Highlights

-

The advances of electrode materials, energy storage mechanisms, electrolytes and applications for Zn-ion hybrid supercapacitors (ZHSCs) are comprehensively summarized.

-

Recent progresses in ZHSCs are discussed by categorizing into two configurations of Zn//Cap and Cap//ZBC.

-

Future opportunities and challenges for the development of ZHSCs are also elaborated.

Abstract

As a new generation of Zn-ion storage systems, Zn-ion hybrid supercapacitors (ZHSCs) garner tremendous interests recently from researchers due to the perfect integration of batteries and supercapacitors. ZHSCs have excellent integration of high energy density and power density, which seamlessly bridges the gap between batteries and supercapacitors, becoming one of the most viable future options for large-scale equipment and portable electronic devices. However, the currently reported two configurations of ZHSCs and corresponding energy storage mechanisms still lack systematic analyses. Herein, this review will be prudently organized from the perspectives of design strategies, electrode configurations, energy storage mechanisms, recent advances in electrode materials, electrolyte behaviors and further applications (micro or flexible devices) of ZHSCs. The synthesis processes and electrochemical properties of well-designed Zn anodes, capacitor-type electrodes and novel Zn-ion battery-type cathodes are comprehensively discussed. Finally, a brief summary and outlook for the further development of ZHSCs are presented as well. This review will provide timely access for researchers to the recent works regarding ZHSCs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As numerous portable electronic devices and electric vehicles are popularized and widely used, energy storage systems (ESSs) with excellent electrochemical performance (e.g., long cycling lifetime and high capacity) are playing a highly vital role in modern society [1, 2]. Thus, various ESSs have been widely investigated and applied for commercial applications in recent years, such as metal-air batteries [3,4,5], aqueous batteries [6,7,8,9,10], supercapacitors [11,12,13] and others [14,15,16,17,18,19,20,21,22]. However, bottlenecks still exist in both batteries and supercapacitors, where the batteries have ultra-high energy density but suffer from the short cycling lifetime due to excessive redox reactions while the supercapacitors possess predominant power density and long cycling lifetime but support fewer capacity than batteries [23,24,25,26,27,28]. Recently, to integrate respective advantages of batteries and supercapacitors into one individual device, the concept of hybrid supercapacitors (HSCs) become quite popular where the battery-type electrodes with abundant redox reaction act as an energy source and the capacitor-type (Cap) electrodes with fast ionic conductivity act as a power source [29,30,31,32,33]. Significantly, it is believed that the well-designed configuration of hybrid supercapacitors can bridge the gap between batteries and supercapacitors, and make the best use of both devices characteristics, showing an optimum ESSs for social demands [34,35,36,37,38,39,40].

Generally, metal-ion HSCs are diverse based on the different charge carriers like lithium-ion (Li-ion) [37, 41,42,43], sodium-ion (Na-ion) [44,45,46,47,48,49], potassium-ion (K-ion) [50,51,52] and zinc-ion (Zn-ion) [34, 53]. These HSCs have been widely studied and enormous developments have been made in recent years, such as Li-ion hybrid supercapacitors [54,55,56,57] and Na-ion hybrid supercapacitors [58,59,60,61]. Nevertheless, compared with the divalent Zn-ion, alkaline metal-ions present some deficiencies in practical applications. For instance, the organic electrolytes employed in Li-ion batteries (LIBs) and the excessively active redox reactions between alkaline metals and water/air, which lead to serious safety risks, potential environmental pollutions and complex manufacturing processes [35, 62,63,64,65]. Against this background, Zn-ions show the smallest radius and highest electrode potential (− 0.76 V vs. standard hydrogen electrode, SHE) among the metal-ions mentioned above, enabling Zn-ions to be highly efficient and safe charge carriers for aqueous HSCs [66, 67]. Notably, the Zn-ion ESSs have already been developed for almost 200 years, many Zn-ion ESSs showed the decisive impact on ESSs researches and have been intensively utilized in electronic devices, such as Zn-air [68,69,70], Zn–Ni [71,72,73], Zn–Ag [74,75,76] and various aqueous Zn-ion batteries (ZIBs) [67, 77]. Nowadays, wide applications of portable mobile electronic devices give rise to stricter requirements on the energy density and cycling ability of ESSs [78,79,80,81]. Hence, recently reported Zn-ion hybrid supercapacitors (ZHSCs) have exhibited attractive prospects include superb energy density, better power density, long cycling lifetime and splendid applications in flexible and micro-scale devices [32, 53, 82, 83]. Although some researches on ZHSCs have been developed, this novel ESS is still in its infancy, a systematic-and-comprehensive review including the design theories of two electrode configurations and energy storage mechanisms is necessary, which can be instructional for future investigations of ZHSCs [35, 84].

Herein, we systematically reviewed the recent progress in researches on ZHSCs. First, we classified the ZHSCs into two configurations according to the electrode materials and elaborated on the energy storage mechanisms of each configuration. As depicted in the Scheme 1, when the battery-type cathode or anode of ZIBs are substituted with Cap electrodes, the corresponding two configurations of ZHSCs are created. The first configuration of ZHSCs is constructed by the Zn anode and Cap cathode, while the second configuration of ZHSCs is assembled by Cap anode and Zn-ion battery-type cathodes (ZBC). For brevity, these two configurations of ZHSCs are named as Zn//Cap ZHSCs and Cap//ZBC ZHSCs, respectively. In addition, the synthesis strategies, typical characteristics and electrochemical performance of electrode materials in each configuration of ZHSCs are introduced, including Zn anodes, various Cap electrodes and novel ZBC. Significantly, the formation mechanisms of by-products are carefully concluded and three typical energy storage mechanisms of Cap electrodes are summarized. The effects of various Zn-based electrolytes and additive electrolytes on the Zn deposition and electrochemical performance of ZHSCs are emphasized. After that, we outlined the interesting application of ZHSCs for Zn-ion hybrid micro-supercapacitors (ZmSCs) and flexible ZHSCs devices. Finally, brief outlooks based on the recent ZHSCs progress are provided. We hope this review can attract more attention to this new generation Zn-ion ESS and promote its further development and even practical applications in modern society.

2 Aqueous Zn-Ion Hybrid Supercapacitors

Due to the special electrode potential of Zn electrodes and suitable Zn-ion salt electrolytes, the aqueous system of ZHSCs can be easily achieved and further promote the development of eco-friendly ESSs. In this section, we will summarize the recently reported aqueous ZHSCs system of two electrode configurations, the corresponding design theory, electrochemical performance and the energy storage mechanisms of electrode materials. Subsequently, some workable synthesis strategies of each electrode are introduced. Note that the Cap electrodes will be discussed between the two electrode configurations of ZHSCs.

2.1 Zn//Cap ZHSCs

The first electrode configuration of Zn//Cap ZHSCs is shown in Fig. 1, where Cap electrodes act as the cathode and power source, Zn foil or electrodeposited Zn composite electrodes act as the anode and energy source, and Zn salt solutions are employed as the electrolytes. To evaluate the energy storage mechanisms of Zn//Cap ZHSCs, the cyclic voltammetry (CV) curves of representative Cap cathode and Zn anode are depicted in Fig. 1 as well. The sharp redox peaks at − 1.2 V/− 0.94 V (vs. saturated calomel electrode, SCE) are detected on the Zn anode, corresponding to the depositing/stripping processes of Zn/Zn2+ redox reactions while the ideal rectangular shape is presented on the N-doped hierarchically porous carbon (HNPC) cathode (represent most Cap electrodes) [85]. Typically, the rectangular CV curve indicated that the physical adsorption/desorption reaction is the dominant process on the surface of Cap electrodes, resulting in an electric double-layer capacitance (EDLC). Although the designed prototype of ZHSC is quite novel, many obstacles appeared when constructing high-performance ZHSCs due to the limitations of various electrode materials. Hence, we reviewed some reported Zn anodes in the system of Zn//Cap ZHSCs and summarized feasible synthesis strategies for Zn anodes.

Zn anode, as the energy source of ZHSCs, proceeds with the depositing/stripping reaction of Zn/Zn2+ during charging/discharging process. Generally, the depositing/stripping reaction equation can be expressed by Eq. (2-1) [34, 85]:

Zn foil is a usual and suitable Zn anode material in the configuration of Zn//Cap ZHSCs owing to the advantages of abundant redox reactions, low flammability, flexibility and low cost [86, 87]. Even so, similar to lithium dendrites in LIBs, Zn dendrite also presented on the surface of bare Zn foil, which can be a potential safety hazard for electronic devices [88, 89]. Generally, the formation mechanism of Zn dendrite can be ascribed to the uneven distribution of Zn-ion contributed by the low-speed charging/discharging speed on the planar of two-dimensional (2D) Zn foil, which results in uneven nucleation and poor reversibility. The weeny tips on the pristine Zn foil can become the charge center of the electric field and further grow to Zn dendrites with the accumulation of charge. Although the formation of Zn dendrite can be suppressed by the fast charging/discharging property of well-designed ZHSCs, efforts should be devoted to thoroughly eliminating the Zn dendrite for the ESSs safety and promoting longevity of ZHSCs. Additionally, the hydrogen evolution induced by the H2O decomposition can greatly affect the depositing/stripping efficiency of flat Zn foil and increase the concentration of OH− in electrolyte, which may lead to the formation of by-products on the surface of both Zn anode and Cap cathode [90]. Therefore, a well-designed Zn anode with fast and high-efficient properties is necessary to realize high-performance ZHSCs. In the following section, we will summarize some strategies from the reported Zn anodes in ZHSCs: (1) Zn foil coating protection; (2) Electrodeposited nanostructure Zn anode; (3) Recoverable Zn anode.

2.1.1 Zn Foil Coating Protection

According to the above analysis of Zn dendrite, bare Zn foil with the planar and smooth surface is unfit for long cycling charging/discharging process. The Zn foil//ZnSO4 (gel) //layered B, N co-doped porous carbon (BN-LDC) ZHSCs reported by Lu et al. can reach a high capacity of 127.7 mAh g−1 but only maintain capacity retention of 81.3% after 6500 cycles at 5 A g−1 [83]. Additionally, Sun et al. reported Zn foil//Ti3C2 ZHSCs with a high capacity of ~ 1 F cm−2 in the aqueous electrolyte of ZnSO4, however, the Zn foil//Ti3C2 ZHSCs presented an inferior cycling performance, where the retention decay to 78% of initial capacity after 4000 cycles at a higher current density of 10 A g−1 [91].

By far, many dendrite-free Zn anodes of ZHSCs have been reported and one of the most promising strategies is the Zn foil coating protection, which can greatly stabilize and improve the performance of Zn anode by covering stable components with a rough surface. As shown in Fig. 2a, Liu et al. applied mesoporous carbon hollow spheres (MCHSs) as the external protective layer of Zn foil anode, and simultaneously, the MCHSs are also employed as the cathode materials of ZHSCs [92]. The MCHS-coated Zn foil remained smooth and porous after long cycling test while some spikes emerged on the surface of the bare Zn foil. Typically, the external MCHSs protective layer can restrain and uniform the Zn dendrite during Zn depositing/stripping process. As a result, the MCHS-coated Zn foil//MCHSs can deliver excellent cycling performance of 96% capacity retention after 10,000 cycles at a low current density of 1 A g−1, indicating the good stability of MCHS-coated Zn foil. When tested at a battery-level current density of 0.1 A g−1, the MCHS-coated Zn foil can circulate stably for 550 cycles, whereas the bare Zn foil suffered a large attenuation of capacity after only ~ 350 cycles. It is believed that the coat-layer strategy can strongly stabilize the depositing/stripping reaction of Zn foil in the conditions of both fast and slow charging/discharging process. Additionally, electrochemical impedance spectroscopy (EIS) measurement presented that the MCHS-coated Zn anodes have smaller charge transfer resistance (Rct, Fig. 2b) and faster ion diffusion rate than bare Zn foil, verifying the high-efficient Zn-ion depositing/stripping processes of MCHS-coated Zn anodes. Considering these results, the coat-layer strategy mentioned above may facilitate the splendid application of Zn foil in the ZHSCs field and then achieve better electrochemical performance.

a Schematic illustration of the synthesis process of MCHSs and corresponding application in electrodes of ZHSCs. b Comparison of Rct value for the three devices. Reproduced with permission from Ref. [92]. Copyright 2019, Elsevier. c SEM image and d schematic illustration of the hierarchically 2D-Zn anode. e Nyquist plots of different 2D-Zn anodes. Reproduced with permission from Ref. [53]. Copyright 2020, Wiley–VCH

2.1.2 Electrodeposited Nanostructure Zn Anode

By achieving a rough and relatively uniform surface, the electrodeposited Zn anode can greatly avoid the formation of Zn dendrite and realize higher electrochemical performance [93]. In addition, electrodeposited Zn materials have been widely used as the Zn anodes in ZIBs before being applied in ZHSCs [32, 94]. However, the strategy is pretty different between the ZIBs and ZHSCs, where the electrodeposited Zn anode for ZHSCs requires not only high energy density but also high power density.

As shown in the scanning electron microscope image (SEM, Fig. 2c) and illustration (Fig. 2d), Cha et al. proposed a well-designed nanostructure of hierarchically electrodeposited Zn anode (2D-Zn) for ZHSCs, where the hierarchical structure of Zn is constructed with the close-knit background Zn and dispersive 2D nanostructure Zn on the surface [53]. Moreover, the electrode depositing strategy is carefully investigated by the three kinds of the electrodeposited 2D-Zn anode. The high voltage of 1.8 V electrodepositing process can uniformly cover the Ni form with close-knit background Zn while the low voltage of 1.0 V electrodepositing process can cover the Ni form with dispersive 2D nanostructure Zn. Therefore, to achieve stable electron transport process and fast ionic diffusion rate simultaneously, the combined electrodepositing process of 1.8/1.0 V can manufacture a suitable hierarchical structure of electrodeposited Zn anode. Figure 2e depicts the EIS test results of three kinds of 2D-Zn anode. The hierarchical structure of 2D-Zn/1.8/1.0 electrodes presented the superb electrochemical performance of low Rct and rapid ionic diffusion rate. Accordingly, two-step electrodepositing strategy can be a great method to synthesize the optimal nanostructure of Zn anode for ZHSCs, the as-assembled ZHSCs delivered an ultra-high energy density of 208 Wh kg−1 and a peak power density of 20,000 W kg−1. Meanwhile, remarkable cycling performance of 99% capacity retention after 10,000 cycles is achieved at 10 A g−1.

Since the formation of Zn dendrite can be effectively circumvented by utilizing electrodepositing strategy, the connection between electrodeposited Zn and substrate becomes very important, which directly relates to the electrochemical characteristics of Zn anode [95]. The substrate used for electrodepositing is a crucial part of achieving high-performance electrodeposited Zn anodes. Notably, the three-dimensional (3D) printing (3DP) technique is employed by Sun et al. to form carbon nanotubes (CNTs) micro-lattice substrate for Zn electrodepositing [91]. Figure 3a displays the illustration of woodpile structure of the 3DP-CNT substrate, the unique structure based on the 3DP technique equipped the Zn@3DP-CNT with outstanding conductivity. Typically, the 3DP technique is a novel strategy for fabricating substrate for Zn anode, and the stereostructure of Zn anode may further promote the development of the electrodepositing method.

a Schematic illustration displaying the manufacturing process of 3DP-CNT/Zn anode. Reproduced with permission from Ref. [91]. Copyright 2021, American Chemical Society. b Cross-section SEM image of Zn@Ti3C2 anode. c, d Digital, SEM and schematic images of Zn@Ti3C2 anode after different time in PBS at 85 °C. Reproduced with permission Ref. [96] Copyright 2019, American Chemical Society. e Schematic illustration of the two-steps Zn plating on ZIF-8. Reproduced with permission from Ref. [90]. Copyright 2019, Elsevier. f Galvanostatic charge/discharge (GCD) curves of the devices after cycling and re-plating. Reproduced with permission from Ref. [97]. Copyright 2018, Royal Society of Chemistry

To implement the combination of high energy density and high power density, the electrodeposited Zn anodes are usually designed as high-surface-area structures and thin flakes. Thus, the as-designed structure of electrodeposited Zn anode may lead to a faster degradation rate than Zn foil due to the accelerated corrosion interaction. As depicted in Fig. 3b, Zhi et al. vertically electrodeposited the Zn nanoflakes onto the Ti3C2 film, the thickness of the Zn nanoflakes is ~ 42 nm [96]. When the Zn@Ti3C2 electrode is soaked in the phosphate buffer saline solution (PBS, Fig. 3c, d) at 85 °C, part of Zn nanoflakes were dissolved into the PBS after 4 days, and finally eliminated as time prolonged to 7 days, which is much faster than the Zn foil (> 30 days). The degradable electrodepositing strategy makes the electrodeposited Zn anode and the ZHSCs more eco-friendly electrode and ESSs, respectively.

Porous structure of metal–organic framework (MOF) is also an excellent host for dendrite-free and fast diffusion Zn-ion storage. Wang et al. prepared MOF Zn-zeolitic imidazolate framework (ZIF-8) electrodes with a 3D cage structure via optimized heat treatment (500 °C) [90]. After the heat treatment, the Zn2+ turned into the evenly distributed Zn0 in porous ZIF-8–500, which can provide uniform nuclei for Zn depositing and high over-potential to reduce the H2O decomposition during the charging/discharging processes. As illustrated in Fig. 3e, the Zn electroplating process is divided into two steps, including the initial Zn plating and further Zn plating. Initial Zn plating normally proceeded in or on the ZIF-8-500 particle due to the uniform nuclei provide by the Zn0, and then further Zn plating occurred on the particle substrate and end with dendrite-free Zn@ZIF-8-500 anode. Subsequently, Zn@ZIF-8-500 anode is coupled with activated carbon cathode to form ZHSCs and delivered an energy density of 140.8 Wh kg−1 as well as splendid longevity up to 20,000 cycles. Similarly, Shen et al. employed annealed ZIF-8 as the substrate of dendrite-free Zn anode and Zapien et al. deposited the Zn onto the flexible carbon cloth (CC) [98, 99]. The combination of electrodeposited Zn and carbon materials enables the composite Zn anode outstanding properties for high-performance ZHSCs.

2.1.3 Recoverable Zn Anode

In the high-performance ZHSCs devices, the irreversible consumption of the Zn anode is unavoidable and the endurance of the battery-type Zn anode is not satisfied with the long-term supercapacitors [100]. Therefore, a suitable strategy that can refresh the Zn electrodes is necessary. Sun et al. reported recoverable Zn anodes for ZHSCs by applying an in-situ electroplating method [97]. After re-plating process, no clear morphology alteration is detected and the re-plating Zn nanosheets presented vertical orientation, which may provide a lower resistance pathway for electron transfer. As presented in Fig. 3f, the re-plating Zn nanosheets anodes exhibited a higher capacity (76 mF cm−2) than the after-cycling (before re-plating) Zn nanosheets anodes (60.9 mF cm−2). Furthermore, the re-plating Zn nanosheets anodes maintained the capacity for additional 1500 cycles. Therefore, this simple operation can efficiently retard the irreversible recession of Zn anode during charging/discharging processes. Notably, the re-plating routine was replenished with in-situ method, thus the device structure will stay intact. Therefore, electronic devices can be easily refreshed through specific charging processes, and the recycling projects of ZHSCs can expediently renew these devices and apply them to other low-demand electronic devices.

Considering the above three strategies for Zn anodes in ZHSCs, it is believed that the hinges of Zn anodes are circumvents of Zn dendrite and the improvement of electron transfer as well as ionic diffusion. Compared with bare Zn foil, the coating protection and well-designed electrodepositing strategies of the Zn electrode enable them more appropriate for irreversible and high-efficient Zn-ion depositing/stripping processes in ZHSCs. Also, the recoverable Zn anode method can promote the lossless realization of renewable ZHSCs. We believe that a well-designed Zn anode should be focused on both the energy-part and power-part. The excellent integration of energy-part and power-part may facilitate the promotion of energy density in ZHSCs.

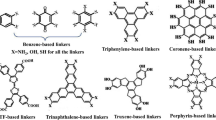

2.2 Cap Electrode

Cap electrode material is a vital part for both two electrode configurations of ZHSCs, which can equip the ZHSCs with good conductivity, fast charge/discharge rate and high electrochemical stability. Among the reported ZHSCs, two kinds of Cap electrodes are investigated, including the carbon electrode and pseudocapacitive electrode. Typically, carbon electrodes like high specific surface area (HSSA) carbon electrode, heteroatom-doped carbon electrode and graphene-based electrode can deliver an excellent power performance based on the fast adsorption/desorption reactions and considerable capacity for ZHSCs. Pseudocapacitive electrodes such as MXenes, polymer-carbon hybrid electrodes and transition metal compounds (TMCs) also present high capacity with some unique properties for ZHSCs. In the following section, we will review recent progress of the Cap electrodes and corresponding electrochemical performance in ZHSCs.

2.2.1 Carbon Electrode

The carbon electrodes with splendid properties of low cost, high chemical stability and good conductivity have been regarded as the optimal Cap electrode candidates for high-performance ZHSCs [31, 101, 102]. By proceeding the fast ion adsorption/desorption processes in the ZHSCs, the carbon electrodes can store some energy and further deliver considerable power performance. Nevertheless, due to the energy storage mechanism of EDLC, the normal carbon electrodes cannot offer sufficient energy because of the limited specific surface area (SSA). Thus, many strategies were proposed to promote the energy and power performance of carbon electrodes, such as (1) HSSA carbon electrode based on active carbon (AC), porous carbons (PCs), hollow carbon spheres (HCSs), flower-like carbons (FCs) and CNTs electrodes, (2) heteroatom-doped carbon electrodes. Additionally, graphene-based electrode is also a promising carbon electrode for ZHSCs. In this section, various recently reported carbon electrodes are expressly reviewed.

2.2.1.1 HSSA Carbon Electrode

As mentioned above, the carbon electrode is the representative cathode for Zn//Cap ZHSCs. Due to the energy storage mechanism of adsorption/desorption reaction, the capacity is highly connected with the SSA of electrode materials, thus, common strategies focus on implementing the HSSA carbon cathode [103,104,105,106]. The conventional AC materials were reported by Tang et al. and the corresponding Zn//AC ZHSCs were fully investigated [101]. To some extent, the AC is a microporous carbon material with HSSA. As shown in Fig. 4a, the rectangular shapes of CV curves demonstrated that the Zn//AC ZHSCs have typical Cap energy storage behaviors, whereas the energy density (52.7 Wh kg−1) of the ZHSCs is much more than normal supercapacitors [107]. After 20,000 cycles of charging/discharging processes (Fig. 4b), the Zn//AC ZHSCs maintained stable electrochemical behavior, and the capacity had no evident decline (remained 91% of initial capacity). Although the ultra-stable property of commercial AC materials provides the ZHSCs with ultra-long longevity, the energy density of as-prepared ZHSCs is not high enough for practical applications. Thus, Kang et al. optimized the electrochemical performance with AC powders and the Zn//AC powders ZHSCs offered a higher capacity of 84 Wh kg−1 [31]. Gratifyingly, the Zn//AC ZHSCs exhibited a splendid cycling performance (91% after 10,000 cycles) at a very low current density of 1 A g−1, which is almost the battery-level cyclic condition but the longevity is ten times longer than batteries. Accompanying with the normal adsorption/desorption reaction, the precipitation and dissolution processes of by-products (Zn4SO4(OH)6·5H2O) is detected by the XRD spectra (Fig. 4c) of AC powders [31]. In addition, more by-products like ZnSO3·2.5(H2O) were demonstrated in various ZHSCs during the charging/discharging processes [34, 77, 103]. The effects and particular mechanisms of the by-products will be carefully discussed in Sect. 3.

a CV curves and b GCD profiles of representative Zn//AC ZHSCs. Reproduced with permission from Ref. [101]. Copyright 2018, Elsevier. c XRD patterns of AC electrodes at different states. Reproduced with permission from Ref. [31]. Copyright 2018, Elsevier. d Schematic diagram illustrating the synthesis processes of PCs. Reproduced with permission from Ref. [108]. Copyright 2020, Wiley–VCH. e SEM image of HCSs. Reproduced with permission from Ref. [92]. Copyright 2020, Elsevier. f SEM image of FCs. Reproduced with permission from Ref. [109]. Copyright 2021, Elsevier. g SEM image of CNTs. Reproduced with permission from Ref. [110]. Copyright 2019, Royal Society of Chemistry

Apart from the commercial AC, many PCs electrode materials can be fabricated through various methods, like template method [111,112,113] and pyrolysis method [108, 114,115,116]. As for the pyrolysis methods, the precursor is a significant part of synthesizing high-quality PC electrode materials. Lu et al. reported molten salt-assisted synthesis of pitch-derived PCs cathodes for Zn//Cap ZHSCs while Guan et al. proposed bamboo-derived PCs cathodes with superb stability when employed in ZHSCs (96% capacity retention after 90,000 cycles) [114, 115]. Moreover, Xu et al. and Shen et al. reported a MOF route for fabricating PCs electrode materials, the ZIF-8-derived PCs presented an splendid performance of 225 mAh g−1 at 0.1 A g−1 and remained 135.5 mAh g−1 at 1 A g−1 [98, 116]. As depicted in Fig. 4d, Alshareef et al. reported a two-step synthesis method including pyrolysis at 800 °C and acid etching for manufacturing PC-800 cathode [108]. After then, the PC-800 cathode showed additional pseudocapacitance which are originated from the variation in oxidation states of oxygen functional groups. The as-assembled Zn//PC-800 ZHSCs reached a high capacity of 179.8 mAh g−1 and surprising capacity retention of 99.2% after 30,000 cycles.

HCSs, which possess hollow structures and micro- or nano-shells, are regarded as a promising HSSA carbon cathode as well. The hollow structure enables the HCSs cathode great specialties of high surface-to-volume ratio and substantial accessible sites. Chen et al. presented the HCSs cathode through the calcination of co-polymer and applied a surfactant as the soft template [99]. After that, the HCSs cathode matched with a flexible Zn@CC anode to assemble Zn@CC//HCSs ZHSCs. The HCSs have a uniform size of ~ 100 nm external diameter and ~ 50 nm inner diameter, and the Brunauer–Emmett–Teller (BET) surface area of HCSs was measured to be 819.5 m2 g−1. Benefiting from the HSSA property and hollow structure of HCSs, the ZHSCs achieved energy density of 59.7 Wh kg−1 in a low concentration of 0.08 M ZnSO4 polyacrylamide (PAM) hydrogel electrolyte and ultra-stable cycling performance (98% of initial capacity) after 15,000 cycles. Due to the low concentration and solid-state property of the applied electrolyte, the energy density of the flexible Zn@CC//HCSs ZHSCs is limited compared to aqueous ZHSCs. To further investigate the performance of HCSs cathode in the aqueous ZHSCs, Liu et al. demonstrated MCHSs cathodes with ultra-high BET surface area of 1275 m2 g−1 [92]. As shown in Fig. 4e, the external and inner diameters of MCHSs are 352 and 210 nm, respectively. With the increasing mass loading of electrodes, the HSSA carbon cathode may suffer from worsening ion and charge transport characteristics in thicker electrodes. However, the interconnected porous of MCHSs can provide a short ion and charge transport path as well as good penetration, leading to its excellent electrochemical performance of ZHSCs even under the condition of high mass loadings. Hence, the as-assembled ZHSCs can deliver a remarkable energy density of 129.3 Wh kg−1 and 100% capacity retention after 1000 cycles at 0.1 A g−1. When increasing the current density and mass loading, the MCHS-based ZHSCs only showed a small capacity degradation.

Recently, a new HSSA carbon cathode of FCs was applied by Hu et al. as the carbon cathode for Zn//Cap ZHSCs [109, 117]. The hierarchical 3D FCs are formed by the spheroidizing growth processes of carbon and low-dimensional carbon nanosheets, which possess large surface area, large surface-to-volume ratios, interconnected conductive network, nanoscale architecture and abundant accessible active sites. The SEM shown in Fig. 4f exhibited that the diameter of the 3D FCs is ~ 40 μm and the size of the carbon nanosheets is ~ 2 × 2 μm2. Based on the unique structure of 3D FCs, the Zn//FC ZHSCs offered 119.7 Wh kg−1 at 890 W kg−1 and splendid cycling performance of 92% capacity retention after 20,000 cycles. In addition, 1D CNTs displayed in Fig. 4g can also be used as HSSA carbon electrodes for ZHSCs depend on their special property of decent electrical conductivity, splendid mechanical property, high chemical stability and uniform distribution of pore size [118, 119]. Although the reported CNTs electrodes possess a low SSA of 200–300 m2 g−1 compared with PCs and HCSs electrodes, the CNT-based carbon electrode can offer incredible capacity for ZHSCs [110, 120, 121]. Han et al. applied B, N co-doped porous carbon microtube (BN-CMTs) as the cathode of ZHSCs and ultimately achieve an ultra-high capacity of 472.6 Wh kg−1 [110]. Moreover, research showed that the electrochemical characteristics of CNTs can be highly improved by many activation methods depending on their intrinsic properties [119, 122]. Based on the excellent mechanical property, Chen et al. applied CNTs as the flexible substrate for both cathode and anode materials, assembling a highly flexible fiber-type ZHSCs [120]. The as-prepared ZHSCs can keep similar CV curves under bent and twisted conditions, delivered an outstanding specific capacity of 104.5 F cm−3 and steady cycling performance of 98.5% capacity retention after 10,000 cycles.

After reviewing the reported HSSA carbon electrode of ZHSCs, one phenomenon can be discovered that the relationship between capacity and surface area is not linear. Two HSSA carbon electrodes with similar BET surface area and configuration of ZHSCs may offer disparate energy density. From our point of view, it can be ascribed to overlapping effects and electronic kinetics. Although the HSSA carbon electrodes are achieved by various nanostructures, the effective solution–surface contact area varies from structure to structure. Sometimes, the inside carbon materials can be shielded by external carbon materials, thus leading to invalid surface area for EDLC. Similarly, the electronic kinetics are also affected by different surface morphology and mass loading of carbon electrodes. Hence, the obsession for extremely high SSA carbon electrodes is inefficient and counter-productive. On the contrary, prominent nanostructure and modified component of carbon electrode with suitable SSA may be the way for realizing higher performance ZHSCs.

2.2.1.2 Heteroatom-Doped Carbon Electrode

Particularly, heteroatom doping is an efficient way to modify the physical and chemical properties of carbon electrodes [123,124,125]. By replacing part of C atoms with other elements like B, N and P, the strategy can not only optimize the synthesis process of heteroatom-doped carbon electrodes but also further improve the electrochemical performance of the as-prepared ZHSCs [126]. For one, heteroatom doping can improve the electrical conductivity, create more electrolyte accessible active sites and alleviate agglomeration of carbon electrodes [127]. For another, heteroatom doping can accelerate the permeation and diffusion character of electrolytes, thus further promote the wettability of carbon electrodes [128, 129].

Accordingly, Lu group reported that the N doping is expected to favor the chemical absorption of Zn-ions and tremendously altered the properties like conductivity, surface wettability, electrochemically active surface area as well as ion/electron transportation of original PCs [85]. The synthesis illustration of HNPC is shown in Fig. 5a. Particularly, the HNPC-based ZHSCs can offer an ultra-high capacity of 177.8 mAh g−1, which is almost three times higher than non-N-doped PC and higher than most carbon-based electrodes. Through the EIS tests shown in Fig. 5b, the fantastic promotion of N-doping strategy in decreasing charge transfer resistance and enhancing the diffusion rate was demonstrated compared with original PCs electrodes. Furthermore, the strategy of heteroatoms doping can even boost the stability of HNPC electrodes. As depicted in Fig. 5c, the HNPC-based ZHSCs maintained 99.7% capacity retention after 20,000 cycles while the PC-based ZHSCs displayed a lower capacity retention of 82.4%. Liu group also proposed an N-doped hierarchical porous carbon (N-HPC) which is derived from commercial chitosan via simultaneous carbonization and activation [130]. Gratifyingly, a remarkable energy density of 191 Wh kg−1 was achieved by N-HPC-based ZHSCs.

a Schematic illustration of the synthesis route of the HNPC. b Nyquist plots and c cycling performance at 16.7 A g−1 of the Zn//PC and Zn//HNPC ZHSCs. Reproduced with permission from Ref. [85]. Copyright 2019, Wiley–VCH. d Schematic of the preparation process of 3D graphene by hydrothermal reduction. Reproduced with permission from Ref. [131]. Copyright 2018, Royal Society of Chemistry. e Schematic illustration of the synthesis of rGO/CNT. Reproduced with permission from Ref. [120]. Copyright 2019, Wiley–VCH. f Schematic illustration of discharging process and g cycling performance of the Zn//aMEGO ZHSCs. Reproduced with permission from Ref. [82]. Copyright 2019, Wiley–VCH

Apart from N atoms, P dopant has been reported in the carbon electrodes of ZHSCs as well, which possesses a lower electronegativity of 2.19 than N atoms [127]. Chen et al. prepared P-doped honeycomb-like porous carbon (PHCA) electrodes by replacing the C atoms in carbon skeletons with P dopant [112]. Subsequently, the P dopants in carbon skeletons lead a chemical bonds transformation from C–OH (C–C–OH) to P–C–OH, which results in a stronger polarization of the hydroxyl group and lower energy barrier (from 0.13 to 0.04 eV). The stronger polarization of the hydroxyl group and lower energy barrier further enable a more attainable reaction during charging/discharging processes. Based on the PHCA electrodes, the Zn//PHCA ZHSCs presented a peak energy density of 129.3 Wh kg−1 at a power density of 1000 W kg−1.

Besides the single heteroatom-doping strategy, co-doping strategy will further promote excellent performances of carbon electrodes based on the synergistic effect of diverse heteroatoms. N, O co-doped hierarchical porous carbon (NO-HPC) was employed as the cathode in ZHSCs by Zhao group, where the ZIF-8 is applied as the template and C source [132]. Although the SSA of the carbon electrode is relatively low (197.45 m2 g−1), the Zn//NO-HPC ZHSCs exhibited splendid energy density of 110 Wh kg−1 and lossless capacity after 10,000 cycles. In addition, P, B co-doped AC (PB-AC) is reported by An et al. and the Zn//PB-AC ZHSCs delivered a high energy density of 169.4 Wh kg−1 and superb longevity of 30,000 cycles [133]. Furthermore, the second-highest energy density (472.6 Wh kg−1) of reported ZHSCs is based on the B, N co-doped BN-CMTs electrodes, which is even higher than most of ZIBs and LIBs [110]. However, the SSA of the BN-CMTs (101.24 m2 g−1) is much lower than most HSSA carbon electrodes mentioned above. It is believed that the B, N co-doping strategy facilitates the faradaic reactions of pseudocapacitance on the electrode surface by changing the electronic structure and density state of carbon, thus realizing prominent energy density even under a relatively low SSA. In short, heteroatom doping is an effective and promising strategy for enhancing the electrochemical performance of carbon electrodes. However, the deep working mechanisms of carbon electrodes heteroatom doping in ZHSCs are still in need. A better understanding of heteroatom doping in ZHSCs is highly significant, which leads to reasonable dopants and reproducible high performance of ZHSCs.

2.2.1.3 Graphene-Based Electrode

In addition to normal active carbon materials, graphene is the most common material used in symmetric supercapacitors [134]. As a novel 2D material with excellent properties such as decent intrinsic electric conductivity in-plane, high theoretical SSA of 2630 m2 g−1, outstanding mechanical strength and chemical stability, graphene and its derivatives have been widely applied in many ESSs [134,135,136]. The intrinsic capacitance of monolayer graphene can reach ~ 21 μF cm−2 according to its theoretical SSA [137]. Also, graphene-based materials are characterized by ultra-low RC constants of less than 200 μs, while the number is about 1 s for typical carbon materials [138]. Hence, it is generally believed that graphene-based materials is a promising candidate for high-performance ZHSCs.

As shown in Fig. 5d, Han et al. fabricated graphene-based electrodes for ZHSCs, where the reduced graphene oxide electrodes (G) are derived from the graphene oxide (GO) via hydrothermal reduction [131]. After further modified the G electrodes with polyaniline (PANI) by novel in-situ polymerization, the highest energy density (205 Wh kg−1) in graphene-based ZHSCs was achieved. However, the G electrodes without further polymerization showed a better cycling performance than G@PANI electrodes, indicating the trade-off between energy density and cycling stability. As a novel material, graphene was widely employed for the modification of other carbon electrodes in ZHSCs. For instance, Wang et al. and Xu et al. improved the cycling performance of ZHSCs by introducing graphene materials into the electrodes [139, 140]. As illustrated in Fig. 5e, Chen group demonstrated a flexible fiber-shaped reduced graphene oxide (rGO) on CNT substrate by capillary hydrothermal method [120]. Moreover, the rGO//CNT cathode was coupled with the electrodeposited Zn//graphene fiber anode to form ZHSCs. Benefiting from the both graphene-based electrodes, the flexible ZHSCs device delivered a splendid energy density of 48.5 mWh cm−3 and decent longevity of 10,000 cycles with merely 1.7% capacity decay.

Furthermore, the ultra-high stability of graphene-based electrodes in ZHSCs was confirmed by various investigations. For one, Wang et al. developed a porous 3D MXenes-rGO aerogel cathode for ZHSCs with an ultra-long cycling lifetime (95% capacity retention after 75,000 cycles) [139]. The introduced MXenes (Ti3C2Tx) in the composite electrodes can provide an additional pseudocapacitive reaction of Zn-ion insertion/desertion, resulting in an improvement of ZHSCs capacity. For another, Zhang group fabricated PC electrodes derived from chemical activated microwave exfoliated graphene oxide (aMEGO) via three-step process of microwave treatment, KOH activation and washing-drying-annealing [134]. As depicted in Fig. 5f, the structure of Zn//aMEGO ZHSCs is illustrated [82]. By applying 3.0 M Zn(CF3SO3)2 and Zn foil as the electrolyte and anode, respectively, the Zn//aMEGO ZHSCs are assembled and provided a battery-level energy density of 106.3 Wh kg−1 and a capacitor-level power density of 31,400 W kg−1. Furthermore, it can achieve incredible stability that remained 93% of initial capacity after 80,000 charging/discharging cycles at 8 A g−1 (Fig. 5g). These two cases are tested in different electrolytes where the former is 2.0 M ZnSO4 and the latter is 3.0 M Zn(CF3SO3)2. Hence, the general adaptability and stability of graphene-based materials in ZHSCs are prominent, and the graphene-based electrodes are proved to be a great choice for high-performance ZHSCs.

2.2.2 Pseudocapacitive Electrode

Although featured with HSSA, special morphologies and splendid electrical conductivity, the energy densities of most pure carbon electrodes are still far from practical applications due to the limited energy storage mechanism of EDLC based on simple physical adsorption/desorption processes. By contrast, pseudocapacitive materials with the co-existence of reversible faradic reactions and EDLC are promising candidates for large capacity of ZHSCs [141, 142]. As we mentioned above, the heteroatom-doped carbon material is a typical pseudocapacitive material for ZHSCs, and the pseudocapacitive mechanisms have been already discussed. Except the heteroatom-doped carbon materials, many carbon-based composite electrodes combined with carbon materials and pseudocapacitive materials can present noteworthy pseudocapacitance, however, have not been applied for ZHSCs [143]. As the important component of pseudocapacitive materials, we believed that more and more carbon-based pseudocapacitive materials with composite energy storage mechanisms will be investigated in the system of ZHSCs, and then lead to high-performance ZHSCs. In the following section, we are going to discuss some reported works of pseudocapacitive electrodes such as MXenes, polymer-carbon hybrid materials and TMCs (e.g., RuO2, TiN), and analyze the corresponding electrochemical performance of as-prepared ZHSCs.

2.2.2.1 MXenes

MXenes, the prominent family of 2D transition metal carbide and nitrides, are widely investigated and employed in many ESSs like LIBs and supercapacitors [26, 144,145,146,147]. It is generally demonstrated that the MXenes electrodes can be hosts for a range of cations such as Na+, K+, NH4+, Mg2+ and Zn2+ [148, 149]. Additionally, the ions penetrations only occur between the MXene sheets because the chemical bonds between M and X are unbreakable, thus occupying electrochemically active sites on the MXenes surfaces and realizing energy storage [150, 151]. Although the CV curves of MXenes electrodes are rectangular shapes without pronounced redox peaks, the energy storage mechanism of MXenes in acid is prominently proved to be pseudocapacitive [152]. As a promising candidate of pseudocapacitive cathode for ZHSCs, MXenes have attracted numerous attentions. Hence, some currently reported researches of MXenes on ZHSCs will be reviewed as follows.

Among the family of MXenes, the Ti3C2Tx is the most studied MXene for capacitors, which can achieve outstanding capacities of 300–400 F cm−3, surpassing most all-carbon-based super capacitors [148, 152]. Accordingly, Zhi group applied Ti3C2 electrode as the cathode of ZHSCs and further fabricated a flexible ZHSCs with the wholly degradable property [96]. The capacity of Zn@Ti3C2//Ti3C2 ZHSCs is enhanced to 330 F cm−3, which can be ascribed to the abundant pseudocapacitive reactions. Notably, the Zn-Ti3C2 ZHSCs can totally degrade within 7 days (Fig. 3c, d), which drastically exceeding the current supercapacitors of ~ 120 days and batteries of ~ 20 days. However, the decent degradable performance is realized at the cost of cycling longevity due to the relatively low thickness of Zn-Ti3C2. Therefore, the Zn@Ti3C2//Ti3C2 ZHSCs can only maintain capacity retention of 82.5% after 1000 cycles. To promote the longevity of Ti3C2-based ZHSCs, many efforts have been devoted. As we reviewed above, graphene-based ZHSCs showed superb cycling performance based on the extraordinary chemical stability. Therefore, Wang et al. prepared an MXenes-rGO electrode with the both excellent performance of MXenes and rGO [139]. The Zn//MXenes-rGO ZHSCs presented a prolonged cycling lifetime of 75,000 cycles and outstanding capacity retention of 95%. Furthermore, an in-situ annealing strategy is employed by Shen group to optimize the cycling performance of Ti3C2Tx-based ZHSCs [153]. Before the annealing, the Ti3C2Tx-based ZHSCs remained only ~ 54.7% of initial capacity after 5000 cycles. However, after annealed at 300 °C for 30 min (Ar atmosphere), the Ti3C2Tx electrodes presented ultra-long lifetime and outstanding stability (~ 80% after 50,000 cycles), which can be attributed to two reasons: (1) surface treatment of oxygen-containing functional group, (2) the generation of micropores in the Ti3C2Tx structure.

As shown in Fig. 6a, Sun group reported a novel synthesis process of Ti3C2Tx electrodes by 3DP technology [91]. The free-design property of 3DP technology enables more possibilities of Ti3C2Tx electrodes including structure, thickness, size, etc. Significantly, the Ti3C2Tx ink is the key part for 3DP technology, as depicted in Fig. 6b, the rheological behavior of Ti3C2Tx ink is altered via introducing the Zn-ion gelation. The electrostatic attraction between Zn2+ and negative charges on Ti3C2Tx further decrease the repulsion of adjacent Ti3C2Tx sheets. When assembled into the ZHSCs, the 3DP Ti3C2Tx-based ZHSCs provide a splendid capacity of 1006.4 mF cm−2 at 0.1 A g−1 and rate capability (remain 71% when the current density up to 10 A g−1). Moreover, laser writing was applied by Li et al. to prepare Ti3C2Tx electrodes, which is facile and matched with micro ZHSCs technology [153].

a Illustration of MXenes ink formulation and the 3DP process. b Schematic illustration of the Zn-ion gelation process targeting the preparation of MXenes ink. Reproduced with permission from Ref. [91]. Copyright 2021, American Chemical Society. c Comparison of self-discharge rate between the Zn//MXenes capacitor and previously reported anti-discharge supercapacitors. Reproduced with permission from Ref. [96]. Copyright 2019, American Chemical Society. d Preparation process of the PDA@PCC electrode. e Nyquist plots and f Raman spectra of CC, PCC and PDA@PCC electrodes. Reproduced with permission from Ref. [154]. Copyright 2020, American Chemical Society. g XPS spectra of poly(1,5-NAPD)/AC cathode, poly(1,5-NAPD) film on Pt, and AC coating. Reproduced with permission from Ref. [77]. Copyright 2020, Elsevier

Furthermore, it is well known that self-discharge behavior is common and fatal for supercapacitors [155]. Lu et al. investigated the self-discharge phenomenon of BN-LDC//Zn ZHSC devices, where the devices can retain a high voltage of 1.4 V after 24 h self-discharge compared to the initial voltage of 1.8 V, offering a fast self-discharge rate of 16.7 mV h−1 [83]. However, as shown in Fig. 6c, Zhi et al. prepared Zn@Ti3C2//Ti3C2 ZHSCs with lowest self-discharge rate of 6.4 mV h−1 (from 1.35 to 0.89 V after 72 h) among various supercapacitors which possess specific anti-self-discharge modification toward the electrode, electrolyte and separator [96, 156,157,158,159]. The key to this excellent behavior lies at the tight fixation between reduced Zn atoms and the anodic surface of MXenes electrodes under open-circuit state, thus, the Zn atoms will not transfer to cathodic area, leading to the remarkable anti-self-discharge property of MXenes. Although numerous advantages MXenes have shown, the operating voltage window of MXenes-based ZHSCs is quite narrow (0–1.4 V), which is limited for practical applications. Therefore, more efforts should be made to promote the higher operating voltage and better cycling performance of MXenes in the future.

2.2.2.2 Polymer-Carbon Hybrid Electrode

Redox-active conducting polymers are also decent pseudocapacitive materials featured with fast and reversible redox reactions, thus the conducting polymer-based supercapacitors are able to provide higher capacity than those EDLC-only Cap materials. However, conducting polymer electrodes also cannot satisfy the longevity demand of high-performance supercapacitors due to the poor stability, active material loss and over-oxidative degradation during charging/discharging processes [160]. Hence, lots of studies try to solve the problem with the polymer-carbon hybrid electrode, where the ultra-stable carbon materials act as the substrate and the conducting polymer materials act as the active mass loadings. The excellent synergetic effect enables the polymer-carbon hybrid materials to become suitable electrodes for ZHSCs.

Gratifyingly, many high-performance ZHSCs based on polymer-carbon hybrid electrodes have been reported recently, including different carbon substrates like CC, AC and rGO [77, 140, 154]. Han et al. employed PANI and rGO as the component of polymer-carbon hybrid electrodes and applied aniline solution on the surface of graphene hydrogel for the in-situ polymerization method [131]. Surprisingly, the PANI@rGO-based ZHSCs presented a capacity of 154 mAh g−1, which is five times higher than individual rGO electrodes. However, the PANI@rGO-based ZHSCs displayed an inferior capacity retention of 80.5% after 6000 charging/discharging cycles. Similarly, Hu group modified the rGO materials with another conducting polymer of p-phenylenediamine (PPD), where the PPD is inserted into the interlayer of rGO, resulting in bigger interlayer spacing and thus expose more ion accessible sites [140]. The PPD@rGO hybrid electrode is fabricated by facial thermal evaporation and hydrothermal process. As a result, PPD@rGO-based ZHSCs presented an incredible capacity of 3012.5 mF cm−2 at a current density of 1 mA cm−2, which is 11.2 times higher than the rGO-based ZHSCs provided. The excellent cycling performance of 100% capacity retention after 4000 cycles was realized by PPD@rGO-based ZHSCs as well. Furthermore, Liu et al. prepared a poly(1,5-naphthalenediamine, NAPD)/AC hybrid electrode via a direct electrodepositing process [77]. Interestingly, the helix-shaped poly(1,5-NAPD) chains tend to be bundled up during the depositing process and ended as salient nanorods. By modifying the morphology of normal AC electrodes, ions can be efficiently inserted/extracted from the molecular chains, and consequently, the poly(1,5-NAPD)/AC-based ZHSCs presented a remarkable energy density of 195 Wh kg−1 and 91% capacity retention after 10,000 cycles. Hence, there is no doubt that the polymer-carbon hybrid electrode can tremendously improve the capacity of carbon materials and relatively stabilize the unstable structure of conducting polymer.

To further investigate the inner mechanism of polymer–carbon hybrid electrode, Huang et al. reported a polydopamine-coated porous carbon cloth (PDA@PCC) electrode and the preparation process of PDA@PCC electrode is illustrated in Fig. 6d [154]. Figure 6e presents the Nyquist plots of three different electrodes of CC, PCC and PDA@PCC electrodes. Typically, PDA@PCC and PCC showed a shorter tail than CC, which represented a better ion diffusion ability based on the hydrophilic property and pore structures. However, due to the defects of PDA polymerization, PDA@PCC exhibited a relatively larger semicircle in the high-frequency region. The Raman spectra of diverse electrodes are studied in Fig. 6f, the intensity ratio (ID/IG) of D band and G band generally indicates the disorder degree of carbon-based materials. The PDA@PCC hybrid electrodes possess the lowest ratio of 0.93, which is beneficial for achieving stable electrochemical performance. It is believed that the introduction of PDA can greatly restore the disorder degree from 1.20 to 0.93 and retain the porosity of PCC during the synthesis processes of PDA@PCC. Hence, with the lowest disorder degree, PDA@PCC-based ZHSCs delivered a great capacity retention of 100% after 10,000 cycles. Moreover, Fig. 6g shows the XPS spectra of poly(1,5-NAPD)/AC, poly(1,5-NAPD)/Pt and bare AC samples. It can be proved that the synergetic effect of polymer–carbon hybrid electrode is not simple superposition but proportional integration according to the N 1 s spectra of each electrode. Simultaneously, the weak S and F signals were reported as the binder between the poly(1,5-NAPD) and AC during the electrodepositing process.

2.2.2.3 Transition Metal Compounds (TMCs)

TMCs electrode materials such as transition metal oxides (TMOs), nitrides (TMNs), hydroxides and sulfides have been widely investigated in the metal-ion batteries and capacitors on account of their outstanding characteristics like multiple metal valences, high theoretical capacitance, abundant natural source and diversiform synthetic methods [161, 162]. Hydrous RuO2·H2O, as the first demonstrated pseudocapacitive materials, have been used as the advanced Cap electrode materials in many ESSs [163, 164]. As a result, Dong et al. employed amorphous RuO2·H2O as the cathodes of Zn//Cap ZHSCs based on a fast and safe Zn-ion pseudocapacitive storage mechanism [165]. The electrochemical performance of anhydrous RuO2 and hydrous RuO2·H2O were compared in the system of ZHSCs. Although the anhydrous RuO2 possess higher electrical conductivity than hydrous RuO2·H2O, the bound H2O in RuO2 can facilitate the ions diffusion and thus lead to a better capacity than anhydrous RuO2. According to Dunn’s method, 79.0–96.4% capacitance of RuO2·H2O cathodes originates from the surface-controlled capacitive process. The capacitance is ascribed to the co-existence of EDLC and redox pseudocapacitance, and the majority part of the capacitance is devoted by the pseudocapacitance since the SSA of RuO2·H2O electrodes is only 57 m2 g−1. Benefiting from the high conductivity (> 100 S cm−1) and abundant surface redox reactions of hydrous RuO2·H2O, the assembled Zn//RuO2·H2O ZHSCs enabled ultra-fast Zn-ion storage speed and presented splendid energy density of 119 Wh kg−1 with a voltage window of 0.4–1.6 V. Particularly, it still kept a high energy density of 82 Wh kg−1 under an ultra-high power output of 16,740 W kg−1. It is amazing to reach such balanced electrochemical performance while the reported LIBs and ZIBs can only deliver a power density of 1–10 kW kg−1. Moreover, the rate performance of the Zn//RuO2·H2O ZHSCs is superior than many TMCs and the ZHSCs also presented an outstanding capacity retention of 87.5% after 10,000 cycles at a current density of 20 A g−1.

Titanium nitride (TiN) with superb electrical conductivity (27 μΩ cm−1) and chemical/electrochemical stability have also been considered as a promising pseudocapacitive electrode material for energy storage [166,167,168]. Zhi group employed the TiN electrode as the cathode materials for Zn//Cap ZHSCs, and coupled with Zn metal anode to form Zn//TiN ZHSCs [169]. Although TiN is a pseudocapacitive material, no evident redox peaks of TiN electrodes are detected in the CV curves during charging/discharging process, indicating the predominant Cap behaviors of the TiN cathode materials in the system of ZHSCs. Owing to the excellent conductivity and splendid stability of TiN, the Zn//TiN ZHSCs delivered an ultra-high capacity of 489.8 F g−1 at 0.2 A g−1 in the ZnSO4 electrolyte. In addition, the self-discharge rate of TiN-based ZHSCs is extremely low due to the high stability of TiN-SO4 structure after adsorption process, which remained 83.9% of initial capacity after 500 h resting time.

Herein, it is believed that the TMCs materials with diverse properties and Zn-ion storage mechanisms are competitive pseudocapacitive electrodes for high-performance ZHSCs. However, we need to draw a distinction between the pseudocapacitive TMCs and the battery-type TMCs like manganese oxides and vanadium oxides, as well as other reported ZBC. Compared with the Cap TMCs electrodes, the redox process of battery-type TMCs is responsible for the phase transition of electrode materials [142]. Additionally, the potential of the battery-type electrodes will remain approximately constant, presenting a distinct charging/discharging platform in the GCD curves, which agrees with the phase rule and follows the Nernst equation. Correspondingly, a couple of well-defined redox peaks can be detected in the CV curves. Hence, the pseudocapacitive TMCs electrodes performed as the Cap cathode in the Zn//Cap ZHSCs while the battery-type TMOs acted as the ZBC in the Cap//ZBC ZHSCs.

In summary, Cap electrode materials including HSSA carbon electrodes, heteroatom-doped carbon electrodes, graphene-based electrodes and pseudocapacitive electrodes (MXenes, polymer-carbon hybrid electrodes and TMCs) are the most investigated materials among all candidate electrodes for ZHSCs. HSSA carbon electrodes can provide sufficient EDLC and power density for ZHSCs, however, the EDLC is not enough to offer balanced energy density which should match with battery-type electrodes in ZHSCs. Graphene-based electrodes possess excellent properties of ultra-high intrinsic capacitance (~ 21 μF cm−2), high theoretical SSA of 2630 m2 g−1, ultra-low RC constants (< 200 μs) and high chemical stability. Therefore, graphene-based ZHSCs present better longevity than other ZHSCs. Heteroatom-doped carbon electrodes and polymer–carbon hybrid electrodes are both based on the fundamental carbon electrodes, equipping the carbon electrodes with abundant chemical pseudocapacitive reactions, which can effectively enhance the energy density of normal carbon electrodes. As for polymer–carbon hybrid electrodes, although the energy density of carbon electrodes is promoted, the conducting polymer materials show poor cycling performance on account of the poor stability, active material loss and over-oxidative degradation. MXenes show balanced electrochemical performance but suffer from the low operating voltage window and short longevity. Notably, owing to the superb electrical conductivity and considerable pseudocapacitance, TMC-based ZHSCs achieve large capacity and fast charging/discharging rate. Therefore, among these reported Cap electrodes, graphene-based electrodes, heteroatom-doped carbon electrodes and TMCs electrodes are considered as the most promising Cap electrodes for the practical application of ZHSCs, and it is believed that more and more excellent Cap electrodes can be discovered as the fast development of ZHSCs. When designing an appropriate Cap electrode for ZHSCs with perfect performance, it is significant to keep the balance between power density, energy density and stability, which can be further attributed to the balance between EDLC and chemical pseudocapacitive reactions.

As overviewed above and summarized in Table 1, the Zn//Cap ZHSCs with different kinds of electrode materials have been expatiated and further concluded. More importantly, the intricate and unique storage mechanisms of Cap electrodes are carefully summarized as several parts, where the adsorption/desorption processes based on the EDLC are always effective while the redox reaction or insertion/desertion processes may exist depending on the diverse strategy of Cap cathodes. Based on the well-designed Zn anodes and various kinds of Cap electrodes, reported Zn//Cap ZHSCs showed ultra-long cycling lifetime and excellent integration of high energy density and power density. The Zn//Cap ZHSCs can reach the approximate energy density of LIBs but higher power density, making the ZHCSs a full-scale ESS for wild applications such as wearable electronics, electric vehicles, large-scale facilities and so on. On account of the splendid rate property, ZHSCs can easily change service conditions as the practical current density demands change. However, the voltage window of Zn//Cap ZHSCs is still too low (lower than 1.8 V) to fulfill the demand of the practical applications. On the contrary, the Cap//ZBC ZHSCs can readily reach 2.0 V in the normal ZnSO4 electrolyte. By far, the reports about Cap//ZBC ZHSCs are few, thus, it is highly recommended to make some explorations on the substantial foundation of various ZBC which have been widely applied in the system of ZIBs.

2.3 Cap//ZBC ZHSCs

Generally, the ZHSCs are constructed by the integration of ZIBs and supercapacitors, where the Cap electrodes are typically carbon and pseudocapacitive electrodes as we reviewed in Sect. 2.2, the battery-type electrodes are ZBC and Zn anodes in the ZIB systems. Before this section, we amply discussed the Zn//Cap ZHSCs, which comprise Zn anodes and Cap cathodes. Conversely, the design theory of Cap//ZBC ZHSCs is to replace the Zn anode in ZIBs with Cap electrodes. Hence, different from the Zn//Cap ZHSCs, the Cap electrodes will act as the anode and Zn-ion battery-type materials will act as the cathode in the Cap//ZBC ZHSCs. Notably, many potential ZBC of ZHSCs have been reported in the ZIBs, such as manganese-based oxide, vanadium-based oxides, prussian blue and analogues, spinels, etc.

As illustrated in Fig. 7, the Cap anodes, ZBC, energy storage mechanism and CV behavior of Cap//ZBC ZHSCs are exhibited. Same as the Zn//Cap ZHSCs, the electrolytes are Zn salt solutions. Basically, Cap electrodes perform the same energy storage mechanism in the Zn//Cap ZHSCs, but act as anode opposed to the ZBC. The CV curve of ACC anodes in Fig. 7 presented a typical rectangular shape of Cap anodes. On the contrary, the CV plot of ZnxMnO2 cathodes showed two obvious redox peaks at approximately 0.33 V/0.88 V (vs. SCE), corresponding to the insertion/desertion reaction processes of ZBC. The Zn-ion insertions happen during the discharging processes of ZHSCs, while the Zn-ion desertions occur during the charging periods. Gratifyingly, many ZBC can reversibly proceed insertion/extraction reactions of Zn-ions, which have been widely confirmed in ZIBs, including manganese oxides (MnO2 with a different crystalline structure, Mn2O3, etc.) [87, 173], vanadium oxides (V2O5, V2O7, V3O8, and homologous derivatives, etc.) [174,175,176,177], prussian blue and analogues [8, 178,179,180] and spinels (ZnMn2O4, etc.) [181,182,183,184]. Although the ionic radius of Zn-ion is small (0.75 Å), the hydrated ionic radius of Zn-ion (3.40—3.82 Å) raises strong demand for suitable insertion cathode materials of ZHSCs [87]. Some special crystal structures like layered structure (δ-MnO2, V-based materials, etc.), tunnel structure (α-MnO2, γ-MnO2, etc.) and framework (prussian blue and analogues, spinels, etc.) can effectively store Zn-ion via reversible insertion/desertion processes. A large and stable crystal structure can store a great number of Zn-ion and then provide considerable capacity by reversible chemical redox reactions between Zn-ion and cathode materials.

When the ZHSCs are assembled based on Cap anodes and ZBC, the Cap//ZBC ZHSCs can provide a higher voltage window of 0–2.0 V and more possibilities like Zn-dendrite-free ZHSCs. However, only a few ZBC (e.g., manganese-based oxides and vanadium-based oxides) have been applied in this configuration of ZHSCs and many problems still exist. Here, we will summarize some reported studies of Cap//ZBC ZHSCs in the following review, trying to draw more attention to the ZBC and the second electrode configuration of Cap//ZBC ZHSCs.

2.3.1 Manganese-Based Oxides

Manganese oxides, with many outstanding properties like low cost, high theoretical capacity, tunable and multifarious crystal structure, etc., have been well investigated in various ESSs [185,186,187]. Among various manganese oxides, MnO2 is one of the most promising manganese oxides. By linking the fundamental units MnO6 octahedra with shared edges and vertices, tunnel-type α-MnO2, β-MnO2, δ-MnO2, ε-MnO2 and layered γ-MnO2 are obtained [87]. Generally, many MnO2 cathodes with diverse crystal structures have been employed in ZIBs while only a few were reported in ZHSCs.

As the pioneer of the Cap//ZBC ZHSCs, Kang group reported the AC//γ-MnO2 ZHSCs with a wide voltage window of 0–2.0 V, the as-assembled ZHSCs showed a capacity of 54.1 mAh g−1 in 2.0 M ZnSO4 electrolyte while exhibited a capacity of 83.8 mAh g−1 in the 2.0 M ZnSO4 and 0.5 M MnSO4 electrolyte [188]. The XRD pattern and tunnel crystal structure of γ-MnO2 cathode are displayed in Fig. 8a, the insertion/desertion processes of Zn-ion occur in the tunnel structure of γ-MnO2 cathodes. However, due to the solubility and poor electrical conductivity of Mn-based materials, the AC//γ-MnO2 ZHSCs can merely keep 65.3% of initial capacity after 3000 cycles without the MnSO4 additive electrolyte. When changing the electrolyte from ZnSO4 to Zn(CF3SO3)2, the cycling performance of AC//γ-MnO2 ZHSCs can be tremendously improved to 93.4% after longer 5000 cycles. Generally, the CF3SO3− anion results in lower charge transfer resistance and higher ion diffusion rate than SO42− anion. Furthermore, the by-products are not visibly detected in the Zn(CF3SO3)2 electrolyte due to the reduced interaction between Zn-ions and adjacent water molecules [82]. When compared with the Zn//γ-MnO2 ZIBs (Fig. 8b), the AC//γ-MnO2 ZHSCs presented a higher power density of 13,000 W kg−1 and the poor rate performance of γ-MnO2-based ZIBs is greatly enhanced in the fast ZHSCs. Although the capacity of AC//γ-MnO2 ZHSCs is still unsatisfactory, the strengths of Cap//ZBC ZHSCs like larger voltage window, high power density, excellent rate performance and unique energy storage mechanisms are presented.

a XRD pattern and crystal structure (inset) of γ-MnO2 cathodes. b Ragone plots of various γ-MnO2-based ESSs. Reproduced with permission from Ref. [188]. Copyright 2019, Elsevier. c Schematic illustration of the Zn-ion storage mechanisms in the tunnel-structure ZnxMnO2 cathode. Reproduced with permission from Ref. [34]. Copyright 2020, Wiley–VCH. d Full cell schematic of AC//2.0 M ZnSO4//V2O5 ZHSCs. e CV curves tested by three-electrode system of V2O5. f Nyquist plots of relevant devices, including ZHSC, ZIB and supercapacitor. Reproduced with permission from Ref. [189]. Copyright 2019, Springer Nature

In addition, Mai group recently investigated the application of tunnel-type α-MnO2 (ZnxMnO2) and layered δ-MnO2 cathodes in ZHSCs, the active carbon cloth (ACC)//ZnxMnO2 and ACC//δ-MnO2 ZHSCs are prepared and tested [34]. As depicted in Fig. 8c, some pre-intercalation Zn-ions are stored in the tunnel structure of ZnxMnO2 cathode before electrochemical tests. Additionally, the Zn-ions are extracted from the tunnel structure when the ZHSCs are charging and conversely, inserted into the tunnel structure during discharging periods. The capacity of MnO2 cathodes may fluctuate a lot at first few cycles since a great number of Zn-ions are left in the tunnel structure, which leads to the unbalanced Zn-ion insertion/desertion reactions. However, depend on the pre-intercalation Zn-ion in the tunnel structure, the ZnxMnO2 cathode is stabilized in advance and then performed steady cycling performance. Compared with the tunnel structure of γ-MnO2 (1 × 1 and 1 × 2 tunnel structure: 2.3 × 2.3 Å and 2.3 × 4.6 Å), the α-MnO2 (2 × 2 tunnel structure: 4.6 × 4.6 Å) possess a larger and more suitable tunnel structure for Zn-ions storage due to the close hydrated ionic radii of Zn-ions (4.3 Å). Accordingly, the ACC//ZnxMnO2 ZHSCs remained 83.1% of initial capacity after 5000 cycles, and the ex-situ XRD spectra of ZnxMnO2 cathode presented no evident excursion during the charging/discharging processes. Layered δ-MnO2 is also a promising Zn-ion storage cathode with an ultra-large interlayer spacing of ~ 7 Å. Nevertheless, the structure of δ-MnO2 is prone to collapse in sulfate solution during the insertion/desertion processes of Zn-ions, thus, the capacity retention of ACC//δ-MnO2 ZHSCs quickly fade to 83.2% after 10 cycles and then drop to 70.4% after 35 cycles, finally end at 45.3% after 5000 cycles. Hence, it is believed that the Zn-ion pre-intercalation can be a way to promote the stability of manganese-based cathodes. The ACC//ZnxMnO2 ZHSCs delivered an ultra-high and stable areal capacity of 1745.8 mF cm−2 at 2 mA cm−2. Meanwhile, ACC//ZnxMnO2 ZHSCs performed a wide operating voltage window of 0–2.0 V and excellent areal power density of 20.1 mW cm−2, which is vital for many flexible and wearable electronic devices.

Notably, a novel ZHSC of Ti3C2Tx//MnO2-CNTs was proposed by Wang et al., the pseudocapacitive MXene materials act as the Cap anode and the battery-type MnO2-CNTs act as the cathode [190]. The electrode properties were demonstrated by the three-electrode system, where the MnO2-CNTs presented typical charge/discharge platforms in the GCD curves and a couple of redox peaks were detected in the CV curves. On the contrary, the Ti3C2Tx anode showed distinct Cap behaviors with straight up and down GCD curves. These results confirmed that the Zn-ion storage mechanism of ZBC is pretty different from the pseudocapacitive electrode. The pseudocapacitive TMCs should not be confused with TMCs ZBC. Benefit from the balanced electrode configuration of Cap//ZBC ZHSCs and excellent electrochemical performance of MnO2, the Ti3C2Tx//MnO2-CNTs ZHSCs exhibited splendid capacity of 115.1 F g−1 as well as remarkable longevity of 83.6% capacity retention after 15,000 cycles, which is the best cycling performance in the system of Cap//ZBC ZHSCs.

For many manganese-based oxide cathodes, the crystal transformations will occur during the insertion/desertion processes of different cations or water molecules, and different structures of manganese-based oxide cathodes may lead to different Zn-ion storage performance in ZHSCs. By far, the α-MnO2 exhibited a prominent electrochemical performance as well as stable tunnel structure among various manganese-based oxide cathodes. Although numerous advantages the manganese-based oxide cathodes have shown, the poor rate capability, easy-dissolution in electrolyte and relatively unstable structure are still challenges in the application of Cap//manganese oxide ZHSCs. Hence, more efforts should be devoted to investigating suitable manganese oxide cathodes for high-performance ZHSCs and create more possibility for Cap//ZBC ZHSCs.

2.3.2 Vanadium-Based Oxides

Apart from the manganese-based oxides, vanadium-based oxides are another widely applied ZBC for ZHSCs. With high theoretical capacity, low cost and stable layer crystal structure, vanadium-based oxide cathodes are suitable for multivalent ions storage [191, 192]. However, by far, only one research has been reported about the ZHSCs based on the vanadium-based oxide cathodes [189]. Therefore, in this section, the rare vanadium-based ZHSC will be discussed in detail.

As illustrated in Fig. 8d, Ma et al. employed V2O5 materials as the cathode of ZHSCs and assembled the AC//V2O5 ZHSCs where the V2O5 materials and AC powder act as the cathode and anode, respectively [189]. Typically, V2O5 cathodes tend to proceed an activated process before longtime charging/discharging according to the CV curves shown in Fig. 8e, where the redox peaks of V2O5 cathode sharply changed at the first three cycles. It is believed that the incipient charging/discharging process of V2O5 cathode leads to structural transformations, and the V2O5 cathodes turn out to be stable after activation. The possible electrochemical reaction is as the following Eq. (2-2):

Similarly, the AC//V2O5 ZHSCs can also achieve a wide voltage window of 0–2.0 V, which is unreachable for vanadium-based ZIBs (most < 1.4 V). Furthermore, based on the EIS results of various ESSs (Fig. 8f), the AC//V2O5 ZHSCs showed the smaller charge transfer resistance and higher ion diffusion rate than Zn//V2O5 ZIBs and normal AC//AC supercapacitors. Thus, ZHSCs present superiority in comparison with ZIBs and supercapacitors. However, the AC//V2O5 ZHSCs only provided a limited capacity of 57.4 mAh g−1 and an energy density of 34.6 Wh kg−1. Also, the ZHSCs cannot maintain appropriate coulombic efficiency at an ultra-low current density of 0.1 A g−1, which can be attributed to the polarization of V2O5 at 1.8–2.0 V. Gratifyingly, the cycling stability test of AC//V2O5 ZHSCs is quite surprised, which presented a capacity retention of 97.3% after 6000 cycles at relatively low cycling current density of 0.5 A g−1, indicating that the V2O5 cathodes possess a suitable and stable structure for ZHSCs. As we all know, the excellent performance of Cap//ZBC ZHSCs is generally determined by the ZBC used. However, only one work about vanadium-based cathode of ZHSCs has been reported, moreover, the Zn-ions storage mechanism of vanadium-based ZHSCs is still ambiguous and the capacity of vanadium-based ZHSCs is unsatisfied. Therefore, more efforts should be devoted to promoting the development of vanadium-based oxide cathodes for high-performance ZHSCs.

As summarized in Table 2, the Cap//ZBC ZHSCs presented prominent characteristics like high voltage window, abundant electrode collocations and special properties depend on various ZBC. More significantly, the Zn-foil-free ZHSCs can avoid the potential safety hazard of Zn dendrite, leading to a Zn-dendrite-free ZHSC. Although the electrochemical performance of Cap//ZBC ZHSCs is not enough for practical applications, we believe that after sufficient investigations and creations, the Cap//ZBC ZHSCs will perform splendid electrochemical performance which may even superior to the Zn//Cap ZHSCs. To sum up, the Cap//ZBC ZHSCs still have many difficulties that need to conquer, here we summarize as the following aspects: (1) relatively low energy density, (2) inferior rate performance and (3) weak cycling stability, particularly the MnO2 cathodes which are easy to dissolve. Nevertheless, the in-depth understandings of energy storage mechanisms of various ZBC are plenarily needed, where the mechanisms and extent of reactions may differ from the conditions in ZIBs. The design theory of ZBC for high-performance ZHSCs should be high porosity, HSSA, stable crystal structure (Zn2+-adapted) and excellent electrical conductivity. By designing ZBC in a way of the Cap electrode may greatly enhance the rate performance and cycling performance of the Cap//ZBC ZHSCs. Momentously, it is strongly believed that with more attempts and investigations, the electrochemical performance of Cap//ZBC ZHSCs will be enhanced and then become a promising candidate for next-generation ESSs.

3 Energy Storage Mechanisms of Cap Electrodes

Importantly, Cap electrodes perform a vital role in both two configurations of ZHSCs, however, the energy storage mechanisms of Cap electrodes are pretty intricate according to the reported ZHSCs [31, 188, 193]. Besides the simple EDLC of the physical adsorption/desorption processes of cations and anions, more results are proved to confirm extra energy storage mechanisms of Cap electrodes, including precipitation/dissolution and chemical pseudocapacitive reactions. Hence, the related investigations of Cap electrodes will be concluded in the following section [31, 85, 188]. As the fundamental energy storage mechanism, the physical adsorption/desorption processes are presented as following Eqs. (3-1, 3-2), where the X− represents the monovalent anion (Cl−, NO3−, CF3SO3− and CH3COO−), the Y2− represents the divalent anion (SO42−) [132]:

3.1 Precipitation/Dissolution of By-Products

Typically, the precipitation/dissolution processes of by-products like Zn4SO4(OH)6·nH2O have been found in the system of ZIBs, especially in the Mn-based and V-based ZIBs [87]. The by-products with loose and porous layers will randomly form on the surface of bare Zn foil during charging/discharging processes, which leads to the uneven surface and Zn dendrite, then the poor cycling performance of ZIBs [194, 195]. Therefore, the investigation of formation mechanisms of the by-products in ZHSCs is more necessary since the Zn anode of ZHSCs can be greatly consumed by the fast charging/discharging processes. Furthermore, the formation of by-products also happened on the Cap electrodes of ZHSCs, thus, the dual formation of by-products may affect the capacity and cycling performance of ZHSCs during charging/discharging processes.

In the ZHSCs systems, Kang group demonstrated the existence of by-products of Zn4SO4(OH)6·5H2O on both AC cathode and Zn anode in ZnSO4 electrolyte after discharging processes (from 1.8 to 0.2 V) [31]. Notably, part of by-products is left on the surface of AC cathode after 10 cycles, indicating the irreversible reactions of precipitation/dissolution. Furthermore, the formation of by-products is also detected in other ZHSCs and even in the Cap//ZBC ZHSCs. Particularly, Mai group reported that the by-products of Zn4SO4(OH)6·nH2O and ZnSO3·2.5(H2O) were also observed on the surface of ACC in ACC//ZnxMnO2 ZHSCs [34]. The ex-situ XRD spectra based on ACC//ZnxMnO2 ZHSCs (Fig. 9a, b) clearly displayed XRD peaks of Zn4SO4(OH)6·nH2O and ZnSO3·2.5(H2O) at state VI and XIII, which correspond to the voltage of 2.0 V. The by-products gradually precipitate during the charging process and dissolve during discharging period. Typically, this process was further demonstrated by the ex-situ SEM images shown in Fig. 9c. Also, the by-product of Zn4SO4(OH)6·0.5H2O is detected by Kang group on the surface of ZBC (γ-MnO2) [196]. On the contrary, the precipitation/dissolution processes are inverse since the Cap electrodes are applied as the cathode in the Zn//Cap ZHSCs, which was proved by the ex-situ XPS spectra of carbon cathode depicted in Fig. 9d [77]. The Zn, O, S signals, which correspond to the formation of by-product Zn4SO4(OH)6·nH2O, are enhanced by degrees during discharging process while the signals decreased during the charging process. Additionally, apart from the Cap electrodes, Zn4SO4(OH)6·5H2O can also be detected on the surface of Zn anodes [31, 82]. Typically, the reaction equation of by-products can be described as following Eqs. (3-3, 3-4) [34, 188]: