Abstract

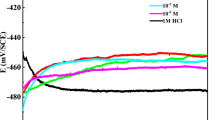

The chemical structure of a polyacrylamide (PA), synthesized by inverse emulsion polymerization, was confirmed by FTIR and 1H NMR. The experimental conditions were conducted to produce high molecular weight of 1.4 × 106 g mol−1 determined by both gel permeation chromatography and viscosity average molecular weight methods. The efficiency of PA was evaluated, on corrosion inhibition of C-steel in 1.0 M HCl solution, by means of electrochemical impedance spectroscopy, potentiodynamic polarization (PP), and mass-loss (ML) measurements, and a very good concordance was obtained from the three techniques. The inhibiting efficiency increased up to 4 × 10−6 mol L−1 and dropped down afterward. The PP curves revealed that PA was of mixed-type, influencing predominantly the anodic process. The electrochemical interface was satisfactorily modeled with the electrical circuit (RS + Qdl/Rct) using CPE(α,Q) reflecting one-time constant. This fact, testifying the dominant character of charge transfer control of the C-steel corrosion process, was well described in both Nyquist along with Bode diagrams which take into account the frequency dependence, justifying the suitable choice of the electrical circuit. The adsorption of PA involved both physical and chemical interactions of non-protonated and protonated molecules with a deeper discussion on the suitable sites of protonation. The performance of PA was maintained if not slightly ameliorated in a more aggressive medium such as 0.5 M H2SO4 at 298 K. Two-time constants were needed to model the electrochemical interface (RS + Qdl/(Rct + RL/L)).

Similar content being viewed by others

References

Kowalski D, Ueda M, Ohtsukat T (2007) The effect of counter anions on corrosion resistance of steel covered by bi-layered polypyrrole film. Corros Sci 49:3442–3452. https://doi.org/10.1016/j.corsci.2007.03.007

Jeyaprabha C, Sathiyanarayanan S, Venkatachari G (2006) Polyaniline as corrosion inhibitor for iron in acid solutions. J Appl Polym Sci 101:2144–2153. https://doi.org/10.1002/app.22579

Elbakari M, Touir R, Ebn Touhami M, Srhiri A, Benmessaoud M (2008) Electrosynthesis of adherent poly(3-amino-1,2,4-triazole) films on brass prepared in nonaqueous solvents. Corros Sci 50:1538–1545. https://doi.org/10.1016/j.corsci.2008.02.014

Lehr IL, Saidman SB (2007) Corrosion protection of iron by polypyrrole coatings electrosynthesised from a surfactant solution. Corros Sci 49:2210–2225. https://doi.org/10.1016/j.corsci.2006.10.033

Migahed MA, Aly RO, Al-Sabagh AM (2004) Impact of gamma-ray-pre-irradiation on the efficiency of corrosion inhibition of some novel polymeric surfactants. Corros Sci 46:2503–2516. https://doi.org/10.1016/j.corsci.2004.01.013

Titz T, Horzenberger F, Bergh KVD, Grundmeier G (2010) Correlation of interfacial electrode potential and corrosion resistance of plasma polymer coated galvanized steel. Part 1: ultra-thin plasma polymer films of varying thickness. Corros Sci 52:369–377. https://doi.org/10.1016/j.corsci.2009.09.024

Umoren SA, Ogbobe O, Okafor PC, Ebenso EE (2007) Polyethylene glycol and polyvinyl alcohol as corrosion inhibitors for aluminium in acidic medium. J Appl Polym Sci 105:3363–3370. https://doi.org/10.1002/app.26530

Umoren SA, Obot IB (2008) Polyvinylpyrollidone and polyacrylamide as corrosion inhibitors for mild steel in acidic medium. Surf Rev Lett 15:277–286. https://doi.org/10.1142/S0218625X08011366

Umoren SA, Lia Y, Wang FH (2010) Electrochemical study of corrosion inhibition and adsorption behaviour for pure iron by polyacrylamide in H2SO4: synergistic effect of iodide ions. Corros Sci 52:1777–1786. https://doi.org/10.1016/j.corsci.2010.01.026

Umoren SA, Solomon MM (2010) Effect of halide ions additives on the corrosion inhibition of aluminum in HCl by polyacrylamide. Arab J Sci Eng 35(2):115. https://www.researchgate.net/publication/259284202

Umoren SA, Li Y, Wang FH (2011) Influence of iron microstructure on the performance of polyacrylic acid as corrosion inhibitor in sulfuric acid solution. Corros Sci 53:1778–1785. https://doi.org/10.1016/j.corsci.2011.01.052

Chamovska D, Cvetkovska M, Grchev T (2007) Corrosion inhibition of iron in hydrochloric acid by polyacrylamide. J Serb Chem Soc 72(7):687–698

Manimaran N, Rajendran S, Manivannan M, John Mary S (2012) Corrosion inhibition of carbon steel by polyacrylamide. Res J Chem Sci 2(3):52–57. http://www.isca.in (ISSN 2231-606X)

Srivastava V, Banerjee S, Singh MM (2010) Inhibitive effect of polyacrylamide grafted with fenugreek mucilage on corrosion of mild steel in 0.5 M H2SO4 at 35 °C. J Appl Polym Sci 116(2):810–816. https://doi.org/10.1002/app.31559

Amin MA, Abd EI-Rehim SS, El-Sherbini Essam EF, Hazzazi OA, Abbas Mohsen N (2009) Polyacrylic acid as a corrosion inhibitor for aluminium in weakly alkaline solutions. Part I: weight loss, polarization, impedance EFM and EDX studies. Corros Sci 51:658–667. https://doi.org/10.1016/j.corsci.2008.12.008

Finšgar M, Fassbender S, Nicolini F, Milošev I (2009) Polyethyleneimine as a corrosion inhibitor for ASTM 420 stainless steel in near-neutral saline media. Corros Sci 51:525–533. https://doi.org/10.1016/j.corsci.2008.12.006

Gupta G, Birbilis N, Khanna (2013) Polyaniline-lignosulfonate/epoxy coating for corrosion protection of AA2024-T3. Corros Sci 67:256–267. https://doi.org/10.1016/j.corsci.2012.10.022

Arthur DE, Jonathan A, Ameh PO, Anya C (2013) A review on the assessment of polymeric materials used as corrosion inhibitor of metals and alloys. Int J Ind Chem 4:2–9. https://doi.org/10.1186/2228-5547-4-2

Saliyan, VR, Adhikari AV (2008) Inhibition of corrosion of mild steel in acid media by N′-benzylidene-3-(quinolin-4-ylthio)propanohydrazide. Bull Mater Sci 31:699–711. https://doi.org/10.1007/s12034-008-0111-4

Benabdellah M, Ousslim A, Hammouti B, Elidrissi A, Aouniti A, Dafali A, Bekkouch K, Benkaddour M (2007) The effect of poly(vinyl caprolactone-co-vinyl pyridine) and poly(vinyl imidazol-co-vinyl pyridine) on the corrosion of steel in H3PO4 media. J Appl Electrochem 37:819–826. https://doi.org/10.1007/s10800-007-9317-1

Müller LB, Schmelich T (1995) High-molecular weight styrene maleic acid copolymers as corrosion inhibitors for aluminium pigments. Corros Sci 37:877–883. https://doi.org/10.1016/0010-938X(94)00171-2

Bereket G, Yurt A, Turk H (2003) Inhibition of corrosion of low carbon steel in acidic solution by selected polyelectrolytes and polymers. Anti-Corros Methods Mater 50:422–435. https://doi.org/10.1108/00035590310501585

Shukla SK, Quraishi MA, Prakash R (2008) A self-doped conducting polymer polyanthranilic acid an efficient corrosion inhibitor for mild steel in acidic solution. Corros Sci 50:2867–2872. https://doi.org/10.1016/j.corsci.2008.07.025

Ren Y, Luo Y, Zhang K, Zhu G, Tan X (2008) Lignin terpolymer for corrosion inhibition of mild steel in 10% hydrochloric acid medium. Corros Sci 50:3147–3153. https://doi.org/10.1016/j.corsci.2008.08.019

Solomon MM, Umoren SA, Udosoro II, Udoh AP (2010) Inhibitive and adsorption behaviour of carboxymethyl cellulose on mild steel corrosion in sulphuric acid solution. Corros Sci 52:1317–1325. https://doi.org/10.1016/j.corsci.2009.11.041

Bhandari H, Srivastav R, Choudhary V, Dhawan SK (2010) Enhancement of corrosion protection efficiency of iron by poly(aniline-co-amino-naphthol-sulphonic acid) nanowires coating in highly acidic medium. Thin Solid Films 519:1031–1039. https://doi.org/10.1016/j.tsf.2010.08.038

Yurt A, Buetuen V, Duran B (2007) Effect of the molecular weight and structure of some novel water-soluble triblock copolymers on the electrochemical behaviour of mild steel. Mater Chem Phys 105:114–121. https://doi.org/10.1016/j.matchemphys.2007.04.009

Abd El-Maksoud SA, Fouda AS (2005) Some pyridine derivatives as corrosion inhibitors for carbon steel in acidic medium. Mater Chem Phys 93:84–90. https://doi.org/10.1016/j.matchemphys.2005.02.020

Rajendran S, Sridevi SP, Anthony N, John Amalraji A, Sundaravadivedi M (2005) Corrosion behavior of carbon steel in polyvinyl alcohol. Anti-Corros Methods Mater 52:102–107. https://doi.org/10.1108/00035590510584816

Jeyaprabha C, Sathiyanarayanan S, Phani KLN, Venkatachari G (2005) Influence of poly(aminoquinone) on corrosion inhibition of iron in acid media. Appl Surf Sci 252:966–975. https://doi.org/10.1016/j.apsusc.2005.01.098

Small PA (1953) Some factors affecting the solubility of polymers. J Appl Chem 3:71–80. https://doi.org/10.1002/jctb.5010030205

Mohsin MA, Attia NF (2015) Inverse emulsion polymerization for the synthesis of high molecular weight polyacrylamide and its application as sand stabilizer. Int J Polym Sci. https://doi.org/10.1155/2015/436583

Fraenkel G, Niemann C (1958) The mode of protonation of amides. Proc Natl Acad Sci USA 44(7):688–691

Morad MS (2008) Inhibition of iron corrosion in acid solutions by Cefatrexy: behaviour near and at the corrosion potential. Corros Sci 50:436–448. https://doi.org/10.1016/j.corsci.2007.08.018

Bentiss F, Jama C, Mernari B, El Attari H, El Kadi L, Lebrini M, Traisnel M, Lagrenée M (2009) Inhibition of iron corrosion in acid solutions by Cefatrexyl: behaviour near and at the corrosion potential. Corros Sci 51:1628–1635. https://doi.org/10.1016/j.corsci.2009.04.009

Bentrah H, Rahali Y, Chala A (2014) Gum Arabic as an eco-friendly inhibitor for API 5L X42 pipeline steel in HCl medium. Corros Sci 82:426–431. https://doi.org/10.1016/j.corsci.2013.12.018

Soltani N, Tavakkoli N, Khayatkashani M, Jalali MR, Mosavizade A (2012) Green approach to corrosion inhibition of 304 stainless steel in hydrochloric acid solution by the extract of saliva officinalis leaves. Corros Sci 62:122–135. https://doi.org/10.1016/j.corsci.2012.05.003

Afia L, Salghi R, Bammou L, Hammouti B, Bazzi L, Bouyanzer A (2014) Anti-corrosive properties of Argan oil on C38 steel in molar HCl solution. J Saudi Chem Soc 18:19–25. https://doi.org/10.1016/j.jscs.2011.05.008

Zarrouk A, Zarrok H, Salghi R, Hammouti B, Bentiss F, Touir R, Bouachrine M (2013) Evaluation of N-containing organic compound as corrosion inhibitor for carbon steel in phosphoric acid. J Mater Environ Sci 4(2):177–192 (ISSN 2028-2508 CODEN: JMESCN)

Bentiss F, Traisnel M, Vezin H, Hildebrand HF, Lagrenée M (2004) 2,5-Bis(4-dimethylaminophenyl)-1,3,4-oxadiazole and 2,5-bis(4-dimethylaminophenyl)-1,3,4-thiadiazole as corrosion inhibitors for mild steel in acidic media. Corros Sci 46:2781–2792. https://doi.org/10.1016/j.corsci.2004.04.001

Qian B, Wang J, Zheng M, Hou B (2013) Synergistic effect of polyaspartic acid and iodide ion on corrosion inhibition of mild steel in H2SO4. Corros Sci 75:184–192. https://doi.org/10.1016/j.corsci.2013.06.001

Zerga B, Hammout Bi, Ebn Touhami M, Touir R, Taleb M, Sfaira M, Bennajeh M, Forssal I (2012) Comparative inhibition study of new synthesized pyridazine derivatives towards mild steel corrosion in hydrochloric acid. Part-II: thermodynamic proprieties. Int J Electrochem Sci 7:471–483. http://www.electrochemsci.org/papers/vol7/7010471.pdf

Solmaz R (2010) Investigation of the inhibition effect of 5-((E)-4-phenylbuta-1, 3-dienylideneamino)-1, 3, 4-thiadiazole-2-thiol Schiff base on mild steel corrosion in hydrochloric acid. Corros Sci 52:3321–3330. https://doi.org/10.1016/j.corsci.2010.06.001

Znini M, Cristofari G, Majidi L, Ansari A, Bouyanzer A, Paolini J, Costa J, Hammouti B (2012) Green approach to corrosion inhibition of mild steel by essential oil leaves of Asteriscus graveolens (Forssk.) in sulphuric acid medium. Int J Electrochem Sci 7:3959–3981. http://www.electrochemsci.org/papers/vol7/7053959.pdf

Bentiss F, Outirite M, Traisnel M, Vezin H, Lagrenée M, Hammouti B, Al-Deyab SS, Jama C (2012) Improvement of corrosion resistance of carbon steel in hydrochloric acid medium by 3,6-bis(3-pyridyl)pyridazine. Int J Electrochem Sci 7:1699–1723. http://www.electrochemsci.org/papers/vol7/7021699.pdf

Wang J, Cao C, Chen J, Zhang M, Ye G, Lin H (1995) Anodic desorption of inhibitors. J Chin Soc Corros Prot 15:241–248. http://www.jcscp.org/EN/Y1995/V15/I4/241

Feng Y, Siow KS, Teo WK, Hsieh AK (1999) The synergistic effects of propargyl alcohol and potassium iodide on the inhibition of mild steel in 0.5 M sulfuric acid solution. Corros Sci 41:829–852. https://doi.org/10.1016/S0010-938X(98)00144-9

Behpour M, Ghoreishi SM, Mohammadi N, Soltani N, Salavati-Niasari M (2010) Investigation of some Schiff base compounds containing disulfide bond as HCl corrosion inhibitors for mild steel. Corros Sci 52:4046–4057. https://doi.org/10.1016/j.corsci.2010.08.020

Ramananda MS (2013) A green Approach: a corrosion inhibition of mild steel by adhatoda vasica plant extract in 0.5 M H2SO4. J Mater Environ Sci 4:119–126 (ISSN 2028-2508 CODEN: JMESCN)

Gualdrón AF, Becerra EN, Peña DY, Gutiérrez JC, Becerra HQ (2013) Inhibitory effect of Eucalyptus and Lippia alba essential oils on the corrosion of mild steel in hydrochloric acid. J Mater Environ Sci 4:143–158 (ISSN 2028-2508 CODEN: JMESCN)

Cole KS, Cole RH (1941) Dispersion and absorption in dielectrics. I. Alternating current characteristics. J Chem Phys 9:341–351. https://doi.org/10.1063/1.1750906

Duval S, Keddam M, Sfaira M, Srhiri A, Hakenouti H (2002) Electrochemical impedance spectroscopy of epoxy-vinyl coating in aqueous medium analyzed by dipolar relaxation of polymer. J Electrochem Soc 149:B520–B529. https://doi.org/10.1149/1.1512667

Davidson DW, Cole RH (1951) Dielectric relaxation in glycerol, propylene glycol, and n-propanol. J Chem Phys 19:1484–1490. https://doi.org/10.1063/1.1748105

Juttner K (1990) Electrochemical impedance spectroscopy (EIS) of corrosion processes on inhomogeneous surfaces. Electrochim Acta 35(90):1501–1508. https://doi.org/10.1016/0013-4686(90)80004-8

Deflorain F, Miscovic-Stankovic VB, Bonora PL, Fedrizzi L (1994) Degradation of epoxy coatings on phosphatized zinc-electroplated steel. Corrosion 50:438–446. https://doi.org/10.5006/1.3293522

Bentiss F, Traisnel M, Gengembre L, Lagrenée M (1999) A new triazole derivative as inhibitor of the acid corrosion of mild steel: electrochemical studies, weight loss determination, SEM and XPS. Appl Surf Sci 152:237–249. https://doi.org/10.1016/S0169-4332(99)00322-0

Bentiss F, Traisnel M, Lagrenée M (2000) Inhibitor effects of triazole derivatives on corrosion of mild steel in acidic media. Br Corros J 35:315–320. https://doi.org/10.1179/000705900101501326

Schultze JW, Wippermann K (1987) Inhibition of electrode processes on copper by AHT in acid solutions. Electrochim Acta 32:823–831. https://doi.org/10.1016/0013-4686(87)85115-0

Jovic VD, Jovic BM BM (2003)EIS and differential capacitance measurements onto single crystal faces in different solutions. Part I: Ag(111) in 0.01 M NaCl. J Electroanal Chem 541:1–11. https://doi.org/10.1016/S0022-0728(02)01309-8

Press WH, Teukolsky SA, Vetterling WT, Flannery BP (1992) Numerical recipes in C: the art of the scientific computing, 2nd edn. Cambridge University Press, New York. ISBN 0-521-43108-5

Barsoukov E, Ross Macdonald J (2005) Impedance spectroscopy: theory, experiment and applications, 2nd edn. Wiley, New York. ISBN 978-0-471-64749-2

Zarrok H, Zarrouk A, Hammouti B, Salghi R, Jama C, Bentiss F (2012) Corrosion control of carbon steel in phosphoric acid by purpald-weight loss, electrochemical and XPS studies. Corros Sci 64:243–252. https://doi.org/10.1016/j.corsci.2012.07.018

Popova A, Christov M, Vasilev A (2007) Inhibitive properties of quaternary ammonium bromides of N-containing heterocycles on acid mild steel corrosion. Part II: EIS results. Corros Sci 49:3290–3302. https://doi.org/10.1016/j.corsci.2007.03.012

Yadav FK, Quraishi MA, Maiti B (2012) Inhibition effect of some benzylidenes on mild steel in 1 M HCl: an experimental and theoretical correlation. Corros Sci 55:254–266. https://doi.org/10.1016/j.corsci.2011.10.030

Lorenz WJ, Mansfeld F (1981) Determination of corrosion rates by electrochemical. DC and AC methods. Corros Sci 21:647–672. https://doi.org/10.1016/0010-938X(81)90015-9

Bentiss F, Traisnel M, Lagrenée M (2001) Influence of 2,5-bis(4-dimethylaminophenyl)-1,3,4-thiadiazole on corrosion inhibition of mild steel in acidic media. J Appl Electrochem 31:41–48. https://doi.org/10.1023/A:1004141309795

Muralidharan S, Phani KLN, Pitchumani S, Ravichandran S, Iyer SVK (1995) Polyamino–benzoquinone polymers: a new class of corrosion inhibitors for mild steel. J Electrochem Soc 142:1478–1483. https://doi.org/10.1149/1.2048599

Funding

This study was supported by BENIKEN.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beniken, M., Driouch, M., Sfaira, M. et al. Anticorrosion Activity of a Polyacrylamide with High Molecular Weight on C-Steel in Acidic Media: Part 1. J Bio Tribo Corros 4, 38 (2018). https://doi.org/10.1007/s40735-018-0155-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-018-0155-y