Abstract

The existence of joints or other kinds of discontinuities has a dramatic effect on the stability of rock excavations and engineering. As a result, a great challenge in rock mass mechanics testing is to prepare rock or rock-like samples with defects. In recent years, 3D printing technology has become a promising tool in the field of rock mass mechanics and engineering. This study first reviews and discusses the research status of traditional test methods in rock mass mechanics tests of making rock samples with defects. Then, based on the comprehensive analysis of previous research, the application of 3D printing technology in rock mass mechanics is expounded from the following three aspects. The first is the printing material. Although there are many materials for 3D printing, it has been found that 3D printing materials that can be used for rock mass mechanics research are very limited. After research, we summarize and evaluate printing material that can be used for rock mass mechanics studies. The second is the printing methodology, which mainly introduces the current application forms of 3D printing technology in rock mass mechanics. This includes printed precise casting molds and one-time printed samples. The last one is the printing model, which includes small-scale samples for mechanical tests and large-scale physical models. Then, the benefits and drawbacks of using 3D printing samples in mechanical tests and the validity of their simulation of real rock are discussed. Compared with traditional rock samples collected in nature or synthetic rock-like samples, the samples made by 3D printing technology have unique advantages, such as higher test repeatability, visualization of rock internal structure and stress distribution. There is thus great potential for the use of 3D printing in the field of rock mass mechanics. However, 3D printing materials also have shortcomings, such as insufficient material strength and accuracy at this stage. Finally, the application prospect of 3D printing technology in rock mass mechanics research is proposed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For rock mass mechanics and engineering, one of the greatest challenges lies in the existence of joints or other kinds of discontinuities (faults, fractures, cracks, bedding planes, etc.). Due to the presence of discontinuities, the mechanical properties of the rock mass will greatly degrade, and the propagation and development of discontinuities will eventually lead to rock failure (Bai et al. 2022; Cao et al. 2016; Fan et al. 2021; Sainoki et al. 2019). It is well concluded that discontinuities in rocks have a significant effect on the macroscopic failure pattern and strength of rock masses and thereby fundamentally influence the stability of rock excavations and the control of rock engineering (Yang et al. 2017; He et al. 2017; Zhao et al. 2020).

The major methodologies in rock mass mechanics and engineering are analytical analysis, numerical modeling and laboratory testing. As a fundamental tool, the laboratory test can comprehensively investigate the mechanical behaviors and properties. It has become an important method for studying the stability of rock structures and verifying numerical simulations (Xia et al. 2021; Song et al. 2018; Bachmann et al. 2004; He et al. 2010; Zhang et al. 2017). Generally, there are two main ways to obtain laboratory test samples: real-rock samples and samples cast from similar materials. Specifically, the acquisition method of real-rock samples usually involves first determining a certain area where the mechanical parameters of the rock mass need to be obtained at the engineering site and then collecting large-size rock samples. After reinforcement and protection, they are transported back to the laboratory for secondary sampling, cutting and grinding. The methods for obtaining real-rock samples mainly include the use of wire saws and water jets. With the deepening of rock mass mechanics research, the shortcomings of real-rock samples are exposed, which brings difficulties to the test of rock mass mechanics. In the process of coring, transportation and preparation, rock samples are greatly affected by on-site engineering conditions and equipment, which are easily worn out, and some weak rock samples are difficult to prepare. Due to the heterogeneity and anisotropy of natural rock, even the rock samples obtained on the same rock mass also have large differences in mechanical properties. It is impossible to produce two identical samples. In addition, rock mass mechanics laboratory tests (compression tests, shear tests, impact tests, etc.) are mostly destructive tests, which makes it impossible to carry out rock mass mechanics tests at the same or different categories and loading conditions at the same time, resulting in the dispersion and unrepeatability of test results.

Due to the limitations of real rock samples above, the physical test method commonly used by researchers is a similar material simulation test. The traditional similar material simulation test usually uses the method of mold-casting to make rock-like samples instead of natural rock materials for research. PMMA, gypsum, ceramics, resin and other materials have been widely used. The main advantage of similar material simulation tests is that they can artificially control and change the experimental conditions to determine the influence law of a single factor or multifactor comparative study. The test effect is intuitive and clear, the test period is short, the effect is fast, and the cost is low. Moreover, compared with the real-rock samples, there is a high similarity between identical rock-like samples. Although many scholars have made many research achievements through similar material simulation tests, at this stage, similar material simulation tests seem to encounter bottlenecks: (1) When casting the mold, some precipitation and bubbles will be unavoidable, which will further affect the mechanical properties of the model samples. (2) The influence of uneven mixing of various materials on the properties of samples and test results. (3) The fractures prepared by the traditional similar material simulation test are mostly simple, uniform and regular, and it is difficult to prepare a rock mass with complex structural characteristics and internal fractures. With the continuous development of rock mass mechanics research, simulating the natural rock mass more realistically in the preparation of a sample model is a problem that all researchers have to solve.

As discussed above, one of the common limitations in laboratory tests is the repeated preparation of rock samples with certain defects (fractures, crack holes, etc.) when laboratory tests are used to study the mechanical and failure properties of a rock mass. Consequently, it is quite difficult and challenging to investigate the complex mechanical behaviors of jointed rock masses with laboratory tests.

A quick expansion of additive manufacturing technology, also known as 3D printing (3DP), has resulted in the continuous growth of this technique as a powerful alternative solution to various research inquiries in different scientific fields (Lee et al. 2007; Tymrak et al. 2014; Rankin et al. 2014). 3D printing (3DP) is capable of replicating the internal defect structure of rock masses (Bourke et al. 2008; Suzuki et al. 2017; Wu et al. 2022), something that is not possible using any previous technique for making artificial rock samples. This technology can create multiple identical samples so that tests can be repeated and hence more reliable conclusions can be drawn (Squelch 2018; Sharafisafa et al. 2018; Gell et al. 2019), which makes it an inspiring method for rock mass mechanics testing (Wang and Qi 2018; Xia et al. 2021).

In this study, the research status of rock mass mechanics tests on jointed samples is first reviewed and discussed. Then, 3DP technology and its application status in rock mass mechanics and engineering are comprehensively analyzed from the three aspects of printing methodology, printing model and printing material. This study will contribute to the future development of using 3DP, a powerful tool, in the unresolved challenges of rock mass mechanics.

2 3D printing technology

2.1 Introduction of 3D printing

The rapidly developed 3DP technology in recent years can batch produce various 3D entities with complex structures and unique shapes and has high consistency in accuracy, details, size, performance and other characteristics for the same batch of repeated printing samples. Different from the previous material removal processing technology, 3DP technology is based on the principle of accumulation and dispersion through a thin layer from bottom to top continuous superposition to form a three-dimensional entity. This technology can accurately characterize and control the internal structure of the test model and avoid the difference in the internal structure of different samples of natural rock. This undoubtedly opens up a new way for the physical simulation of rock test methods.

As a rapidly developing technology, 3DP has the following five advantages compared with traditional manufacturing technology.

-

(1)

Short production cycle. Traditional processes often require the design and production of molds and usually require secondary processing on machine tools, resulting in a long manufacturing cycle. The 3DP technology can generate a 3D solid model directly from the computer software without the molding process, which differs from the traditional mold processing. 3DP greatly reduces the production time of the model, simplifies the manufacturing process and saves molding costs.

-

(2)

The printed model is of high precision. After years of development, the accuracy of 3DP has been greatly improved. At present, the accuracy of the mainstream 3D printers on the market can be basically controlled below 0.2 mm, which is sufficient for general product requirements.

-

(3)

Diversity of printing materials. Usually, a 3D printer can print using different materials, such as plastics, metals, resins, gypsum, and ceramics. The diversity of printing materials can meet the needs of different fields.

-

(4)

Implementing personalized printing of the model. Using computer modeling can obtain some models that cannot be obtained by traditional processing methods, in theory, as long as the shape created by the computer can be printed by the 3D printer. On one hand, the model established by computers is different from entity production. It is easy to modify the size, shape and proportion of the model, and it is easy to control some details, which greatly facilitates the production of personalized products. On the other hand, the model established by computer can obtain some curves that cannot be obtained by traditional processes, which will make 3DP products have a more personalized appearance.

-

(5)

Manufacture of complex one-piece parts. Some parts with special shapes are difficult to manufacture by traditional processing technology, while 3DP technology easily manufactures. 3DP printing difficulty does not increase much compared with printing simple items.

2.2 3D printing technology and material for rock simulation

3DP technology can be divided into fused deposition modeling (FDM), stereo lithography appearance (SLA), selective laser sintering (SLS) and binder jetting technology (BJT) according to the printing molding process. Printing materials used in various processes are also different (Wang and Qi 2018), and the mechanical properties of samples prepared by different materials and printing processes are the key to whether this technology can be scientifically and reasonably used as rock-like materials in the field of rock mass mechanics.

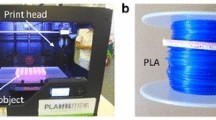

In recent years, many scholars have also carried out preliminary explorations of 3DP technology in the field of rock mass mechanics. At present, printing materials such as PLA (polylactic acid), resin, gypsum-like powder and sand powder have been used for the fabrication of rock samples (Ju et al. 2017a, 2019, 2020a, 2020b; Hart and Wetzel 2017). Usually, the mechanical properties of rock materials are generally characterized by high strength and high brittleness. However, from the perspective of the printing materials currently used, the experimental results show low strength and high ductility, different from those of real rock materials. Therefore, to apply 3DP to rock mass mechanics research, it is necessary to overcome these problems. To solve this problem, Xu et al. (2021) investigated the effect of printing layer thickness on the physical and mechanical properties of rock-like samples with sand powder 3DP. The study found that increasing the layer thickness from 0.2 to 0.4 mm resulted in a decrease in the weight, density, uniaxial compression strength, and elastic modulus of the samples. It is proposed that rock-like samples with small layer thicknesses should be prepared in future research. Fereshtenejad and Song (2016) studied the material properties of powder layer printing technology. It was found that the uniaxial compressive strength and stress‒strain behavior of the printed samples can be affected by testing the printing direction, the thickness of the printing layer, the concentration of the binder and the heating process. By adjusting the printing parameters and using some postprocessing techniques, the strength of the sample can be improved, the ductility of the sample can be reduced, and its brittleness can be increased. Although some research results have been achieved, more improvements are needed to enhance the application effect of 3DP in rock mass mechanics in the future. Jiang and Zhao (2015) studied the effect of structural changes (granular structure and flake structure) on the mechanical properties of the samples, and the results showed that polylactic acid used as the FDM printing material is not suitable for directly modeling rocks. Vogler et al. (2017) used 3DP technology to fabricate two samples of different particle sizes and compared them with three types of natural sandstone samples. The 3D-printed samples were found to be very similar to the weakest sandstone samples in terms of roughness, tensile strength, and fracture process. Zhou and Zhu (2017) compared and analyzed samples printed by contrast FDM and SLA through uniaxial compression tests and Brazilian splitting tests. It was found that the samples printed by SLA technology were more brittle and most suitable for simulating hard rock. Combined with CT scanning technology, the internal structure of igneous rock was reconstructed. The results show that the resin material samples printed by SLA have good brittleness and are most suitable for the physical test of simulating hard rock. However, its strength and brittleness are still less than those of natural rocks. Therefore, the focus of further research should be on improving the strength and brittleness of the sample through postprocessing and other means or finding a hard and brittle material as a substrate for 3DP to simulate rock materials.

3 Application of 3D-printed molds in rock mass mechanics and engineering

With the rise and progress of 3DP technology, solid modeling of complex structures has gradually become possible. In view of the various bottlenecks faced by traditional test methods in rock mass mechanics research, compared with the unique advantages of 3DP, this technology has received increasing attention and application by rock mass mechanics workers in recent years. Ju et al. (2014) pointed out that mechanical behaviors and processes such as stress change, fracture evolution and instability under excavation disturbance of fractured rock mass can be realized based on 3DP technology, which plays an important role in promoting the progress of research methods of deep rock mass mechanics. Thus, 3DP technology has broad application prospects in the field of rock mass mechanics.

3.1 3D-printed mold for rock mass structures

Rock samples with natural structure planes can be prepared either with natural rock or artificial rock-like materials. The main problems faced by the former method in the preparation are the difficulty in preparing natural rock samples, high cost, poor repeatability of the test, and easy destruction of the integrity of the natural structure plane. Although the artificially prepared samples containing natural structure planes can reflect the mechanical properties of natural rock masses to a certain extent, they still have large differences from the irregular undulation and rough nature structure plane. Therefore, there are many limitations in analyzing the failure mechanism of the nature structure plane.

The emergence of 3DP technology provides a way to solve these problems. Kim et al. (2016) transformed Barton’s typical joint profile into a three-dimensional model, printed it into a mold by 3DP technology with PMMA as printing material, and then used the mold to manufacture a batch of plaster samples with Barton’s typical joint profile (Fig. 1). In addition, 3DP technology can be used to reconstruct the structure plane of a natural rock mass. Jiang et al. (2016a) used a three-dimensional laser scanner to obtain the shape of the natural structural plane. Next, a 3D virtual model with a natural structural plane was obtained (Fig. 2a). Then, the scanned data were imported into a 3D printer, PLA was used as the material to print a 3D structural surface mold (Fig. 2b), and mass production was carried out by 3DP technology. This not only solves the repeatability problem of the structural plane test but also ensures the manufacturing accuracy of the structural plane. Compared with the natural structure plane, the deviation is less than 2.4%. In the direct shear test, due to the deviation of the traditional manufacturing method, the shear strength data of the sample obtained by the traditional method are relatively discrete, and the deviation is approximately 20%, while the shear strength deviation of the sample manufactured by the mold printed by the 3D printer is less than 6.7%. Xiong et al. (2015) and Ban et al. (2020) also conducted similar experiments and obtained similar results.

3D printed plaster model with Barton’s joint profile (Kim et al. 2016)

Process of making a model with a natural structural plane (Jiang et al. 2016a)

The studies above indicated that the reverse structural plane samples created using 3D scanning and 3DP technologies have small modeling errors and uniform material strength, and they produce the same mechanical results, which can obviously improve the quality of replications of natural planes and facilitate the further study of the mechanism of the formation of natural planes.

3.2 3D-printed mold for jointed rock mass

In the prefabrication of samples containing joints, the commonly used research methods in laboratory tests are the traditional preembedded thin slice method, join-cutting method and heart-inducted method. On one hand, these methods often make it difficult to accurately control the position, size, and angle of joints, and it is difficult to obtain ideal specific samples, which increases the difficulty of analyzing the test results; On the other hand, these methods are mostly applicable to joints with regular morphology and cannot prepare joints buried in rock masses, so it is difficult to simulate the real geological defect morphology. Therefore, it is necessary to continuously explore new joint model preparation methods.

3DP technology provides an effective method for the study of the mechanical properties of jointed rock masses. To overcome the above bottlenecks, the researchers introduced 3DP technology into the sample preparation for the dynamic expansion test of fractures in rock bodies. Zhao et al. (2017) made casting mold and parallel, merge, T-shaped, orthogonal, and oblique joint models by 3DP technology with resin as the material and made joint samples with different spatial distributions by mold-casting (Fig. 3). Jin et al. (2020) studied the influence of cross joints on the fracture mechanism of rock masses. With PLA as the material, the joint model that can simulate the cross structural plane of the rock mass is made by FDM 3DP equipment, and the samples with prefabricated cross joints are formed by casting similar materials. It is found that the closed joint model made by 3DP technology can effectively replace the open joint cracks formed by traditional cutting and slotting methods. At present, scholars have used 3D printed molds to conduct research on complex fracture networks. Wang et al. (2018) proposed a method for preparing joint network models with different geometric shapes based on 3DP technology and carried out uniaxial compression experiments for the RDFN (rough discrete fracture network) model, linear DFN (discrete fracture network) model and solid model with different sample sizes. The size effect was analyzed. This method builds a 3D fracture network model by a 2D fracture network (Figs. 4a, b). The joint model was prepared by a 3D printer with PLA (polylactic acid) polymer plastic as the material, and a similar model of the jointed rock mass was prepared by the sulfoaluminate fast-hardening cement casting model (Fig. 4c).

Casted sample with 3D printed joint mold (Zhao et al. 2017)

Prefabrication process of the DFN model sample (Wang et al. 2018)

It is true that with 3DP, mold preparation becomes much easier, especially for those with complex geometries. However, the joints in samples prepared by mold-casting are still exposed or connected to the surface. Samples with internal joints or fracture networks are extremely difficult to prepare with mold-casting; however, they are simple to prepare with 3DP, which is the most revolutionary feature of 3DP besides high accuracy, homogeneity and efficiency.

The studies above show that 3D printed molds have been widely used in rock mass mechanics tests. On one hand, it confirms the feasibility of 3DP technology, and on the other hand, it also confirms that PLA as a printing material has good application effect and huge development potential in making molds.

However, the preparation of samples in the above study is still limited to the category of traditional methods. Although the accuracy of the mold made by 3DP technology is high, there are still unstable factors, such as bubble precipitations, when manually allocating materials. Therefore, the internal heterogeneity of the samples is high. If the samples are directly prefabricated by 3DP technology, not only should the error be further reduced but also the sample containing a complex fracture network and internal fracture should be easier to prepare.

4 Application of 3D-printed samples and models in rock mass mechanics and engineering

With the development and progress of 3DP technology, an increasing number of researchers have begun to use 3DP technology to directly prepare samples. Through continuous exploratory research in the field of rock mass mechanics, a series of research results have been achieved.

4.1 3D-printed jointed samples

3DP technology has many kinds of printing materials and printing processes. Generally, different printing materials correspond to different printing processes. However, the mechanical properties of samples prepared by different printing materials and printing processes vary greatly. Due to the wide variety of natural rocks at engineering sites, the mechanical properties of different rocks are very different. For example, the uniaxial compressive strength of some soft rocks in coal mines is generally between 5 and 25 MPa, while the uniaxial compressive strength of hard rocks such as granite in metal mines can reach more than 200 MPa. Therefore, it is difficult to prepare various rock-like samples with different mechanical properties by a single printing material and printing process. It is of great research significance to obtain rock-like samples with different mechanical properties by changing the printing material, printing process, or printing parameters. On this basis, many scholars domestically and abroad have carried out various mechanical experimental studies on samples prepared by different printing materials.

4.1.1 Polylactic acid (PLA)

Jiang and Zhao (2015) used polylactic acid (PLA) as a printing material to prepare samples by the FDM printing process and carried out uniaxial compression tests and Brazilian splitting tests. PLA was found to be a very desirable elastic‒plastic material. However, its failure pattern shows very strong ductility characteristics, which are quite different from real rock samples (Figs. 5a–c). Furthermore, as seen from the stress‒strain curves (Figs. 5d, e), the 3D-printed PLA samples exhibit low strength and high ductility compared to real rock samples. Song et al. (2018) and Jiang et al. (2016b) also found that the failure characteristics of PLA samples are different from those of real rock samples, and their mechanical properties are more similar to metal than rock. As mentioned above, PLA materials currently used for 3DP are not suitable for directly simulating rocks. Nevertheless, the ability for 3DP on manufactured rock remains appealing for researchers of rock mass mechanics. Future research should focus on appropriate printing materials, especially in terms of brittleness and stiffness.

Failure pattern and stress‒strain curve of 3D-printed samples and real rock samples in the UCS test (Jiang and Zhao 2015)

4.1.2 Gypsum powder

In recent years, gypsum powder has been used in several studies to reconstruct rock samples using 3DP (Song et al. 2018; Wu et al. 2020; Kong et al. 2019a, 2019b; Sharafisafa et al. 2019, 2021; Sharafisafa and Shen 2020). Song et al. (2018) prepared rock-like samples and carried out related mechanical experiments using plaster-based 3DP (PP) printers with gypsum powder as the printing material. It was found that the stress‒strain curve characteristics of 3DP gypsum samples are similar to the compression deformation characteristics of natural rocks (Fig. 6a). At the same time, the failure characteristics of the 3DP gypsum samples are consistent with those of natural rock materials (Fig. 6b). In the study of Jiang et al. (2016c), it was found that although compared with PLA (Jiang and Zhao 2015), the 3DP gypsum sample had higher brittleness and its failure pattern was closer to that of natural rock, its uniaxial compressive strength was lower (less than 10 MPa) (Fig. 7). Therefore, it is necessary to continuously optimize the printing process to improve the strength of 3DP gypsum samples so that they can better simulate natural rocks (Liu et al. 2019; Wu et al. 2020). Jiang et al. (2016d) directly used gypsum-like materials to prepare jointed samples by 3DP and carried out dynamic loading tests. The failure pattern of the 3DP gypsum samples was close to that of the Portland pozzola cement (PPC) samples (Fig. 8). Although the failure pattern is very similar, since the 3DP gypsum sample is a homogeneous material and the real rock material is heterogeneous, it cannot be confirmed whether the 3DP gypsum material and heterogeneous natural rock material have the same fracture pattern. Therefore, further research is still needed.

Experimental results of 3DP gypsum samples (Song et al. 2018)

A comparison of the stress–strain curve of the 3DP PLA sample with the 3DP gypsum sample (Jiang and Zhao 2015)

A comparison between the failure patterns on 3DP samples (left) and the cement samples (right) (Jiang et al. 2016d)

4.1.3 Resin

A research team used different printing materials to simulate brittle and hard rocks (Zhou and Zhu 2016, 2017, 2018; Zhu et al. 2018). It was found that the mechanical properties and failure patterns of the samples prepared by SLA technology with resin as the printing material were very similar to those of natural volcanic rocks, and they were most suitable for simulating brittle and hard rock materials. However, the difference is that the elastic modulus of the 3DP resin sample is quite different from that of natural rock (Fig. 9). In addition, the dynamic mechanical test results show that the failure pattern and dynamic cracking evolution of 3DP resin samples are similar to those of natural rock. In addition, it is well known that the accurate description and visualization of the complex internal structure and stress distribution of a rock mass is of great significance to solve various underground engineering problems, and the transparency of some resin materials provides the possibility for the aforementioned research. Ju et al. (2014) used CT technology to scan the internal structure of natural coal and rock samples (Fig. 10) as well as concrete samples (Ju et al. 2017b). The above samples were reconstructed with one resin material as the main body and another nontransparent material as the support, and then the fracture structure hidden in the internal was successfully visualized. In addition, the visualization of internal stress distribution was realized by cooperating with 3D frozen stress and photoelastic technologies. The studies above show that resin materials have great potential and prospects in simulating the mechanical behavior of hard brittle rock materials and studying the fracture failure mechanism of rocks.

a Comparison of a stress‒strain curves and failure patterns in static uniaxial compression tests of b Volcanic rock and c Resin-based 3DP rock samples (Zhu et al. 2018)

3DP models with actual fracture network and visualization of stress distributions (Ju et al. 2014)

4.1.4 Sand powder

In addition to PLA, gypsum and resin materials, sand powder has been used in many studies to reconstruct rock samples (Osinga et al. 2015; Primkulov et al. 2017; Vogler et al. 2017; Perras and Vogler 2019; Gomez et al. 2019; Qi et al. 2021). The mechanical behaviors of 3DP samples with sand powder as printing materials and natural sandstone samples have been compared (Tian and Han 2017a), and it is found that the failure patterns of 3DP samples are mainly divided into two categories: shear failure (Fig. 11a) and tensile failure (Fig. 11b). It can be seen from the test results that the 3DP samples with sand powder as material have similar failure patterns with natural sandstone samples. In another study (Tian and Han 2017b), the stress‒strain response of 3DP samples with sand powder as printing material was very similar to that of natural sandstone (Fig. 11c), and the peak strain of 3DP samples was almost equivalent to that of natural sandstone, indicating that they had similar microstructures, such as porosity. However, similar to gypsum samples, 3DP samples with sand powder as the material showed low strength characteristics. Jiang et al. (2022) explored the failure law of sand-power 3DP samples under dynamic mechanical testing and found that the dynamic mechanical response of sand-power 3DP samples was similar to that of natural coal and rock. Subsequently, the fragmentation distribution of the 3DP sample and the granular structure of the sample section under the dynamic mechanical test were analyzed (Figs. 12, 13), and it was found that the crushing law was similar to that of the complete coal and rock sample. The above research shows that sand-power 3DP samples may be more suitable for simulating soft rock, providing a new method and idea for coal and rock dynamics research.

Fragmentation distribution of 3DP samples under dynamic mechanical testing (Jiang et al. 2022)

Granular structure of the sample section under dynamic mechanical testing (Jiang et al. 2022)

4.1.5 Ceramic

At present, ceramic materials have been proven to be suitable for 3DP (Goulas et al. 2016; Costa et al. 2017; Goodman 2017; Singh et al. 2017; Ferrage et al. 2018; Owen et al. 2018; Shen et al. 2021). However, there is almost no research on the application of ceramic-based 3DP in the mechanical properties of rock masses. It has been claimed that 3DP ceramic samples are not similar to natural brittle rocks owing to their inadequate strength and brittleness (Zhou and Zhu 2018). One possible reason is that the temperature change of ceramic samples produced by the SLS printing process usually produces unexpected cracks, which makes them prone to breakage and makes it difficult to prepare samples. 3DP ceramic samples are worth further study in simulating natural rocks due to their various mechanical properties being closer to those of natural rocks than those of polymers.

By summarizing the previous studies, we find that the problem faced by using PLA as a printing material is that the prepared samples have obvious elastic‒plastic characteristics, which are significantly different from the mechanical properties of rock materials. The samples have high tensile strength and compressive strength, which are not suitable for direct use to simulate rocks. However, this technology can be used to prepare the mold, and then similar materials closer to the rock are used for batch production of the same structural plane (Jiang et al. 2016a; Xiong et al. 2015; Ban et al. 2020). It can also be combined with the conventional laboratory test method to prepare rock samples containing complex fracture networks for related research (Wang et al. 2018; Zhao et al. 2017; Jin et al. 2020) or can also simulate engineering bolts, linings and other supporting structures to a certain extent (Jiang and Song 2018; Song et al. 2018). The printing material used in SLA technology is photosensitive resin, which can generate hundreds of kinds of composite digital materials by a certain proportion of various basic photopolymer materials. Some printing materials are transparent, which can directly reflect the internal structural characteristics of printing samples and provide a new direction for the study of crack propagation and failure mode in rock. The resin material samples used by SLA technology have good brittleness and are most suitable for physical tests simulating hard rock, but their strength and brittleness are still less than those of natural rocks. The mechanical characteristics of gypsum powder and sand powder are close to those of natural soft rock samples, and the application of 3DP ceramic samples in rock mechanics is still rare. However, it is still worthy of further research, and more researchers are needed to explore this topic. The main problem is that the strength of the sample is not high, even lower than that of the weakest rock. Therefore, further research should focus on the strength and brittleness of the material. On one hand, the strength and brittleness of the sample can be improved by postprocessing and other means; On the other hand, efforts should be made to find a hard and brittle material as a base material for 3DP to simulate rocks.

The 3DP has become a powerful tool in creating jointed samples. However, the 3DP sample shows the characteristics of low brittleness and strength or strong ductility, there is still a certain gap with the mechanical properties of natural rocks. Therefore, it is necessary to select the corresponding printing materials and printing process for the specific rock samples studied, and further research on the material is also needed to make the 3DP material closer to the mechanical properties of rock.

The above research examples show that 3DP technology provides a new way to study rock mass mechanics at the sample scale. Solid samples with complex internal structures and external morphologies can be rapidly prepared in batches, which provides a new and effective method for the study of the mechanical properties and mechanisms of rock masses.

4.2 3D-printed physical models for rock engineering

Physical model tests can truly reflect the geological structure and engineering structure and intuitively observe the test results and the mechanical properties of the research object, which makes it easier for scholars to take a global view of the mechanical characteristics, deformation trend and stability characteristics of rock mass engineering. Therefore, a physical model test has been an important means to study the stability of rock engineering structures, the optimization design of support systems and the verification of numerical simulation results.

Song et al. (2018) studied the feasibility of 3DP technology in tunnel physical model tests. Four kinds of tunnel models are prepared by 3D printers, including a general tunnel model, single-fault tunnel model, double-fault tunnel model and tunnel model with rockbolt holes, with gypsum powder and PLA (polylactic acid) material used as the printing materials. The tunnel models were prepared with a PP printer using powder gypsum as the print material, and the rockbolt model and lining support model were constructed using an FDM printer with PLA material used as the printing material. Uniaxial compression tests of the 3DP tunnel samples show that the deformation curves and failure characteristics of similar 3D printed tunnel models are consistent, indicating that 3DP technology can reliably produce physical models of a tunnel with complex structures; the deformation and failure characteristics (Fig. 14) of the general tunnel model and single-fault tunnel model are similar to those of the artificial model. A comparative study also shows that the printed rockbolt and lining support structures significantly improve the bearing capacity of the tunnel, while faults significantly reduce the stability of the tunnel. These experimental results are similar to those of the artificial models, tunnel engineering case studies and numerical simulation results, demonstrating that 3DP technology can be applied to the experimental study of physical models of tunnels.

Typical test curve and macroscopic failure evolution process of the single-fault tunnel model (Song et al. 2018)

Multiple adjacent tunnels or caverns widely exist in underground engineering, such as the twin railroad tunnels for urban and mountain highways (Suwansawat and Einstein 2007; Merlini et al. 2018; Afifipour et al. 2011; Sharifzadeh et al. 2013), large caverns in hydropower stations (Tezuka and Seoka 2003; Plasencia et al. 2015), twin tunnels of freeways and railways in both urban and mountainous areas and roadway groups in deep mines (Islam and Shinjo 2009; Huang et al. 2018). The stability analysis of multitunnel structures (including caverns) is one of the key issues for avoiding engineering disasters during the design and construction of underground engineering. Jiang et al. (2021) exhibited the overall failure process of twin tunnels by a physical simulation based on the 3DP sandstone analog model. The dimensions of each model were 200 mm × 200 mm × 20 mm, and the cross-sectional shape of the tunnel was circular. Then, overloading tests for the twin-tunnel model were carried out and exposed the critical position of the overall failure of the twin-tunnel structure through visual observation and automatic measurement (Fig. 15), and a safety factor method was also presented for evaluating the general safety of the multitunnel structure. The testing results and corresponding numerical back analysis indicated that the connectivity of the plastic strain between tunnels can be deemed the conservative instability criterion and that the inflection point of the tunnel displacement can be deemed the overall failure criterion for the twin-tunnel structure. This study proves that the reconstruction of twin tunnels by 3DP technology is an effective method to study the failure and stability of tunnels and indicates that this method can provide a reference for the quantitative and reasonable evaluation of the general safety of multitunnels or caverns and the local instability zone of surrounding rock.

Crack evolution of 3DP twin tunnels with the same elevation model under the loading process (Jiang et al. 2021)

Although 3DP technology has achieved some results in the physical model test, it is still only a preliminary exploration stage. 3DP can directly print out physical models with complex shapes and structures according to a given scale, such as tunnels, slopes, landslides, and roadway models with fracture structures. To give full play to the technical advantages of 3DP, more scholars need to continue to study and explore it.

5 Prospects

3DP technology has great advantages and development prospects in the field of rock mass mechanics, but there are still some limitations in the research of 3DP rock mass technology. To apply 3DP technology to the study of rock mass mechanics in a truly mature and wide range, the following problems need to be focused on and solved.

-

(1)

Printing materials are rich in variety, but their use in rock mass mechanics test research is relatively limited. The commonly used materials are sand powder, gypsum powder, organic resin, etc. Their material properties for simulating complex and diverse rocks in nature have great limitations. At present, among the printing materials that can be used for 3DP mechanical samples in rock mass mechanics research, the strength of 3DP samples with them can approach those of some natural rock masses with weak strength, but there is still a certain distance from the natural rock masses with high strength. To make 3DP rock masses more widely analogous to various types of natural rock masses, improving the strength of 3DP rock masses is the key, and material innovation is the key to solving the strength of 3DP rock masses. In the future, it is still necessary to develop more materials and further study the relationship between the processing, structure and properties of materials as well as clarify the advantages and limitations of materials and provide normative standards.

-

(2)

The accuracy of printing remains to be improved, although the printing of a 0.05 mm layer thickness can be realized. Due to the existence of deviations during printing as well as the jitter and instability of the printing equipment itself, the actual accuracy that can be achieved is very limited, and it is unable to accurately reconstruct the internal microstructure of the rock mass. For example, when printing small pores, pores will be deformed greatly and even cause pore blockage. In addition, there is a serious conflict between printing accuracy and printing speed, so it is urgent to improve the printing accuracy without reducing the printing speed.

-

(3)

The printing layer thickness will have a great influence on the mechanical properties of the printed sample, so whether some other printing parameters and postprocessing operations, such as the particle size of the printing material, binder saturation level, hardener saturation level, the curing time of the sample, the curing temperature of the sample, printing angle, will affect the mechanical properties of the 3DP sample and what kind of influence law there is on the sample needs to be further explored.

-

(4)

At present, the prepared samples with prefabricated cracks are mostly simple, regular and uniform cracks, and the advantages of 3DP technology in the preparation of complex cracks and the reduction of the real structure of natural rock masses have not been fully utilized. Next, research on complex natural rock masses can be strengthened.

6 Conclusions

This paper makes a systematic review for 3D printing technology with printing materials, printing methodologies and printing models as three research clues. The following conclusions were obtained:

-

(1)

Although there are many materials for 3D printing technology, it has been found that 3D printing materials that can be used for the study of rock mass mechanics are very limited, such as PLA, resin, gypsum-like powder and sand powder. However, the samples prepared by these materials often show characteristics of low brittleness and strength or strong ductility, and there is still a certain gap with the mechanical properties of natural rocks. It is necessary to make a profound study of the influence of printing molding process, base material, binding material, parameters and other factors on the mechanical properties of samples, in order to select the appropriate printing process, materials and parameters according to the mechanical properties of rock to be simulated in specific research.

-

(2)

There are two methodologies to apply 3D printing technology in the field of rock mass mechanics: printed precise casting molds and one-time printed samples. Compared with the traditional casting mold, the mold prepared by 3D printing has higher accuracy, but the method still needs to prepare samples by casting, which is difficult to avoid some limitations, such as the difficulty of preparing samples with complex fracture structure, long curing time. The problems above can be solved by preparing samples using direct one-time printing.

-

(3)

The samples prepared by 3D printing technology are mainly divided into two categories according to different research objectives and molding scales: small-scale samples for mechanical tests and large-scale physical models. The small-scale mechanical samples have been widely used in rock mass mechanics research, while there are relatively few studies on large-scale physical models prepared by 3D printing for rock mass mechanics testing, and it is still in the preliminary exploration stage. 3D printing technology can not only directly prepare large-scale physical models with complex shapes and structures, but also overcome some limitations in the process of traditional physical model testing, such as the consumption of huge manpower and material resources, long curing time, complex operation procedures.

The presented research shows that 3D printing technology has broad application prospects in the field of rock mass mechanics. The samples or physical models with complex internal defects prepared by 3D printing can be used for testing of different types and loading paths, which provides a key technology for the testing study of fractured rock mass. Some existing application limitations will be solved with the continuous breakthrough of technology, and the application of 3D printing technology in the field of rock mass mechanics will be more extensive and in-depth.

References

Afifipour M, Sharifzadeh M, Shahriar K, Jamshidi H (2011) Interaction of twin tunnels and shallow foundation at Zand underpass, Shiraz metro, Iran. Tunn Undergr Space Technol 26:356–363

Alber M, Fritschen R, Bischoff M, Meier T (2009) Rock mechanical investigations of seismic events in a deep longwall coal mine. Int J Rock Mech Min Sci 46:408–420

Bachmann D, Bouissou S, Chemenda A (2004) Influence of weathering and pre-existing large scale fractures on gravitational slope failure: insights from 3-D physical modelling. Nat Hazard 4:711–717

Bai QS, Zhang C, Paul Young R (2022) Using true-triaxial stress path to simulate excavation-induced rock damage: a case study. Int J Coal Sci Technol 9(1):49. https://doi.org/10.1007/s40789-022-00522-z

Ban L, Qi C, Chen H, Yan F, Ji C (2020) A new criterion for peak shear strength of rock joints with a 3D roughness parameter. Rock Mech Rock Eng 53:1755–1775

Bourke M, Viles H, Nicoli J, Lyew-Ayee P, Ghent R, Holmlund J (2008) Innovative applications of laser scanning and rapid prototype printing to rock breakdown experiments. Earth Surf Process Landf J Br Geomorphol Res Group 33:1614–1621

Cao RH, Cao P, Lin H, Pu CZ, Ou K (2016) Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: experimental studies and particle mechanics approach. Rock Mech Rock Eng 49:763–783. https://doi.org/10.1007/s00603-015-0779-x

Costa ECE, Duarte JP, Bartolo P (2017) A review of additive manufacturing for ceramic production. Rapid Prototyp J 23:954–963

Fan W, Yang H, Jiang X, Cao P (2021) Experimental and numerical investigation on crack mechanism of folded flawed rock-like material under uniaxial compression. Eng Geol 291:106210

Fereshtenejad S, Song JJ (2016) Fundamental study on applicability of powder-based 3D printer for physical modeling in rock mechanics. Rock Mech Rock Eng 49:2065–2074. https://doi.org/10.1007/s00603-015-0904-x

Ferrage L, Bertrand C, Lenormand P (2018) Dense yttria-stabilized zirconia obtained by direct selective laser sintering. Addit Manuf 21:472–478

Gell EM, Walley SM, Braithwaite CH (2019) Review of the validity of the use of artificial specimens for characterizing the mechanical properties of rocks. Rock Mech Rock Eng 52:2949–2961. https://doi.org/10.1007/s00603-019-01787-8

Gomez JS, Chalaturnyk RJ, Zambrano-Narvaez G (2019) Experimental investigation of the mechanical behavior and permeability of 3D printed sandstone analogues under triaxial conditions. Transp Porous Media 129:541–557

Goodman WA (2017) A review on the advances in 3D printing and additive manufacturing of ceramics and ceramic matrix composites for optical applications. In: Proceedings of SPIE 10372 103720B

Goulas A, Harris RA, Friel RJ (2016) Additive manufacturing of physical assets by using ceramic multicomponent extra-terrestrial materials. Addit Manuf 10:36–42

Hart KR, Wetzel ED (2017) Fracture behavior of additively manufactured acrylonitrile butadiene styrene (ABS) materials. Eng Fract Mech 177:1–13

He MC, Gong WL, Zhai HM, Zhang HP (2010) Physical modeling of deep ground excavation in geologically horizontal strata based on infrared thermography. Tunn Undergr Space Technol 25:366–376

He P, Li SC, Li LP, Zhang QQ, Xu F, Chen YJ (2017) Discontinuous deformation analysis of super section tunnel surrounding rock stability based on joint distribution simulation. Comput Geotech 91:218–229

Huang X, Liu Q, Shi K, Pan Y, Liu J (2018) Application and prospect of hard rock TBM for deep roadway construction in coal mines. Tunn Undergr Space Technol 73:105–126

Islam MR, Shinjo R (2009) Mining-induced fault reactivation associated with the main conveyor belt roadway and safety of the Barapukuria Coal Mine in Bangladesh: constraints from BEM simulations. Int J Coal Geol 79:115–130

Jiang Q, Song LB (2018) Application and prospect of 3D printing technology to physical modeling in rock mechanics. Chin J Rock Mech Eng 37:23–37

Jiang C, Zhao GF (2015) A preliminary study of 3D printing on rock mechanics. Rock Mech Rock Eng 48:1041–1050. https://doi.org/10.1007/s00603-014-0612-y

Jiang Q, Feng X, Gong Y, Song L, Ran S, Cui J (2016a) Reverse modelling of natural rock joints using 3D scanning and 3D printing. Comput Geotech 73:210–220

Jiang Q, Feng X, Song L, Gong Y, Zheng H, Cui J (2016b) Modeling rock specimens through 3D printing: Tentative experiments and prospects. Acta Mech Sin PRC 32:101–111. https://doi.org/10.1007/s10409-015-0524-4

Jiang C, Zhao GD, Gao MZ, Zhao YX (2016c) A trial of 3D printing on rock dynamics. In: Li H, Li J, Zhang Q, Zhao J (eds) Rock dynamics: from research to engineering. Taylor & Francis, London, pp 123–128

Jiang C, Zhao GF, Zhu J, Zhao YX, Shen L (2016d) Investigation of dynamic crack coalescence using a gypsum-like 3D printing material. Rock Mech Rock Eng 49:3983–3998

Jiang Q, Liu X, Yan F, Yang Y, Xu D, Feng G (2021) Failure performance of 3DP physical twin-tunnel model and corresponding safety factor evaluation. Rock Mech Rock Eng 54:109–128. https://doi.org/10.1007/s00603-020-02244-7

Jiang LS, Wu XY, Wang QW, Feng H, Wu QH (2022) Dynamic mechanical behaviors of sand-powder 3D printing rock-like specimens under coupled static and dynamic loads. J China Coal Soc 47:1196–1207

Jin AB, Wang SL, Wang BX, Sun H, Chen SJ, Zhu DF (2020) Fracture mechanism of specimens with 3D printing cross joint based on DIC technology. Rock Soil Mech 41:3862–3872

Ju Y, Xie H, Zheng Z, Lu J, Mao L, Gao F, Peng R (2014) Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin Sci Bull 59:5354–5365. https://doi.org/10.1007/s11434-014-0579-9

Ju Y, Zheng Z, Xie H, Lu J, Wang L, He K (2017a) Experimental visualisation methods for three-dimensional stress fields of porous solids. Exp Tech 41:331–344

Ju Y, Wang L, Xie H, Ma G, Mao L, Zheng Z, Lu J (2017b) Visualization of the three-dimensional structure and stress field of aggregated concrete materials through 3D printing and frozen-stress techniques. Constr Build Mater 143:121–137

Ju Y, Ren Z, Li X, Wang Y, Mao L, Chiang FP (2019) Quantification of hidden whole-field stress inside porous geomaterials via three-dimensional printing and photoelastic testing methods. J Geophys Res Solid Earth 124:5408–5426

Ju Y, Ren Z, Zheng J, Gao F, Mao L, Chiang FP, Xie H (2020a) Quantitative visualization methods for continuous evolution of three-dimensional discontinuous structures and stress field in subsurface rock mass induced by excavation and construction—an overview. Eng Geol 265:105443

Ju Y, Wan C, Ren Z, Mao L, Fu G, Chiang FP (2020b) Quantification of continuous evolution of full-field stress associated with shear deformation of faults using three-dimensional printing and phase-shifting methods. Int J Rock Mech Min Sci 126:104187

Kim DH, Gratchev I, Hein M, Balasubramaniam A (2016) The application of normal stress reduction function in tilt tests for different block shapes. Rock Mech Rock Eng 49:3041–3054. https://doi.org/10.1007/s00603-016-0989-x

Kong L, Ostadhassan M, Liu B, Li C, Liu K (2019a) Multifractal characteristics of MIP-based pore size distribution of 3D-printed powder-based rocks: a study of post-processing effect. Transp Porous Media 129:599–618

Kong L, Ostadhassan M, Zamiran S, Liu B, Li C, Marino GG (2019b) Geomechanical upscaling methods: comparison and verification via 3D printing. Energies 12:382

Lee CS, Kim SG, Kim HJ, Ahn SH (2007) Measurement of anisotropic compressive strength of rapid prototyping parts. J Mater Process Tech 187:627–630

Liu QS, He F, Deng PH, Tian YC (2019) Application of 3D printing technology in physical modelling in rock mechanics. Rock Soil Mech 40:3397–3404

Merlini D, Stocker D, Falanesca M, Schuerch R (2018) The ceneri base tunnel: construction experience with the southern portion of the flat railway line crossing the swiss alps. Engineering 4:235–248

Osinga S, Zambrano-Narvaez G, Chalaturnyk RJ (2015) Study of geomechanical properties of 3D printed sandstone analogue. In: 49th US rock mechanics/geomechanics symposium. OnePetro

Owen D, Hickey J, Cusson A, Ayeni OI, Rhoades J, Deng Y, Zhang Y, Wu L, Park H-Y, Hawaldar N, Raikar PP, Jung Y-G, Zhang J (2018) 3D printing of ceramic components using a customized 3D ceramic printer. Prog Addit Manuf 3:3–9

Perras MA, Vogler D (2019) Compressive and tensile behavior of 3D-printed and natural sandstones. Transp Porous Media 129:559–581

Plasencia N, Carvalho JM, Cavaco T (2015) Groundwater monitoring impacts of deep excavations: hydrogeology in the Venda Nova repowering schemes (NW Portugal). Environ Earth Sci 73:2981–2995

Primkulov B, Chalaturnyk J, Chalaturnyk R, Zambrano Narvaez G (2017) 3D printed sandstone strength: curing of furfuryl alcohol resin-based sandstones. 3D Print Addit Manuf 4:149–156

Qi FF, Zhang K, Xie JB (2021) Fracturing mechanism of rock-like specimens with different joint densities based on DIC technology. Rock Soil Mech 42:1669–1680

Rankin TM, Giovinco NA, Cucher DJ, Watts G, Hurwitz B, Armstrong DG (2014) Three-dimensional printing surgical instruments: are we there yet? J Surg Res 189:193–197

Sainoki A, Mitri HS, Chinnasane D, Schwartzkopff AK (2019) Quantitative energy-based evaluation of the intensity of mining-induced seismic activity in a fractured rock mass. Rock Mech Rock Eng 52:4651–4667. https://doi.org/10.1007/s00603-019-01861-1

Sharafisafa M, Shen L (2020) Experimental investigation of dynamic fracture patterns of 3D printed rock-like material under impact with digital image correlation. Rock Mech Rock Eng 53:3589–3607

Sharafisafa M, Shen L, Xu Q (2018) Characterisation of mechanical behaviour of 3D printed rock-like material with digital image correlation. Int J Rock Mech Min Sci 112:122–138

Sharafisafa M, Shen L, Zheng Y, Xiao J (2019) The effect of flaw filling material on the compressive behaviour of 3D printed rock-like discs. Int J Rock Mech Min Sci 117:105–117

Sharafisafa M, Aliabadian Z, Tahmasebinia F, Shen L (2021) A comparative study on the crack development in rock-like specimens containing unfilled and filled flaws. Eng Fract Mech 241:107405

Sharifzadeh M, Tarifard A, Moridi MA (2013) Time-dependent behavior of tunnel lining in weak rock mass based on displacement back analysis method. Tunn Undergr Space Technol 38:348–356

Shen M, Qin W, Xing B, Zhao W, Gao S, Sun Y, Zhao Z (2021) Mechanical properties of 3D printed ceramic cellular materials with triply periodic minimal surface architectures. J Eur Ceram Soc 41:1481–1489

Singh S, Ramakrishna S, Singh R (2017) Material issues in additive manufacturing: a review. J Manuf Process 25:185–200

Song LB, Jiang Q, Shi YE, Feng XT, Li Y, Su F, Liu C (2018) Feasibility investigation of 3D printing technology for geotechnical physical models: study of tunnels. Rock Mech Rock Eng 51:2617–2637. https://doi.org/10.1007/s00603-018-1504-3

Squelch A (2018) 3D printing rocks for geo-educational, technical, and hobbyist pursuits. Geosphere 14:360–366

Suwansawat S, Einstein HH (2007) Describing settlement troughs over twin tunnels using a superposition technique. J Geotech Geoenviron Eng 133:445–468

Suzuki A, Watanabe N, Li K, Horne RN (2017) Fracture network created by 3-D printer and its validation using CT images. Water Resour Res 53:6330–6339

Tezuka M, Seoka T (2003) Latest technology of underground rock cavern excavation in Japan. Tunn Undergr Space Technol 18:127–144

Tian W, Han N (2017a) Preliminary research on mechanical properties of 3D printed rock structures. Geotech Test J 40:483–493

Tian W, Han NV (2017b) Mechanical properties of rock specimens containing pre-existing flaws with 3 D printed materials. Strain 53:e12240

Tymrak BM, Kreiger M, Pearce JM (2014) Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater Des 58:242–246

Vogler D, Walsh SD, Dombrovski E, Perras MA (2017) A comparison of tensile failure in 3D-printed and natural sandstone. Eng Geol 226:221–235

Wang CL, Qi SW (2018) Application and prospect of 3D printing for rock mechanics. Prog Geophys 33:842–849

Wang PT, Liu Y, Zhang L, Huang ZJ, Cai MF (2018) Preliminary experimental study on uniaxial compressive properties of 3D printed fractured rock models. Chin J Rock Mech Eng 37:364–373

Wu Z, Zhang B, Weng L, Liu Q, Wong LNY (2020) A new way to replicate the highly stressed soft rock: 3D printing exploration. Rock Mech Rock Eng 53:467–476

Wu H, Ju Y, Han X, Ren ZY, Sun Y, Zhang YL, Han TY (2022) Size effects in the uniaxial compressive properties of 3D printed models of rocks: an experimental investigation. Int J Coal Sci Technol 9(1):83. https://doi.org/10.1007/s40789-022-00556-3

Xia Y, Meng Q, Zhang C, Liu N, Zhao Z, Chen J, Yang G (2021) Application of 3D Printing Technology in the Mechanical Testing of Complex Structural Rock Masses. Geofluids 7278131

Xiong ZQ, Jiang Q, Gong YH, Song LB, Cui J (2015) A method for preparing natural joints of rock mass based on 3D scanning and printing techniques and its experimental validation. Rock Soil Mech 36:1557–1565

Xu Q, Jiang L, Ma C, Niu Q, Wang X (2021) Effect of layer thickness on the physical and mechanical properties of sand-powder 3D printing specimens. Front Earth Sci 9:1112

Yang SQ, Chen M, Jing HW, Chen KF, Meng B (2017) A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng Geol 217:89–101

Zhang QY, Duan K, Jiao YY, Xiang W (2017) Physical model test and numerical simulation for the stability analysis of deep gas storage cavern group located in bedded rock salt formation. Int J Rock Mech Min Sci 94:43–54

Zhao K, Wang HL, Xu WY, Xia J (2017) Experimental study on seepage characteristics of rock-like materials with consecutive and filling fractures. Chin J Geotech Eng 39:1130–1136

Zhao JJ, Zhang Y, Ranjith PG (2020) Numerical modelling of blast-induced fractures in coal masses under high in-situ stresses. Eng Fract Mech 225:106749

Zhou T, Zhu JB (2016) Application of 3D printing and micro-CT scan to rock dynamics. In: Li H, Li J, Zhang Q, Zhao J (eds) Rock dynamics: from research to engineering, 2nd international conference on rock dynamics and applications, Suzhou 2016, p 247

Zhou T, Zhu J (2017) An experimental investigation of tensile fracturing behavior of natural and artificial rocks in static and dynamic Brazilian disc tests. Procedia Eng 191:992–998

Zhou T, Zhu JB (2018) Identification of a suitable 3D printing material for mimicking brittle and hard rocks and its brittleness enhancements. Rock Mech Rock Eng 51:765–777. https://doi.org/10.1007/s00603-017-1335-7

Zhu JB, Zhou T, Liao ZY, Sun L, Li XB, Chen R (2018) Replication of internal defects and investigation of mechanical and fracture behaviour of rock using 3D printing and 3D numerical methods in combination with X-ray computerized tomography. Int J Rock Mech Min Sci 106:198–212

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (52074166) and Shandong Province (ZR2021YQ38), and the Open Grant of State Key Laboratory of Mining Response and Disaster Prevention and Control in Deep Coal Mines (SKLMRDPC20KF02).

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Niu, Q., Jiang, L., Li, C. et al. Application and prospects of 3D printing in physical experiments of rock mass mechanics and engineering: materials, methodologies and models. Int J Coal Sci Technol 10, 5 (2023). https://doi.org/10.1007/s40789-023-00567-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-023-00567-8