Abstract

Optical metasurfaces consisting of two-dimensional nanostructures have rapidly developed over the past two decades thanks to their potential for use as optical components, such as metalenses or metaholograms, with ultra-compact form factors. Despite these rapid developments, major challenges for the commercialization of metasurfaces still remain: namely their mass production and use in real-life devices. A lot of effort has been made to overcome the limitations of electron beam lithography which is commonly used to fabricate metasurfaces. However, a breakthrough in mass production is still required to bring the cost of metasurfaces down into the price range of conventional optics. This review covers deep-ultraviolet lithography, nanoimprint lithography, and self-assembly-based fabrication processes that have the potential for the mass production of both cost-effective and environmentally friendly metasurfaces. We then discuss metalenses and future displays/sensors that are expected to take advantage of these mass-produced metasurfaces. The potential applications of mass-produced optical metasurfaces will open a new realm for their practical applications and commercialization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Optical metasurfaces comprised of two-dimensional subwavelength nanostructures have been extensively studied owing to their ultra-compact form factors and potential alternatives to conventional optical components [1,2,3]. The properties of light incident on metasurfaces can be controlled by changing the structural parameters of the constituent nanostructures, known as meta-atoms. By designing these properties, metasurfaces can simultaneously control all of the fundamental properties of light such as phase, amplitude, polarization, and frequency [4,5,6,7]. These versatile functionalities have led to a variety of applications such as metalenses [8,9,10,11], metaholograms [12,13,14], color filters [15,16,17], sensors [18,19,20,21], and absorbers [22,23,24].

The spotlight has shifted from fundamental research of optical metasurfaces to their integration into practical applications through mass manufacturing processes [25, 26]. However, to find their way into real-world applications, metasurfaces must be produced in quantities that can meet market demands. The conventional fabrication method of using electron beam lithography (EBL) is limited by low production volumes, excessive costs, and small patterning areas [27,28,29,30]. To solve these problems, complementary metal-oxide semiconductor (CMOS) techniques have recently been applied to metasurface fabrication [31, 32]. The mass manufacture of optical metasurfaces could see their evolution from the laboratory into commercial products that are integrated into existing technologies [33, 34]. Therefore, the cost-effective and environmentally friendly mass production of metasurfaces is indispensable for the commercial success of metasurfaces.

In this review, we introduce cost-effective and environmentally friendly manufacturing methods for metasurfaces, such as deep-ultraviolet (DUV) lithography, nanoimprint lithography, and self-assembly-based fabrication, which have the potential for mass production. We also explore the diverse array of applications of such metasurfaces such as metalenses and future displays/sensors, which promise to revolutionize various industries. In conclusion, we summarize the entire review paper and suggest future research directions for the commercialization of metasurfaces.

2 Mass Manufacturing of Optical Metasurfaces

The current limitations in nanoscale manufacturing prevent optical metasurfaces from being applicable across a wide range of practical uses [33]. Metasurfaces designed to operate in the optical range are composed of nanostructures that are smaller than what can be achieved with conventional photolithography, making EBL the fabrication method of choice [35]. Although producing large-scale metasurfaces using EBL has been reported [36,37,38], the cost and production challenges remain for practical utilization. Furthermore, achieving high-efficiency metasurfaces necessitates the use of high refractive index and low extinction coefficient dielectric materials like titanium dioxide (TiO2), but problems associated with depositing and etching these materials cause environmental pollution and hinder mass production [39]. Addressing the challenges of cost-effectiveness [40,41,42] and eco-friendliness for mass fabrication is a crucial issue within the realm of optical metasurfaces. In this section, we will discuss new innovations in nanofabrication and how they have been applied to the mass production of metasurfaces.

2.1 DUV Lithography

A fundamental restriction of conventional photolithography due to the diffraction limit can be overcome by simply employing shorter wavelengths of light. By using i-line stepper lithography operating at ultraviolet (UV) wavelengths, namely 365 nm, 2-cm-diameter metalenses have been successfully demonstrated with operation in the near-infrared (NIR) (Fig. 1a) [43]. While this study displayed the feasibility of creating metasurfaces using this CMOS-compatible process, the issue lies in the fact that the wavelength is too large to produce nanostructures with the resolution required for operation at visible wavelengths. Furthermore, 1-cm-diameter all-glass metalenses working in the visible spectrum, at the wavelength of 633 nm, have been produced by using krypton fluoride (KrF) stepper lithography (Fig. 1b) [44]. The KrF stepper lithography uses an even shorter wavelength (248 nm), so it can be used to fabricate smaller meta-atoms than i-line stepper lithography. However, the stepper’s critical dimension (CD) is over 250 nm, making it unsuitable for creating full-phase modulation. In addition to mass-producing metalenses, KrF lithography has been used for wafer-scale biosensing and polarization control metasurfaces in the mid-infrared (MIR) range (Fig. 1c) [45]. Both high-Q resonant dielectric metasurfaces and birefringent polarization-selective metasurfaces have been uniformly manufactured. KrF stepper lithography has also been utilized for mass manufacturing of beam steering metasurfaces [46]. Argon fluoride (ArF) lithography utilizing a 193 nm wavelength has also been investigated for the mass manufacturing of metasurfaces [28, 47, 48]. The CD achievable through ArF scanner lithography can be reduced down to 65 nm. While this is larger than what conventional EBL achieves, it is still sufficient for creating metasurfaces in the visible range. High-Q photonic crystal microcavities designed specifically for wavelength-pitch arrays have been demonstrated using the commercial ArF water-immersion lithography line (Fig. 1d) [48]. The quality of this novel technique depends on a blend of reverse-tone lithography that has been optimized for dosage, precision laser-written masks, and finely tuned etch termination. In addition to increasing the production scale of metasurfaces, there have been also developments in the fabrication of single, large-diameter metalenses for the space industry with 80 mm [49] and 100 mm [50] diameter metalenses on 4-inch wafers using DUV lithography.

Mass manufacturing metasurfaces using DUV lithography. a An illustrative diagram depicting the cost-effective and high-yield production of metalenses through the utilization of conventional i-line stepper lithography [43]. b All-glass 1-cm-diameter metalens operating 633 nm using KrF stepper lithography (i) The manufacturing procedure of the large metalens through the utilization of a selective etching process. (ii) Scanning electron microscope (SEM) images on the tilted view. (iii) SEM images on the top-view scale bar of the inset: 10 μm. (iv) Image of 45 mass-produced metalenses on 4 inch-sized wafer, focusing the white light [44]. c Wafer-scale MIR biosensing metasurfaces using KrF stepper lithography. (i) The schematic of the fabrication process and the photograph of the 4-inch wafer. (ii–v) SEM images of all-dielectric high-Q resonant metasurfaces [45]. d Wavelength-pitch arrays of high-Q photonic crystal microcavities using ArF immersion scanner lithography. (i) Photograph of the full wafer which contains 64 reticles. (ii) Photography of zoomed sample. (iii) SEM image of photonic crystal cavities [48]

2.2 Nanoimprint Lithography

Nanoimprint lithography (NIL) is a method of creating nanostructures using specialized stamps with nanoscale features [51, 52]. The fundamental NIL process involves coating a substrate with a resist, pressing the stamp onto the resist, solidifying the resist through temperature elevation or UV exposure, and subsequently separating the stamp (Fig. 2a) [53]. As a result, the resist takes on the inverse shape of the stamp, serving as an etching mask for underlying films. Notably faster than EBL, NIL also enables large-scale production when employing scalable stamps. The reusability of stamps further contributes to significantly reducing fabrication costs and even protecting the environment. In contrast to conventional photolithography, which has a patterning resolution constrained by the diffraction limit, NIL bypasses this limitation. This allows NIL to achieve sub-25 nm nanostructures. The utilization of jet-and-flash NIL can lead to the establishment of a stepper system, making it particularly advantageous for the cost-effective and environmentally friendly mass production of metasurfaces featuring nanostructures smaller than 100 nm [54].

However, the manufacturing of dielectric metasurfaces remains a problem. Dielectric metasurfaces must be composed of high refractive index and low extinction coefficient materials to achieve high efficiency. Typically, the refractive index of the resins used for NIL is too low to be utilized as a metasurface. Therefore, research has been conducted to develop highly functional metasurfaces that take advantage of the high yield of NIL [55,56,57,58]. A cost-effective and high-efficiency metalens has been demonstrated through a single step of NIL (Fig. 2b) [56]. This metalens is composed of TiO2 nanoparticle-embedded-resin (nano-PER) to enhance performance by increasing the effective refractive index. The produced metalens attained a focusing efficiency of 33% at the desired wavelength of 532 nm with imaging capabilities comparable to other diffraction-limited systems. This approach can also be used to fabricate metasurfaces on flexible and curved surfaces, an ability that conventional EBL does not possess. The primary benefit of this technique is its capability to incorporate materials suitable for metasurfaces, even those that are challenging to manipulate, in the form of nanoparticles. NIL methods utilizing these nano-PERs have been extended beyond visible frequencies to the NIR [59] and DUV regions [60].

The throughput and cost-effectiveness of NIL can be enhanced further by utilizing roll-to-roll systems [61, 62] or integrating them with commercial CMOS processes [28]. By integrating ArF immersion scanner lithography and wafer-scale NIL, cost-effective, environmentally friendly, and high-throughput mass manufacturing processes have been reported (Fig. 2c) [28]. After creating a 12-inch master stamp, 669 1-cm-diameter metalenses can be manufactured in a single step. High-index atomic layer-polymer hybrid structures have been used to overcome the low refractive index of the commercial resin. By depositing 23 nm of TiO2, the conversion efficiency was significantly increased from 10 to 90%. As a proof of concept, virtual reality (VR) devices were demonstrated with the printed hybrid metalenses.

Mass manufacturing process using NIL. a Schematic of conventional NIL in (i) thermal and (ii) UV curable conditions [53]. b Schematic of one-step printing method using nano-PER NIL. SEM images of (i) master mold, (ii) soft mold, and (iii) printed metalens. All scale bars: 100 μm [56]. c Scalably manufactured large aperture-sized hybrid metalenses by integrating DUV lithography and wafer-scale NIL. (i) Schematic of fabrication process. (ii) Mass-manufactured hybrid metalenses on 4, 6, 8, and 12 inch-sized wafers. (iii–v) Photographs and SEM images of the master stamp [28]

2.3 Self-Assembly-Based Fabrication

Top-down techniques including photolithography and EBL offer the advantage of creating a variety of patterns with precise control. However, these approaches inherently consume considerable time and energy, and achieving large-scale production of micro- and nano-structures remains challenging due to their limited throughput. Conversely, methods that involve the self-assembly [63, 64] of intricate structures provide an effective means for mass-producing the nanostructures required for metasurfaces. For example, Fig. 3a illustrates the process of dewetting glass thin films, enabling the creation of cutting-edge nanophotonic structures on extensive surfaces composed of both flexible and rigid substrates [65]. By adjusting the interaction among texture reflow, spinodal instabilities, and capillary break-up, a 20-cm-sized metasurface has successfully been demonstrated through the autonomous formation of diverse optical nanostructures. These structures exhibit feature sizes as small as 100 nm and interparticle distances reduced to 10 nm by integrating commercial photolithography lines.

Colloidal lithography, also referred to as nanosphere lithography, generates a lithographic mask composed of a monolayer of self-organized nanospheres through the Langmuir–Blodgett technique. This method enables the precise definition of large-scale nanopatterns uniformly distributed across a substrate while preventing environmental pollution. Polystyrene (PS) beads have been a popular choice as nanospheres in colloidal lithography due to their easy size reduction via oxygen plasma etching and easy lift-off via acetone and tape following the self-assembly process. The monolayers of PS beads offer versatile means to construct metasurfaces. This novel patterning method has been employed to create extensive arrays of periodic nanostructures with an exceptionally high production rate, all achieved in a cost-effective manner (Fig. 3b) [66]. A micropropulsive injection (MPI) technique has been newly developed to disperse the PS beads colloidal solution directly onto the water’s surface. Using the MPI technique, a monolayer of PS has been effectively manufactured over a substantial surface area (1 × 1 m² on glass) and with a notable production (6 × 6 wafers). Moreover, multiple-patterning colloidal lithography (MPCL) has been proposed to realize a substantial near-perfect absorber, measuring 2.5 × 2.5 cm2, composed of ring-shaped titanium nitride (TiN) structures (Fig. 3c) [67]. This achievement marks the first instance of applying MPCL to etch a refractory metal, with a specific focus on the fabrication process aimed at overcoming practical limitations for large-scale absorbers. This method can also be applied to broadband absorbers [68]. Furthermore, efficient electromagnetic manipulation, both in the near-field and far-field, has been achieved through the demonstration of self-assembled 2.5-dimensional metasurfaces on a wafer scale (Fig. 3d) [69]. These devices encompass wideband electromagnetic absorption (with an average absorption exceeding 91% across the 400–1200 nm range), structural color display (encompassing primary colors of red, green, and blue (RGB)), and surface-enhanced Raman scattering (with the most substantial enhancement factor measuring 3.29 × 107 and a relative standard deviation lower than 9%).

Mass manufacturing process using self-assembly-based fabrication. a Self-assembled nanostructured glass using template dewetting method. (i) Schematic and SEM images illustrated by the progress of dewetting optical glass. Scale bar: 400 nm (top), 1 μm (middle), 1 μm (bottom) [65]. b Large-area PS monolayer fabrication method using MPI technique. (i) Schematic of MPI technique. (ii, iii) Photographs and SEM images of deposited PS monolayer on 1 × 1 m² glass and 6 × 6 wafers [66]. c Scalable manufacturing of near-perfect absorber using MPCL. (i) Schematic of MPCL. (ii) SEM images corresponding to each fabrication steps [67]. d Wafer-sized electromagnetic manipulation metasurface using colloidal lithography. (i) Schematic of fabrication. (ii, iii) SEM and photograph of fabricated sample [69]

3 Metalenses

Conventional lenses focus light by refracting it through the curved surface of the glass. However, such lenses suffer from problems such as bulky systems, chromatic aberrations, and difficulty fabricating multi-level diffraction modes. Metalenses [2, 70,71,72,73] are flat lenses composed of sub-wavelength-sized meta-atoms. The working principle of metalens is to control the geometric dimensions or rotation of the nanostructures and through the interaction of light, induce anomalous refraction via a generalized Snell’s law [4]. As a result, desired refractive properties can be achieved to focus light. Through the use of metalenses, optical systems can be miniaturized, while various aberrations and additional functionalities can be addressed by designing the desired properties. Therefore, metalenses can lead to major advances in optical systems that previously used bulky optical components.

With these trends, metalenses have been extensively studied to replace the conventional lenses of augmented reality (AR) [34, 74,75,76], VR [38, 77], cameras [78, 79], and microscopes [80, 81]. Among these, achromatic metalenses and multi-focal metalenses are being actively studied. These lenses can overcome the technical limitations of conventional optical systems by providing accurate, sharp images and a wide choice of focal points in the area of camera and video technology. In the next section, we will review the principles and applications of achromatic metalenses and multi-focal metalenses.

3.1 Achromatic Metalenses

Existing metalenses suffer from chromatic aberration because the refractive index of the material varies depending on the wavelength, which renders it impossible to obtain a clear image using white light. However, achromatic metalenses, shown in Fig. 4a [82], have focusing properties regardless of the wavelength by correcting for this chromatic aberration. They can then be used to obtain well-focused images and can be used for optical communications. Achromatic metalenses have been actively researched to have high efficiency through various methods such as phase compensation and inverse design. We will briefly present the background to these realizations achromatic metalenses.

Phase compensation, also known as dispersion engineering, realizes smooth and linear phase dispersion through a resonant unit cell. In general, the focal length of a metalens varies with the wavelength as shown in the phase (\(\varphi\)) profile equation below.

\(R=\sqrt{{x}_{0}^{2}+{y}_{0}^{2}}\) represents distance from the center of metalens to an arbitrary point \(({x}_{0},{y}_{0})\), \(\lambda\) is the wavelength of the incident light and \(f\) is the focal length. Equation (1) can be rewritten as

The first part of Eq. (2) is the basic phase profile. \(\varphi \left(R,{\lambda }_{max}\right)\) is independent of the incident wavelength (\(\lambda\)). Summarizing \(\varDelta \varphi \left(R,\lambda \right)\) is equivalent to the equation below.

This local phase compensation across the metalens has been typically achieved by rotating anisotropic meta-atoms to impart the Pancharatnam-Berry (PB) phase [83], which is wavelength-independent. In this way, metalenses using phase compensation can realize phase retardation over a wide range of wavelengths at focal length regardless of the wavelength. This means that achromatic metalenses can be realized by having the same phase at the focal length regardless of the wavelength.

Additionally, Fig. 4b(i) [84] shows achromatic metalens with vertically stacking [85] structures fabricated through metallic disc-shaped nanoparticles. Each metalens is composed of gold, silver, and aluminum discs. Each nanoresonator compensates for the phase shift at a specific wavelength. The design parameters for each metal have been optimized for localized surface plasmon resonance visible in a specific frequency. The use of gold is for red, silver is for green, and aluminum is for blue as the target spectrum. With localized surface plasmon resonance, each metalens strongly scatters light at the targeted color. The focal point of the red targeted metalens is 2.6 μm, green targeted metalens is 2.43 μm, and blue targeted metalens is 2.11 μm. The focal intensity shows good performance at RGB wavelengths in Fig. 4b(ii).

In addition, metalens made of TiO2 [8, 86, 87] divided into quadrant parts to match the phase can be used for the visible spectrum. Also, achromatic metalens of various materials can be realized using dielectric materials such as hydrogenated amorphous silicon (a-Si:H) [88,89,90] and gallium nitride (GaN) [11]. Delay dispersion can be controlled by varying geometric parameters such as diameter or height and rotation of unit cells of various materials. The achromatic metalens via phase compensation method can be applied to meter-scale-single mode metafiber and used for optical focusing and imaging. It is polarization-independent and can be used in the NIR telecommunication area. This suggests that metalens can also be applied in the field of optical fibers [91, 92].

Inverse design [93,94,95,96] is a numerical method of inversely designing and realizing a system with a goal or desired properties to solve a physical problem. Once the desired properties are set, the design of the nanoscale meta-atoms to achieve them can be uncovered through computer algorithms. The existing metalens design method (forward methodology) considers each meta-atom as a single localized phase modulator. However, metalenses designed through inverse design are not limited to a single unit cell with a single shape, and can therefore be used to optimize the metalens design as a whole, or to provide complex structures beyond the imagination of human researchers. This can lead to the maximization of the focused light intensity at the focal plane.

An RGB-achromatic polarization-insensitive metalens design using the gradient-based optimization method [97, 98] is shown in Fig. 4c(i) [38]. With the meta-atom library and optimization cost function, the initial meta-atom design is calculated through the forward simulator to check the response such as focal length and chromatic aberration. This method calculates the gradient of the objective function through the criterion and difference, and updates the meta-atom design through constraint computation. After the iteration of optimization loops, the final meta-atom designs are created. The 1 cm large-scale achromatic metalens via inverse design showed good experimental performance (Fig. 4c(ii)).

The geometries of metalenses have also been optimized using an adjoint-based approach to achieve various numerical apertures (NA) from 0.1 to 0.9 as shown in Fig. 4d [99]. In comparison to gradient-based optimization which directly calculates the gradient through design variables and repeated simulations, the adjoint method calculates the gradient using the adjoint field derived by solving the adjoint Maxwell equation.

Large-scale aperiodic metalens requires a lot of time (~ 100 h) and a lot of memory (~ 100 Gb) to design 50 µm2 size metalens with forward methodology. However, designing through inverse design has the advantage that even large-scale metalens (1 cm2) can be designed in a relatively short time (~ few hours). By using inverse design, it is possible to design optimal metalens by considering more various variables, which can lead to rapid development in metalens design [38].

3.2 Multifocal Metalenses

Multi-focusing plays an important role in coupling waves to multiple channels in optical connections [100]. Multifocal metalenses can solve not only the problem of the bulk optical system used to realize multifocal length but also the problem of instantaneous response due to the limited number of focal points. Multifocal metalenses have been proposed using the PB phase to change the focal length through polarization [101,102,103,104,105], the interleaved method [100] that divides the metalens into different areas, and through control of the lattice constant of the meta-atoms [106]. Tunable multifocal metalenses can be a promising technology that can form images through fast real-time focus conversion through flexible response in the optical system and can be sensed in multi-focus mode. We will review tunable multifocal metalenses by dividing them into mechanically tunable and electrically tunable multifocal metalenses.

Mechanically tunable multifocal metalenses [107,108,109,110] are metalenses whose focal lengths can be changed by applying an external force. Among the various parameters that affect the focal length, mechanically tunable multifocal metalens mainly use the lattice pitch. If the period is modified using a flexible substrate such as polydimethylsiloxane (PDMS) that can increase the lattice pitch and then the phase discontinuity changes as the period increases. This in turn changes the anomalous refraction angle and thus the focal length. In addition, it has the advantage of being able to realize various focal lengths through external force in a miniaturized system in real-time.

Figure 4e(i) [111] shows a fully embedded gold nanorod array that can be uniformly stretched in four directions after fabrication on the PDMS substrate. When unstretched, the lattice pitch is 400 nm. After being mechanically stretched, the geometric parameters such as height, width, and length of the gold nanorod do not change, only the lattice pitch changes. When the streching ratios are 100% and 130%, the focal length has been shifted to 150 μm and 250 μm. In Fig. 4e(ii) the intensity does not change even when the PDMS substrate is stretched and reconfigurable while performing continuous wavefront shape tuning. Also, other materials like alumina (Al2O3) [106] can be applied instead of gold.

In addition, reflection-type tunable multifocal metalens can change the focal length in the visible area by 45% by stretching the substrate by 0 ~ 20% in the lateral direction [107]. A stretchable continuous metallic ground plane must be stretched without sacrificing electromagnetic resonance. The stretching ratio is substituted into the phase profile equation. So, the focal length changes with the stretching ratio. The silver-silica-silver triple layer encapsulated in PDMS and lattice pitch is 330 nm. The focal length is 3.7 μm when unstretched, then changed to 4.7 μm and 5.6 μm when the stretching ratio are increased to 10% and 20%.

Electrically tunable multifocal metalenses [112,113,114,115,116] can change the focal length in response to external electrical signals like voltage. Electrically tunable multifocal metalenses have been actively studied owing to their high compatibility with conventional controllers and rapid response time. These metalenses have been fabricated by integrating materials whose optical properties can be changed by electric charges. For example, the input polarization can be adjusted using the tunable properties of materials that respond sensitively to external electrical signals, such as liquid crystal (LC). By using LC, the input polarization state can be tuned. This makes it possible to realize electrical tunability of polarization-sensitive multifocal metalens.

Electrically tunable bifocal metalens can be realized by utilizing the electrically tunable property of LC shown in Fig. 4f [117]. By introducing an electrical bias to the LC cell, the polarization of incident light can be controlled between right circularly polarized light and left circularly polarized light. This modulation in polarization induces a shift in the focal length of the polarization-sensitive multifocal metalens. When the right circularly polarized light passes through the LC layer, the focal length is 7.5 mm and when the left circularly polarized light passes through the LC layer, the focal length is 3.7 mm. By integrating LC into metalens, a high degree of multifocal metalens can be realized.

In addition, the focal length of barium titanate (BTO) nanofin bifocal metalens [118] can be changed by modulating the intensity of the electric field by using the characteristic that the refractive index changes as the symmetry of the molecular structure of a crystalline material is broken depending on the voltage applied through an indium tin oxide (ITO) layer. When the voltage is 0, the refractive index of the BTO layer is 2.4, resulting in a focal length of 9 μm, and when the voltage is 60 V, the refractive index of the BTO layer is 3.07, resulting in a focal length of 15 μm. In this way, the focal length can be controlled through intensity modulation.

Overall concept of metalens applications. a Schematic of (i) chromatic and (ii) achromatic metalenses [82]. b Research of vertically stacking achromatic metalens using localized surface plasmon resonance. (i) Schematic of vertically stacking metalens (ii) Measured focal intensity distribution in the YZ plane at RGB wavelengths. [84]. c Large-scale 1 cm diameter metalens using inverse design. (i) Photograph of fabricated metalens. (ii) Measured focal intensity in XZ plane at RGB wavelengths. [38]. d Optimized structures using an adjoint-based approach for various NA (0.1–0.9) metalenses. [99]. e Mechanically tunable multifocal metalens using a stretchable PDMS substrate. (i) Schematic of mechanically tunable multifocal metalens extending in four linear direction. (ii) Measured longitudinal beam intensity, s = 100% (top), 115% (middle), 130% (bottom). [111]. f Schematic of electrically tunable bifocal metalens using LC cell [117]

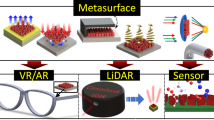

4 Future Displays/Sensors

The integration of metasurfaces in displays, including elements like color filters and metaholograms, has bolstered existing display technologies by offering improved resolution and spatial benefits. Moreover, the use of metasurfaces in diverse sensing applications has not only enabled high-sensitivity and selective sensing through distinct features like bound states in the continuum (BIC) but also introduced tunable properties. Incorporating metasurfaces into various applications holds the potential to elevate the performance of existing devices and propel future advancements.

4.1 Displays

Display technologies integrated with metasurfaces, metaholograms, and color filters have a spatial advantage because optical properties of light can be controlled through an ultra-compact system. This enables high-resolution colorful displays and miniaturization, and applications using metasurface displays can be used in various fields. Encryption systems [14, 119, 120] through optical data storage metahologram and full-color imaging [121,122,123,124,125,126] have been actively studied. In this section, we will review the principles and applications of metaholograms and metasurface-based color filters.

4.1.1 Metaholograms

Holography is an optical technique that generates an optical image in the far-field by reconstructing the amplitude and the phase information of light using interference and diffraction. By introducing a metasurface to the conventional hologram, the efficiency is improved by controlling the optical properties more precisely by using various nanostructures, and the resolution can be improved by designing more structures in the same space. Metaholograms designed using inverse design [127] to increase efficiency and for orbital angular momentum (OAM) multiplexing [128] have been demonstrated for efficiency and multi-functionality. We will review the inverse design and OAM multiplexing as ways to realize effective metaholograms.

To realize the conventional multi-functional metahologram, complex designs such as interleaved [129], pixelated [12], and complex meta-atom [130] have been required. However, by introducing inverse design into metahologram design, it is possible to design high-performance metaholograms through optimized algorithms and computer modeling.

Figure 5a(i) [131] shows a metahologram realized by minimizing the objective function, which is the difference between the target image and the reconstructed image on the target plane, through gradient-descent optimization. By using the inverse design, a multifunctional metasurface can be designed with a simple single-cell rather than a complex meta-atoms. The objective function is defined through mean squared error, and meta-atom through iteration imparts the desired phase profile. The single-cell metasurface produced in this way realizes a target image with high conversion efficiency on the target plane. Also, three-dimensional (3D) holographic images can be demonstrated through inverse design. The phase profile has been optimized to split the 3D image into multiplanes and project the desired image on each target plane. Fig. 5a(ii) shows that a 3D holographic image is realized through the reconstruction of multiple sliced target plane images. In this way, the fabrication difficulty can also be lowered comparing to interleaved or multi-layer metasurfaces.

OAM [132,133,134,135,136] is one of the optical properties and represents the spiral-like phase in which the electric or magnetic field of light rotates through the following equation, exp(ilφ) (i is the imaginary unit, l is helical mode index and φ is the azimuthal angle of helical wavefront). Multiplexing OAMs and introducing them into a metahologram has the advantage of having a high degree of freedom thanks to the theoretically unbounded helical mode index and improving optical data security. This means that the OAM metahologram allows the simultaneous transmission of multiple channels of information with varying degrees of rotation.

Fig. 5b(i) [137] shows the OAM selective metahologram by creating spatial frequency distribution on the image plane through the Fourier transform and adding the phase function of the spiral phase with a helical index. When the incident beam of the planar wavefront with a helical index of 0 reaches the OAM selective metahologram, the encoded images appear overlapping. However, when OAM beams with helical indices of − 2, − 1, 1, and 2 are incident, each OAM-dependent holographic image of ‘A’, ‘B’, ‘C’, and ‘D’ are reconstructed as shown in Fig. 5b(ii).

In addition, an ultrahigh security information system of 210 OAM-dependent distinctive holographic images can be realized by multiplexing the helical mode index ranging from − 50 to 50. OAM selective metahologram can transmit multiple pieces of information with high security through multiple channels due to characteristics of numerous helical indices and suggests potential as an application for high-security communication [138].

4.1.2 Color Filters

Conventional color filters [139, 140] use dyes or pigments to absorb, transmit, or reflect only wavelengths of specific color and block wavelengths of other colors. In display, color filters have been widely used due to the realization of various colors. However, it is not chemically stable against high temperatures or intense UV rays.

By utilizing metasurfaces as the color filter, it is possible to improve performance by adjusting optical properties such as polarization, phase, and amplitude of light and to provide various colors through various nanostructure sizes. Metasurface color filters can realize high spatial resolution by packing many pixels in a small area, so they can be applied to fields requiring high-resolution imaging. In addition, a metasurface color filter has the advantage of being thin and light because it does not require additional devices. Since the size and weight of the device can be reduced, it can be applied to mobile phones and display devices with limited space. These metasurface color filters utilize transmission and reflection by inducing resonance through the interaction of nanostructures and light. Until now, many color filters using various structures such as nanograting [141, 142], nanodisk [143], and metal-insulator-metal [144] have been demonstrated. We will review these metasurface color filters by dividing them into plasmonic and dielectric color filters.

Plasmonic color filters [145,146,147] use local surface plasmon formed by the collective vibration of light waves and free electrons on the metal surface. In the case of plasmon of metal nanostructures, an electric field and absorption of light in the visible spectrum occur, resulting in vivid color, so it can act as a color filter. By adjusting the type of metal and structural parameters such as the width or length of the nanostructure, the resonant wavelength can be controlled, allowing the desired hue to be selectively realized. In general, gold or silver has been widely used owing to their chemical and mechanical stability.

Fig. 5c(i) [148] shows the sharp reflectance peak of a specific wavelength by multiplying the scaling factor after optimizing the basic length (l), width (w), and thickness (h) of the pixel on the silver film. The optimized basic parameters are l = 200 nm, w = 60 nm, and h = 40 nm. By adjusting the scaling factor from 1.20 to 2.65, most colors can be expressed by redshifting from 452 to 682 nm wavelength. In addition, by adjusting the orientation of the nanoaperture, the reflectance of cross-polarization is proportional to cos2α according to Malus’ law, and the chiaroscuro can be adjusted. Furthermore, it can express B (black) or H (hard) marked in conventional pencils. The larger Arabic numeral in front of B and H can express the meaning of softer the graphite and harder the texture through the size and rotation angle of the nanoaperture. By realizing the grayscale in Fig. 5c(ii), a 3D plasmonic microscale sketch can be created. In addition, through the hue and brightness information of the artwork, spectral and spatial information can be encoded to minimize the difference between the target image and color palette photographed by a charge-coupled device camera.

Dielectric color filters [149,150,151] reflect or transmit specific wavelengths through the interaction of nanoscale repetitive patterns of dielectric materials with various structures such as nanodisks, nanoblocks, nanogratings, and nanopillars. Color selectivity can be realized by controlling the thickness, shape, and arrangement of the structure. Due to materials with high refractive index and low extinction coefficient (k), such as a-Si:H [152] and TiO2 [153], ohmic loss (absorption) is less than plasmonic color filters, resulting in high efficiency and low cost. High refractive index dielectric materials can support electric dipole, magnetic dipole, and multiple modes.

A schematic of realizing a broadband wavelength dielectric color filter by enhancing scattering and hybridizing the lattice resonance to the Mie resonance is shown in Fig. 5d (top) [15]. Scattering is enhanced three times when it is in the form of an array rather than a single scatter. To realize various colors, a color palette can be created by adjusting the filling ratio f (f = r/P, where r is the radius and P is the grating period). The high refractive index a-Si:H (P25) has been grown at 25 mTorr pressure fixed at the height of 150 nm, and the low refractive index a-Si:H (P45) has grown at 45 mTorr pressure fixed at the height of 250 nm. A colorful butterfly and rose were realized by adjusting the period and radius shown in Fig. 5d (bottom). The red part of (i) has a larger period than the blue part of (ii). In the green part of (iii), the brightness can be adjusted through the size of the radius. Also, vivid colors can be realized by using various materials such as polyvinyl alcohol (PVA) [154, 155] and silicon nitride (Si3N4) [156], considering their optical properties.

Overall concept of metasurface display applications. a Single-cell multicolor metahologram using inverse design. (i) Illustration of a multifunctional metasurface that realizes RGB images in various focal plane. (ii) 3D metahologram targeted object of airplane composed of sliced images [131]. b OAM-dependent metahologram system through OAM-multiplexing. (i) Reconstruction of complex interference holographic image when topological charge is 0. (ii) Reconstruction of OAM-dependent holographic images when topological charges are − 2, − 1, 1, 2 [137]. c Versatile full color nanopainting by plasmonic metasurface. (i) Schematic of full color pixelated plasmonic metasurface color filter with high color saturation and wide color gamut according to scaling factor and orientation of nanoapertures. (ii) Experimental grayscale optical image of geometric objects sketch [148]. d Spectral modulation through hybridization of Mie-scatterers and Quasi-Guided mode resonances. (top) Schematic of dielectric metasurface color filter spectral modulation by adjusting period and radius, (bottom) butterfly and rose microprint using P25 and P45 a-Si:H and additional SEM images indicate (i) red, (ii) blue and (iii) green [15]

4.2 Sensors

Sensors can collect physical and chemical information about the target and convert it into signals that can be processed. However, some sensors cannot detect subtle signals over a wide range of frequencies and cannot perform multi-sensing functions. If metasurface is introduced to the sensor, signals in various frequencies can be detected, and multiple sensing that detects multiple variables simultaneously is possible. Also, a sensor with a metasurface is compatible with the CMOS process, so it can be used in various fields through miniaturization and compactness, which means that the performance of existing sensors can be upgraded.

Among them, beam steering integrated with metasurface can detect multiple directions and can be miniaturized. In addition, the sensor integrated with the BIC metasurface is capable of ultrasensitive sensing due to the ultrasharp resonance of the BIC metasurface. Beam steering and BIC metasurfaces can overcome the technical limitations of existing sensors and improve performance, so light detection and ranging (LiDAR) [18, 157, 158] or biosensors [159,160,161,162] have been actively studied. In this aspect, we will review beam steering and BIC metasurfaces.

4.2.1 Beam Steering Metasurfaces

Beam steering can control electromagnetic waves in the desired direction. The arrangement and orientation of antennas are adjusted to focus electromagnetic waves on specific areas. A wider field of view (FoV) than existing beam steering can be realized through numerous subwavelength nanoantennas. Beam steering using metasurface can be applied to the miniaturization of LiDAR, a sensor for measuring distance in autonomous vehicles through a wide FoV, and can be applied to existing systems such as large sensing range and coverage communication. We will review metasurface beam steering by dividing it into passive and tunable beam steering metasurface.

Passive beam steering metasurfaces [163, 164] perform constant beam steering through the interaction of light with fixed nanostructures regardless of external conditions. By designing an array of nanostructures, beam steering can be performed in the desired path through phases according to each array.

Conventional MHz ultrafast scanning devices, acousto-optic deflectors (AOD), have been unable to be used in LiDAR due to their very low FoV of ~ 2°. The schematic of a system that realizes FoV of 150° × 150° by extending the FoV from − 75° to 75° through a metasurface capable of steering light by 75° at a specific wavelength is shown in Fig. 6a(i) [165]. In addition, distance information can be obtained through 3D multizone imaging when the depth position is 1.2, 2.7, and 4.9 m by post-processing with simultaneous localization and mapping algorithm shown in Fig. 6a(ii). This compensates for the low FoV of the conventional AOD and realizes better performing LiDAR of real-time ultrafast imaging through the post-processing algorithm of the data received from the detector.

In addition, structured light pattern-based beam steering metasurface [19] realized 180° FoV depth sensing with accurate depth information by using ~ 10 K high-density dots irradiated through diffraction order and post-processing stereo matching algorithm. This means that the performance of LiDAR can be improved through passive beam steering metasurface.

Tunable beam steering metasurface is the integration of a metasurface made of material with tunable properties to beam steering. This enables free beam steering by controlling external conditions even after fabrication. For example, by introducing LC [166,167,168,169] or phase change materials [170, 171] with instantly changing properties, switchable beam steering can be realized. This marks a milestone in the performance of LiDAR through free control of beam steering.

Figure 6b(i) [172] shows the tunable steered beam by the voltage as the reflection coefficient changes according to Vt, which controls the voltage of the Au nanoantenna layer, and Vb, which controls the voltage of the Al layer. Depending on the voltage, a charge accumulation or depletion layer is formed between the ITO layer and the separated insulating oxide layer, so the decay rate and angular frequency change, resulting in a different reflection coefficient. Vb is fixed at -6.4, 3.2, and 6.4 V, and Vt is adjusted from − 4 to 4 V in each case to properly adjust the real and imaginary values of the reflection coefficient. Also, the splitting angle can be controlled by adjusting the period (\({{\Lambda }}_{\text{c}}\)). Also, the steered beam through the metasurface is reflected from the object, then the reflected beam enters the detector, and distance information can be 3D range mapping using the working principle of LiDAR as shown in Fig. 6b(ii). Electrically tunable beam steering enables LiDAR to act as an ultrafast distance scanner.

In addition, complex permittivity can be modulated by forming a charge accumulation or depletion layer through field effect modulation by applying an electrical bias to the ITO layer. Permittivity is one of the factors that determine the refractive index and means that the refractive index changes as voltage is applied. So, the reflection of the incident light can be controlled. Also, as the grating period decreases, the diffraction angle increases, allowing the angle of the steered beam to be freely controlled [173]. In this way, by introducing tunable materials to beam steering, free detection is possible, which means remarkable development in various devices using beam steering.

4.2.2 Bound States in the Continuum (BIC)

BICs [174,175,176,177] are special states in which a wave or particle exists in bound states at a specific wavelength or energy in continuum states. BICs are leak-free with infinite Q-factor and lifetime. Metasurfaces can allow it to exist bound only at specific wavelengths in continuous states due to the interaction of nanostructures and waves. The designed metasurface considering the interference and structure of waves shows a spectrum like Fano resonance and can realize quasi-BIC with a very high Q factor at a specific wavelength. Selective high-Q factors can improve sensing performance. BIC metasurfaces are suitable for high-sensitivity sensing through their high-Q factor at specific wavelengths. In the case of biosensors, high sensitivity and specificity are required, BIC metasurfaces are suitable alternatives. Also, advantage such as miniaturization is available. We will review BIC metasurfaces by dividing them into passive and tunable BIC metasurfaces in this section.

Passive BIC metasurfaces [178,179,180] have been formed by design such as the shape, size, and arrangement of meta-atoms on metasurface in a static state regardless of external conditions. When specific wavelength and nanostructure design match, the high-Q factor can be realized through strong absorption or scattering resonance. With this, better high-sensitivity performance can be expected than existing sensors.

MIR range sensing can be improved through a passive BIC metasurface. Barcode that represents high-Q reflectance peak at discrete wavelengths through electric near-field enhancement by varying the scaling factor of anisotropic a-Si:H resonators from 1.0 to 1.3 with a vertical length of 1.96 μm and horizontal length of 0.96 μm shown in Fig. 6c(i) [181]. Protein or specific molecules physisorption reduces the reflectance and the presence of any substance can be detected through the absorption fingerprint shown in Fig. 6c(ii). This 1.5 mm2 small molecular barcode metasurface suggests that it can be applied to high-performance biosensors. In addition, the nanoresonator optical sensor of asymmetry crescent meta-atom [182] that realizes BIC suggests that ultrasharp peak can be realized through various shapes. As such, the BIC metasurface dramatically improved the performance of the sensor.

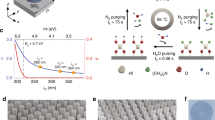

Tunable BIC metasurfaces [183,184,185] can adjust BIC properties by integrating metasurface with tunable material that can be controlled by external conditions such as temperature and voltage. It can realize properties of the tunable high Q factor in a specific wavelength band in real time.

Using arsenic sulfide (As2S3), which is a tunable chalcogenide glasses whose refractive index changes when light is received, tunable BIC metasurface has been demonstrated. The short bar length is 365 nm and the asymmetry parameter is α = 0.064, which is shown in Fig. 6d(i) [186]. Q factor follows inverse quadratic law for asymmetry parameter. Based on these properties that can control the Q factor through the degree of asymmetry, when the dosage is 20 J/cm2, the refractive index is saturated to 0.08 due to optical annealing, so the ultrasharp transmission peak is shifted by 14 nm in real-time as shown in Fig. 6d(ii). The tunable BIC metasurface can serve as a high-photosensitivity sensor with a low-loss nanoscale.

In addition, the 3 pairs of p-n junctions along a vertical direction elliptical silicon nanodisk structure [187], which uses the properties that the refractive index changes as the free carrier concentration changes according to the voltage of the semiconductor material, realizes tunable BIC by adding an asymmetry parameter. Also, depending on the Brewster-tilted light incident angle, a high Q factor tunable BIC metasurface can be realized. By introducing the optical properties of tunable materials with BIC, a high degree of freedom and sensitivity sensor can be realized, and it has opened the way for new applications of BIC.

Overall concept of metasurface sensing applications. a Metasurface-enhanced light detection and ranging technology. (i) Schematic of cascade AOD-metasurface deflection system with enhanced FoV of 150°×150° through metasurface. (ii) 3D distance imaging using cascade AOD-metasurface deflection system [165]. b All-solid-state spatial light modulator (SLM) for LiDAR. (i) Schematic of electrically tunable beam steering metasurface with periodic top Au nanoantenna, tunable ITO layer in the middle and bottom Al mirror. (ii) Scanned depth image using metaphotonic SLM [172]. c Imaging based molecular barcoding with pixelated dielectric metasurfaces. (i) High-Q reflectance peak by scaling factor S of metapixels of anisotropic a-Si:H zigzag structures and electric near-field intensity enhancement (ii) Absorption protein fingerprint due to reflectance response change in regions 1 and 2 by protein physisorption [181]. d Photosensitive chalcogenide BIC metasurface. (i) Design of metasurface square array of Ae2S3 bar pairs with different lengths by the symmetry parameter α, (ii) SEM image of fabricated metasurface and experimental results of initial and exposed transmission wavelength peak of metasurface [186]

5 Conclusions

The potential for cost-effective and environmentally friendly mass manufacturing of metasurfaces and their diverse range of applications has been explored. By utilizing techniques like DUV lithography, NIL lithography, and self-assembly-based fabrication, the mass production of metasurfaces has become a realistic prospect. These methods offer efficient and scalable solutions that can bridge the gap between complex nanostructures and massive-scale production. In terms of applications, metalenses offer breakthroughs in imaging and focusing capabilities, promising advancements in fields like microscopy and imaging devices. Display technologies, incorporating metasurfaces for color filtering and holography stand to revolutionize visual experiences with enhanced resolutions. Additionally, the integration of metasurfaces into sensors holds the potential to revolutionize sensing technologies, enabling high sensitivity and selective detection across various fields.

Further, development of effective fabrication techniques will be crucial to achieve higher production rates, eco-friendliness, and lower costs, driving metasurface technology towards commercialization. Additionally, enhancing the efficiency and broadband performance of metasurfaces will unlock their full potential across applications, such as energy harvesting, communication systems, and more. In addition, complex design and optimization of optical metasurfaces need advanced computational tools and multidisciplinary collaboration. Materials engineering and durability considerations are also vital, particularly when integrating metasurfaces into real-world devices.

In conclusion, the cost-effective and environmentally friendly mass manufacturing of metasurfaces and their practical applications hold immense promise for commercialization. Advancements in fabrication techniques and continued research efforts will pave the way for transformative innovations across industries, propelling metasurface technology from the laboratory to widespread implementation.

References

Yu, N., & Capasso, F. (2014). Flat optics with designer metasurfaces. Nature Materials,13(2), 139–150. https://doi.org/10.1038/nmat3839

Chen, W. T., Zhu, A. Y., & Capasso, F. (2020). Flat optics with dispersion-engineered metasurfaces. Nature Reviews Materials,5(8), 604–620. https://doi.org/10.1038/s41578-020-0203-3

Kim, I., Yoon, G., Jang, J., Genevet, P., Nam, K. T., & Rho, J. (2018). Outfitting next generation displays with optical metasurfaces. ACS Photonics,5(10), 3876–3895. https://doi.org/10.1021/acsphotonics.8b00809

Yu, N., Genevet, P., Kats, M. A., Aieta, F., Tetienne, J. P., Capasso, F., & Gaburro, Z. (2011). Light propagation with phase discontinuities: Generalized laws of reflection and refraction. Science,334(6054), 333–337. https://doi.org/10.1126/science.1210713

Overvig, A. C., Shrestha, S., Malek, S. C., Lu, M., Stein, A., Zheng, C., & Yu, N. (2019). Dielectric metasurfaces for complete and Independent control of the optical amplitude and phase. Light: Science & Applications,8(1), 92. https://doi.org/10.1038/s41377-019-0201-7

Yoon, G., Jang, J., Mun, J., Nam, K. T., & Rho, J. (2019). Metasurface Zone plate for light manipulation in vectorial regime. Communications Physics,2(1), 156. https://doi.org/10.1038/s42005-019-0258-x

Yang, Y., Kang, H., Jung, C., Seong, J., Jeon, N., Kim, J., Oh, D. K., Park, J., Kim, H., & Rho, J. (2023). Revisiting optical material platforms for efficient linear and nonlinear dielectric metasurfaces in the ultraviolet, visible, and infrared. ACS Photonics,10(2), 307–321. https://doi.org/10.1021/acsphotonics.2c01341

Khorasaninejad, M., Chen, W. T., Devlin, R. C., Oh, J., Zhu, A. Y., & Capasso, F. (2016). Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science,352(6290), 1190–1194. https://doi.org/10.1126/science.aaf6644

Chen, X., Huang, L., Mühlenbernd, H., Li, G., Bai, B., Tan, Q., Jin, G., Qiu, C. W., Zhang, S., & Zentgraf, T. (2012). Dual-polarity plasmonic metalens for visible light. Nature Communications,3(1), 1198. https://doi.org/10.1038/ncomms2207

Chen, W. T., Zhu, A. Y., Sanjeev, V., Khorasaninejad, M., Shi, Z., Lee, E., & Capasso, F. (2018). A broadband achromatic metalens for focusing and imaging in the visible. Nature Nanotechnology,13(3), 220–226. https://doi.org/10.1038/s41565-017-0034-6

Wang, S., Wu, P. C., Su, V. C., Lai, Y. C., Chen, M. K., Kuo, H. Y., Chen, B. H., Chen, Y. H., Huang, T. T., Wang, J. H., Lin, R. M., Kuan, C. H., Li, T., Wang, Z., Zhu, S., & Tsai, D. P. (2018). A broadband achromatic metalens in the visible. Nature Nanotechnology,13(3), 227–232. https://doi.org/10.1038/s41565-017-0052-4

Chen, W. T., Yang, K. Y., Wang, C. M., Huang, Y. W., Sun, G., Chiang, I. D., Liao, C. Y., Hsu, W. L., Lin, H. T., Sun, S., Zhou, L., Liu, A. Q., & Tsai, D. P. (2014). High-efficiency broadband meta-hologram with polarization-controlled dual images. Nano Letters,14(1), 225–230. https://doi.org/10.1021/nl403811d

Mehmood, M. Q., Seong, J., Naveed, M. A., Kim, J., Zubair, M., Riaz, K., Massoud, Y., & Rho, J. (2022). Single-cell-driven tri-channel encryption meta-displays. Advanced Science,9(35), 2203962. https://doi.org/10.1002/advs.202203962

Kim, I., Jang, J., Kim, G., Lee, J., Badloe, T., Mun, J., & Rho, J. (2021). Pixelated bifunctional metasurface-driven dynamic vectorial holographic color prints for photonic security platform. Nature Communications,12(1), 3614. https://doi.org/10.1038/s41467-021-23814-5

Jang, J., Badloe, T., Yang, Y., Lee, T., Mun, J., & Rho, J. (2020). Spectral modulation through the hybridization of Mie-scatterers and quasi-guided mode resonances: Realizing full and gradients of structural color. ACS Nano,14(11), 15317–15326. https://doi.org/10.1021/acsnano.0c05656

Jung, C., Kim, S. J., Jang, J., Ko, J. H., Kim, D., Ko, B., Song, Y. M., Hong, S. H., & Rho, J. (2022). Disordered-nanoparticle–based etalon for ultrafast humidity-responsive colorimetric sensors and anti-counterfeiting displays. Science Advances,8(10), eabm8598. https://doi.org/10.1126/sciadv.abm8598

Joo, W. J., Kyoung, J., Esfandyarpour, M., Lee, S. H., Koo, H., Song, S., Kwon, Y. N., Song, S. H., Bae, J. C., Jo, A., Kwon, M. J., Han, S. H., Kim, S. H., Hwang, S., & Brongersma, M. L. (2020). Metasurface-driven OLED displays beyond 10,000 pixels per inch. Science,370(6515), 459–463. https://doi.org/10.1126/science.abc8530

Kim, I., Martins, R. J., Jang, J., Badloe, T., Khadir, S., Jung, H. Y., Kim, H., Kim, J., Genevet, P., & Rho, J. (2021). Nanophotonics for light detection and ranging technology. Nature Nanotechnology,16(5), 508–524. https://doi.org/10.1038/s41565-021-00895-3

Kim, G., Kim, Y., Yun, J., Moon, S. W., Kim, S., Kim, J., Park, J., Badloe, T., Kim, I., & Rho, J. (2022). Metasurface-driven full-space structured light for three-dimensional imaging. Nature Communications,13(1), 5920. https://doi.org/10.1038/s41467-022-32117-2

Basiri, A., Chen, X., Bai, J., Amrollahi, P., Carpenter, J., Holman, Z., Wang, C., & Yao, Y. (2019). Nature-inspired chiral metasurfaces for circular polarization detection and full-stokes polarimetric measurements. Light: Science & Applications,8(1), 78. https://doi.org/10.1038/s41377-019-0184-4

Pyo, S., & Park, K. (2023). Mechanical metamaterials for sensor and actuator applications. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-023-00549-w.

So, S., Yang, Y., Lee, T., & Rho, J. (2021). On-demand design of spectrally sensitive multiband absorbers using an artificial neural network. Photonics Research,9(4), B153–B158. https://doi.org/10.1364/PRJ.415789

Ko, B., Badloe, T., Kim, S. J., Hong, S. H., & Rho, J. (2020). Employing vanadium dioxide nanoparticles for flexible metasurfaces with switchable absorption properties at near-infrared frequencies. Journal of Optics,22(11), 114002. https://doi.org/10.1088/2040-8986/abbc55

Yoon, G., So, S., Kim, M., Mun, J., Ma, R., & Rho, J. (2017). Electrically tunable metasurface perfect absorber for infrared frequencies. Nano Convergence,4(1), 36. https://doi.org/10.1186/s40580-017-0131-0

Yang, Y., Seong, J., Choi, M., Park, J., Kim, G., Kim, H., Jeong, J., Jung, C., Kim, J., Jeon, G., Lee, K., Yoon, D. H., & Rho, J. (2023). Integrated metasurfaces for re-envisioning a near-future disruptive optical platform. Light: Science & Applications,12(1), 152. https://doi.org/10.1038/s41377-023-01169-4

Metasurfaces go mainstream. (2023). Nature Photonics,17(1), 1–1. https://doi.org/10.1038/s41566-022-01137-1

Badloe, T., Seong, J., & Rho, J. (2023). Trichannel spin-selective metalenses. Nano Letters,23(15), 6958–6965. https://doi.org/10.1021/acs.nanolett.3c01588

Kim, J., Seong, J., Kim, W., Lee, G. Y., Kim, S., Kim, H., Moon, S. W., Oh, D. K., Yang, Y., Park, J., Jang, J., Kim, Y., Jeong, M., Park, C., Choi, H., Jeon, G., Lee, K., Yoon, D. H., Park, N., … Rho, J. (2023). Scalable manufacturing of high-index atomic layer–polymer hybrid metasurfaces for metaphotonics in the visible. Nature Materials,22(4), 474–481. https://doi.org/10.1038/s41563-023-01485-5

Yoon, G., Tanaka, T., Zentgraf, T., & Rho, J. (2021). Recent progress on metasurfaces: Applications and fabrication. Journal of Physics D: Applied Physics,54(38), 383002. https://doi.org/10.1088/1361-6463/ac0faa

Hu, J., Bandyopadhyay, S., Liu, Y., & Shao, L. (2021). A review on metasurface: From principle to smart metadevices [Review]. Frontiers in Physics. https://doi.org/10.3389/fphy.2020.586087

Li, N., Xu, Z., Dong, Y., Hu, T., Zhong, Q., Fu, Y. H., Zhu, S., & Singh, N. (2020). Large-area metasurface on CMOS-compatible fabrication platform: Driving flat optics from lab to fab. Nanophotonics,9(10), 3071–3087. https://doi.org/10.1515/nanoph-2020-0063

Kim, H., Chavan, V. D., Aziz, J., Ko, B., Lee, J. S., Rho, J., Dongale, T. D., Choi, K. K., & Kim, D. K. (2022). Effect of ALD processes on physical and electrical properties of HfO 2 dielectrics for the surface passivation of a CMOS image sensor application. IEEE Access : Practical Innovations, Open Solutions,10, 68724–68730. https://doi.org/10.1109/ACCESS.2022.3183593

Gu, T., Kim, H. J., Rivero-Baleine, C., & Hu, J. (2023). Reconfigurable metasurfaces towards commercial success. Nature Photonics,17(1), 48–58. https://doi.org/10.1038/s41566-022-01099-4

Lee, G. Y., Hong, J. Y., Hwang, S., Moon, S., Kang, H., Jeon, S., Kim, H., Jeong, J. H., & Lee, B. (2018). Metasurface eyepiece for augmented reality. Nature Communications,9(1), 4562. https://doi.org/10.1038/s41467-018-07011-5

Lalanne, P., & Chavel, P. (2017). Metalenses at visible wavelengths: Past, present, perspectives. Laser & Photonics Reviews,11(3), 1600295. https://doi.org/10.1002/lpor.201600295

Liang, H., Lin, Q., Xie, X., Sun, Q., Wang, Y., Zhou, L., Liu, L., Yu, X., Zhou, J., Krauss, T. F., & Li, J. (2018). Ultrahigh numerical aperture metalens at visible wavelengths. Nano Letters,18(7), 4460–4466. https://doi.org/10.1021/acs.nanolett.8b01570

Paniagua-Domínguez, R., Yu, Y. F., Khaidarov, E., Choi, S., Leong, V., Bakker, R. M., Liang, X., Fu, Y. H., Valuckas, V., Krivitsky, L. A., & Kuznetsov, A. I. (2018). A metalens with a near-unity numerical aperture. Nano Letters,18(3), 2124–2132. https://doi.org/10.1021/acs.nanolett.8b00368

Li, Z., Pestourie, R., Park, J. S., Huang, Y. W., Johnson, S. G., & Capasso, F. (2022). Inverse design enables large-scale high-performance meta-optics reshaping virtual reality. Nature Communications,13(1), 2409. https://doi.org/10.1038/s41467-022-29973-3

Devlin, R. C., Khorasaninejad, M., Chen, W. T., Oh, J., & Capasso, F. (2016). Broadband high-efficiency dielectric metasurfaces for the visible spectrum. Proceedings of the National Academy of Sciences,113(38), 10473–10478. https://doi.org/10.1073/pnas.1611740113

Ji, S., Kim, Y., & Cha, S. W. (2022). Operating cost savings in the atomic layer deposition process of ultrathin electrolyte for solid oxide fuel cells by applying oxygen plasma. International Journal of Precision Engineering and Manufacturing,23(5), 573–579. https://doi.org/10.1007/s12541-022-00626-1

Roos, M. M., Winkler, A., Nilsen, M., Menzel, S. B., & Strehle, S. (2022). Towards green 3D-microfabrication of Bio-MEMS devices using ADEX dry film photoresists. International Journal of Precision Engineering and Manufacturing-Green Technology,9, 43–57. https://doi.org/10.1007/s40684-021-00367-y

Go, D., Shin, J. W., Lee, S., Lee, J., Yang, B. C., Won, Y., Motoyama, M., & An, J. (2023). Atomic layer deposition for thin film solid-state battery and capacitor. International Journal of Precision Engineering and Manufacturing-Green Technology,10(3), 851–873. https://doi.org/10.1007/s40684-022-00419-x

She, A., Zhang, S., Shian, S., Clarke, D. R., & Capasso, F. (2018). Large area metalenses: Design, characterization, and mass manufacturing. Optics Express,26(2), 1573–1585. https://doi.org/10.1364/OE.26.001573

Park, J. S., Zhang, S., She, A., Chen, W. T., Lin, P., Yousef, K. M. A., Cheng, J. X., & Capasso, F. (2019). All-glass, large metalens at visible wavelength using deep-ultraviolet projection lithography. Nano Letters,19(12), 8673–8682. https://doi.org/10.1021/acs.nanolett.9b03333

Leitis, A., Tseng, M. L., John-Herpin, A., Kivshar, Y. S., & Altug, H. (2021). Wafer-scale functional metasurfaces for mid-infrared photonics and biosensing. Advanced Materials,33(43), 2102232. https://doi.org/10.1002/adma.202102232

Tao, J., You, Q., Li, Z., Luo, M., Liu, Z., Qiu, Y., Yang, Y., Zeng, Y., He, Z., Xiao, X., Zheng, G., & Yu, S. (2022). Mass-manufactured beam-steering metasurfaces for high-speed full-duplex optical wireless-broadcasting communications. Advanced Materials,34(6), 2106080. https://doi.org/10.1002/adma.202106080

Choi, H., Kim, J., Kim, W., Seong, J., Park, C., Choi, M., Kim, N., Ha, J., Qiu, C. W., Rho, J., & Lee, H. (2023). Realization of high aspect ratio metalenses by facile nanoimprint lithography using water-soluble stamps. PhotoniX,4(1), 18. https://doi.org/10.1186/s43074-023-00096-2

Panuski, C. L., Christen, I., Minkov, M., Brabec, C. J., Trajtenberg-Mills, S., Griffiths, A. D., McKendry, J. J. D., Leake, G. L., Coleman, D. J., Tran, C., St Louis, J., Mucci, J., Horvath, C., Westwood-Bachman, J. N., Preble, S. F., Dawson, M. D., Strain, M. J., Fanto, M. L., & Englund, D. R. (2022). A full degree-of-freedom spatiotemporal light modulator. Nature Photonics,16(12), 834–842. https://doi.org/10.1038/s41566-022-01086-9

Zhang, L., Chang, S., Chen, X., Ding, Y., Rahman, M. T., Duan, Y., Stephen, M., & Ni, X. (2023). High-efficiency, 80 mm aperture metalens telescope. Nano Letters,23(1), 51–57. https://doi.org/10.1021/acs.nanolett.2c03561

Parkj, J. S., Lim, S. W. D., Amirzhan, A., Kang, H., Karrfalt, K., Kim, D., Leger, J., Urbas, A. M., Ossiander, M., Li, Z., & Capasso, F. (2023). All-glass 100 mm diamter visible metalens for imaing the cosmos. arXiv preprint arXiv:2307.08186. https://doi.org/10.48550/arXiv.2307.08186.

Le, T. H. H., Morita, A., Mawatari, K., Kitamori, T., & Tanaka, T. (2018). Metamaterials-enhanced infrared spectroscopic study of nanoconfined molecules by plasmonics–nanofluidics hydrid device. ACS Photonics,5(8), 3179–3188. https://doi.org/10.1021/acsphotonics.8b00398

Kim, W., Yoon, G., Kim, J., Jeong, H., Kim, Y., Choi, H., Badloe, T., Rho, J., & Lee, H. (2022). Thermally-curable nanocomposite printing for the scalable manufacturing of dielectric metasurfaces. Microsystems & Nanoengineering,8(1), 73. https://doi.org/10.1038/s41378-022-00403-0

Oh, D. K., Lee, T., Ko, B., Badloe, T., Ok, J. G., & Rho, J. (2021). Nanoimprint lithography for high-throughput fabrication of metasurfaces. Frontiers of Optoelectronics,14(2), 229–251. https://doi.org/10.1007/s12200-021-1121-8

Sreenivasan, S. V. (2017). Nanoimprint lithography steppers for volume fabrication of leading-edge semiconductor integrated circuits. Microsystems & Nanoengineering,3(1), 17075. https://doi.org/10.1038/micronano.2017.75

Kim, K., Yoon, G., Baek, S., Rho, J., & Lee, H. (2019). Facile nanocasting of dielectric metasurfaces with sub-100 nm resolution. ACS Applied Materials & Interfaces,11(29), 26109–26115. https://doi.org/10.1021/acsami.9b07774

Yoon, G., Kim, K., Huh, D., Lee, H., & Rho, J. (2020). Single-step manufacturing of hierarchical dielectric metalens in the visible. Nature Communications,11(1), 2268. https://doi.org/10.1038/s41467-020-16136-5

Kim, J., Oh, D. K., Kim, H., Yoon, G., Jung, C., Kim, J., Badloe, T., Kang, H., Kim, S., Yang, Y., Lee, J., Ko, B., Ok, J. G., & Rho, J. (2022). Metasurface holography reaching the highest efficiency limit in the visible via one-step nanoparticle-embedded-resin printing. Laser & Photonics Reviews,16(8), 2200098. https://doi.org/10.1002/lpor.202200098

Einck, V. J., Torfeh, M., McClung, A., Jung, D. E., Mansouree, M., Arbabi, A., & Watkins, J. J. (2021). Scalable nanoimprint lithography process for manufacturing visible metasurfaces composed of high aspect ratio TiO2 meta-atoms. ACS Photonics,8(8), 2400–2409. https://doi.org/10.1021/acsphotonics.1c00609

Yoon, G., Kim, K., Kim, S. U., Han, S., Lee, H., & Rho, J. (2021). Printable nanocomposite metalens for high-contrast near-infrared imaging. ACS Nano,15(1), 698–706. https://doi.org/10.1021/acsnano.0c06968

Kim, J., Kim, W., Oh, D. K., Kang, H., Kim, H., Badloe, T., Kim, S., Park, C., Choi, H., Lee, H., & Rho, J. (2023). One-step printable platform for high-efficiency metasurfaces down to the deep-ultraviolet region. Light: Science & Applications,12(1), 68. https://doi.org/10.1038/s41377-023-01086-6

Ok, J. G., Seok Youn, H., Kyu Kwak, M., Lee, K. T., Shin, J., Guo, Y. J., Greenwald, L., A., & Liu, Y. (2012). Continuous and scalable fabrication of flexible metamaterial films via roll-to-roll nanoimprint process for broadband plasmonic infrared filters. Applied Physics Letters.https://doi.org/10.1063/1.4767995.

Lee, S. H., & Lee, S. (2022). Fabrication of comb-structured acceleration sensors by roll-to-roll gravure printing. International Journal of Precision Engineering and Manufacturing-Green Technology,9(2), 409–420. https://doi.org/10.1007/s40684-021-00342-7

Kim, S., Jung, C., Mun, J., Kim, M., Yoon, H., Jang, J., Go, M., Lee, J., Rho, J., & Kim, J. K. (2022). Self-assembled pagoda-like nanostructure-induced vertically stacked split-ring resonators for polarization-sensitive dichroic responses. Nano Convergence,9(1), 40. https://doi.org/10.1186/s40580-022-00331-9

Kang, H., Lee, D., Yang, Y., Kyo Oh, D., Seong, J., Kim, J., Jeon, N., Kang, D., & Rho, J. (2023). Emerging low-cost, large-scale photonic platforms with soft lithography and self-assembly. Photonics Insights,2(2), R04–R04. https://doi.org/10.3788/PI.2023.R04

Das Gupta, T., Martin-Monier, L., Yan, W., Le Bris, A., Nguyen-Dang, T., Page, A. G., Ho, K. T., Yesilköy, F., Altug, H., Qu, Y., & Sorin, F. (2019). Self-assembly of nanostructured glass metasurfaces via templated fluid instabilities. Nature Nanotechnology,14(4), 320–327. https://doi.org/10.1038/s41565-019-0362-9

Gao, P., He, J., Zhou, S., Yang, X., Li, S., Sheng, J., Wang, D., Yu, T., Ye, J., & Cui, Y. (2015). Large-area nanosphere self-assembly by a micro-propulsive injection method for high throughput periodic surface nanotexturing. Nano Letters,15(7), 4591–4598. https://doi.org/10.1021/acs.nanolett.5b01202

Lee, D., Go, M., Kim, M., Jang, J., Choi, C., Kim, J. K., & Rho, J. (2021). Multiple-patterning colloidal lithography-implemented scalable manufacturing of heat-tolerant titanium nitride broadband absorbers in the visible to near-infrared. Microsystems & Nanoengineering,7(1), 14. https://doi.org/10.1038/s41378-020-00237-8

Go, M., Lee, D., Kim, S., Jang, J., Kim, K. W., Lee, J., Shim, S., Kim, J. K., & Rho, J. (2023). Facile fabrication of titanium nitride nanoring broad-band absorbers in the visible to near-infrared by shadow sphere lithography. ACS Applied Materials & Interfaces,15(2), 3266–3273. https://doi.org/10.1021/acsami.2c17875

Huang, Y., Yang, R., Xiao, T., Li, H., Tian, M., Xie, Z., Zheng, J., Zhu, J., Su, Y., Chen, W., Liu, K., Tang, M., & Li, L. (2022). Wafer-scale self-assembled 2.5D metasurface for efficient near-field and far-field electromagnetic manipulation. Applied Surface Science,601, 154244. https://doi.org/10.1016/j.apsusc.2022.154244

Arbabi, A., & Faraon, A. (2023). Advances in optical metalenses. Nature Photonics,17(1), 16–25. https://doi.org/10.1038/s41566-022-01108-6

Khorasaninejad, M., & Capasso, F. (2017). Metalenses: Versatile multifunctional photonic components. Science,358(6367), eaam8100. https://doi.org/10.1126/science.aam8100

Kim, J., Seong, J., Yang, Y., Moon, S. W., Badloe, T., & Rho, J. (2022). Tunable metasurfaces towards versatile metalenses and metaholograms: A review. Advanced Photonics,4(2), 024001–024001. https://doi.org/10.1117/1.AP.4.2.024001

Jeon, D., Shin, K., Moon, S. W., & Rho, J. (2023). Recent advancements of metalenses for functional imaging. Nano Convergence,10(1), 1–26. https://doi.org/10.1186/s40580-023-00372-8

Lan, S., Zhang, X., Taghinejad, M., Rodrigues, S., Lee, K. T., Liu, Z., & Cai, W. (2019). Metasurfaces for near-eye augmented reality. ACS Photonics,6(4), 864–870. https://doi.org/10.1021/acsphotonics.9b00180

Runji, J. M., Lee, Y. J., & Chu, C. H. (2023). Systematic literature review on augmented reality-based maintenance applications in manufacturing centered on operator needs. International Journal of Precision Engineering and Manufacturing-Green Technology,10(2), 567–585. https://doi.org/10.1007/s40684-022-00444-w

Nam, Y. G., Park, S. Y., & Kwon, B. S. (2023). Rehabilitation exercise using a smart-bar device with augmented reality guide function. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-023-00815-6

Li, Z., Lin, P., Huang, Y. W., Park, J. S., Chen, W. T., Shi, Z., Qiu, C. W., Cheng, J. X., & Capasso, F. (2021). Meta-optics achieves RGB-achromatic focusing for virtual reality. Science Advances,7(5), eabe4458. https://doi.org/10.1126/sciadv.abe4458

Lin, R. J., Su, V. C., Wang, S., Chen, M. K., Chung, T. L., Chen, Y. H., Kuo, H. Y., Chen, J. W., Chen, J., & Huang, Y. T. (2019). Achromatic metalens array for full-colour light-field imaging. Nature Nanotechnology,14(3), 227–231. https://doi.org/10.1038/s41565-018-0347-0

Colburn, S., Zhan, A., & Majumdar, A. (2018). Metasurface optics for full-color computational imaging. Science Advances,4(2), eaar2114. https://doi.org/10.1126/sciadv.aar2114

Ye, X., Qian, X., Chen, Y., Yuan, R., Xiao, X., Chen, C., Hu, W., Huang, C., Zhu, S., & Li, T. (2022). Chip-scale metalens microscope for wide-field and depth-of-field imaging. Advanced Photonics, 4(4), 046006–046006. https://doi.org/10.1117/1.AP.4.4.046006.

Rho, J., Ye, Z., Xiong, Y., Yin, X., Liu, Z., Choi, H., Bartal, G., & Zhang, X. (2010). Spherical hyperlens for two-dimensional sub-diffractional imaging at visible frequencies. Nature Communications,1(1), 143. https://doi.org/10.1038/ncomms1148

Wang, S., Wu, P. C., Su, V. C., Lai, Y. C., Chu, H., Chen, C., Lu, J. W., Chen, S. H., Xu, J., & Kuan, C. H. (2017). Broadband achromatic optical metasurface devices. Nature Communications,8(1), 187. https://doi.org/10.1038/s41467-017-00166-7

Javed, I., Kim, J., Naveed, M. A., Oh, D. K., Jeon, D., Kim, I., Zubair, M., Massoud, Y., Mehmood, M. Q., & Rho, J. (2022). Broad-band polarization-insensitive metasurface holography with a single-phase map. ACS Applied Materials & Interfaces,14(31), 36019–36026. https://doi.org/10.1021/acsami.2c07960

Avayu, O., Almeida, E., Prior, Y., & Ellenbogen, T. (2017). Composite functional metasurfaces for multispectral achromatic optics. Nature Communications,8(1), 14992. https://doi.org/10.1038/ncomms14992

Zhou, Y., Kravchenko, I. I., Wang, H., Nolen, J. R., Gu, G., & Valentine, J. (2018). Multilayer noninteracting dielectric metasurfaces for multiwavelength metaoptics. Nano Letters,18(12), 7529–7537. https://doi.org/10.1021/acs.nanolett.8b03017

Chen, W. T., Zhu, A. Y., Sisler, J., Bharwani, Z., & Capasso, F. (2019). A broadband achromatic polarization-insensitive metalens consisting of anisotropic nanostructures. Nature Communications,10(1), 355. https://doi.org/10.1038/s41467-019-08305-y

Wang, Y., Chen, Q., Yang, W., Ji, Z., Jin, L., Ma, X., Song, Q., Boltasseva, A., Han, J., & Shalaev, V. M. (2021). High-efficiency broadband achromatic metalens for near-IR biological imaging window. Nature Communications,12(1), 5560. https://doi.org/10.1038/s41467-021-25797-9

Baek, S., Kim, J., Kim, Y., Cho, W. S., Badloe, T., Moon, S. W., Rho, J., & Lee, J. L. (2022). High numerical aperture RGB achromatic metalens in the visible. Photonics Research,10(12), B30–B39. https://doi.org/10.1364/PRJ.470004

Aieta, F., Kats, M. A., Genevet, P., & Capasso, F. (2015). Multiwavelength achromatic metasurfaces by dispersive phase compensation. Science,347(6228), 1342–1345. https://doi.org/10.1126/science.aaa2494

Yang, Y., Yoon, G., Park, S., Namgung, S. D., Badloe, T., Nam, K. T., & Rho, J. (2021). Revealing structural disorder in hydrogenated amorphous silicon for a low-loss photonic platform at visible frequencies. Advanced Materials,33(9), 2005893. https://doi.org/10.1002/adma.202005893

Ren, H., Jang, J., Li, C., Aigner, A., Plidschun, M., Kim, J., Rho, J., Schmidt, M. A., & Maier, S. A. (2022). An achromatic metafiber for focusing and imaging across the entire telecommunication range. Nature Communications,13(1), 4183. https://doi.org/10.1038/s41467-022-31902-3

Joe, H. E., Yun, H., Jo, S. H., Jun, M. B., & Min, B. K. (2018). A review on optical fiber sensors for environmental monitoring. International Journal of Precision Engineering and Manufacturing-Green Technology,5, 173–191. https://doi.org/10.1007/s40684-018-0017-6

Molesky, S., Lin, Z., Piggott, A. Y., Jin, W., Vucković, J., & Rodriguez, A. W. (2018). Inverse design in nanophotonics. Nature Photonics,12(11), 659–670. https://doi.org/10.1038/s41566-018-0246-9

Lee, C., Chang, G., Kim, J., Hyun, G., Bae, G., So, S., Yun, J., Seong, J., Yang, Y., & Park, D. Y. (2022). Concurrent optimization of diffraction fields from binary phase mask for three-dimensional nanopatterning. ACS Photonics,10(4), 919–927. https://doi.org/10.1021/acsphotonics.2c01324

So, S., Mun, J., Park, J., and Rho, J. (2022). Revisiting the design strategies for metasurfaces: Fundamental physics, optimization, and beyond. Advanced Materials,35(43), 2206399. https://doi.org/10.1002/adma.202206399.

Kim, D. H., Kim, T. J., Wang, X., Kim, M., Quan, Y. J., Oh, J. W., Min, S. H., Kim, H., Bhandari, B., & Yang, I. (2018). Smart machining process using machine learning: A review and perspective on machining industry. International Journal of Precision Engineering and Manufacturing-Green Technology,5, 555–568. https://doi.org/10.1007/s40684-018-0057-y