Abstract

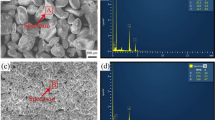

In this paper 0.8, 1.2, 1.6 and 2 wt.% of submicron-TiB2 particulate reinforced Al 7075 metal matrix composites (MMCs) were fabricated following a modified liquid metallurgy technique, which included ball milling, semi-solid stirring and ultrasonic agitation assisted squeeze casting method. Objective was to investigate their reinforcement incorporation factors (RIFs), microstructure through optical microscopy (OM) and scanning electron microscopy (SEM), and phase identification through X-ray diffraction (XRD) analysis. Phase distribution of different elements was analyzed through energy dispersive X-ray spectroscopy (EDS), and spatial distributions of elemental constituents were verified through elemental mapping. Mechanisms of TiB2 particulate dispersion and cluster segregation were highlighted. Results revealed excellent incorporation and dispersion uniformity of the reinforcements in the matrix phase. Squeeze casting process promoted the heterogeneous nucleation rate and rapid solidification, which resulted formation of Al-Zn-Mg-Cu based compounds in the dendritic regions. Occasional formation of reaction by-products (Al4C3) was observed at the interface of 1.2 wt.% TiB2 reinforced MMC. Reduction of precipitates and large grain refinements were observed for the MMC containing 1.6 wt.% of TiB2. In the microstructure of Al 7075/2 wt.% TiB2 MMC, superior dispersion of reinforcements at grain boundaries and inter-dendritic regions, along with presence of metastable η-MgZn2 phases was identified. Crystalline phase identification of all the composite samples was also performed through XRD analysis, which validated the elemental phase distribution results of EDS.

Similar content being viewed by others

References

Selvakumar N, Gnanasundarajayaraja B, Rajeshkumar P (2016) Enhancing the properties of Al–WC nanocomposites using liquid metallurgy. Exp Tech 40(1):129–135

Karthikeyan R, Balasubramanian V (2013) Statistical optimization and sensitivity analysis of friction stir spot welding process parameters for joining AA 7075 aluminum alloy. Exp Tech 37(2):6–15

Rashad M, Pan F, Asif M (2015) Room temperature mechanical properties of mg–cu–Al alloys synthesized using powder metallurgy method. Mater Sci Eng A 644:129–136

Jun GOU, Tang AT, Pan FS, Jia SHE, Luo SQ, Ye JH, Shi DW, Rashad M (2016) Influence of Sn addition on mechanical properties of gas tungsten arc welded AM60 Mg alloy sheets. Trans Nonferrous Metals Soc China 26(8):2051–2057

Rashad M, Pan F, Tang A, Lu Y, Asif M, Hussain S, She J, Gou J, Mao J (2013) Effect of graphene nanoplatelets (GNPs) addition on strength and ductility of magnesium-titanium alloys. J Magnes alloy 1(3):242–248

Rashad M, Pan F, Asif M, Li L (2015) Enhanced ductility of Mg–3Al–1Zn alloy reinforced with short length multi-walled carbon nanotubes using a powder metallurgy method. Progress Nat Sci: Mater Int 25(4):276–281

Das D, Mishra PC, Singh S, Thakur RK (2015) Tool wear in turning ceramic reinforced aluminum matrix composites-A review. J Compos Mater 49(24):2949–2961

Saravanan MS, Babu SK, Sivaprasad K (2014) Mechanical properties and corrosion behavior of carbon nanotubes reinforced AA 4032 nanocomposites. Exp Tech 38(1):48–52

Ekinci VS, Bağci C, Arik H (2014) Effect of Al2O3 content and milling time on microstructure and mechanical properties of aluminum metal matrix composites. Exp Tech 38(2):66–73

Rokni MR, Zarei-Hanzaki A, Roostaei AA, Abedi HR (2011) An investigation into the hot deformation characteristics of 7075 aluminum alloy. Mater Des 32(4):2339–2344

Xu D, Li Z, Wang G, Li X, Lv X, Fan Y, Xiong B (2017) Phase transformation and microstructure evolution of an ultra-high strength Al-Zn-Mg-Cu alloy during homogenization. Mater Charact 131:285–297

Khalil AM, Loginova IS, Pozdniakov AV, Mosleh AO, Solonin AN (2019) Evaluation of the microstructure and mechanical properties of a new modified cast and laser-melted AA7075 alloy. Materials 12(20):3430

Ghosh A, Ghosh M (2018) Microstructure and texture development of 7075 alloy during homogenisation. Philos Mag 98(16):1470–1490

Huo W, Hou L, Lang Y, Cui H, Zhuang L, Zhang J (2015) Improved thermo-mechanical processing for effective grain refinement of high-strength AA 7050 Al alloy. Mater Sci Eng A626:86–93

Birol Y (2007) Production of Al–Ti–B master alloys from Ti sponge and KBF4. J Alloys Compd 440(1–2):108–112

Wrobel T (2011) Review of inoculation methods of pure aluminium primary structure. Arch Mater Sci Eng 50(2):110–119

Ghosh A, Ghosh M, Seikh AH, Alharthi NH (2020) Phase transformation and dispersoid evolution for Al-Zn-Mg-Cu alloy containing Sn during homogenisation. J Mater Res Technol 9(1):1–12

Yang X, Li YD, Luo XM, Zhou HW, Cai QY, Li M, Ma Y (2019) Microstructural evaluation and mechanical properties of 7075 aluminum alloy prepared by controlled diffusion solidification. China Foundry 16(4):238–247

Tee KL, Lu L, Lai MO (1999) Synthesis of in situ Al–TiB2 composites using stir cast route. Compos Struct 47(1–4):589–593

Wu L, Li X, Han G, Deng Y, Ma N, Wang H (2017) Precipitation behavior of the high-Li-content in-situ TiB2/Al-Li-cu composite. Mater Charact 132:215–222

Rane K, Dhokey N (2018) On the formation and distribution of in situ synthesized TiB2 reinforcements in cast aluminium matrix composites. J Compos Sci 2(3):52

Li H, Wang X, Chai L, Wang H, Chen Z, Xiang Z, Jin T (2018) Microstructure and mechanical properties of an in-situ TiB2/Al-Zn-mg-cu-Zr composite fabricated by melt-SHS process. Mater Sci Eng A720:60–68

Pazhouhanfar Y, Eghbali B (2018) Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater Sci Eng A710:172–180

Lee J, Jung JY, Lee ES, Kim NJ, Ahn S (1998) Strengthening mechanism of a spray-formed Cu-TiB2 composite. Met Mater 4(4):610–615

Gyawali G, Cho SH, Lee SW (2013) Electrode position and characterization of Ni-TiB2 composite coatings. Met Mater Int 19(1):113–118

Lee DB (2002) Effect of SiC, Si3N4 and TiB2 additions on the oxidation resistance of TiAl alloys. Met Mater Int 8(1):69–75

Akbari MK, Shirvanimoghaddam K, Hai Z, Zhuiykov S, Khayyam H (2017) Nano TiB2 and TiO2 reinforced composites: a comparative investigation on strengthening mechanisms and predicting mechanical properties via neural network modeling. Ceram Int 43(18):16799–16810

Ozdin K (2014) Production of metal matrix composites by the vortex method and investigation of the effect of changing casting temperature on particles ratio of product-composite. Exp Tech 38(6):16–20

Rajan HM, Ramabalan S, Dinaharan I, Vijay SJ (2013) Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites. Mater Des 44:438–445

Gan GS, Yang B, Gao Q, Wu Y, Yang MB (2016) Microstructure and viscosity of particles reinforced 7075 Al matrix composites. Mater Trans 57(8):1296–1299

Chandana A, Lawrence ID, Jayabal S (2018) Characterization of particulate-reinforced aluminium 7075/TiB2 composites. Mater Today: Proc 5(6):14317–14326

Ku MH, Hung FY, Lui TS, Chen LH (2012) Effect of tool rotational speed on the microstructures and tensile properties of 7075 aluminum alloy via Friction Stir Process (FSP). Light Metals:475–480

Xi L, Kaban I, Nowak R, Korpala B, Bruzda G, Sobczak N, Mattern N, Eckert J (2015) High-temperature wetting and interfacial interaction between liquid Aland TiB2 ceramic. J Mater Sci 50(7):2682–2690

Akbari MK, Shirvanimoghaddam K, Hai Z, Zhuiykov S, Khayyam H (2017) Al-TiB2 micro/nanocomposites: particle capture investigations, strengthening mechanisms and mathematical modelling of mechanical properties. Mater Sci Eng A682:98–106

Chen Z, Sun GA, Wu Y, Mathon MH, Borbely A, Chen D, Ji G, Wang ML, Zhong SY, Wang HW (2017) Multi-scale study of microstructure evolution in hot extruded nano-sized TiB2 particle reinforced aluminum composites. Mater Des 116:577–590

Robson JD (2004) Microstructural evolution in aluminum alloy 7050 during processing. Mater Sci Eng A 382(1–2):112–121

Ghiaasiaan R, Zeng X, Shankar S (2014) Controlled diffusion solidification (CDS) of Al- Zn-Mg-Cu (7050): microstructure, heat treatment and mechanical properties. Mater Sci Eng A 594:260–277

Ghiaasiaan R, Amirkhiz BS, Shankar S (2017) Quantitative metallography of precipitating and secondary phases after strengthening treatment of net shaped casting of Al-Zn-Mg-Cu (7000) alloys. Mater Sci Eng A698:206–217

Fan X, Jiang D, Meng Q, Zhong L (2006) The microstructural evolution of an Al–Zn–Mg–Cu alloy during homogenization. Mater Lett 60(12):1475–1479

Liu Z, Han Q, Li J (2012) A developed method for producing in situ TiC/Al composites by using quick preheating treatment and ultrasonic vibration. Compos Part B 43(5):2429–2433

Liu Z, Han Q, Li J, Huang W (2012) Effect of ultrasonic vibration on microstructural evolution of the reinforcements and degassing of in situ TiB2p/Al–12Si–4Cu composites. J Mater Process Technol 212(2):365–371

Fard HSP, Baharvandi HR, Abdizadeh H, Shahbahrami B (2008) Chemical synthesis of nano-titanium diboride powders by borothermic reduction. Int J Mod Phys B 22(18–19):3179–3184

Chen XH, Yan H (2016) Solid–liquid interface dynamics during solidification of Al 7075–Al2O3np based metal matrix composites. Mater Des 94:148–158

Ghomashchi MR, Vikhrov A (2000) Squeeze casting: an overview. J Mater Process Technol 101(1–3):1–9

Fan CH, Chen ZH, He WQ, Chen JH, Chen D (2010) Effects of the casting temperature on microstructure and mechanical properties of the squeeze-cast Al–Zn–Mg–Cu alloy. J Alloys Compd 504(2):L42–L45

Kannan C, Ramanujam R (2017) Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J Adv Res 8(4):309–319

Schaffer PL, Miller DN, Dahle AK (2007) Crystallography of engulfed and pushed TiB2 particles in aluminium. Scr Mater 57(12):1129–1132

Mondal C, Mukhopadhyay AK (2005) On the nature of T (Al2Mg3Zn3) and S (Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater Sci Eng A 391(1–2):367–376

Zhu HG, Wang HZ, Ge LQ, Shi CHEN, Wu SQ (2007) Formation of composites fabricated by exothermic dispersion reaction in Al-TiO2-B2O3 system. Trans Nonferrous Metals Soc China 17(3):590–594

Murty BS, Kori SA, Chakraborty M (2002) Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying. Int Mater Rev 47(1):3–29

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahoo, B., Das, D. Investigation on Reinforcement Incorporation Factor and Microstructure of Al 7075/Submicron-TiB2 Metal Matrix Composites Processed through a Modified Liquid Metallurgy Technique. Exp Tech 45, 179–193 (2021). https://doi.org/10.1007/s40799-020-00429-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-020-00429-x