Abstract

In recent years, flexible electronics has emerged as a promising field that has attracted significant attention as a potential industry of the future. To realize full potential of flexible electronics, flexible power sources are essential. Polymer electrolyte membrane fuel cells (PEMFCs) are well-suited for this purpose, but the high cost of the catalyst, specifically platinum (Pt), is a major hurdle. This study sought to determine the optimal Pt loading for flexible PEMFCs, to reduce waste of catalyst and find a cost-effective solution. The optimal catalyst loading for flexible fuel cells varies depending on the operating environment and conditions. In environments requiring the generation of high power regardless of operating voltage, the optimal Pt loading is 0.1 mgPt cm−2. In contrast, in environments where higher voltage is required with a minimum stacking, the optimal Pt loading is between 0.3 and 0.4 mgPt cm−2. These results demonstrate optimal catalyst loading for flexible fuel cells in consideration of the operating environment and conditions. These results contribute valuable insight into the optimal catalyst loading for various applications, reducing the cost of flexible fuel cells, and paving the way for wider adoption of flexible electronics.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Gong, M., Zhang, L., & Wan, P. (2020). Polymer nanocomposite meshes for flexible electronic devices. Progress Polymer Science, 107, 101279. https://doi.org/10.1016/j.progpolymsci.2020.101279

Wang, Y., et al. (2019). Organic crystalline materials in flexible electronics. Chemical Society Reviews, 48(6), 1492–1530. https://doi.org/10.1039/c8cs00406d

S. Huang, Y. Liu, Y. Zhao, Z. Ren, and C. F. Guo, “Flexible electronics: stretchable electrodes and their future,” Advanced Functional Materials, vol. 29, no. 6, 2019, doi: https://doi.org/10.1002/adfm.201805924.

Kang, M., Kang, KT. "Flexible 2-layer paper printed circuit board fabricated by inkjet printing for 3-D origami electronics," Int. J. of Precis. Eng. and Manuf.-Green Tech. 5, 421–426 (2018). https://doi.org/10.1007/s40684-018-0045-2

Wang, P., et al. (2020). The evolution of flexible electronics: From nature, beyond nature, and to nature. Advanced Science, 7(20), 1–29. https://doi.org/10.1002/advs.202001116

Khalid, S., Raouf, I., Khan, A. et al. "A review of human-powered energy harvesting for smart electronics: recent progress and challenges," Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 821–851 (2019). https://doi.org/10.1007/s40684-019-00144-y

Kim, S., et al. (2023). Design and characterization of flexible strain sensors using pressure-sensitive material with multi-walled carbon nanotubes and polydimethylsiloxane. International Journal of Precision Engineering and Manufacturing, 24(12), 2361–2369.

So, SY., Park, SH., Park, SH. et al. "Additive-Manufactured Flexible Triboelectric Sensor Based on Porous PDMS Sponge for Highly Detecting Joint Movements," Int. J. of Precis. Eng. and Manuf.-Green Tech. 10, 97–107 (2023). https://doi.org/10.1007/s40684-022-00432-0

Y. Wang, X. Wu, Y. Han, and T. Li, “Flexible supercapacitor: Overview and outlooks,” Journal of Energy Storage, vol. 42, no. May, p. 103053, 2021, doi: https://doi.org/10.1016/j.est.2021.103053.

M. Park, et al. "Scalable Production of High Performance Flexible Perovskite Solar Cells via Film-Growth-Megasonic-Spray-Coating System." Int. J. of Precis. Eng. and Manuf.-Green Tech. 10.5 (2023): 1223–1234.

Y. Yang, X. Zhu, Q. Wang, D. Ye, R. Chen, and Q. Liao, “Towards flexible fuel cells: development, challenge and prospect,” Applied Thermal Engineering, vol. 203, no. September 2021, p. 117937, 2022, doi: https://doi.org/10.1016/j.applthermaleng.2021.117937.

Shahriar, M., Vo, C.P. & Ahn, K.K. "Self-powered Flexible PDMS Channel Assisted Discrete Liquid Column Motion Based Triboelectric Nanogenerator (DLC-TENG) as Mechanical Transducer," Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 907–917 (2019). https://doi.org/10.1007/s40684-019-00148-8

Zhang, L., Shi, X. L., Yang, Y. L., & Chen, Z. G. (2021). Flexible thermoelectric materials and devices: From materials to applications. Materials Today, 46(June), 62–108. https://doi.org/10.1016/j.mattod.2021.02.016

M. He et al., “Flexible and stretchable triboelectric nanogenerator fabric for biomechanical energy harvesting and self-powered dual-mode human motion monitoring,” Nano Energy, vol. 86, no. March, p. 106058, 2021, doi: https://doi.org/10.1016/j.nanoen.2021.106058.

Yu, Zhijing, et al. "Flexible stable solid‐state Al‐ion batteries." Advanced functional materials 29.1 (2019): 1806799.

Xie, F., et al. (2019). Recent progresses in H2-PEMFC at DICP. Journal of Energy Chemistry, 36, 129–140. https://doi.org/10.1016/j.jechem.2019.07.012

Liu, Z., et al. (2016). Novel fuel cell stack with coupled metal hydride containers. Journal of Power Sources, 328, 329–335. https://doi.org/10.1016/j.jpowsour.2016.07.096

Wang, H., et al. (2020). Flexible and adaptable fuel cell pack with high energy density realized by a bifunctional catalyst. ACS Applied Materials and Interfaces, 12(4), 4473–4481. https://doi.org/10.1021/acsami.9b18511

Daud, W. R. W., Rosli, R. E., Majlan, E. H., Hamid, S. A. A., Mohamed, R., & Husaini, T. (2017). PEM fuel cell system control: A review. Renewable Energy, 113, 620–638. https://doi.org/10.1016/j.renene.2017.06.027

Chen, T., Liu, S., Zhang, J., & Tang, M. (2019). Study on the characteristics of GDL with different PTFE content and its effect on the performance of PEMFC. International Journal of Heat and Mass Transfer, 128, 1168–1174. https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.097

Zhang, J., Hu, Y., Han, C., & Zhang, H. (2021). Stress response and contact behavior of PEMFC during the assembly and working condition. International Journal of Hydrogen Energy, 46(59), 30467–30478. https://doi.org/10.1016/j.ijhydene.2021.06.200

Atyabi, S. A., Afshari, E., Wongwises, S., Yan, W. M., Hadjadj, A., & Shadloo, M. S. (2019). Effects of assembly pressure on PEM fuel cell performance by taking into accounts electrical and thermal contact resistances. Energy, 179, 490–501. https://doi.org/10.1016/j.energy.2019.05.031

Gamburzev, S., & Appleby, A. J. (2002). Recent progress in performance improvement of the proton exchange membrane fuel cell (PEMFC). Journal of Power Sources, 107(1), 5–12. https://doi.org/10.1016/S0378-7753(01)00970-3

Owejan, J. P., Owejan, J. E., & Gu, W. (2013). Impact of Platinum Loading and Catalyst Layer Structure on PEMFC Performance. Journal of The Electrochemical Society, 160(8), F824–F833. https://doi.org/10.1149/2.072308jes

Houchins, C., et al. (2012). U.S. doe progress towards developing low-cost, high performance, durable polymer electrolyte membranes for fuel cell applications. Membranes, 2(4), 855–878. https://doi.org/10.3390/membranes2040855

Etesami, M., Mehdipour-Ataei, S., Somwangthanaroj, A., & Kheawhom, S. (2022). Recent progress of electrocatalysts for hydrogen proton exchange membrane fuel cells. International Journal of Hydrogen Energy, 47(100), 41956–41973. https://doi.org/10.1016/j.ijhydene.2021.09.133

Ostroverkh, A., et al. (2019). Optimization of ionomer-free ultra-low loading Pt catalyst for anode/cathode of PEMFC via magnetron sputtering. International Journal of Hydrogen Energy, 44(35), 19344–19356. https://doi.org/10.1016/j.ijhydene.2018.12.206

Fu, K., et al. (2020). Magnetron sputtering a high-performance catalyst for ultra-low-Pt loading PEMFCs. Journal of Alloys and Compounds, 815, 152374. https://doi.org/10.1016/j.jallcom.2019.152374

Radev, I., et al. (2012). Optimization of platinum/iridium ratio in thin sputtered films for PEMFC cathodes. International Journal of Hydrogen Energy, 37(9), 7730–7735. https://doi.org/10.1016/j.ijhydene.2012.02.015

Chaparro, A. M., Gallardo, B., Folgado, M. A., Martín, A. J., & Daza, L. (2009). PEMFC electrode preparation by electrospray: Optimization of catalyst load and ionomer content. Catalysis Today, 143(3–4), 237–241. https://doi.org/10.1016/j.cattod.2008.12.003

Dong, P., Jia, Y., Xie, G., & Ni, M. (2019). The energy performance improvement of a PEM fuel cell with various chaotic flowing channels. International Journal of Energy Research, 43(10), 5460–5478. https://doi.org/10.1002/er.4665

Yılmaz, M. S., Kaplan, B. Y., Gürsel, S. A., & Metin, Ö. (2019). Binary CuPt alloy nanoparticles assembled on reduced graphene oxide-carbon black hybrid as efficient and cost-effective electrocatalyst for PEMFC. International Journal of Hydrogen Energy, 44(27), 14184–14192. https://doi.org/10.1016/j.ijhydene.2018.11.228

Woo, S., Kim, I., Lee, J. K., Bong, S., Lee, J., & Kim, H. (2011). Preparation of cost-effective Pt-Co electrodes by pulse electrodeposition for PEMFC electrocatalysts. Electrochimica Acta, 56(8), 3036–3041. https://doi.org/10.1016/j.electacta.2011.01.002

Ning, F., et al. (2017). Flexible and Lightweight Fuel Cell with High Specific Power Density. ACS Nano, 11(6), 5982–5991. https://doi.org/10.1021/acsnano.7b01880

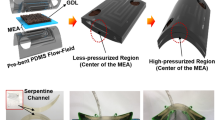

H. Yoo et al., “3D-printed flexible flow-field plates for bendable polymer electrolyte membrane fuel cells,” Journal of Power Sources, vol. 532, no. December 2021, p. 231273, 2022, doi: https://doi.org/10.1016/j.jpowsour.2022.231273.

Hsu, F. K., Lee, M. S., Lin, C. C., Lin, Y. K., & Hsu, W. T. (2012). A flexible portable proton exchange membrane fuel cell. Journal of Power Sources, 219, 180–187. https://doi.org/10.1016/j.jpowsour.2012.07.054

Park, T., Kang, Y. S., Jang, S., Cha, S. W., Choi, M., & Yoo, S. J. (2017). A rollable ultra-light polymer electrolyte membrane fuel cell. NPG Asia Materials, 9(5), e384–e388. https://doi.org/10.1038/am.2017.72

Hwang, W., Kim, S., Ahn, C. Y., Cho, Y. H., & Sung, Y. E. (2021). Origami-based flexible and simple tubular polymer electrolyte membrane fuel cell stack. ACS Energy Letters, 6(9), 3195–3202. https://doi.org/10.1021/acsenergylett.1c01460

Chang, I., Park, T., Lee, J., Lee, M. H., Ko, S. H., & Cha, S. W. (2013). Bendable polymer electrolyte fuel cell using highly flexible Ag nanowire percolation network current collectors. Journal of Materials Chemistry A, 1(30), 8541–8546. https://doi.org/10.1039/c3ta11699a

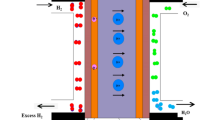

R. O’Hayre, S. W. Cha, W. Collela, and F. B. Prinz, Fuel Cell Fundamentals, 3rd ed., Wiley, 2016.

Park, T., Chang, I., Lee, H. B., Ko, S. H., & Cha, S. W. (2017). Performance variation of bendable polymer electrolyte fuel cell based on Ag nanowire current collector under mixed bending and twisting load. International Journal of Hydrogen Energy, 42(3), 1884–1890. https://doi.org/10.1016/j.ijhydene.2016.08.022

Park, T., et al. (2017). Effect of assembly pressure on the performance of a bendable polymer electrolyte fuel cell based on a silver nanowire current collector. Energy, 134(June), 412–419. https://doi.org/10.1016/j.energy.2017.05.197

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) granted by the Ministry of Science and ICT (RS-2023-00209146).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, G., Yoo, H., Baek, J. et al. Experimental Study of Electro-Catalyst Loading on Flexible Polymer Electrolyte Membrane Fuel Cell Performance. Int. J. of Precis. Eng. and Manuf.-Green Tech. (2024). https://doi.org/10.1007/s40684-024-00603-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40684-024-00603-1