Abstract

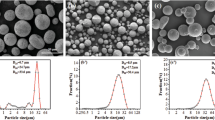

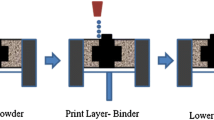

Gadolinium-doped ceria (GDC) is sought-after as an electrolyte layer in solid oxide fuel cells because of its high ionic conductivity and low treatment temperature. Recently, some studies have been reported to produce a component layer of solid oxide fuel cell using a Roll-to-Roll (R2R) system because of its characteristics of the cost-effective and eco-friendly advantages. However, the brittleness and low density of GDC prevent it from being mass-produced via the R2R continuous process. Therefore, we attempted to improve the density of GDC-based multi-electrolyte layers through an optimized R2R calendaring process. The finite element method was employed to determine suitable materials for the calendering rolls and the maximum calendering pressure that would reduce the thickness and porosity of the coated electrolyte layer without producing cracks in the layer. The effect of the number of calendering processes on the thickness and porosity of the electrolyte layers was examined as well. Silicon and steel were observed to be best-suited as the materials for the top and bottom rolls, respectively. Moreover, the maximum permissible calendering pressure was determined to be 15 MPa, while the ideal number of calendering processes was found to be 5. Experimental observations using scanning electron microscopy confirmed that the optimized calendering process reduced the thickness and porosity of the coated electrolyte layers by 16.99% and 7.04%, respectively. Thus, our findings suggest that large-area, high-density GDC-based multi-electrolyte layers with smooth surfaces can be produced via the R2R process, which can enable mass production of SOFCs.

Similar content being viewed by others

References

Søndergaard, R., Hösel, M., Angmo, D., Larsen-Olsen, T. T., & Krebs, F. C. (2012). Roll-to-roll fabrication of polymer solar cells. Materials today, 15(1–2), 36–49. https://doi.org/10.1016/S1369-7021(12)70019-6

Schwartz, E. (2006). Roll to roll processing for flexible electronics (p. 11). Cornell University.

Ma, L., Chen, J., Tang, W., & Yin, Z. (2017). Transverse vibration and instability of axially travelling web subjected to non-homogeneous tension. International Journal of Mechanical Sciences, 133, 752–758. https://doi.org/10.1016/j.ijmecsci.2017.09.047

Jo, M., Lee, J., Kim, S., Cho, G., Lee, T. M., & Lee, C. (2021). Resistance control of an additively manufactured conductive layer in roll-to-roll gravure printing systems. International Journal of Precision Engineering and Manufacturing-Green Technology, 8(3), 817–828. https://doi.org/10.1007/s40684-021-00345-4

Lee, Y., Jo, M., Cho, G., Joo, C., & Lee, C. (2021). Impact of sensor data characterization with directional nature of fault and statistical feature combination for defect detection on roll-to-roll printed electronics. Sensors, 21(24), 8454. https://doi.org/10.3390/s21248454

Kim, S., Jo, M., Lee, J., & Lee, C. (2021). Transmittance control of a water-repellent-coated layer on a tensioned web in a roll-to-roll slot-die coating system. Polymers, 13(22), 4003. https://doi.org/10.3390/polym13224003

Lee, J., Jo, M., & Lee, C. (2021). Advanced tension model for highly integrated flexible electronics in roll-to-roll manufacturing. IEEE/ASME Transactions on Mechatronics. https://doi.org/10.1109/TMECH.2021.3128992

Lee, J., Kim, S., & Lee, C. (2019). Taper tension profile in roll-to-roll rewinder: Improving adhesive force of pressure-sensitive adhesive film. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(5), 853–860. https://doi.org/10.1007/s40684-019-00100-w

Lee, C., Kim, S., Jo, M., & Lee, J. (2021). Residual interfacial deformation in flexible copper clad laminate occurring during roll-to-roll composite film manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology, 8(3), 805–815. https://doi.org/10.1007/s40684-021-00349-0

Kang, H. K., Lee, C. W., Shin, K. H., & Kim, S. C. (2011). Modeling and matching design of a tension controller using pendulum dancer in roll-to-roll systems. IEEE Transactions on Industry Applications, 47(4), 1558–1566. https://doi.org/10.1109/TIA.2011.2156376

Mollamahmutoglu, C., & Good, J. K. (2015). Modeling the influence of web thickness and length imperfections resulting from manufacturing processes on wound roll stresses. CIRP Journal of Manufacturing Science and Technology, 8, 22–33. https://doi.org/10.1016/j.cirpj.2014.10.004

Chen, Z., Zheng, Y., Zhou, M., Wong, D. S. H., Chen, L., & Deng, Z. (2016). Model-based feedforward register control of roll-to-roll web printing systems. Control Engineering Practice, 51, 58–68. https://doi.org/10.1016/j.conengprac.2016.03.009

Lee, J., Kim, S., & Lee, C. (2019). Surface drying for brittle material coating without crack defects in large-area roll-to-roll coating system. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(4), 723–730. https://doi.org/10.1007/s40684-019-00104-6

Xia, Z. C., & Hutchinson, J. W. (2000). Crack patterns in thin films. Journal of the Mechanics and Physics of Solids, 48(6–7), 1107–1131. https://doi.org/10.1016/S0022-5096(99)00081-2

Jo, M., Lee, J., Kim, S., Cho, G., Lee, T. M., & Lee, C. (2020). Web unevenness due to thermal deformation in the roll-to-roll manufacturing process. Applied Sciences, 10(23), 8636. https://doi.org/10.3390/app10238636

Ebler, N. A., Arnason, R., Michaelis, G., & D’Sa, N. (1993). Tension control: Dancer rolls or load cells. IEEE Transactions on Industry Applications, 29(4), 727–739.

Sakamoto, T., & Fujino, Y. (1995). Modelling and analysis of a web tension control system. In 1995 Proceedings of the IEEE International Symposium on Industrial Electronics (Vol. 1, pp. 358–362). IEEE. https://doi.org/10.1109/ISIE.1995.497022

Lynch, A. F., Bortoff, S. A., & Röbenack, K. (2004). Nonlinear tension observers for web machines. Automatica, 40(9), 1517–1524. https://doi.org/10.1016/j.automatica.2004.03.021

Shin, K. H., & Kwon, S. O. (2007). The effect of tension on the lateral dynamics and control of a moving web. IEEE Transactions on Industry Applications, 43(2), 403–411. https://doi.org/10.1109/TIA.2006.889742

Lee, C., Kang, H., Kim, C., & Shin, K. (2010). A novel method to guarantee the specified thickness and surface roughness of the roll-to-roll printed patterns using the tension of a moving substrate. Journal of Microelectromechanical Systems, 19(5), 1243–1253. https://doi.org/10.1109/JMEMS.2010.2067194

Lee, J., Shin, K., & Lee, C. (2015). Analysis of dynamic thermal characteristic of register of roll-to-roll multi-layer printing systems. Robotics and Computer-Integrated Manufacturing, 35, 77–83. https://doi.org/10.1016/j.rcim.2015.02.008

Cho, G. Y., Yu, W., Lee, Y. H., Lee, Y., Tanveer, W. H., Kim, Y., & Cha, S. W. (2020). Effects of nanoscale PEALD YSZ interlayer for AAO based thin film solid oxide fuel cells. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(2), 423–430. https://doi.org/10.1007/s40684-019-00082-9

Lee, J., Choi, M., & Lee, W. (2021). Encapsulation of metal catalysts for stable solid oxide fuel cell cathodes. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-020-00290-8

Karimaghaloo, A., Koo, J., Kang, H. S., Song, S. A., Shim, J. H., & Lee, M. H. (2019). Nanoscale surface and interface engineering of solid oxide fuel cells by atomic layer deposition. International Journal of Precision engineering and Manufacturing-green Technology, 6(3), 611–628. https://doi.org/10.1007/s40684-019-00090-9

Shim, J. H., Han, G. D., Choi, H. J., Kim, Y., Xu, S., An, J., & Prinz, F. B. (2019). Atomic layer deposition for surface engineering of solid oxide fuel cell electrodes. International Journal of Precision Engineering and Manufacturing-Green Technology, 6(3), 629–646. https://doi.org/10.1007/s40684-019-00092-7

Son, J., Hwang, S., Hong, S., Heo, S., & Kim, Y. B. (2020). Parameter study on solid oxide fuel cell heat-up process to reaction starting temperature. International Journal of Precision Engineering and Manufacturing-Green Technology, 7(6), 1073–1083. https://doi.org/10.1007/s40684-019-00129-x

Leng, Y. J., Chan, S. H., Jiang, S. P., & Khor, K. A. (2004). Low-temperature SOFC with thin film GDC electrolyte prepared in situ by solid-state reaction. Solid State Ionics, 170(1–2), 9–15. https://doi.org/10.1016/j.ssi.2004.02.026

Steele, B. C. (2000). Appraisal of Ce1− yGdyO2− y/2 electrolytes for IT-SOFC operation at 500° C. Solid State Ionics, 129(1–4), 95–110. https://doi.org/10.1016/S0167-2738(99)00319-7

Mogensen, M., Sammes, N. M., & Tompsett, G. A. (2000). Physical, chemical and electrochemical properties of pure and doped ceria. Solid State Ionics, 129(1–4), 63–94. https://doi.org/10.1016/S0167-2738(99)00318-5

Liu, Q. L., Khor, K. A., Chan, S. H., & Chen, X. J. (2006). Anode-supported solid oxide fuel cell with yttria-stabilized zirconia/gadolinia-doped ceria bilalyer electrolyte prepared by wet ceramic co-sintering process. Journal of Power Sources, 162(2), 1036–1042. https://doi.org/10.1016/j.jpowsour.2006.08.024

Jeong, C., Lee, J. H., Park, M., Hong, J., Kim, H., Son, J. W., Lee, J. H., Kim, B. K., & Yoon, K. J. (2015). Design and processing parameters of La2NiO4+ δ-based cathode for anode-supported planar solid oxide fuel cells (SOFCs). Journal of Power Sources, 297, 370–378.

Kim, S., Lee, J., Jo, M., & Lee, C. (2020). Numerical modeling of ink widening and coating gap in roll-to-roll slot-die coating of solid oxide fuel cell electrolytic layer. Polymers, 12(12), 2927. https://doi.org/10.3390/polym12122927

Lee, J., Byeon, J., & Lee, C. (2020). Fabrication of thickness-controllable double layer electrolyte using roll-to-roll additive manufacturing system. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 1–8.

Kim, S., Lee, J., & Lee, C. (2019). Computational fluid dynamics model for thickness and uniformity prediction of coating layer in slot-die process. The International Journal of Advanced Manufacturing Technology, 104(5), 2991–2997. https://doi.org/10.1007/s00170-019-04093-3

Song, X., Meng, F., Kong, M., Liu, Z., Huang, L., Zheng, X., & Zeng, Y. (2017). Relationship between cracks and microstructures in APS YSZ coatings at elevated temperatures. Materials Characterization, 131, 277–284. https://doi.org/10.1016/j.matchar.2017.07.008

Roisum, D. R. (1996). The Mechanics of Rollers. Tappi press.

Kim, J., Kim, J., Yoon, K. J., Son, J. W., Lee, J. H., Lee, J. H., Lee, H. W., & Ji, H. I. (2020). Solid oxide fuel cells with zirconia/ceria bilayer electrolytes via roll calendering process. Journal of Alloys and Compounds. https://doi.org/10.1016/j.jallcom.2020.156318

Toor, S. Y., & Croiset, E. (2020). Reducing sintering temperature while maintaining high conductivity for SOFC electrolyte: Copper as sintering aid for Samarium Doped Ceria. Ceramics International, 46(1), 1148–1157. https://doi.org/10.1016/j.ceramint.2019.09.083

Wang, Y., Jia, C., Lyu, Z., Han, M., Wu, J., Sun, Z., Iguchi, F., Yashiro, K., & Kawada, T. (2021). Performance and stability analysis of SOFC containing thin and dense gadolinium-doped ceria interlayer sintered at low temperature. Journal of Materiomics. https://doi.org/10.1016/j.jmat.2021.09.001

Kim, J., Ahn, J., Shin, J., Yoon, K. J., Son, J. W., Lee, J. H., Shin, D., Lee, H. W., & Ji, H. I. (2019). Enhanced sinterability and electrochemical performance of solid oxide fuel cells via a roll calendering process. Journal of Materials Chemistry A, 7(16), 9958–9967. https://doi.org/10.1039/c9ta01818b

Jambhapuram, M., Good, J. K., & Azoug, A. (2021). Finite element investigation of lamination-induced curl due to residual stresses. Forces in Mechanics, 4, 100034. https://doi.org/10.1016/j.finmec.2021.100034

Liu, Y., Zhang, R., Wang, J., & Wang, Y. (2021). Current and future lithium-ion battery manufacturing. IScience, 24(4), 102332. https://doi.org/10.1016/j.isci.2021.102332

Cordill, M. J., Jörg, T., Többens, D. M., & Mitterer, C. (2021). Improved fracture resistance of Cu/Mo bilayers with thickness tailoring. Scripta Materialia, 202, 113994. https://doi.org/10.1016/j.scriptamat.2021.113994

Acknowledgements

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No.2020R1A2C1012428) & (No.2020R1A5A1019649).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

This manuscript has not been published or presented elsewhere in part or in entirety and is not under consideration by another journal. We have read and understood your journal’s policies, and we believe that neither the manuscript nor the study violates any of these. There are no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jo, M., Kim, S. & Lee, C. Morphology Engineering for Compact Electrolyte Layer of Solid Oxide Fuel Cell with Roll-to-Roll Eco-production. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 431–441 (2022). https://doi.org/10.1007/s40684-022-00425-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-022-00425-z