Abstract

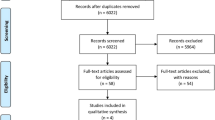

The study aimed to assess the alterations in the morphology, elemental composition, and biocompatibility of infra-zygomatic crest (IZC) miniscrews, before and after their insertion in the patient’s oral cavity. The study was conducted on 16 IZC miniscrews (8 as-received and 8 retrieved). Scanning electron microscopy (SEM) was used to evaluate the miniscrew surfaces. Micrographs were obtained at ×50, ×100, and ×500 magnification. The miniscrews were subjected to Energy-dispersive x-ray (EDX) analysis to investigate the elemental composition. It was performed at four zones of each miniscrew- head, neck, body, tip. Corrosion of the miniscrews was analyzed through the potentiodynamic polarization (PDP) test by immersing the stainless steel (SS) miniscrews in an artificial saliva medium (pH 5.8) and then allowing it to obtain a steady-state open-circuit potential (OCP) for 15 min. Gingival fibroblasts were cultured using gingival tissue which was used to check the biocompatibility of the miniscrews by observing their proliferation and viability by MTT colorimetric assay. The SEM analysis showed generalized surface dullness, variable corrosion, craters, and blunting in the retrieved miniscrews. EDX analyses showed the deposition of additional elements: carbon, oxygen, calcium, and nitrogen in the retrieved miniscrews. PDP tests showed a higher corrosion rate in the retrieved miniscrews, but the results were not significant. The MTT assay showed that the cell viability was higher in the as-received group and the results were statistically significant with a p value of 0.002. It was concluded that the retrieved miniscrews exhibited morphologic surface changes in the form of dullness, blunting of threads and tips, corrosion, craters, and cracks which were not seen in the as-received miniscrews. A higher percentage of adsorbed elements were seen on the retrieved miniscrew surface. The corrosion rate assessed through the PDP test for both groups was comparable. The fibroblast cell viability was significantly reduced in the retrieved miniscrews when compared to as-received miniscrews.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tooth movement in all three planes of space requires support in the form of anchorage to resist reactive forces. Temporary Anchorage Devices (TADs) provide absolute anchorage to carry out tooth movement [1]. A temporary anchorage device is a device that is temporarily fixed to the bone to enhance orthodontic anchorage either by supporting the teeth of the reactive unit or by obviating the need for the reactive unit altogether and which is subsequently removed after use [2].

The first attempt to place a TAD for orthodontic tooth movement can be credited to Gainsforth and Higley [3] who placed Vitallium screws in the mandibular ramus of pigs in 1945. Kanomi [4] in 1997 was the first to describe the “mini-implant” specifically designed for orthodontic applications. Nejat Erverdi et al. [5] in 2002 used skeletal anchorage plates in the zygomatic buttress area for the intrusion of the maxillary posterior teeth for correction of open bite. Over the last two decades, titanium miniscrews have gained enormous popularity in orthodontics and are often regarded as the source of absolute intraoral anchorage for clinical purposes. Recently, reports proposing a new anchorage site suitable for single miniscrew insertion for corrections in the vertical dimension have appeared in the literature: the infra-zygomatic crest (IZC). Topographically, this insertion site is located on the buccal surface of the zygomatic process of the maxilla, above the first permanent molar. [6]

An infra-zygomatic crest miniscrew will not interfere with tooth movement due to the relatively long distance from the root region. The risk of contact of the miniscrew with tooth root is also reduced. However, vital anatomic structures like the maxillary sinus can limit the placement of a miniscrew in the infra-zygomatic crest. 1 mm thickness of cortical bone is generally required for good stability and a high success rate of orthodontic miniscrews. This means that to obtain adequate primary stability, the mini-implant may have to penetrate through double cortical bone plates. [7]

The thickness of the bone in the infra-zygomatic region above the maxillary first molar is 5 to 9 mm when it is measured at 40° to 75° to the maxillary occlusal plane and 13 to 17 mm above the maxillary occlusal plane. By adopting the minimum IZC thickness for sustaining a miniscrew of 6 mm, throughout treatment and to avoid bone stripping, injury to the mesiobuccal root of the maxillary first molar, and alveolar/buccal mucosa irritation, the site for mini-screw insertion in the IZC of adults should be 14 to 16 mm above the maxillary occlusal plane and the maxillary first molar, at an angle of 55° to 70° to the maxillary occlusal plane. [3]

The extraoral location of IZC bone screws is best suited for retracting buccal segments in order to resolve crowding. It can also be successfully used for retraction and intrusion of the entire maxillary arch. The surgical procedure is a two-step process: (1) The tip of the TAD is screwed in perpendicular to the axis of the tooth, and (2) as the screw tip penetrates the cortical plate, the driver is rotated ~ 70° in the frontal plane to position the bone screw buccal to the roots of the molars. This is a novel approach that secures extraoral anchorage in the posterior region of the maxilla. The head of the miniscrew is positioned at least 5 mm above the level of the surrounding soft tissue for the facilitation of oral hygiene and the prevention of soft tissue irritation [8]. Once the required orthodontic treatment objectives have been achieved, the miniscrews are removed from the patient’s bone. [9]

A miniscrew surface can be divided into four regions- head, neck body, and tip. Out of these regions, the head and neck are constantly in contact with the oral mucosa and are subjected to saliva along with food debris, etc. It is important that the characteristics of the miniscrews including biological, structural, and mechanical properties are maintained until the miniscrew is removed from the oral cavity.

The intensive use of metallic materials in the field of orthodontics has generated an interest in clinical studies focused on the surface properties, biocompatibility, and the interactions of these metals and their detrimental effects on one’s general health. The oral environment is potentially corrosive. Resistance to the corrosive processes of orthodontic alloys is dependent on the oral environment which is under the influence of various factors, like the quality and amount of saliva, and pH of food and beverages. Orthodontic devices can lead to the release of metallic ions, which is a genuine concern. [10]

With the introduction of IZC screws, stainless steel (SS) appeared as the material of choice for achieving skeletal anchorage. SS has long been the material of choice for orthopedic applications requiring sharp self-drilling screws that are tough. SS was selected because of its toughness (resistance to fracture) for extra-oral anchorage in the posterior maxilla which has a high bone density (> 1250 HU). [10]

In long-term applications, Austenitic SS is prone to localized attack in the oral cavity due to the aggressive biologic effects. The corrosion products include iron (Fe), chromium (Cr), nickel (Ni), molybdenum (Mo), etc. Ion accumulation can occur in tissues surrounding the implant or these ions can be transported to distant parts of the body [11]. It has been demonstrated that metallic ions resulting from the in vitro corrosion of austenitic stainless steel cause alteration of expression of human lymphocyte-surface antigen and inhibit the immune response as assessed by lymphocyte proliferation [12]. Several investigations have demonstrated that metal ions can be released from metallic materials as the result of corrosion. Local adverse tissue reactions originate from the release of metal ions [13]. Studies have shown that metallic ions associated with 316L SS are toxic to osteogenic cells, and affect their proliferation and differentiation [14]. To reduce the toxic reactions coating these implants with an inert material has been suggested to improve the histopathological response and tissue reaction around the dental implants. Fathi et al. [13] conducted a study where they used three types of coatings, hydroxyapatite (HA), titanium (Ti), and double-layered HA/Ti on 316L SS miniscrews. Improvement in corrosion resistance was seen in implants that were coated with a double-layer of HA/Ti. The corrosion current densities were much lower in the coated specimens than in the uncoated and single HA-coated specimens. Ti coating also has a beneficial effect on corrosion behavior. These results demonstrated that coated stainless steel implants exhibit improved corrosion resistance and bone osteointegration. The damage by corrosion also results in a high cost for maintenance and protection of the materials used [15]. Among various methods developed for corrosion protection, the use of inhibitors is an attractive and practical method for the protection of metals in contact with corrosion medium. Inhibitors reduce the corrosion of metallic materials by controlling metal dissolution and consumption. The majority of the well-known inhibitors for the corrosion of steel in acidic medium are the organic compounds containing nitrogen, sulfur, oxygen atoms, or N-hetero cyclic compounds with polar groups. A large number of scientific studies have been devoted to the subject of corrosion inhibitors for steel in acidic media. [16,17,18,19,20]

Hameed et al. [15] conducted a study to investigate the use of Indomethacin in the form of expired drugs as a corrosion inhibitor for carbon steel in 1.0 M HCl solution using chemical and electrochemical techniques, namely, weight loss, electrochemical impedance spectroscopy (EIS), potentiodynamic polarization, and scanning electron microscopy (SEM). The results showed that expired Indocin capsules were a good inhibitor of corrosion where the inhibition efficiency reached 83% at 500 ppm of the used inhibitors.

The retrieval analyses of mini-implants provide important information regarding their behavior and performance in the oral environment. International standards have been developed for the retrieval analyses of biomaterials to assess how the materials would perform when subjected to the conditions they were intended for [21,22,23,24]. Retrieval analyses of orthodontic miniscrews can help an orthodontist in understanding the rate and causes of breakage of implants and their failure, the corrosion processes occurring on the metal surface, and the release of metal ions.

Patil et al. [6] conducted a study where they assessed the surface and elemental properties of retrieved mini-screws and their behavior after being subjected to the oral environment. Energy-dispersive x-ray analysis and scanning electron microscopy were used to assess the alterations in surface elemental composition and their surface topography. The retrieved mini-implants displayed morphological and structural changes such as overall dullness, corrosion in certain areas, and blunting of threads and tips. Several adsorbed elements like calcium were observed on the body area of the retrieved mini-implants. Eliades et al. [10] studied the morphologic, structural, and compositional changes in retrieved micro-implants. Loss of gloss from the implant surface with discoloration and morphological changes with integuments were observed in the retrieved mini-implants. Several adsorbed elements such as sodium, potassium, chlorine, iron, calcium, and phosphorus were observed on the implant surface. Masahiro Iijima et al. [25] conducted a study to investigate the degradation of titanium mini-implants in vivo. Scanning electron microscopy, microscale X-ray photoelectron spectroscopy, elastic recoil detection analysis, and nanoindentation testing was done on retrieved mini-implants. A small change in the mechanical properties of mini-implants was observed. Hydrogen absorption and formation of bone-like structures were seen on the implant surface. Mattos et al. [26] conducted a study to investigate the surface changes and fracture torque resistance of as-received, sterilized, and retrieved titanium miniscrews and the possibility of their reuse. SEM images showed worn implant surfaces and scratch marks in the retrieved implants. No major defects or corrosion were seen in the autoclaved and as-received group. It was concluded that since the torque resistance of retrieved implants is reduced and reuse is not recommended. As-received miniscrews that have undergone sterilization in an autoclave can be used clinically.

Natarajan et al. [27] compared the morphological and elemental composition changes occurring in retrieved titanium and stainless steel mini-implants. Surface alterations, such as dullness, cracks, craters, and blunting of miniscrews in both groups were observed through scanning electron microscopy. More craters were observed in the stainless steel mini-implants. When subjected to energy-dispersive X-ray spectroscopy the titanium implant group showed adsorption of O, C, Ca, and N on the surface, whereas in the stainless steel implant group only carbon and oxygen were observed.

Past studies that have been conducted on retrieved mini-implants to study the structural and mechanical properties have focused mainly on titanium implants. There is a lack of literature on IZC screws which are primarily made up of stainless steel. This study highlights and compares the changes seen in the IZC screws before and after their insertion into the oral cavity when they come in contact with soft tissues, oral fluids, and bone. Most of the retrieval studies done on orthodontic implants focus on the mechanical and structural characteristics. This study in addition to the topographical changes also highlights the biocompatibility and corrosion aspects of orthodontic miniscrews.

This study was designed to account for any changes that may occur in the surface characteristics, topography, and elemental composition of IZC miniscrews after their insertion into the oral cavity and to check if any inadequate properties may lead to corrosion processes affecting the biocompatibility of these stainless steel miniscrews.

2 Materials and Methods

The present study was performed in the Department of Orthodontics and Dentofacial Orthopaedics at Manipal College of Dental Sciences, Mangalore. Ethics committee approval was obtained from the institution before starting the study (Protocol Ref. no 18132).

The type of implant evaluated was A-1PIZC-212014 (stainless steel, diameter of 2.0 mm, thread length of 14 mm) manufactured by the same company (Bio-Ray Biotech Instrument Co., Ltd.) placed surgically by self-drilling.

The sample size was derived with 1% alpha error, 90% power of the study, and a clinically significant difference of 0.5 units based on a previous study [15]. The required sample was 8 in each group.

The sample consisted of two groups: The IZC screws retrieved after their successful use in patients who received orthodontic treatment and new IZC screws of the same type as the retrieved ones, procured from the same manufacturer.

Patients with infra-zygomatic bone thickness ranging from 5 to 9 mm in whom the IZC screws had been placed for a minimum of 5 months and a maximum of 18 months were included. Patients with systemic conditions like diabetes, a history of smoking, and bone pathologies were excluded.

Each retrieved miniscrew was gently washed with water as soon as it was removed from the patient’s oral cavity and stored in a desiccator till the tests were performed on them. The new miniscrews from the manufacturer were tested in the as-received state.

2.1 Evaluation of Surface Topography

SEM (EVO MA18 with Oxford EDS(X-act)) was used to evaluate the miniscrew surfaces. Micrographs were obtained at ×50, ×100, and ×500 magnification at four zones of each miniscrew- head, neck, body, and tip. The procedure was performed low vacuum and a 30-kV voltage with a working distance of 10 mm for the magnification of ×1000 and aperture size of 100 µm. The surface topography of the miniscrews at the four zones was studied through the micrographs. Surface changes if any such as dullness, cracks, craters, fractures, or blunting of the implant were evaluated through the micrographs.

2.2 Evaluation of Elemental Composition

The elemental composition of the miniscrews and elements adsorbed on the mini-screw surface was evaluated with EDX- Energy-dispersive X-Ray Spectroscopy (Oxford EDS [X-act]; Abingdon, Oxfordshire, UK) coupled to the SEM. It was performed at four zones of each miniscrew- head, neck, body, tip. The EDX-generated graphics were composed of chemical compounds found in the miniscrews and their respective amounts (Fig. 1).

2.3 Evaluation of Corrosion Resistance

Corrosion analysis of five miniscrews—One as-received miniscrew (labeled ‘A’) and four retrieved miniscrews (labeled ‘1’, ‘2’, ‘3’ and ‘4’) was carried out by the potentiodynamic polarization (PDP) method. Corrosion studies of SS miniscrews with a surface area of 0.3141 cm2 were carried out using an electrochemical workstation (CH604 E─series US model with beta software) and a corrosion cell connected to a personal computer. The electrochemical cell used was a conventional three-electrode compartment pyrex glass vessel with stainless steel miniscrew as the working electrode. A saturated calomel electrode was used as a reference electrode and platinum as an auxiliary electrode (Fig. 2). The potential values were recorded with respect to the reference saturated calomel electrode. To allow for electrode connection and isolation of only the IZC screws for electrochemical testing, the threaded tip of each screw was coated with nail polish and mounted in epoxy resin, thus allowing the remainder of the miniscrew towards the neck/head to be exposed to test solution. The electrical connection was established via a copper attachment designed specially to connect the screw to the copper electrode. This attachment was insulated from the test solution by a coating of nail polish. The test was performed at mouth temperature.

The potentiodynamic polarization (PDP) study was carried out by immersing the SS miniscrews in an artificial saliva medium (pH 5.8) and then allowing it to obtain a steady-state open-circuit potential (OCP) for 15 min. The working electrode was then polarized to − 250 mV cathodically and + 250 mV anodically with respect to OCP at the scan rate of 1 mV sec─1 and the plot of current vs. potential was acquired. The useful electrochemical parameters like corrosion potential (Ecorr), corrosion current density (icorr), and Tafel slopes like anodic slope (βa), and cathodic slope (−βc), were obtained from the polarization studies. [15]

2.4 Evaluation of Biocompatibility

Gingival fibroblasts were cultured using gingival tissue which was used to check the biocompatibility of the miniscrews by observing their proliferation and viability by MTT colorimetric assay. Direct contact cell culture testing was conducted following International Organization for Standardization (ISO) methods 10993-5 and 10993-12 (MTT assay Test) to most accurately resemble an in vivo situation and to evaluate the cytotoxicity of the IZC screws being investigated.

Fibroblasts were cultured in Dulbecco’s modified Eagle medium (DMEM). Cultures were incubated at 37 °C in a humidified atmosphere of 5% CO2 in the air. Cells were passaged and frozen till the cytotoxicity study. The culture vessel was trypsinized after the cells showed confluent growth and the cells were counted using Trypan blue dye exclusion method. The cells were plated around 1 × 104 cells/well in a 96-well plate (100 µl/well). They were then incubated for 24 h at 37 degrees Celsius in a CO2 incubator for the cells to attach to the culture vessel. After 18–24 h the miniscrew specimens were added to 100ul of media. A blank control and a positive control (Mitomycin) were also kept. Control specimens were defined as cell cultures with no exposure to the miniscrews. Incubation of the cells with the miniscrew specimens placed over the cell layer was done for 48 h. After 48 h MTT was added. 20 µl (5.0 mg/ml) was added to each well and incubated for 4 h in a CO2 incubator at 3degreesee Celsius for the development of insoluble formazan crystals. After 4 h of incubation, the plate was centrifuged at a speed of 3000 rpm for 10 min to spin down formazan. The supernatant was aspirated, and Dimethyl Sulfoxide (DMSO) was added to lyse the cells and solubilize the insoluble formazan crystals. A reading was taken at 570:630 dual-wavelength using an ELISA plate reader. A graph was plotted with the miniscrew specimens (on the X-axis) against the percentage of cell viability (on the Y-axis).

3 Statistical Analysis

The collected data were analyzed using SPSS version 20.0.2. The present study analyzed 2 groups (as-received and retrieved miniscrews).

Each miniscrew was studied at 4 zones (head, neck, body, and tip) under SEM and through EDX. The Independent T-test was applied to compare the EDX data between the two groups. To understand the variations, 2 types of analysis were performed: comparisons among the groups and zones. Paired t-test was used to compare the elemental composition among the four areas of the miniscrews. The Chi-square test was used for the comparison of the SEM results. One sample t-test was used to compare the corrosion rates of the as-received and retrieved miniscrews. Cell viability assessed through the MTT assay in the two groups was compared using the Independent T-test.

4 Results

4.1 Elemental Composition Analysis

In all 4 areas (Area 1-body, Area 2-tip, Area 3- neck, and Area 4-head) of the miniscrew statistically significant differences were observed between the two groups with higher weight percentages of Carbon(C), Nitrogen(N), and Oxygen(O) in the retrieved miniscrew group. In all 4 areas, the weight percentage of Ca was higher in the retrieved miniscrew group which was statistically non-significant. Statistically significant differences were observed between the two groups in all 4 areas, with a higher weight percentage of Chromium (Cr), Manganese (Mn), Iron (Fe), Nickel (Ni), and Molybdenum (Mo) in the as-received miniscrew group. (Tables 1, 2).

In the comparison of the mean values of Weight percentage of Carbon, Nitrogen, and Oxygen of Area 1 vs Area 3 and Area 4 the mean values of the weight percentage of Area 1 were higher and statistically significant. While comparing Area 2 with Area 3 and Area 4 the mean values of the weight percentage of Area 2 were higher and statistically significant. In comparison to Area 3 and Area 4, the mean values of the weight percentage of Area 4 were higher and statistically significant.

4.2 Surface Topography Analysis

SEM was performed on both as-received and retrieved miniscrews to evaluate their surfaces. A reduction in the glossy surface and surface finish was observed in all four examined areas in the retrieved miniscrew group (Fig. 3). Micrographs were obtained at ×50, ×100, and ×500 magnification at four areas of each mini-screw body, tip, neck, and head. All miniscrews in the retrieved group showed blunting of the tip (Fig. 4). This was not observed in the as-received group. No fractures were observed in any miniscrews in either of the groups. The effects of corrosion processes were evident in the retrieved group (Fig. 5).

a Threaded body of as-received miniscrew at ×50 magnification. b Threaded body of as-received miniscrew at ×100 magnification. c Threaded body of as-received miniscrew at ×500 magnification. d Threaded body of retrieved miniscrew at ×50 magnification. e Threaded body of retrieved miniscrew at ×100 magnification. f Threaded body of retrieved miniscrew at ×500 magnification

a Wear type of corrosion defect on the thread of retrieved miniscrew at ×500 magnification. b Crevice corrosion at the junction between the body and thread regions at ×50 magnification. c Crevice corrosion at the junction between the body and thread regions at ×100 magnification. d Crevice corrosion at the junction between the body and thread regions at ×500 magnification

4.3 Corrosion Analysis

The corrosion rate measurements were done by the PDP method [15]. The potentiodynamic polarization curves for corrosion of SS miniscrews in artificial saliva are shown in Fig. 6.

From the obtained plots, the electrochemical parameters like corrosion current density (icorr), anodic slope (βa), and cathodic (− βc) Tafel slopes, corrosion potential (Ecorr), and corrosion rate (CR) were obtained (Table 3). The corrosion rates for the retrieved miniscrews (labeled as ‘1’, ‘2’, ‘3’, and ‘4’) were higher than that of the as-received miniscrew (labeled as ‘A’) which suggests that retrieved miniscrews have undergone corrosion in the oral cavity of the patient. However, the results were statistically non-significant.

4.4 Biocompatibility Analysis

The viability of cells was checked by MTT colorimetric assay (Fig. 7). The as-received miniscrews were labeled as ‘A’, ‘B’, ‘C’, ‘D’, ‘E’, ‘F’, ‘G’, and ‘H’ and the retrieved miniscrews were labeled as ‘1’, ‘2’, ‘3’, ‘4’, ‘5’, ‘6’, ‘7’ and ‘8’. A comparison of the viability between the two groups showed that viability was higher in the as-received group and was statistically significant with a p-value of 0.002 (Table 4).

5 Discussion

To eliminate variability in results, IZC miniscrews of the same dimension (diameter of 2.0 mm, thread length of 14 mm) were obtained from the same manufacturer (Bio-Ray Biotech Instrument Co., Ltd.) and used in the current study.

The EDX analysis that was performed on the miniscrews showed the presence of oxygen, calcium, nitrogen, and carbon apart from the parent elements like nickel, molybdenum, chromium, and iron. (Tables 1, 2).

Higher percentages of carbon, nitrogen, and oxygen were seen in the retrieved miniscrew group when compared to the as-received group with the difference being statistically significant. A higher percentage of calcium was also seen in the retrieved miniscrew group. However, the difference was not statistically significant when compared to the as-received group. The percentages of the parent elements (nickel, molybdenum, chromium, and iron) were significantly lower in the retrieved miniscrew group.

The higher percentage of oxygen in the retrieved group could be attributed to the atmospheric oxygen exposure of the miniscrew surface during insertion/removal [2]. The higher oxygen content is proof of the oxidation process that has occurred on the implant surface which is an indication of the increased corrosion rate of the retrieved miniscrew group.

The results showed an increase in the percentage of carbon after intra-oral use. The difference in carbon content between the two groups was statistically significant, which indicates that the intra-oral usage has made the mini-screws brittle and more corrosion-prone. The source of carbon could be contamination from hydrocarbons in the atmosphere.

The retrieved miniscrews exhibited a higher percentage of nitrogen. The increased nitrogen could have been derived from chemical erosion and passivation. The presence of nitrogen on the surface implies that proteins were adsorbed from body fluids. In a study conducted by Knop et al. [2], 1.59% of nitrogen was found on a miniscrew surface. Morra et al. [28] suggested that nitrogen contamination is the result of inadequate surface treatment or implant handling (during packaging) and not due to chemical or biochemical modifications.

The source of calcium on the surface of the retrieved miniscrews could be from the contact of the miniscrew surface with blood involving mainly adsorption of proteinaceous integuments, which are calcified later with the precipitation of calcium [29]. In the present study, the percentage of calcium found on the miniscrew surface was not statistically significant. Patil et al. [6] observed a significant amount of calcium on the implant surface in their study. However, titanium implants were used in their study. This could be explained by the precipitation of calcium phosphate that occurs on the implant surface when the passive titanium oxide layer of the titanium implants reacts with the calcium phosphate present in the bone. Since in the present study stainless steel implants were used instead of titanium the precipitation of calcium on the miniscrew surface can be expected to be less when compared to titanium.

The retrieved miniscrews exhibited a decrease in the percentage of chromium. Precipitation of the carbon carbide layer causes a reduction in the chromium content. This in turn leads to a decrease in the passivating effect. Loss of passivation due to a fall in the chromium content is one of the major reasons for the increase in the corrosion rate of the retrieved miniscrews.

The percentage of other parent elements (Fe, Ni, Mo, Mn) was significantly lower in the retrieved miniscrew group. This could indicate that the leaching of elements occurs over a period of time when the miniscrew surface is exposed to the oral cavity and its associated fluids.

On comparing the four areas of the miniscrews (Body, Tip, Neck, and Head) highest percentages of adsorbed elements i.e., Carbon, Nitrogen, and Oxygen were seen in the threaded body of the miniscrew followed by the tip, head, and neck regions. Both the body and the tip of the miniscrew are inside the bone whereas the neck and the head regions are outside the bone in the oral cavity. These results indicate that more aggressive elemental changes lead to increased corrosion rates on the implant surfaces that are in contact with the bone.

The percentages of the parent elements were significantly lower in the body and tip of the miniscrews when compared to the head and neck region. This could indicate that the leaching of elements occurs over a period of time with the miniscrew inserted in the bone. Another explanation for this reduction in the parent elements in the retrieved miniscrew group could be the adsorption of other elements over the surface from the local biologic milieu leading to the masking of the percentage of parent elements. [6]

Natrajan et al. [27] studied the differences in elemental composition between the titanium and stainless steel implants. In their study, the SS mini-implant group showed only carbon and oxygen as adsorbed elements and no calcium and nitrogen. Similarly, in the present study, although a higher percentage of calcium was seen in the retrieved miniscrew group, the results were statistically non-significant. Chin et al. [30] observed traces of nitrogen, calcium, iron, chromium, copper, lead, zinc, and silicon among 5 mini-implants assessed in their study.

The SEM images revealed that all retrieved implants showed signs of debris and contaminations on their surfaces. In the retrieved miniscrews, a reduction in the glossy surface and surface finish was observed which resulted in a dull surface in all four examined areas. The insertion and removal of a miniscrew can cause some amount of surface wear (Fig. 3). The process of insertion and removal can also lead to the blunting of threads and tip of the miniscrews (less sharp thread and tip compared with the as-received screws) [31] (Fig. 6).

When the implant is being placed, it pierces the mucosa before drilling into the bone. This can cause inflammation due to the trauma experienced, causing the pH to fall. In response cells such as macrophages and polymorphonuclear granulocytes get activated and they release certain proteins, enzymes, and oxidizing agents that can further contribute to the changes seen on the miniscrew surface [32].

The main requirement for any metal that is being used in the oral cavity is biocompatibility. It should not undergo corrosion when it comes in contact with the tissues. Corrosion depends on several variables such as salivary quality and quantity, temperature and pH of the oral cavity, the properties of foods and beverages consumed, and the oral health of the patient [33]. Although stainless steel alloys are considered corrosion-resistant, they are not impervious to corrosion processes.

Corrosion can lead to the formation of wear particles. This can lead to the release of metal ions in the tissues [34]. In constricted areas between two surfaces, when a stagnant layer of solution is trapped, no oxygen exchange is possible. This leads to the process of crevice corrosion. The pH in these crevices can be as low as 2 which is highly acidic [35]. The reduced pH can further initiate and propagate the phenomenon of crevice corrosion.

In the present study, crevice-like geometric patterns were observed on threads, tips, heads, and junctions of the head-neck and neck-thread regions. This phenomenon explains why more crevice corrosion occurred in these areas of the retrieved miniscrews (Fig. 5).

A crater is a cavity or hole in a surface [36]. A crack is a line on the surface of something along which it has split without breaking apart. A fracture is the cracking or breaking of a hard object or material [37]. All retrieved implants showed signs of debris and contaminations on their surfaces. Cracks and craters were found to be significantly present in the retrieved miniscrews. Due to the extended period, the miniscrews were in the bone, which led to an increase in contact of these implants with the oral tissues and fluids subjecting them to the wear processes. The body region of the miniscrews showed more surface changes. This could be due to the increased surface contact area of the threads. The thread and the tip regions exhibited more cracks. This can be explained by the decreased thickness of material in these areas. No fractures were observed in any miniscrews in either of the groups.

These SEM results in the present study agree with the results seen in previous studies where similar changes in the surface topography of retrieved miniscrews were observed. [6, 27, 28]

Orthodontic appliances are subject to electrochemical corrosion when placed in the oral cavity. This can cause a gradual degradation of the surface material by oxidative processes leading to the release of allergic and toxic materials [34]. Corrosion processes can cause a severe reduction in the fatigue life and strength of the material causing mechanical failure of the miniscrews. [38]. The release of metal ions and corrosion products can lead to allergic reactions in extreme cases. Kasemo et al [39] in their study showed the corrosion products being dissolved into the bioliquid and adjacent tissues. Corrosion products can influence the mechanism of wound healing by impairing the activity of participating cells [40]. Olmedo et al. [38] reported that macrophages in peri-implant soft tissues induced by a corrosion process play an important role in implant failure.

In the current study, the corrosion rate measurements were done by the PDP method [15]. The potentiodynamic polarization curves for corrosion of stainless steel miniscrews in artificial saliva medium at mouth temperature were obtained.

From the obtained plots, the electrochemical parameters like corrosion current density (icorr), anodic slope (βa) and cathodic (− βc) Tafel slopes, corrosion potential (Ecorr), and corrosion rate (CR) were obtained.

The anodic curve shows the metal dissolution while the cathodic reaction is represented by the cathodic curve. The possible reduction reaction is the reduction of oxygen in a neutral medium. In addition, the anodic Tafel slope (βa) and the cathodic Tafel slope (−βc) have changed from person to person. This shows that the medium influences both the anodic and cathodic reactions taking place.

The corrosion current densities for the retrieved miniscrews were higher than that of the as-received miniscrew which suggests that the retrieved miniscrews have undergone corrosion in the oral cavity of the patient. However, the results were not statistically significant. The PDP test could be carried out only on the neck region of the miniscrew since it requires an exact surface volume calculation. The body of the miniscrew which is in contact with bone is expected to show the maximum corrosion but since it is a threaded region an accurate surface area calculation of the region was not possible and hence it was not feasible to carry out a PDP test on the body of the miniscrew. This might explain the non-significant results that were obtained.

Nascimento et al [41] studied the corrosion rates of SS and Ti anchorage devices. The SS group showed higher corrosion rates when subjected to potentiodynamic polarization tests which were similar to the results of the current study.

Biocompatibility of the as-received and retrieved miniscrews was compared using MTT Assay. In the present study, cells were selected that would represent the intra-oral adjacent to orthodontic miniscrews as closely as possible since previous studies have reported that results of cytotoxicity assays may vary with cell type [24, 42]. Hence human gingival fibroblasts were used to reflect the response of adjacent connective tissue.

The results showed that cell viability was significantly higher in the as-received group when compared to the retrieved group indicating that once the miniscrew is placed in the oral cavity it can undergo biological and chemical changes leading to increased cytotoxicity of the implant over a period of time.

According to ISO 10993-5, cytotoxicity should be assumed if a specimen reduces cell viability by > 30% (quantitative analysis) or induces decoloration in > 50% of cells and/or decoloration extending beyond the outlines of the specimen (qualitative analysis) [24]. Fibroblast viability was significantly reduced in the retrieved miniscrew group when compared to the as-received group. However, this reduction in cell viability did not exceed 30%. Thus, all findings remained well below the defined threshold and none of the miniscrews induced decoloration beyond the outlines of a specimen.

6 Limitations

-

Corrosion analysis carried out through the PDP method could only be done on the neck region of the miniscrew.

-

Only fibroblast cell cultures were subjected to viability tests. Osteoblast cells could have also been tested in addition to the gingival fibroblasts.

7 Summary and Conclusion

The retrieval analysis of the IZC miniscrews revealed the following:

-

Retrieved miniscrews exhibited morphologic surface changes in the form of dullness, blunting of threads and tips, corrosion, craters, and cracks which were not seen in the as-received miniscrews.

-

The assessment of the elemental composition of retrieved miniscrews revealed a higher percentage of adsorbed elements on the miniscrew surface in the form of carbon, nitrogen, and oxygen. The body of the miniscrews showed the maximum adsorption of elements and the neck of the miniscrew showed the least.

-

The PDP test showed a higher corrosion rate of the retrieved miniscrews than the as-received miniscrew but the difference was not statistically significant.

-

Fibroblast cell viability was significantly reduced in the retrieved miniscrews when compared to as-received miniscrews.

Data Availability

All data generated or analyzed during this study are included in this published article. Any further datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Upadhyay M, Yadav S, Nagaraj K, Nanda R (2009) Dentoskeletal and soft tissue effects of mini-implants in Class II division 1 patients. Angle Orthod 79(2):240–247

Knop LA, Soares AP, Shintcovsk RL, Martins LP, Gandini LG Jr (2015) Characterization of surface topography and chemical composition of mini-implants. Braz J Oral Sci 14:251–255

Gainsforth BL, Higley LB (1945) A study of orthodontic anchorage possibilities in basal bone. Am J Orthod Oral Surg 31(8):406–417

Kanomi R (1997) Mini-implant for orthodontic anchorage. J clin Orthod 31:763–767

Erverdi N, Keles A, Nanda R. The use of skeletal anchorage in open bite treatment: a cephalometric evaluation, vol 74, Angle Orthodontist. 2004.

Patil P, Kharbanda OP, Duggal R, Das TK, Kalyanasundaram D (2015) Surface deterioration and elemental composition of retrieved orthodontic miniscrews. Am J Orthod Dentofac Orthop 147(4):S88-100

Cope JB (2005) Temporary anchorage devices in orthodontics: a paradigm shift. Semin Orthod 11(1):3–9

Linkow IL (1970) Implanto-orthodontics. J Clin Orthod 4:685–705

Creekmore TD (1983) The possibility of skeletal anchorage. J Clin Orthod 17:266–269

Eliades T, Zinelis S, Papadopoulos MA, Eliades G (2009) Characterization of retrieved orthodontic miniscrew implants. Am J Orthod Dentofac Orthop 135(1):10.e1-10.e7

Lei MK, Zhu XM (2001) In vitro corrosion resistance of plasma source ion nitrided austenitic stainless steels. Biomaterials 22(7):641–647

Tracana RB, Sousa JP, Carvalho GS (1994) Mouse inflammatory response to stainless steel corrosion products. J Mater Sci 5(9):596–600

Fathi MH, Salehi M, Saatchi A, Mortazavi V, Moosavi SB (2003) In vitro corrosion behavior of bioceramic, metallic, and bioceramic–metallic coated stainless steel dental implants. Dent Mater 19(3):188–198

Morais S, Sousa JP, Fernandes MH, Carvalho GS, De Bruijn JD, Van Blitterswijk CA (1998) Decreased consumption of Ca and P during in vitro biomineralization and biologically induced deposition of Ni and Cr in presence of stainless steel corrosion products. J Biomed Mater Res 42(2):199–212

Abdel Hameed RS, Al-Bagawi AH, Shehata HA, Shamroukh AH, Abdallah M (2020) Corrosion inhibition and adsorption properties of some heterocyclic derivatives on C-steel surface in HCl. J Bio- Tribo Corros 6(2):1–1

Abdallah M, Al-Gorair AS, Fawzy A, Hawsawi H, Abdel Hameed RS (2022) Enhancement of adsorption and anticorrosion performance of two polymeric compounds for the corrosion of SABIC carbon steel in hydrochloric acid. J Adhes Sci Technol 36(1):35–53

Hameed RS, Al-Bonayan AM (2021) Recycling of some water soluble drugs for corrosion inhibition of steel materials: analytical and electrochemical measurements. J Optoelectron Biomed Mater 13:23–35

Alfakeer M, Abdallah M, Abdel Hameed RS (2020) Propoxylated fatty esters as safe inhibitors for corrosion of zinc in hydrochloric acid. Prot Met Phys Chem Surf 56(1):225–232

Hameed RA (2019) Schiff’bases as corrosion inhibitor for aluminum alloy in hydrochloric acid medium. Tenside Surf Deterg 56(3):209–215

Hameed RA (2018) Cationic surfactant-zn+ 2 systems as mixed corrosion inhibitors for carbon steel in a sodium chloride corrosive medium. Port Electrochim Acta 36(4):271–283

Erverdi N, Keles A, Nanda R. The use of skeletal anchorage in open bite treatment: a cephalometric evaluation, Vol 74, Angle Orthodontist. 2004. http://meridian.allenpress.com/angle-orthodontist/article-pdf/74/3/381/1372755/0003-3219

Ochsenbein C, Ross S (1969) A reevaluation of osseous surgery. Dent Clin North Am 13(1):87–102

Chugh T, Jain AK, Jaiswal RK, Mehrotra P, Mehrotra R (2013) Bone density and its importance in orthodontics. J Oral Biol Craniofac Res 3:92–97

Finke H, Koos B, Fischer-Brandies H, Es-Souni M (2018) In vitro biocompatibility of orthodontic miniscrews with human gingival fibroblast and SAOS-2 osteoblast cultures. J Orofac Orthop 79(5):328–336

Iijima M, Muguruma T, Kawaguchi M, Yasuda Y, Mizoguchi I (2015) In vivo degradation of orthodontic miniscrew implants: surface analysis of as-received and retrieved specimens. J Mater Sci 26(2):1–7

Mattos CT, Ruellas AC, Elias CN (2010) Is it possible to re-use mini-implants for orthodontic anchorage? Results of an in vitro study. Mater Res 13(4):521–525

Natarajan M, Rao KB (2017) Topographical and elemental changes of retrieved stainless steel and titanium mini-implants after orthodontic treatment. J World Fed Orthod 6(4):171–176

Morra M, Cassinelli C, Bruzzone G, Carpi A, Santi GD, Giardino R, Fini M. Surface chemistry effects of topographic modification of titanium dental implant surfaces: 1. Surface analysis. Int J Oral Maxillofac Implants. 2003;18(1).

Lu L, Park HS (2018) Surface characteristics and mechanical behavior of retrieved orthodontic micro implants. J Zhejiang Univ Sci B 19(5):372–382

Chin MYH, Sandham A, de Vries J, van der Mei HC, Busscher HJ (2007) Biofilm formation on surface characterized micro-implants for skeletal anchorage in orthodontics. Biomaterials 28(11):2032–2040

Trindade C, Carlos A, Ruellas DO, Nelson C (2010) Mattos 13(4):521–525

Eliades T, Athanasiou AE (2002) In vivo aging of orthodontic alloys: implications for corrosion potential, nickel release, and biocompatibility. Angle Orthod 72(3):222–237

Locci P, Lilli C, Marinucci L, Calvitti M, Belcastro S, Bellocchio S et al (2000) In vitro cytotoxic effects of orthodontic appliances. J Biomed Mater Res 53(5):560–567

Mikulewicz M, Chojnacka K (2011) Release of metal ions from orthodontic appliances by in vitro studies: a systematic literature review. Biol Trace Elem Res 139(3):241–256

Sato N (1989) Toward a more fundamental understanding of corrosion processes. Corrosion 45(5):354–368

Cochis A, Fini M, Carrassi A, Migliario M, Visai L, Rimondini L (2013) Effect of air polishing with glycine powder on titanium abutment surfaces. Clin Oral Implants Res 24(8):904–909

Yokoyama K, Ichikawa T, Murakami H, Miyamoto Y, Asaoka K (2002) Fracture mechanisms of retrieved titanium screw thread in dental implant. Biomaterials 23(12):2459–2465

Olmedo D, Fernández MM, Guglielmotti MB, Cabrini RL (2003) Macrophages related to dental implant failure. Implant Dent 12(1):75–80

Kasemo B (2002) Biological surface science. Surf Sci 500(1–3):656–677

Kirkpatrick CJ, Barth S, Gerdes T, Krump-Konvalinkova V, Peters K (2002) Pathomechanisms of impaired wound healing by metallic corrosion products. Mund Kiefer Gesichtschir 6(3):183–190

do Nascimento CA, Barbosa JA, Montalli VAM, Micheletti F, Milani R, Pereira V et al (2020) Corrosion and micromorphological analysis of temporary stainless steel and titanium alloy anchorage devices. J Bio- Tribo-Corrosion. 6(2):1–8

Wataha JC, Hanks CT, Sun Z (1994) Effect of cell line on in vitro metal ion cytotoxicity. Dent Mater 10(3):156–161

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal. The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

AS: conceptualization, methodology development, investigation, data curation, SS: conceptualization, methodology development, formulation of research goals, supervision. RK: methodology development, visualization. PR: resources. MP: investigation.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical Approval

The study was approved by the Institutional Ethics Committee, Manipal College of Dental Sciences, Mangalore, Manipal Academy of Higher Education (Ref. No. 18132).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Singh, A., Shetty, S., Kotian, R. et al. The Evaluation of Biocompatibility, Elemental Composition and Surface Analysis of Retrieved Infra-zygomatic Screws. J Bio Tribo Corros 8, 85 (2022). https://doi.org/10.1007/s40735-022-00673-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-022-00673-1