Abstract

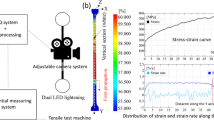

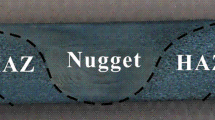

The comprehensive determination of mechanical properties of heterogeneous objects such as welding joint remains challenging in various scientific fields. This paper develops a Local-micro-zone-wise Time-resolved Integrated Digital Image Correlation (LTIDIC) method, which can self-divide different regions of the material and get the multiple elastic–plastic parameters of each region through parameter inversion simultaneously, including elastic modulus, yield strength, hardening coefficient, and hardening exponent. First, the principle and process of the LTIDIC method are demonstrated, and the method of automatically dividing regions is introduced. Then, the reliability of the LTIDIC is analyzed and optimized, based on evaluating the influence of the correlation criteria, the area size, the noise type, and the number of pictures on the results of parameter inversion. Finally, a uniaxial tensile test was performed on the friction stir welding joint of aluminum alloy 6061T6 thin plate sample, and the distribution of multiple mechanical parameters was measured by the LTIDIC method. The results show that the modulus in the weld zone ranges between 30 and 70 GPa, with the lowest modulus in the thermo-mechanical affected zone and the highest modulus in the heat affected zone. The yield strength in the weld zone ranged from 75–115 MPa. The elastic modulus distribution shows an asymmetric W-shape, and the plastic parameters generally show a decreasing trend from the weld nugget to both sides. The feasibility and accuracy of the LTIDIC method were verified by comparing the consistency with the localized DIC method. The proposed method can obtain multiple elastic–plastic parameter distributions in different areas of material simultaneously through a single tensile experiment and provide important experimental data for the evaluation of mechanical properties of heterogeneous materials similar to welding joints.

Highlights

1. The developed LTIDIC method can obtain multiple elastic–plastic parameter distributions including elastic modulus, yield strength, hardening coefficient, and hardening exponent simultaneously through a single tensile experiment.

2. Automatically identify areas of heterogeneous materials with different mechanical properties.

3. The parameter inversion error is less than 1% by analyzing the factors that affect parameter identification. It can effectively reduce the influence of random noise on the inversion and improve the accuracy of the results.

Similar content being viewed by others

References

Mahoney MW, Rhodes CG, Flintoff JG, Bingel WH, Spurling RA (1998) Properties of friction-stir-welded 7075 T651 aluminum. Metall and Mater Trans A 29(7):1955–1964. https://doi.org/10.1007/s11661-998-0021-5

Fu RD, Zhang JF, Li YJ, Kang J, Liu HJ, Zhang FC (2013) Effect of welding heat input and post-welding natural aging on hardness of stir zone for friction stir-welded 2024–T3 aluminum alloy thin-sheet. Mater Sci Eng, A 559:319–324. https://doi.org/10.1016/j.msea.2012.08.105

Jones EM, Quintana EC, Reu PL, Wagner JL (2020) X-ray stereo digital image correlation. Exp Tech 44(2):159–174. https://doi.org/10.1007/s40799-019-00339-7

Pan R, Zhang G, Li S, Zheng X, Xu C, Fan Z (2021) Influence of the fracture process zone on fracture propagation mode in layered rocks. J Petrol Sci Eng 202:108524. https://doi.org/10.1016/j.petrol.2021.108524

Zappa E, Hasheminejad N (2017) Digital image correlation technique in dynamic applications on deformable targets. Exp Tech 41(4):377–387. https://doi.org/10.1007/s40799-017-0184-3

Zhang K, Qi F, Bao R, Xie J (2021) Physical reconstruction and mechanical behavior of fractured rock masses. Bull Eng Geol Env 80(6):4441–4457. https://doi.org/10.1007/s10064-021-02206-5

Boufaida Z, Boisse J, André S, Farge L (2017) Mesoscopic strain field analysis in a woven composite using a spectral solver and 3D-DIC measurements. Compos Struct 160:604–612. https://doi.org/10.1016/j.compstruct.2016.10.030

Peng Y, Wu C, Gan J, Dong J (2018) Determination of the local constitutive properties of the welded steel joints using digital image correlation method. Constr Build Mater 171:485–492. https://doi.org/10.1016/j.conbuildmat.2018.03.182

Ramachandran S, Lakshminarayanan AK, Reed PAS, Dulieu-Barton JM (2019) Development of high-fidelity imaging procedures to establish the local material behavior in friction stir welded stainless steel joints. Metals 9(5):592. https://doi.org/10.3390/met9050592

Mani C, Balasubramani S, Karthikeyan R, Kannan S (2021) Digital Image Correlation of Tensile Properties for Monel 400/SS 316L Dissimilar Metal Welding Joints. Materials 14(6):1560. https://doi.org/10.3390/ma14061560

Bai R, Wei Y, Lei Z, Jiang H, Tao W, Yan C, Li X (2018) Local zone-wise elastic-plastic constitutive parameters of Laser-welded aluminium alloy 6061 using digital image correlation. Opt Lasers Eng 101:28–34. https://doi.org/10.1016/j.optlaseng.2017.09.023

Li G, Xu F, Sun G, Li Q (2014) Identification of mechanical properties of the weld line by combining 3D digital image correlation with inverse modeling procedure. Int J Adv Manufac Technol 74(5–8):893–905. https://doi.org/10.1007/s00170-014-6034-x

Pan B, Xie H, Guo Z, Hua T (2007) Full-field strain measurement using a two-dimensional Savitzky-Golay digital differentiator in digital image correlation. Opt Eng 46(3):033601. https://doi.org/10.1117/1.2714926

Gu J, Zhu F, Bai P, Lei D (2021) An optimized design for a field-of-view splitting-based long-gauge-length optical extensometer using two rhombic prisms. Meas Sci Technol 32(5):054001. https://doi.org/10.1088/1361-6501/abdf9f

Pan B, Tian L (2016) Advanced video extensometer for non-contact, real-time, high-accuracy strain measurement. Opt Express 24(17):19082–19093. https://doi.org/10.1364/OE.24.019082

Neggers J, Hoefnagels JP, Geers MGD, Hild F, Roux S (2015) Time-resolved integrated digital image correlation. Int J Numer Meth Eng 103(3):157–182. https://doi.org/10.1002/nme.4882

Piao M, Huh H, Lee I, Park L (2017) Characterization of hardening behaviors of 4130 Steel, OFHC Copper, Ti6Al4V alloy considering ultra-high strain rates and high temperatures. Int J Mech Sci 131:1117–1129. https://doi.org/10.1016/j.ijmecsci.2017.08.013

Jiang H, Lei Z, Bai R, Liu J, Guo Z, Dong H, Feng W (2021) Virtual Field Characterization for Ratcheting Effect Under Cyclic Loading. Exp Mech 1-17.https://doi.org/10.1007/s11340-021-00709-6

Pan B, Xie H, Wang Z (2010) Equivalence of digital image correlation criteria for pattern matching. Appl Opt 49(28):5501–5509. https://doi.org/10.1364/AO.49.005501

Park J, Yoon S, Kwon TH, Park K (2017) Assessment of speckle-pattern quality in digital image correlation based on gray intensity and speckle morphology. Opt Lasers Eng 91:62–72. https://doi.org/10.1016/j.optlaseng.2016.11.001

Lava P, Cooreman S, Debruyne D (2010) Study of systematic errors in strain fields obtained via DIC using heterogeneous deformation generated by plastic FEA. Opt Lasers Eng 48(4):457–468. https://doi.org/10.1016/j.optlaseng.2009.08.013

Ghosh M, Kumar K, Mishra RS (2011) Friction stir lap welded advanced high strength steels: Microstructure and mechanical properties. Mater Sci Eng, A 528(28):8111–8119. https://doi.org/10.1016/j.msea.2011.06.087

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation matlab software. Exp Mech 55(6):1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Fadaeifard F, Pakmanesh MR, Esfahani MS, Matori KA, Chicot D (2019) Nanoindentation analysis of friction stir welded 6061–T6 Al alloy in as-weld and post weld heat treatment. Phys Met Metall 120(5):483–491. https://doi.org/10.1134/S0031918X1905003X

Huang YX, Wan L, Lv ZL, Lv SX, Zhou L, Feng JC (2016) Microstructure and microhardness of aluminium alloy friction stir welds with heat treatment. Sci Technol Weld Joining 21(8):638–644. https://doi.org/10.1080/13621718.2016.1152748

Bertin M, Hild F, Roux S, Mathieu F, Leclerc H, Aimedieu P (2016) Integrated digital image correlation applied to elastoplastic identification in a biaxial experiment. J Strain Anal Eng Design 51(2):118–131. https://doi.org/10.1177/0309324715614759

Baldi A (2014) Residual stress measurement using hole drilling and integrated digital image correlation techniques. Exp Mech 54(3):379–391. https://doi.org/10.1007/s11340-013-9814-6

Gazeau C, Gillibert J, Blond E, Geffroy PM, Richet N (2015) Experimental set up for the mechanical characterization of plane ITM membrane at high temperature. J Eur Ceram Soc 35(14):3853–3861. https://doi.org/10.1016/j.jeurceramsoc.2015.06.026

Mathieu F, Leclerc H, Hild F, Roux S (2015) Estimation of elastoplastic parameters via weighted FEMU and integrated-DIC. Exp Mech 55(1):105–119. https://doi.org/10.1007/s11340-014-9888-9

Dong J, Liu Z, Gao J (2017) Multi-parameter inversion and thermo-mechanical deformation decoupling using I-DIC. Exp Mech 57(1):31–39. https://doi.org/10.1007/s11340-016-0203-9

Wan L, Huang Y, Lv Z, Lv S, Feng J (2014) Effect of self-support friction stir welding on microstructure and microhardness of 6082–T6 aluminum alloy joint. Mater Des 55:197–203. https://doi.org/10.1016/j.matdes.2013.09.073

Wang DA, Lee SC (2007) Microstructures and failure mechanisms of friction stir spot welds of aluminum 6061–T6 sheets. J Mater Process Technol 186(1–3):291–297. https://doi.org/10.1016/j.jmatprotec.2006.12.045

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China [Grant Nos. 11972084], National Science and Technology Major Project (2017-VI-0003-0073) and Beijing National Science Foundation (1192014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Y., Zhao, J., Zhou, J. et al. Local-Micro-Zone-Wise Time-Resolved Integrated Digital Image Correlation for Evaluating the Mechanical Properties of Welding Joints. Exp Tech 47, 973–987 (2023). https://doi.org/10.1007/s40799-022-00608-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-022-00608-y