Abstract

Geotechnical monitoring currently plays a key role in the research of the processes taking place in the ground medium and preventing hazardous events. In the case of open-pit mining, several solutions are commonly used to monitor various geotechnical parameters. However, geotechnical situation is usually assessed based on recorded values of deep and surface displacement, which allow to accurately predict landslides. The measurements are most often carried out manually, which, due to the difficult terrain conditions in the case of open-pit mining, are often timeconsuming and complicated, especially taking into account dangerous landslide movements. Therefore, in order to ensure a higher degree of safety against the risk of landslides, modern solutions are required in the field of geotechnical monitoring. This article presents modern automatic measurement techniques, compares various solutions available on the market and illustrates the benefits of their application in open-pit mining. It also discusses the expansion and modernization of the control and measurement network at KWB Turów, carried out in recent years, as well as the observational method for controlling the efficiency of stackers, developed after the installation of automated measuring stations, with its impact on the geotechnical safety of an internal waste heap. The paper as a case study presents, what a modern and effective geotechnical monitoring system should look like, which in practice will ensure continuous observation of selected parameters and enable a quick response in the event of a landslide threat. Last but not least, the author focuses on the creation of an innovative landslide early warning system, implemented at KWB Turów.

Similar content being viewed by others

1 Introduction

Monitoring is the process of systematic collection of data obtained by means of observation and measurement for further processing and analysis of the results. Careful examination and proper interpretation of the results enables an assessment of the variability of the recorded parameters. The observation of selected parameters (the so-called hazard precursors) is an important element of risk management in open-pit mines (Severin et al. 2014; Mazzanti 2012; Carri et al. 2021).

The use of various types of measurements is mainly aimed at optimising the mining processes, protection of the environment and prevention of dangerous situations. What is of particular importance is the monitoring of natural hazards, as it is often the only way to prevent disasters threatening human life and health. In open-pit mining, one of the greatest dangers are landslides. Hence, it is necessary to continuously monitor the ground base by assessing deformation dynamics and identifying the resulting processes.

In Polish open-pit lignite mines, geotechnical monitoring is often based on manual measurements which provide data with fairly low frequency. In recent years, however, as a result of technological advancement, the Polish mining industry has been implementing more and more innovative automatic measurement equipment that transmits the results remotely for analysis. After being sent to appropriate entities, measurement data is used to assess the geotechnical situation and to take appropriate engineering measures to prevent the risk of landslides. By providing large amounts of data measured at numerous stations in near real time, geotechnical monitoring also plays a key role in the identification of correlations between parameters describing deformation of the ground substrate. It is also an indispensable element in the implementation of landslide hazard warning systems, which inform about dangers at an early stage, thus allowing to take appropriate actions in time. At present, in a large number of open-pit mines around the world, slope stability monitoring systems are based on the integration of different measurement instruments (Carla et al. 2017b).

Technological advancements in the field of monitoring have led to the development of numerous innovative solutions used to control slope stability. Cutting-edge monitoring methods based on 3D laser scanners, GNSS, optical fibre sensors, InSAR, deep displacement sensors based on electromagnetic induction and unmanned aerial vehicles UAVs, etc. are used in mining areas (Shentu et al. 2011; Shentu et al. 2012; Liu et al. 2015; Ren et al. 2019; Xiao et al. 2019; Silva et al. 2021; Minardo et al. 2021).

2 Geotechnical monitoring at KWB Turów

The Lignite Mine in Turów (KWB Turów) is characterised by a complex geological structure of the heap substrate and difficult management conditions of overburden, consisting mainly of clay soils. The loss of slope stability is the greatest danger for open-pit mines and affects most of the works carried out at mining sites (Masoudian et al. 2019). At KWB Turów, geotechnical control concerns mainly the internal heap, which is particularly prone to landslides. The geotechnical situation is assessed based on monitoring of 3 parameters: (1) Surface displacements; (2) Deep displacement; (3) Pore water pressure.

The conventional methods of monitoring surface displacement are based on precise measurements taken with such geodetic devices as total stations and GPS (Brunner et al. 2007).

The most common method for controlling slope stability and determining potential slip area on the slopes of open-pit mines is the measurement of deep displacement (Hongze et al. 2020) with inclinometer columns, which take the form of a long duct placed vertically or diagonally in the ground. As a result of displacement of the ground layers, the inclinometer column is deformed and deflected from its original state. The purpose of the monitoring is to detect the direction and magnitude of ground displacement at particular depths, as well as the speed of deformation over time.

The pore pressure of water is one of the precursors of landslide hazard. Its value allows to estimate tension in the ground. This, in turn, allows to predict landslide movements. Sudden fluctuations of that value at the depth of the potential slip surface may indicate a rapid deterioration of slope stability.

Similar geotechnical monitoring systems are used at the Żelazny Most Reservoir and Bełchatów Open Pit Mine, where both manual and automatic measurements are used. As in KWB Turów, the control and measurement equipment consists of inclinometers, open piezometers and surface benchmarks, however, due to the specificity, both sites feature additional seismic monitoring, while KWB Bełchatów does not use pore pressure sensors (Stefanek and Romaniuk 2015; Świdźiński et al. 2015; Świdźiński and Janicki 2016; Bednarczyk 2018).

3 Manual measurement techniques used in KWB Turów

For many years, the ongoing monitoring of the geotechnical situation at KWB Turów was based exclusively on data provided by manual (direct, non-automated) measurements of selected geotechnical parameters.

Direct measurement of surface displacement is carried out with the use of various types of geodetic devices, most often GPS receivers and total stations, as well as control objects, i.e. measurement points dispersed in the field. Monitoring consists in cyclic control of changes in location of these objects which move along with the top layer of soil in the event of surface deformation of slopes. Manual measurement of surface deformations requires a team of people to operate geodetic tools. Portable devices are transported to the surface benchmark, where the surveyor takes the measurement. In this method, the control point may be a steel rod partially buried in the ground.

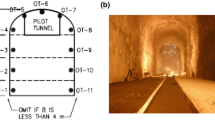

Manual monitoring of deep deformations makes use of inclinometer tubes with special grooves (Fig. 1a) and measurement kits, consisting of an inclinometer probe, thick cable and an implicator (Fig. 1b). The one metre or half metre long probe is equipped with sensors registering deviations from the vertical position and guide wheels ensuring smooth insertion of the probe into the tubes. Before taking measurement, the tool is connected via a cable to the datalogger. The probe is inserted into the column made of the tubes so as to allow the guide wheels to travel down the column along the grooves. After the activation of the datalogger, the tool is then gradually pulled out of the column, in one or half metre increments, depending on the length of the probe. While one member of the team pulls the probe out, causing the tool to move upwards, another one measures the tool's deviation relative to the vertical position. The measured data is recorded. Once the probe has been fully pulled out from the opening it is rotated 180° along its axis and re-inserted into the column. A second measurement of deviation is taken in the opposite direction relative to the first measurement. Its purpose is to compensate for measurement errors resulting from imperfections in the structure of the sensors. For interpretation of the data, the arithmetic mean of probe deviation at the considered depth from both measurements is taken into account. Based on the obtained results, deep displacement diagrams in the selected direction, as well as a diagram of deformation speed relative to previous measurements are prepared.

Manual measurement of pore pressure of water is made in an open system by means of a vibrating string sensor placed inside the well. A membrane is placed at the bottom of the opening. The membrane becomes deformed as the pressure exerted on it increases. The string attached to it changes its tension depending on how the membrane is deformed. The measurement is made with a datalogger connected to the cables at the surface of the opening, which reads the frequency of vibrations of the string. Based on that, the pore pressure of the water is then calculated.

Each manual measurement of any geotechnical parameter required involvement of the measurement team, travelling to the measurement site, conducting the survey, going back and processing the results. Due to the time required for taking measurement and size of the Turów Mine, the whole process for a single station usually took from 1.5 to 3.0 h. In the event of difficult weather and field conditions, access to the measurement site could take longer or even be impossible. In order to properly assess the geotechnical situation of a given region, it was usually necessary to examine changes of various parameters at several measuring stations, which necessitated involvement of several teams and entailed longer waiting time for the results.

4 Automatic measurement techniques used in KWB Turów

Works on the development and modernisation of the geotechnical monitoring system, including installation of automatic sensors for geotechnical parameters, are currently underway at KWB Turów. Almost all automated measuring stations are located in the area of the internal dump, as this region is particularly prone to deformations and must be constantly monitored.

Currently, in the area of the dump of KWB Turów there are: (1) 12 automatic inclinometers; (2) 96 surface benchmarks of the GeoMoS system operated by 4 measuring containers; (3) 27 water pore pressure stations equipped in total with over 50 sensors.

The locations of measuring stations on a fragment of mine map are shown in Fig. 2.

Additional measuring stations are installed every year, and thus the system is constantly being developed. At present, the automated monitoring network covers about 85% of the area of the internal dump. Manual measurements are taken in non-critical areas of the mine, as well as in special cases. The Lignite Mine in Turów plans to fully automate the geotechnical monitoring system by 2030.

Section 4.1–4.3 discussed individual automatic measurement techniques used at KWB Turów.

4.1 Automatic surface displacement monitoring

Automatic monitoring of upper soil layer displacement may be based on various solutions using, for example, radar interferometry, satellite images, terrestrial 3D laser scanning as well as software for remote activation and operation of geodetic devices. Their task is to analyse spatial ground displacement over a large area with high accuracy, in accordance with the adopted survey programme.

Monitoring of surface displacement at KWB Turów is currently based on the GeoMoS system developed by Leica. The software enables the creation of a monitoring network and integration of numerous devices and other software. GeoMoS can be adjusted to individual needs of the users, thanks to different personalisation packages and survey programmes.

Due to the large area of the Turów Coal Mine, GeoMoS is used exclusively for the monitoring of surface displacement. The measurement network includes total stations installed inside measurement containers and surface benchmarks in the form of long steel poles equipped with geodesic mirrors. The containers are usually installed on permanent slopes, so as to ensure good visibility for the device. The total station is connected to a battery, which guarantees continuous operation for weeks. The interior of a measuring container is shown in Fig. 3a. Benchmarks are partially buried in the ground and rotated so that the mirror faces the measuring container. Control points are placed, as far as possible, at regular intervals, in areas where displacement is monitored. A surface benchmark is shown in Fig. 3b.

When creating the system, a survey programme is prepared with determined parameters for performing measurements, such as measurement frequency for particular benchmarks and values of alarm thresholds. The total stations are automatically activated, oriented in relation to the geodetic control network and rotated in the direction of the point to be measured. Then a stream of several dozen laser beams is emitted, which—after hitting a mirror—is reflected back to the device. On the basis of the time required for the beam to return to the device, the distance between the container and the pole (mirror) is determined, which, combined with the known measurement direction, enables the software to calculate the location of the measurement point. The measurement results are then transmitted online to a database. Comparison with previous data allows the software to determine the change of location of the measurement points in both horizontal and vertical directions.

KWB Turów currently uses the Leica GeoMoS Now! application for data analysis, which allows for easy visualisation of the results in several ways, including as vectors on a reference map of the mine, in the form of tables and graphs. This facilitates interpretation of results and reduces response time to potential hazards. By analysing the direction and magnitude of displacement of individual points, it is possible to determine the impact of natural processes and conducted works on surface deformation. The cloud-based GeoMoS Now! software enables easy access to data, at any time, on any device. An example of visualisation of results in the GeoMoS Now! application is presented in Fig. 4.

The GeoMoS system automatically verifies the accuracy of the data read, filters out errors and performs additional measurements to ensure the highest possible accuracy. In the event of a significant displacement of a point, exceeding a preset alarm threshold, the software sends e-mail reports to the relevant mine authorities, allowing them to undertake appropriate measures immediately in order to prevent possible danger.

The application of the surface displacement monitoring system based on automatic measurements is limited to weather conditions. In the event of precipitation or fog, the laser beam is not able to determine the change in the location of the control points. Strong gusts of wind are also a frequent source of measurement errors.

4.2 Automatic subsurface displacement monitoring

Most commercially available solutions for deep displacement monitoring are based on special probes permanently installed along the entire length of the inclinometer columns. These devices take the form of long cables made up of measuring and blank segments of various lengths, usually 0.5 m or 1 m. The measuring rods are equipped with tilt sensors and allow to monitor deformation of the inclinometer column along the segments of the probe with sensors. The blind segments are not equipped with any measuring devices, but their task is to fill in the remaining sections of the inclinometer column for which there is no need to monitor deep deformations. The use of segments with no sensors reduces the cost of the entire set. The measuring probes are cemented inside the tubes, which ensures continuous contact of the measuring segments with the deforming inclinometer column and guarantees accurate measurements.

Due to relatively large deep displacement in the area of the internal heap of KWB Turów and frequent shearing of the inclinometer columns, it was necessary to apply solutions that do not require cementing the measuring kit inside the tubes. Therefore, it was decided to use SAAV measuring probes by Measurand, in the form of a flexible cable, composed of one metre or half-metre long blind or measuring segments. This solution is characterised by an innovative assembly system, which consists in inserting the cable in a zigzag pattern, so that the joints between the segments touch the tube wall.

Within the internal heap of KWB Turów, the average length of an inclinometer is approximately 100 m. Automatic measuring kits usually consist of two blank segments and one measuring segment. The blank segments are not equipped with sensors and are placed at the bottom and top of the column. Their purpose is to extend the length of the kit at the lowest possible cost. The measuring segments are placed at critical points where ground movement is most frequent. An average automatic inclinometer is 100 m long and is equipped with sensor rods of a total length of 50 m. Along with progressing works and in order to monitor deep deformations more accurately, increasingly often kits consisting only of measuring segments are installed at KWB Turów.

Remote measurements require a datalogger, which is connected to a probe outside the inclinometer column casing. The datalogger is used to activate the measuring devices and carry out the measurement in accordance with a predetermined frequency. The inclination of each sensor inside the measuring segment is measured, which allows to determine the position of the inclinometer cable. The data measured is sent by the datalogger via the cellular network to a server, from where it can be downloaded for analysis. SAASuite enables comparing measurement data over a long period of time by plotting 2D and 3D cumulative displacement, as well as displacement in time at selected elevations. Visualisation of deep displacement at selected depths facilitates quick identification of slip surfaces, as well as allows to determine the trend, direction and speed of deformation. An example of graphic interpretation of cumulative displacement with respect to X and Y axes is presented in Fig. 5.

A significant advantage of the solution applied at KWB Turów is simplicity of installation of the measuring devices and possibility of extending the inclinometer column along with the progress of mining works. Extension of the measuring kit is possible by disconnecting the spring box, inserting an additional segment of the inclinometer tube along with several blind rods and reinstalling the upper section. No auxiliary equipment is required for this purpose. The technology used for extending the inclinometer column is shown in Fig. 6. The possibility of removal of the measuring tools from the opening is helpful in situations, when large displacements are observed, posing a threat of shearing the column and destroying the measuring probe. It also makes it possible to transfer the measuring tools to another column, where greater measurement frequency is required.

SAAV probes have no protruding elements and do not need guide grooves for installation. For this reason, they can be installed in any tube with a diameter between 50 and 100 mm. Based on practical experience with the use of this solution in difficult conditions, it was found that it can be used even in sharply curved tubes, for which it is not possible to perform measurements manually, thus extending the service life of the inclinometer column.

The system is highly susceptible to measurement errors in the event of improper installation of the probe inside the inclinometer column. The registration of depth displacements is possible only when the joints of the measuring segments adhere exactly to the tube wall.

4.3 Automatic pore water pressure monitoring

Automatic measurement of pore water pressure is based on measuring stations, which perform the measurements remotely and transmit the data wirelessly for interpretation.

Monitoring of pore water pressure at KWB Turów is modernised by installation of field measuring stations, consisting of a datalogger and sensors installed at selected depths. A schematic diagram of the measuring station is presented in Fig. 7a. The dataloggers are placed inside the connection head, on the surface. Its purpose is to protect the device from damage and facilitate extension of the measuring station along with the progress of the heap front. Currently, LS-G6-VW dataloggers by World Sensing are used within the internal heap of KWB Turów. They allow to perform measurements remotely and transmit data according to a predetermined frequency. Up to 5 sensors by any manufacturer can be connected to each datalogger via cables. Due to their design and small size, Geosense's VWP-3400 and Glötzl's PP4 RS VW sensors were selected. The sensors have a conical structure similar to that used for CPTu sounding and are equipped with membranes and transducers with a vibrating string. A diagram of the sensor is shown in Fig. 7b.

The water pressure exerted on the sensor causes the membrane to deform and thus changes the tension of the string attached to it. The transducer reads the frequency of the string vibration and uses it to calculate the pressure in the ground medium and the temperature at a given depth. The data is sent to a datalogger, which transmits it via a cellular network to the relevant mine server.

The Loadsensing Data Server application is used for analysing the results. It allows to download the data and visualise it in the form of a graph showing the pore pressure of water at a given time. Graphical analysis of the results facilitates quick interpretation of the pressure changes trend, which allows for early detection and prevention of hazards. An example of a graph plotted by the Loadsensing Data Server application is presented in Fig. 8.

The pore water pressure sensors are installed at a selected depth of the ground in a closed system. Due to the conical structure of the tools, they can be installed by pressing them in, without the need for drilling holes. At KWB Turów, pore water pressure sensors are inserted into the ground by means of a CPTu static sounding device. The measuring devices are pressed to a given depth using a rod and a special cap. The process significantly reduces the total time and cost of installation of the measuring stations.

The limitation of the system is the difficulty in assessing the impact of the pore pressure change on the geotechnical situation. Under the conditions of an opencast mine, it is not possible to accurately determine the state of stress inside the heap, because its structure is basically random. At the moment, unlike deep and surface displacements, the pore pressure change does not directly translate into deterioration of the stability conditions. The system is additionally very sensitive to breaking of the connection cables during the placement of the embankment soil.

5 Early warning system

The implementation of modern measuring technologies involves innovative solutions in the field of early warning systems. Automatic measurements, carried out with increased frequency, allow for continuous monitoring of specific parameters informing about deformation processes taking place in the heap. This allows to create a system that, based on the predetermined alarm thresholds, detects a hazard and signals it to the relevant authorities. On the basis of the information received, preventive measures are taken to ensure safety. Early detection of precursors of slope deformation that may lead to loss of slope stability in the future is one of the ways to control and reduce the risk of landslides (Liu et al. 2015; Carla et al. 2017a, 2017b; Minardo et al. 2021).

At KWB Turów, the early warning system is based on an observation method for controlling the capacity of the stacker. Currently, works are in progress to develop an innovative early warning system, which is expected to be implemented in 2022. Both solutions are based on data provided by automatic measuring stations for surface displacement, deep deformation and pore water pressure.

Sections 5.1 and 5.2 described both systems.

5.1 Observation method

The observation method is one of the ways of detecting landslide precursors (Bonazzo et al. 2017). It consists in conducting measurements of selected parameters at specific intervals and then comparing the values with predetermined alarm and critical thresholds.

Based on the conducted observations, decisions are made concerning the operation of the stacker—suspension of works in case the critical value is exceeded; reduction of the machine capacity in case the alarm value is reached; or maintaining the capacity of the stacker if the values are below the warning (threshold) level. Geotechnical observations allow to reduce the risk of loss of slope stability, limit possible damages caused by landslides, while at the same time ensuring optimal capacity of the stacker. Determination of warning (threshold) values for individual geotechnical parameters and development of appropriate procedures in case those values are exceeded requires years of experience and considerable knowledge on the behaviour of the ground medium.

The observation method can be illustrated schematically as shown in Fig. 9.

The procedure of the observation method for the control of stacker capacity (Bąk and Bagińska 2022)

The technological advancement in the field of monitoring has expanded the possibilities of using geotechnical observations to control the processes taking place in the ground medium (Spross and Johansson 2017). The observation method has so far ensured safe operation of stackers, while maintaining the highest possible operational capacity.

5.2 Innovative early warning system against geotechnical threats

The innovative early warning system is a pioneering solution implemented at KWB Turów, which combines different geotechnical monitoring systems into a whole. The system examines empirically correlations between deep deformations recorded by inclinometers, surface displacement recorded by the GeoMoS system, as well as changes in pore water pressure indicated by automatic sensors. This allows for a comprehensive assessment of the stress in the ground medium of the heap.

In order to study the correlations between deformation and pore pressure, 3 types of thresholds (warning, alarm and critical) were established as benchmarks for comparing the measured data. The purpose of the first threshold is to draw attention to the increased values of particular parameters. Once the alarm threshold is exceeded, it is necessary to take appropriate actions, e.g. limit the capacity of the machines and increase the frequency of measurements. When the critical value is exceeded, an evacuation of the stacker should be initiated.

Based on data analysis, it was found that often stacking works carried out in the vicinity of the measuring stations lead to temporary exceeding of the threshold values, which does not pose a threat to the loss of stability. For this reason, special calculation algorithms were developed, which set different threshold values for individual monitoring systems, depending on the distance of the measuring devices from the stacker.

An additional functionality of the system is the possibility of visualisation of the values recorded by individual measuring stations on a reference map of the mine. This facilitates interpretation of the results and a quick determination of the areas at risk.

A similar early warning system is used at the Żelazny Most hydrotechnical facility owned by KGHM Polska Miedź S.A. The SyZeM system collects all measurement data obtained by monitoring systems and enables quick access to them and almost immediate assessment of the safety status and the potential degree of danger of individual elements (Świdźiński and Janicki 2016).

6 Summary and conclusions

Innovative monitoring systems based on automatic measuring stations are gaining popularity due to the high frequency of measurements and the number of parameters that can be examined, as well as easier identification of cause-and-effect relationships of various phenomena (Segalini et al. 2019; Carri et al. 2021). Upgraded measuring tools allow for automatic measurements in accordance with a predetermined frequency and subsequent remote data transmission to a selected server. The implementation of innovative measurement technologies in geotechnics enables comprehensive control of selected hazard precursors and contributes to improving slope stability (Minardo et al. 2021). In this paper, modern measurement technologies used at KWB Turów, as well as their contribution to the development of landslide early warning systems were presented.

The use of the above-mentioned elements of the displacement monitoring system in the Turów Coal Mine allows for continuous control of deformations occurring on the surface as well as dangerous deep movements, which allow for a direct assessment of the geotechnical system. Due to the geological structure of the overburden, which is mainly made of clay soils with poor hydraulic conductivity, the pore pressure monitoring is a precursor to the threat, which allows for the identification of dangerous phenomena well in advance.

The experience gained during modernisation of geotechnical monitoring systems at KWB Turów allowed for comparison of manual and automatic measurement techniques. The following conclusions were drawn:

-

(1)

The use of automatic measurement techniques is one of the ways to improve geotechnical safety. The observation of selected landslide hazard precursors, such as surface and deep displacement and the trend of changes in pore water pressure, allow for ongoing control of the ground medium (Silva et al. 2021).

-

(2)

The use of networks of automatic measuring stations allows to cover a wide area with monitoring.

-

(3)

Increased frequency of measurements allows for the detection of sudden changes in the values of individual parameters, which could signal potential dangers.

-

(4)

Remote transmission of data to servers allows for easy access to data in any place and at any time, on various types of devices.

-

(5)

Automatic measurements allows for quick verification of the obtained results, which reduces the response time for taking preventive actions (Minardo et al. 2021).

-

(6)

Remote measurements and data transmission via the Internet or mobile networks eliminate the need for involvement of several measurement teams. This aspect is particularly important in open-pit mining, where difficult terrain and weather conditions often prevent or extend the time required to transport measurement tools to the station.

-

(7)

The cost of automatic measuring stations is in most cases much higher compared to older solutions based on manual techniques. Full automation of a large geotechnical monitoring system can amount to several million dollars.

-

(8)

The use of automatic measuring stations in mining allows for the development of an early warning system and significantly facilitates the analysis of the speed of changes in values of individual geotechnical parameters (Alekseev et al. 2021; Fernandez-Steeger et al. 2015).

-

(9)

Comparing the geotechnical monitoring systems used in Turów Coal Mine with those used in Żelazny Most and in Bełchatów Coal Mine, it can be noticed that the same components are used in each of them—inclinometers, surface benchmarks and open piezometers. Due to the geological structure of the deposit and overburden, mainly made of impermeable clay, in the case of KWB Turów pore pressure sensors are additionally used. The combination of these types of monitoring allows for a comprehensive assessment of the geotechnical situation and the identification of hazardous events. Contrary to the other mentioned objects, in KWB Turów, due to the lack of seismic hazard, no tremors of the rock mass are recorded.

-

(10)

Due to the quantity and quality of the installed measuring equipment, as well as the frequency, efficiency and scale of geotechnical monitoring, the innovative system used in Turów Coal Mine may be a model for other opencast mines in Poland and in the European Union.

References

Alekseev A, Shilova L, Mefedov E (2021) An approach for automatization of geotechnical monitoring in cryolithzone. In: IOP Conference series: materials science and engineering. vol 1083, p 012080

Bąk M, Bagińska I (2022) Observation method in the control of stacker capacity under landslide hazard – case study. Studia Geotechnica et Mechanica (in press)

Bednarczyk Z (2018) Nowoczesne metody monitorngu geotechnicznego w polskich kopalniach odkrywkowych węgla brunatnego. Sci Rev Eng Environ Sci 27(2):152–166. https://doi.org/10.22630/PNIKS.2018.27.2.15

Bonazzo F, Esposito C, Fantini A, Fiorucci M, Martino S, Mazzanti P, Prestininzi A, Rivellino S, Rocca A, Scarascia Mugozza G (2017) Multisensor landslide monitoring as a challenge for early warning: from process based to statistic based approaches. In: Conference: Workshop on World Landslide Forum, pp 33–39. https://doi.org/10.1007/978-3-319-53487-9_3

Brunner F, Macheiner K, Woschitz H, (2007) Monitoring of deepseated mass movements. In: Proceedings of the third international conference on structural health monitoring of inteligent infra-structure. Vancouver, pp 13–16

Carla T, Farina P, Intrieri E, Botsialas K, Casagli N (2017a) On the monitoring and early warning of brittle slope failures in hard rock masses: Examples from and open-pit mine. Eng Geol 228:71–81

Carla T, Intrieri E, Farina P, Casagli N (2017b) A new method to identify impending failure in rock slopes. Int J Rock Mech Min Sci 93(C):76–81. https://doi.org/10.1016/j.ijrmms.2017.01.015

Carri A, Valletta A, Cavalca E, Savi R, Segalini A (2021) Advantages of IoT-based getochnical monitoring systems integrating automatic procedures for data acquisition and elaboration. Sensors 21(6):2249. https://doi.org/10.3390/s21062249

Fernandez-Steeger TM, Hu H, Li C, Azzam R (2015) Wireless sensor networks and sensor fusion for early warning in engineering geology. In: Lollino G et al (eds) Engineering Geology for Society and Territory, vol 2. Springer, Cham. https://doi.org/10.1007/978-3-319-09057-3_251

Hongze Z, Dongyu W, Ming M et al (2020) Parameter inversion and location determination of evolutionary weak layer for open-pit mine slope. Int J Coal Sci Technol 7:714–724. https://doi.org/10.1007/s40789-020-00337-w

Liu S, Wang H, Huang J et al (2015) High-resolution remote sensing image-based extensive deformation-induced landslide displacement field monitoring method. Int J Coal Sci Technol 2:170–177. https://doi.org/10.1007/s40789-015-0087-9

Masoudian MS, Zevgolis IE, Deliveris AV, Marshall AM, Heron CM, Koukouzas NC (2019) Stability and characterisation of spoil heaps in European surface lignite mines: a state-of-the-art review in light of new data. Environ Earth Sci 78(16):505. https://doi.org/10.1007/s12665-019-8506-7

Mazzanti P (2012) Remote monitoring of deformation. An overview of the seven methods described in previous GINs. Geotech News 30(4):24–29

Minardo A, Zeni L, Coscetta A, Ester C, Zeni G, Damiano E, De Cristofaro M, Olivares L (2021) Distributed optical fiber sensor applications in geotechnical monitoring. Sensors 21:7514

Ren H, Zhao Y, Xiao W et al (2019) A review of UAV monitoring in mining areas: current status and future perspectives. Int J Coal Sci Technol 6:320–333. https://doi.org/10.1007/s40789-019-00264-5

Segalini A, Carri A, Valletta A, Cavalca E (2019) Internet-of-Things principles applied to geotechnical monitoring activities: The Internet of Natural Hazards (IoNH) approach. In: 3rd ICITG – International Conference on Information Technology in Geo-Engineering.

Severin J, Eberhardt E, Leoni L, Fortin S (2014) Development and application of a pseudo-3D pit slope displacement map derived from ground-based radar. Eng Geol 181:202–211

Shentu N, Zhang H, Li Q, Zhou H (2011) Research on an electromagnetic induction-based deep displacement sensor. IEEE Sens J 11(6):1504–1515. https://doi.org/10.1109/JSEN.2010.2086056

Shentu N, Zhang H, Li Q, Zhou H, Tong R, Li X (2012) A theoretical model to predict both horizontal and vertical displacement for electromagnetic induction-based deep displacement sensors. Sensors 12(1):233–259. https://doi.org/10.3390/s120100233

Silva A, Girao Sotomayor JM, Torres VFN (2021) Correlations of geotechnical monitoring data in open pit slope back-analysis—a mine case study. J South Afr Inst Min Metall 121(10):557–564

Spross J, Johansson F (2017) When is the observational method in geotechnical engineering favourable? Struct Saf 66:17–26. https://doi.org/10.1016/j.strusafe.2017.01.006

Stefanek P, Romaniuk D (2015) Zastosowanie monitoringu geotechnicznego i środowiskowego na Obiekcie Unieszkodliwiania Odpadów Wydobywczych Żelazny Most. Inżynieria Morska i Geotechnika, nr 3.

Świdziński W, Tschuschke W, Świerczyński W, Wolski W (2015) Obiekt Unieszkodliwiania Odpadów Wydobywczych “Żelazny Most” – olbrzymie wyzwanie geotechniczne. Inżynieria Morska i Geotechnika, nr 3(2015):186–193.

Świdziński W, Janicki K (2016) Dobrze rozwinięty system Monitoringu podstawą bezpiecznej eksploatacji obiektów hydrotechnicznych na przykładzie OUOW Żelazny Most. J Civ Eng Environ Archit 63(1/11/16):33–40

Xiao W, Chen J, Zhao Y et al (2019) Identify Maize chlorophyll impacted by coal mining subsidence in high groundwater table area based on UAV remote sensing. J China Coal Soc 44(1):302–313

Acknowledgements

This study is supported by the PGE GiEK S.A., KWB Turów.

Author information

Authors and Affiliations

Contributions

The author read and approved the final manuscript.

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bąk, M. The use of automatic measurement techniques in the geotechnical monitoring system of PGE GiEK S.A., KWB Turów branch. Int J Coal Sci Technol 9, 89 (2022). https://doi.org/10.1007/s40789-022-00555-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-022-00555-4