response of the 3DIO Pt-decorated ZnO@ZIF-8 sensor towards halitosis breath was 4.0, which was 2.4-fold enhancement of healthy counterparts (1.7), demonstrating that 3DIO Pt-decorated ZnO@ZIF-8 sensor could efficiently detect halitosis. Moreover, compared with untreated automobile exhaust gas, the response of 3DIO Pt-decorated ZnO@ZIF-8 sensor towards 1 L automobile exhaust with 330 ppb H2S was 3 times higher, indicating that it could be utilized to detect microscale concentrations of H2S. In summary, combining the MOF as outer filter membrane and Pt modification was an efficient strategy to develop an efficient sensor for trace H2S detection.

3.1.2 Pt-decorated SnO 2 Gas Sensors

As a typical n-type SMO, SnO2 is currently attracting tremendous attention owing to its environmentally friendly synthesis and wide application in the detection of various gases. In terms of various Pt decorated SnO2 nanostructures, 1D nanostructures like nanotubes and nanowires are efficient structures for SnO2 to detect gas owing to the specific surface area and high gas accessibility [93]. Electrospinning was utilized to synthesize 1D nanotubes, nanofibers, nanowires, and core–shell structures, due to its easy control of morphological [94]. It is suggested that various porous structures are obtained by changing the solution components and electrospinning conditions. For example, Bulemo et al. [55] reported Pt-decorated SnO2 hollow microbelts by electrospinning and calcination. The SnO2 hollow microbelts structure exhibited large specific surface area, small mean crystal size, and high porosity, which were advantages for promoting oxygen adsorption–desorption kinetics. The Pt (0.12%)-SnO2 hollow microbelts sensor exhibited a high response of 93.7 towards a low acetone concentration of 2 ppm, short response time (9.2 s), and long-term stability for over six-month. The better sensing behavior of Pt-SnO2 was owing to the specific surface area of microbelts and electrical and chemical sensitization of Pt. In addition, the Pt (0.12%)-SnO2 hollow microbelts-based sensor also showed high stability with response of 93.70 ± 0.89 to 2 ppm acetone for 25 repeated tests in a humid environment of 90% relative humidity (RH). Shin et al. [95] reported the hierarchical SnO2 fibers with wrinkled thin tubes produced by electrospinning and then decorated by Pt NPs via polyol method. The structure of Pt-decorated SnO2 fibers composed of wrinkled thin tubes is shown in Fig. 6a. The hierarchical SnO2 fibers with wrinkled thin tubes with high porosity not only promoted the decoration of Pt NPs, but also made gas molecules transfer to the entire sensing layer, shortening the response/recovery time less than 11/6 s. In conclusion, synthesizing the structures with high porosity and large specific surface area under various preparation conditions would facilitate the uniform distribution of Pt NPs, enhancing the sensing behaviors for the potential use of exhaled breath sensor. In addition, it is essential to uniformly decorate Pt NPs on SnO2 nanostructures to further maximize the catalyzation of Pt NPs. Jang et al. [96] synthesized the Pt-decorated meso/macro SnO2 nanotubes through an advanced electrospinning method, which is shown in Fig. 6b. In this work, the hollow protein nanocage was used to synthesize Pt NPs with different diameters distributing on SnO2 nanotubes. Thus, combining the porous nanotubes could lead to enhanced sensing performance because of the large specific surface area and high gas accessibility. The Pt decorated-SnO2 nanotubes sensor displayed high response of 192 to 5 ppm acetone at 350 °C.To sum up, electrospinning is an efficient method to synthesize the porous 1D structure composited with uniformly distributed Pt NPs, which is useful for developing excellent sensing behaviors.

Reproduced with permission from Ref. [95]. Copyright 2012, Wiley–VCH. b Synthesis of pore loaded SnO2 nanotubes decorated by Pt NPs. Reproduced with permission from Ref. [96]. Copyright 2016, Wiley–VCH. c Response versus time curves of the SnO2-PVP, 0.1% Pt-SnO2, 0.3% Pt-SnO2, and 0.5% Pt-SnO2 based-sensors to 100 ppb ~ 5 ppm H2S. d Selectivity behaviors of SnO2-PVP, 0.1% Pt-SnO2, 0.3% Pt-SnO2, and 0.5% Pt-SnO2 based-sensors [101]. Reproduced with permission from Ref. [101]. Copyright 2020, Elsevier. e Response of pure SnO2, 0.5 wt% Pt-decorated SnO2, 1 wt% Pt-decorated SnO2, and 2 wt% Pt-decorated SnO2 sensors towards various isopropanol concentrations at 220 °C. Reproduced with permission from Ref. [56]. Copyright 2014, Royal Society of Chemistry. f AFM characterization of Pt-SnO2 thin films. g Response and recovery behaviors of SnO2 and Pt-decorated SnO2 films sensor to 10 ppm TEA at 200 °C. Reproduced with permission from Ref. [104]. Copyright 2020, Royal Society of Chemistry. h Schematic of the well-designed filter-sensor system, exhibiting the adsorption of hydrophilic compounds on the activated alumina filter with no retention of hydrophobic isoprene. i Dynamic response curves of a Pt-SnO2 NPs sensor to 500 ppb isoprene, acetone, ethanol, methanol, and ammonia without and with an activated alumina filter at 90% RH. Reproduced with permission from Ref. [106]. Copyright 2018, American Chemical Society

a Back scattered electrons (BSE) images of 20 wt% Pt-modified thin-wall assembled SnO2 fibers.

Hydrothermal is a facile process of synthesizing 1D SnO2 nanostructures, which is widely used for fabricating gas sensors [97]. For example, Zhou et al. [98] fabricated Pt-modified SnO2 nanoneedles through a hydrothermal method. For 3.125 at% Pt- modified SnO2 nanoneedle composites, a high sensing response of 23.18 is recorded towards 100 ppm CO gas at 250 °C with the response/recovery speed of 15/14 s, respectively. Chen et al. [99] synthesized SnO2 nanorods via hydrothermal strategy, followed by the ultraviolet (UV)-irradiated photochemical reduction method to functionalize Pt NPs. With decoration of 3.63% Pt NPs, the response of sensor toward 1000 ppm H2 was enhanced from 1.4 to 7.9 at room temperature (RT). Generally speaking, sensors work at RT are attractive for reducing cost and improving stability, but they often need long response time and recovery time, limiting their practical application [100]. Functionalizing of Pt NPs on the SnO2 could promote the oxygen adsorption, which are spilled over on the SnO2 to react with more gas molecules. Moreover, Pt NPs were beneficial to the electrons transfer owing to the higher work function than the SnO2. The Pt-SnO2 nanorods-based sensor responded to 1000 ppm H2 with short response time (0.4 s), owing to the sensitization effect of Pt. Therefore, functionalizing Pt NPs was potential to enhance the response speed of RT sensors. In addition, Sun et al. [101] reported a Pt-decorated SnO2 mesoporous nanoflowers H2S sensor working at RT through a mixed template method followed by selective calcination. As exhibited in Fig. 6c, the response towards ppb-level H2S at RT was significantly improved by decorating Pt NPs. The 0.3 wt% Pt-decorated SnO2 nanoflowers sensor showed high response of 68 towards 1 ppm H2S at 30 °C, which was 11-time improvement of pristine SnO2 sensor. Meanwhile, as shown in Fig. 6d, the decoration of Pt NPs significantly improved the selectivity of Pt-SnO2 sensors compared with pristine SnO2 sensor. The catalytic Pt NPs could effectively promote electron transfer, thus accelerating the reaction not only between chemisorbed oxygen and H2S but also between SnO2 and H2S molecules (\(Sn{O}_{2}+{H}_{2}S\to Sn{S}_{2}+{H}_{2}O\)). Therefore, the selectivity of Pt-decorated SnO2 sensors were further enhanced. Besides, the sensor also displayed short response/recovery time of 11/75 s. The enhanced sensing behavior was due to the porous structure with high specific surface area and the catalyzation effects by Pt NPs. In summary, the surface decoration of Pt is a promise method to promote the gas sensing behaviors at the field of RT H2S gas sensors.

There are various techniques to fabricate 2D SnO2 structures. Solution combustion synthesis has been regarded as an efficient, rapid, and energy-effective method for producing large-scale nanostructures [102]. For instance, Dong et al. [56] synthesized Pt-decorated SnO2 porous sheets with different Pt concentration via solution combustion method. The 2 wt% Pt-decorated SnO2 sensor exhibited the highest response to a wide range concentration (5 ~ 100 ppm) of isopropanol gas, as displayed in Fig. 6e. Specifically, the response of the 2 wt% Pt–decorated SnO2 sensor towards 100 ppm isopropanol was 190.50, which was 9-time enhancement of the pure SnO2 based sensor. The enhanced response was ascribed to the electronic sensitization as well as the catalytic oxidation of Pt NPs. Atomic layer deposition (ALD) technique has a great advantage of precisely controlling the film thickness at the atomic level [103], which is beneficial to prepare efficient gas sensors. Besides, Xu et al. [104] reported Pt decorated SnO2 films sensor by ALD with different thicknesses varying from 4 to 18 nm. The morphologies of pristine SnO2 and Pt-decorated SnO2 film were analyzed by atomic force microscopy (AFM). The Pt-SnO2 film exhibited in Fig. 6f had a surface root mean square roughness of 420 pm, which was similar with SnO2 thin film (470 pm), indicating both have similar surface features. Thus, ALD technique could synthesize thin film with uniform thickness, which was advantageous to fabricate stable sensing layers. The Pt-decorated SnO2 ultrathin film sensor could reduce the working temperature from 260 to 200 °C. The Pt-decorated 9 nm SnO2 film sensor exhibited high response of 136.2 to 10 ppm TEA, which was 9 times improvement to the pure SnO2 sensor, and ultrafast response/recovery speed (3/6 s), as shown in Fig. 6g. Moreover, the Pt-decorated 9 nm SnO2 film sensor could detect the TEA as low as 7 ppb, illustrating the high potential development for sensitive detection of VOCs at ppb-levels. Owing to the appropriate thickness of SnO2 film synthesized by ALD, oxygen vacancies in films, and catalyzation of single atom Pt, the Pt-SnO2 thin film sensor showed an outstanding sensing performance.

Moreover, since selectivity is considered as one of the most crucial aspects for gas sensors in practical applications surrounded with diverse interfering gases, many efforts on constructing an efficient filter have also been devoted to further improve the selectivity of Pt-decorated SnO2 gas sensors. The filters, including sorption, size-selective, and catalytic filters, will help to change the composition and/or concentration of molecules in gas mixtures before reaching the sensor as expected [105], thus contributing to the enhancement of selectivity. For example, Broek et al. [106] designed an effective filter consisted of a packed bed of activated alumina powder with high porosity upstream of the flame-made Pt-SnO2 NPs sensor (Fig. 6h), achieving highly selective and rapid breath isoprene detection at the ppb-level and high humidity. Specifically, as shown in Fig. 6h, the well-designed filter can adsorb hydrophilic breath analytes like acetone, ethanol, methanol, and ammonia, as well as water molecules, leaving hydrophobic isoprene unhindered and transported to the downstream sensor. Finally, the well-designed filter-sensor system exhibited remarkable selectivity (> 100) to ppb-level isoprene at 90% RH in Fig. 6i, which was significantly enhanced comparing to the pristine nonspecific Pt-SnO2 NPs sensor. In addition, Oliaee et al. [107] reported a catalytic filter comprised of Au NPs decorated Fe2O3 for the Pt-SnO2 sensor and realized highly selective detection to propane or methane in the presence of CO and ethanol. Actually, CO will be completely converted to insensitive CO2 by the catalytic filter at room temperature, and ethanol will be adsorbed/oxidized by the filter at room temperature/temperatures higher than 200 °C. Similarly, a Au NPs-promoted Ce0.8Zr0.2O2 catalytic filter was designed for the Pt-SnO2 sensor by Fateminia et al. [108], demonstrating selective detection of ethanol and methane in the presence of interfering gases. From their observations, the operating temperatures of the filter and the sensor will both affect the selectivity of the filter-sensor system, which require meticulously selection and control for different applicaion scenarios.

3.1.3 Pt-decorated WO 3 Gas Sensors

WO3 is an important n-type SMO with a wide band gap (2.8 eV), which is a potential material for developing excellent gas sensors toward various gases due to its excellent physical and chemical properties and superior sensing characteristics [109]. Functionalization of WO3 with Pt NPs could enhance the sensing performance of the resultant material due to the catalytic properties of Pt.

Pt-decorated WO3 is often used for detecting H2 due to the ability of Pt to dissociate hydrogen atoms effectively at RT [110]. Horprathum et al. [53] successfully developed Pt-loaded WO3 nanorods through the glancing angle deposition (GLAD) method. As exhibited in Fig. 7a, the high response of the optimal Pt-loaded WO3 nanorods sensor was 2.2 × 105 (Ra/Rg) towards 3000 ppm H2 at 200 °C, while pristine WO3 nanorods sensor was almost no response, indicating that Pt decoration was an efficient method to promote the H2 detection. Moreover, the optimal Pt-loaded WO3 sensor showed high sensitivity to 150 ppm at 150 °C and high selectivity toward H2 among various gases. The improved sensing behavior was ascribed to the chemical sensitization of Pt, which dissociated H2 molecules into H atoms and reacted with WO3 through spillover effect, decreasing the depletion width and electrical resistance. Fan et al. [110] developed a Pt-decorated WO3 nanorods sensor through evaporation method and sputtering process. The Pt-decorated WO3 sensor exhibited very fast response of 80 ms toward pure H2 at 110 °C due to the chemical sensitization of Pt. Nishijima et al. [111] deposited Pt-WO3 nano/micro powder films on a silica glass substrate using nanosecond pulsed laser ablation. They reported that the low limit of H2 detection (10 ppm) and short response time of 20 s towards 40,000 ppm H2 was obtained.

Reproduced with permission from Ref. [53]. Copyright 2014, American Chemical Society. b SEM image of meso- and macroporous Pt-decorated WO3 microbelts. c PCA result of the sensor array. Reproduced with permission from Ref. [113]. Copyright 2018, American Chemical Society. d Synthesis route of Pt-decorated macroporous WO3 nanofibers. e PCA result of the healthy bodies and halitosis patients through the human exhaled breath. Reproduced with permission from Ref. [114]. Copyright 2016, American Chemical Society. f Fabrication process of Pt loaded ordered mesoporous WO3 composites. Reproduced with permission from Ref. [32]. Copyright 2017, Wiley–VCH

a Response of different Pt decoration times decorated WO3 nanorods sensors toward 100–3000 ppm of H2 at 200 °C.

Pt-decorated WO3 sensors are also utilized for effectively detecting H2S gas. Yao et al. [112] synthesized Pt-decorated WO3 nanorods hydrothermal and chemical reduction methods. The response of the 0.2 at% Pt-decorated WO3 sensor was 1,638 towards 10 ppm H2S at 200 °C, with the short response/recovery time of 42/37 s, respectively. In comparison with pristine WO3 sensor, Pt-WO3 sensor exhibited enhanced gas sensing behavior because of the electronic modulation and its catalysis reaction between H2S and oxygen ions. The porous microstructure has advantages of numerous reaction sites and gas diffusing channels, leading to better response performance. In this regard, Kim et al. [113] reported Pt-decorated WO3 microbelts with a large amount of porosity via the electrospinning combined with sacrificial templates and subsequent calcination. Figure 7b showed the structure of meso- as well as macroporous Pt-modified WO3 microbelts. Moreover, Pt NPs were fabricated by using biological protein cages, such as apoferritin to prevent the agglomeration of particles after calcination, thus further improving the gas sensing properties. The 0.05 wt% Pt-decorated WO3 microbelts sensor displayed excellent sensing performance including high response of 372 towards 5 ppm H2S in 95% humid condition and excellent selectivity to H2S among other gases, which were owing to the bimodally porous nanostructure and catalysis effect of Pt NPs. Furthermore, as exhibited in Fig. 7c, the principal component analysis (PCA) result showed that the sensor arrays could clearly classify H2S from the other gases without overlapping, indicating the potential application of the sensor arrays to detect H2S to diagnose halitosis. In addition, Choi et al. [114] developed Pt decorated microporous WO3 nanofibers via electrospinning technique and calcination. In addition, Pt infiltrated block copolymers microparticles (Pt-BCP MPs) were made through an oil-in-water emulsion technique, which could be evenly distributed on the WO3, further enhancing the gas sensing behavior. The fabrication process of Pt-modified macroporous WO3 nanofibers is shown in Fig. 7d. The 0.042 wt% Pt-WO3 nanofibers sensor exhibited an excellent response of 834.2 ± 20.1 toward 5 ppm H2S at 350 °C in a high humid condition (95% RH) and low H2S detection of 100 ppb. The PCA result indicated that the sensor arrays achieve distinguish pattern recognition of various gases, demonstrating their high selectivity. Moreover, as shown in Fig. 7e, the healthy breath and the halitosis breath was obviously distinguished, indicating the sensor arrays was a potential method for the breath diagnosis. In this regard, the porous structure and catalytic character of uniformly distributed Pt NPs are crucial to enhance the sensing performance to target gases.

In addition, Pt-loaded WO3 sensors are reported to detect other gases including CO, NO2, acetone, and ammonia. Ma et al. [32] synthesized Pt-decorated highly ordered mesoporous WO3 via a multicomponent co-assembly method. The fabrication process of the Pt-decorated WO3 nanocomposite was shown in Fig. 7f. Owing to the sensitizing effect of the Pt NPs, the Pt-WO3 sensor showed the response of 10 to 100 ppm CO at 125 °C, short response/recovery speed (16/1 s), and remarkable selectivity. Besides, Liu et al. [115] reported a Pt decorated WO3 thin film sensor based on the MEMS devices through GLAD and conventional planar deposition. The Pt-decorated WO3 film sensor displayed high response of 1,308.26 toward 10 ppm NO2, low detection of limit (80 ppb), and excellent selectivity to NO2 among NH3, CO, acetone, and ethanol. Alev et al. [54] fabricated WO3 nanoflakes through a hydrothermal route and further loaded Pt NPs via a sputtering method. The catalytic effect of Pt could dramatically enhance the gas sensing behaviors of Pt-WO3 sensor which could detect acetone even at a low concentration of 237 ppb at 250 °C. Chao et al. [116] fabricated Pt loaded square-like WO3 via a facile hydrothermal and reduction method. It was found that the response of the 1 wt% Pt-decorated WO3 sensor was 100.09 towards 1000 ppm NH3 with short response/recovery time (8 /11 s), low detection of limit (1 ppm), and long-term stability (70 days). In summary, Pt functionalized WO3 sensor exhibits improved sensing properties toward target gases due to the sensitizing effect of Pt.

3.1.4 Pt-decorated Other SMOs-Based Gas Sensors

Apart from ZnO, SnO2, and WO3, there are various other metal oxide semiconductors like In2O3, NiO, CuO, and Fe2O3 have been investigated to enhance the gas sensing performance by decorating Pt NPs.

In2O3 with wide band gap (3.6 eV), is a potential gas sensing material owing to its high electrical conductivity and stability [117]. In particular, Pt functionalized 1D In2O3 structures were widely used for detecting NO2 and acetone. Liu et al. [118] fabricated Pt-loaded mesoporous nanofibers through electrospinning and subsequent reduction method. Because of the porous microstructure, specific surface area, and catalytic effect of Pt, the Pt-In2O3 mesoporous nanofibers sensor could detect NO2 at as low as 10 ppb at 40 °C (Rg/Ra = 2.8). Lee et al. [119] synthesized Pt decorated In2O3 nanorods through vapor–liquid-solid growth and calcination treatment. The Pt-modified In2O3 nanorods calcined at 600 °C displayed highest response towards NO2, which was 7 times improvement of the pure In2O3 nanorods. Liu et al. [120] reported a Pt-loaded In2O3 porous nanofibers sensor fabricated through electrospinning method and calcination, as exhibited in Fig. 8a. Due to the spillover effect of Pt NPs and the large specific surface area of the porous 1D structure, the Pt-In2O3 sensor displayed improved gas sensing properties towards 1 ppm acetone with high response of 15.1 at 180 °C with fast response/recovery speed (6/9 s) and excellent long-term stability (50 days). In addition, Liu et al. [121] fabricated Pt-In2O3 core–shell nanowires via co-electrospinning method, as displayed in Fig. 8b. The Pt-In2O3 core–shell nanowires-based sensor exhibited enhanced sensing performance with a high response up towards 27 to 10 ppm acetone which was six-fold enhancement of pristine In2O3 nanofibers. Beyond that, a Santa Barbara Amorphous-15 (SBA-15) molecular sieve containing 2D hexagonal channels was employed on top of the sensing layer, effectively reducing the impact of humidity on the sensor. Thus, the as designed sensor could be potential to detect microscale acetone in exhaled breath. The Fig. 8c shows a portable sensing device include the Pt-In2O3 nanowires sensor with the moisture filter layer. In summary, Pt decorated In2O3 1D nanostructures is highly sensitive to NO2 and acetone, which is an effective strategy to diagnose diseases through exhaled breath detection.

Reproduced with permission from Ref. [120]. Copyright 2019, Elsevier. b Fabrication process for Pt-In2O3 nanowires. c Schematic diagram of a portable device including the Pt-decorated In2O3 nanowire sensor. Reproduced with permission from Ref. [121]. Copyright 2018, Springer Nature. d TEM image of Pt-decorated NiO nanotubes. e Response curves of the pristine NiO, 0.3% Pt-decorated NiO, and 0.7% Pt-decorated NiO nanotube gas sensors towards different concentration of ethanol varying from 1 to 100 ppm at 200 °C; the inset image displayed linear relation of the response and the gas concentration. Reproduced with permission from Ref. [122]. Copyright 2013, American Chemical Society. f Resistance changes of Pt-Fe2O3 to acetone under different conditions. Reproduced with permission from Ref. [126]. Copyright 2019, Elsevier. g Responses of pristine CuO, Pt-CuO, Pd-CuO, and Au-CuO-based sensors to 100 ppb HCHO at 225 °C. Reproduced with permission from Ref. [128]. Copyright 2019, Elsevier

a Synthesis process of pristine In2O3 porous nanofibers and Pt-decorated In2O3 porous nanofibers.

NiO has been extensively investigated because of its important qualities such as wide energy bandgap (~ 3.8 eV), high chemical stability, and unique electrical properties [122]. The sensors based on Pt functionalized 1D NiO structures show improved sensing behaviors owing to their high specific surface area and electrical and chemical sensitization of Pt NPs. For instance, Fu et al. [122] synthesized Pt-decorated NiO composite nanotubes via a facile electrospinning method. The morphology of Pt-decorated NiO nanotubes is shown in Fig. 8d. The Pt-decorated NiO nanotubes sensor displayed the response to 100 ppm ethanol of 20.85 at 200 °C, which was tenfold enhancement of pristine NiO based sensor (2.06), as shown in Fig. 8e. Wu et al. [123] prepared Pt@NiO NPs through sol–gel method and investigated its sensing performance. The response of core–shell Pt@NiO (4.25) to 5000 ppm H2 was higher than that of NiO (1.02) with rapid response/recovery speed (91/8 s) at RT. In addition, Pt decorated 2D NiO structures sensors were widely employed owing to their numerous active sites during the adsorption and desorption of target gaseous species. For instance, Chen et al. [124] synthesized NiO thin film via radio frequency (RF) sputtering and then deposited Pt film via thermal evaporation followed by an annealing process. The Pt/NiO thin film-based sensor exhibited improved sensing behavior including high response of 13.75 towards 1000 ppm NH3 at 300 °C with short response/recovery time (15/76 s) and low limit of detection of 10 ppb. Liang et al. [125] synthesized Pt loaded NiO nanosheets through hydrothermal and photo reduction method. The enhanced sensing behaviors of Pt-decorated NiO porous nanosheets could be attributed to the synergistic effect and facer-selective Pt decoration. In summary, Pt decoration is regarded as a useful way to enhance the sensing behaviors of NiO gas sensors.

Moreover, Pt functionalized Fe2O3 and CuO gas sensors are often used to detect VOCs. For instance, Zhang et al. [126] reported Pt-decorated Fe2O3 nanocubes via hydrothermal and reduction method. Compared with pristine Fe2O3, the Pt-loaded Fe2O3 composites exhibited a higher response of 25.7 towards 100 ppm acetone at a 139 °C, with rapid response/recovery speed of 3/22 s. The sensitizing effect of Pt was crucial to the acetone detection. Besides, the sensor was investigated to detect acetone under various environment conditions. As displayed in Fig. 8f, the resistance changes of the Pt-Fe2O3 sensor to 100 ppm acetone were very similar under four conditions mimicking exhaled breath. Guo et al. [127] synthesized Pt-decorated Fe2O3 nanowires with the Pt content varying from 0.5 to 3 mol% via homotaxial electrospinning method. The 1 mol% Pt-decorated Fe2O3 nanowires was demonstrated to have the best sensing behavior with high response of 157 to 10 ppm H2S at 175 °C due to the catalytic character of Pt and high specific surface area of Fe2O3 nanowires. As for Pt decorated CuO-based sensor, Lee et al. [128] produced porous CuO structure derived from MOFs of copper benzene-1,3,5-tricarboxylate (HKUST-1), and then decorated Pt NPs with 1 ~ 2 nm diameters via sonochemical synthetic process. The 0.06 wt% Pt-decorated CuO exhibited high response to HCHO (2.64 at 100 ppb) at 225 °C, and the linear relation between the concentration and the response. Due to the porous structure derived from MOF and the sensitizing effect of Pt NPs, the Pt@CuO-based sensor achieved better sensing performance. Moreover, Pd and Au NPs could be decorated on CuO using the same method. Figure 8g shows that the response for Pd-CuO and Au-CuO to 100 ppb HCHO were 1.52 and 1.77, respectively, much lower than that of Pt-CuO, demonstrating that Pt is the best choice to functionalize CuO for HCHO detection.

3.1.5 Pt-decorated Heterostructured SMOs-based Gas Sensors

Designing hybrid structures with SMO is an efficient method to promote gas sensing behaviors. In particular, core–shell structure has been extensively utilized to enhance sensing response because of the formation of a depletion layer [129]. Moreover, the attachment of Pt NPs to the core–shell structure can modulate its resistance and further enhance the sensing behavior. For instance, Kim et al. [130] fabricated SnO2-ZnO core–shell nanowires through ALD and attached Pt NPs via γ-ray radiolysis, as shown in Fig. 9a. The Pt-decorated SnO2-ZnO core–shell nanowires based-sensor realized an extraordinarily high response of 279 to 100 ppb toluene at 300 °C, which was higher than that of SnO2-ZnO core–shell nanowires, pristine SnO2, and pristine ZnO sensor, as shown in Fig. 9b. The enhancement of the toluene sensitivity was depended on the formation of the electron-depleted region and the catalytic effect of Pt NPs. Wu et al. [131] synthesized SnO2-ZnO core–shell nanosheets through ALD and hydrothermal route, and then deposited Pt NPs via magnetron sputtering. Moreover, the sensing materials were fabricated on the MEMS devices which had many advantages including low power consumption, easy integration, and large-scale, as shown in Fig. 9c. The Pt-decorated SnO2-ZnO core–shell nanosheets-sensor exhibited the response of 30.43 towards 5 ppm H2S at 375 °C with high selectivity among NO2, NH3, ethanol, and CH4. The improved sensing behavior could be attributed to the heterojunctions and the sensitization effect of Pt NPs. In summary, core–shell heterogenous nanostructures functionalized with Pt NPs demonstrate great potential for developing excellent gas sensors towards various target gases.

Reproduced with permission from Ref. [130]. Copyright 2015, American Chemical Society. c Synthesis scheme of Pt-decorated SnO2-ZnO core–shell nanosheets in-situ on MEMS. Reproduced with permission from Ref. [131]. Copyright 2022, American Chemical Society. d Selectivity of pristine SnO2, SnO2-α-Fe2O3, and Pt-decorated SnO2-α-Fe2O3 sensors to various gases (10 ppm) at 206 °C. e Energy band diagram of Pt-SnO2-α-Fe2O3. Reproduced with permission from Ref. [132]. Copyright 2018, Elsevier. f Response/recovery speed of Pt-decorated ZnO/In2O3 sensor towards 100 ppm acetone at 300 °C, the inset is the five periods of response and recovery curves. Reproduced with permission from Ref. [134]. Copyright 2018, Elsevier

a Schematic illustrations of the fabrication process of the Pt-decorated SnO2/ZnO nanowires. b Responses of the Pt-decorated SnO2/ZnO nanowires, SnO2/ZnO nanowires, pristine SnO2 nanowires, and pristine ZnO nanowires-based sensor to toluene.

In addition, many heterojunctions functionalized Pt NPs were also developed for remarkable gas sensors. For example, Liu et al. [132] fabricated SnO2-α-Fe2O3 hollow nano-heterojunctions via hydrothermal and then loaded ultrafine Pt NPs through in-situ reduction and subsequent calcination treatment. The 6.45 wt% Pt embellished SnO2-α-Fe2O3-based sensor in Fig. 9d exhibited outstanding gas sensing behavior with a high response of 10.56 to 10 ppm styrene with ultrafast response/recovery speed (3/15 s), low limit of detection (50 ppb), and excellent selectivity among other malodorous gases. Compared to pure SnO2 and SnO2-α-Fe2O3 sensors, the improvement in styrene sensing behavior of the Pt embellished SnO2-α-Fe2O3 sensor could be mainly attributed to the electronic sensitization. As exhibited in Fig. 9e, the n–n heterojunction led to band bending at the interface of SnO2-α-Fe2O3 and the formation of metal–semiconductor contact could induce band bending at the interface of Pt-α-Fe2O3. Thus, the electron would move from SnO2 to α-Fe2O3 until the Fermi level was balanced, leading to the 6electron accumulation layer in α-Fe2O3 which could adsorb more oxygen molecules and modulate its resistance. Simultaneously, the metal–semiconductor contact would migrate electron from Pt to α-Fe2O3, further increasing the electron concentration of α-Fe2O3 side. Therefore, these two factors could facilitate the adsorption of oxygen molecules on the α-Fe2O3 side and significantly change the resistance of Pt-SnO2-α-Fe2O3. Besides, the catalytic effect of Pt NPs was crucial to the styrene sensing owing to its selective catalytic oxidation of styrene. Overall, it is promising to design n–n heterogenous nanostructures functionalized Pt NPs in the detection of specific gases. In addition, Chang et al. [133] synthesized In2O3-WO3 nano powder via calcination method and then functionalized Pt NPs through reduction process. The obtained Pt functionalized In2O3-WO3 nano powder-based sensor could achieve ppb-level detection of nitric oxide (NO) at RT due to the n–n heterojunction of In2O3 and WO3 and the catalytic effect of Pt NPs. In particular, the 0.25% Pt-decorated In2O3-WO3 nano powder-based sensor exhibited high response of 330 and 15.2 to 0.1 ppm and 25 ppb NO, respectively. In addition, Guo et al. [134] prepared Pt functionalized ZnO-In2O3 nanofibers through using ZIF-8 and electrospinning method. Owing to the noble metal NPs could be encapsulated in the cavity of ZIF-8 resulting in ultra-small nanometers, it was found that the average diameter of Pt NPs was only 3 nm which could maximize their catalytic effect. As exhibited in Fig. 9f, the Pt-decorated ZnO-In2O3 sensor displayed an excellent gas sensing behavior toward acetone with the response of 57.1 to 100 ppm at 300 °C, short response/recovery speed (1/44 s), and low limit of detection (500 ppb). The improved sensing properties was attributed to: (i) the expanded electron depletion layer on the In2O3 caused by the n–n nano-heterojunctions, (ii) the sensitizing effect of decorated ultra-small Pt NPs, and (iii) the increased sensor resistance induced by the p–n heterojunction. In summary, MOF could be utilized as an efficient platform to produce ultra-small catalysts decorated on SMOs, promoting the development of highly sensitive gas sensors.

3.2 Pd-Decorated SMOs-based Gas Sensors

3.2.1 Pd-Decorated ZnO Gas Sensors

Various morphologies of nanostructures for ZnO including nanorods, nanowires, nanofibers, nanosheets, agaric-like, coral-like, and core–shell nanostructures have been fabricated and employed in Pd-decorated gas sensors to help increasing the selectivity and response value, reducing operating temperature, and shortening the response and recovery time. Gao et al. [135] fabricated Pd-decorated ZnO nanorods through the impregnation process and proposed that the Pd/PdOx covered on the ZnO surface has a significant enhancement on H2 sensing performance. The effect of Pd0 and PdOx content under different temperature was further studied using in-situ Raman technique and found out that the appropriate variation of Pd/PdOx ratio can effectively improve the response value and shorten the response/recovery time of pure ZnO sensor. Cao et al. [136] grew perpendicularly aligned ZnO nanorods by chemical vapor deposition (CVD) method, followed by precise decoration of Pd NPs on their surface through magnetic sputtering and annealing process. The response of Pd-decorated ZnO nanorods sensor to ethanol was significantly enhanced owing to the catalytic effect of Pd NPs accelerating the dissociation and the chemisorption of oxygen. In addition, the Pd-decorated ZnO nanorods also respond well to trimethylamine. Meng et al. [137] reported Pd-decorated ZnO nanorod arrays which is in-situ synthesized on ceramic tubes by a simple wet-chemical method. Compared to pure ZnO nanorods, Pd-decorated ZnO nanorods sensor exhibited better sensing properties in the lower operating temperature region with a large response of 5.5 to 5 ppm trimethylamine. What’s more, photoactivation can also effectively improve metal oxide semiconductors gas sensing performance owing to the generation of photogenerated carrier favors the creation of reactive oxygen species at low temperature and promotes chemisorption photocatalytic oxidation reactions. Chen et al. [138] synthesized oxygen vacancy-enriched Pd-decorated ZnO (OV Pd/ZnO) nanorods by heating the solution-fabricated ZnO nanorods at 450 °C in H2 atmosphere for one hour. The sensors based on OV Pd/ZnO and Pd/ZnO both showed low responses of 5.4% and 1.1% to 0.1% CH4, respectively. As presented in Fig. 10a, under visible-light illumination, OV Pd/ZnO exhibited an ultrahigh response of 36.8% at 80 °C, while ZnO sensor showed no response and Pd/ZnO sensor showed a weak response of 2.3%. The temperature-programmed desorption of chemisorbed oxygen results revealed that the synergetic effect of various surface chemisorbed oxygen species, Pd NPs, and visible light illumination played a decisive role in forming active chemisorbed oxygen species on the surface of ZnO, which could be attributed to the improved sensing properties. Beyond that, Luo et al. [139] demonstrated a method to further enhance the selectivity of the sensor. They fabricated a core–shell nanostructured ZnO/Pd@ZIF-8 through self-templating process. Under visible light illumination, the ternary compound showed a response of 16.9% to 0.1% CH4 at 80 °C and successfully excluded the interference of NO2, as the kinetic molecule (4.5 Å) of NO2 is larger than the aperture size (4.0–4.2 Å) of ZIF-8, while the diffusion of CH4 (3.8 Å) is less influenced. Chen et al. [140] presented Pd-decorated ZnO nanowires for NO2 sensor via one-pot hydrothermal process. The Pd NPs were self-assembled on the surface of ZnO nanowires, helping to lower the operating temperature, increase the response value, and enhance the selectivity towards NO2, as shown in Fig. 10b. Lupan et al. [141] displayed a RT H2 sensor based on Pd/ZnO nanowires synthesized via one-step electrochemical deposition, and the schematic illustration of the nano-sensor is shown in Fig. 10c. The sensitivity of gas sensors increases as the grain size of metal oxide decreases [142, 143]. The authors also derived the response value of nanowires as a function of diameter, indicating that nanowires with smaller diameters typically have greater sensitivity. Their theory is also confirmed by the experimental results in Fig. 10d. Furthermore, the sensor exhibited high-performance sensing properties with response value of 13,100, response/recovery time of 6.4/7.4 s to 100 ppm H2 at RT. The low current values (pA-nA), ultralow power consumption, and great long-term stability (> 30 days) also demonstrate the prospect of handheld instruments. Uddin et al. [144] fabricated a H2 sensor based on Pd-modified ZnO nanorods arrays for monitoring dissolved H2 in transformer oil, as shown in Fig. 10e. The Pd catalysts modified on ZnO nanorods not only enhance the sensing performance of H2 at RT, but also protect the ZnO nanorods in liquid oil, which makes the prepared devices have long-term stability. The prepared sensor exhibited a large response in the transformer oil working environment for low concentrations (5–100 ppm) of dissolved H2 at oil temperatures of 40–80 °C, rendering it a potential candidate for transformer oil applications. Rashid et al. [145] reported a flexible RT H2 sensor based on Pd/ZnO nanorods on polyimide (PI) through aqueous solution and magnetron sputtering process. The gas sensor exhibited fabulous sensing properties with a great response of 91% to 1000 ppm H2, response time of 18.8 s, and LOD of 0.2 ppm. What’s more, as presented in Fig. 10f the sensor showed no degradation even under 90° bend and maintained high performance after 105 bending/relaxing cycles, showing excellent flexibility properties.

Reproduced with permission from Ref. [138]. Copyright 2020, Elsevier. b Selectivity of the sensors based on pristine (@150 °C) and Pd-ZnO nanowires (@100 °C) to different gases. Reproduced with permission from Ref. [140]. Copyright 2019, Elsevier. c Schematic diagram of the Pd-ZnO nanowires-based nanosensor device. d Transient response of the sensors based on single Pd-ZnO nanowire with different diameters. Reproduced with permission from Ref. [141]. Copyright 2018, Elsevier. e Measurement system for the detection of dissolved H2 in transformer oil. Reproduced with permission from Ref. [144]. Copyright 2016, Elsevier. f Optical images of the flexible RT H2 sensor based on Pd/ZnO nanorods under different bending angles. Reproduced with permission from Ref. [145]. Copyright 2013, Elsevier. g Selectivity of the sensors based on ultrathin agaric-like Pd-decorated ZnO nanosheets with the background of Pd/ZnO SEM image. Reproduced with permission from Ref. [148]. Copyright 2020, American Chemical Society. h SEM image of porous coral-like Pd-decorated ZnO nanosheets. Reproduced with permission from Ref. [149]. Copyright 2021, Elsevier. i Selectivity performance and BET surface area of the Pd@ZnO core–shell NPs. Reproduced with permission from Ref. [150]. Copyright 2021, Elsevier

a Transient response of the sensors to 0.1% CH4 based on the ZnO, OV ZnO, ZnO/Pd and OV ZnO/Pd composites under 590 nm light illumination.

Besides, Pd-decorated 2D ZnO nanomaterials have also attracted the interest of researchers due to their small thickness and high specific surface area, which are ideal for the enhanced surface reactions and detections of target gas. Kim et al. [146] prepared 2D ZnO nanosheets with a thickness of approximately 1 nm via facile hydrothermal process and modified with Pd through UV radiation. The Pd-modified nanosheet successfully detects H2 at the concentration down to 0.1 ppm with excellent selectivity. In addition, the Pd/ZnO nanosheets were further prepared on PI substrates and tested by bending, tilting and stretching to demonstrate the great mechanical flexibility. Xiao et al. [147] synthesized high-performance acetone sensors based on the Pd-modified porous single-crystal ZnO nanosheets. The ZnO nanosheets was produced by solvothermal method, while Pd NPs were self-assembled on their surface. The authors contributed the fabulous sensing properties to the Pd modification effect and the high percentage of the single-crystal ZnO nanosheets encased in (100) facets. Furthermore, they proposed that different 2D and 3D ZnO nanocrystals encapsulated in high index facets could greatly enhance the sensing performance of chemical sensors. Beyond that, a variety of interesting morphologies based on ZnO nanosheet have also been prepared for high-performance gas sensors. Zhang et al. [148] prepared Pd-modified ultrathin agaric-like ZnO nanosheets aniline sensors by facile hydrothermal process. As shown in Fig. 10g, the sample exhibited superior selectivity and sensitivity to aniline, which is approximately two orders larger than pristine ZnO nanosheets. Beyond that, the aniline sensor has a low detection limit of 0.5 ppm with a response/recovery time of 29/23 s. Hung et al. [149] synthesized porous coral-like ZnO nanosheets by hydrothermal method and modified them by direct reduction of Pd ions, as shown in Fig. 10h. With Pd modification, the optimal operating temperature was significantly reduced from 450 to 350 °C, with a threefold improved response to acetone, about threefold faster response/recovery time, and a very low theoretical detection limit of 17 ppt compared to the pristine ZnO nanosheets sensor. In addition to the modification of Pd NPs on the ZnO surface, a H2 sensor based on hydrothermally synthesized Pd@ZnO core–shell NPs was reported by Nguyen et al. [150] The high Barrett-Emmett-Teller (BET) specific surface area of the core–shell material also provides a large number of active sites for accelerating the sensing reaction, which is beneficial for enhancing the sensing performance, as illustrated in Fig. 10i. Secondly, they also found that the sensing performance of the core–shell samples calcined in argon was superior to that in air, attributed to the high content of metal Pd0 species.

3.2.2 Pd-Decorated SnO 2 Gas Sensors