Abstract

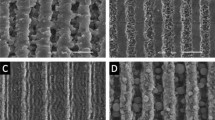

As well as the micro patterns, many functional surfaces exhibit micro/nano hierarchical patterns. Micro- and nano-patterned surfaces can be fabricated using various techniques including photolithography, electron-beams, and so on. However, these processes were developed for semiconductor fabrication and are not convenient for large-area applications. In this paper, we describe a manufacturing process for micro/nano hierarchical patterns using a laser and an abrasive air jet, whereby the laser is used to manufacture microscale patterns, and an abrasive air jet is applied to the micro-patterned surface to generate the nanoscale patterns. This method is a simple process that can be used to rapidly manufacture hierarchical patterns, making it suitable for large-area applications. We also developed a friction test system, which minimizes external vibrations and sample wear during the measurements. Our results showed that the coefficient of friction of the hierarchical patterns was 12% smaller than that of microscale patterns.

Similar content being viewed by others

Abbreviations

- C s :

-

Coefficient of maximum static friction

- C k =C f :

-

Coefficient of kinematic friction

- μ :

-

Dynamic viscosity

- U :

-

Velocity in friction test

- P :

-

Pressure in friction test

- O :

-

Initial sapphire surface

- N :

-

Nano patterned surface

- M :

-

Micro patterned surface

- M+N :

-

Micro/Nano hierarchical patterned surface

References

Kim, J., Je, T. J., Cho, S. H., Jeon, E. C., and Whang, K. H., “Micro-Cutting with Diamond Tool Micro-Patterned by Femtosecond Laser,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 6, pp. 1081–1085, 2014.

Kurniawan, R. and Ko, T. J., “Friction Reduction on Cylindrical Surfaces by Texturing with a Piezoelectric Actuated Tool Holder,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 5, pp. 861–868, 2015.

Tsipenyuk, A. and Varenberg, M., “Use of Biomimetic Hexagonal Surface Texture in Friction Against Lubricated Skin.” Journal of the Royal Society Interface Vol. 11, No. 94, Paper No. 20140113, 2014.

Wu, C.W., Kong, X. Q., and Wu, D., “Micronanostructures of the Scales on a Mosquito’s Legs and their Role in Weight Support,” Physical Review E, Vol. 76, No. 1, Paper No. 017301, 2007.

Rykaczewski, K., Paxson, A. T., Staymates, M., Walker, M. L., Sun, X., et al., “Dropwise Condensation of Low Surface Tension Fluids on Omniphobic Surfaces,” Scientific Reports, Vol. 4, No. 4158, 2014.

Borghi, A., Gualtieri, E., Marchetto, D., Moretti, L., and Valeri, S., “Tribological Effects of Surface Texturing on Nitriding Steel for High-Performance Engine Applications,” Wear, Vol. 265, No. 7, pp. 1046–1051, 2008.

Wanga, X., Katoa, K., Adachia, K., and Aizawab, K., “Loads Carrying Capacity Map for the Surface Texture Design of SiC Thrust Bearing Sliding in Water,” Tribology International, Vol. 36, No. 3, pp. 189–197, 2003.

Hao, L., Meng, Y., and Chen, C., “Experimental Investigation on Effects of Surface Texturing on Lubrication of Initial Line Contacts,” Lubrication Science, Vol. 26, No. 5, pp. 363–373, 2014.

Myshkin, N. K. and Grigoriev, A. Y., “Morphology: Texture, Shape, and Color of Friction Surfaces and Wear Debris in Tribodiagnostics Problems,” Journal of Friction and Wear, Vol. 29, No. 3, pp. 192–199, 2008.

Shao, J., Ding, Y., Wang, W., Mei, X., Zhai, H., et al., “Generation of Fully-Covering Hierarchical Micro-Nano-Structures by Nanoimprinting and Modified Laser Swelling,” Small, Vol. 10, No. 13, pp. 2595–2601, 2014.

Röhrig, M., Thiel, M., Worgull, M., and Hölscher, H., “3D Direct Laser Writing of Nano- and Microstructured Hierarchical Gecko-Mimicking Surfaces,” Small, Vol. 8, No. 19, pp. 3009–3015, 2012.

Ajayi, O. O., Greco, A. C., Erck, R. A., and Frenske, G. R., “Surface Texturing for Friction Control,” Argonne National Laboratory, pp. 1–13, 2010.

Wang, W.-Z., Huang, Z., Shen, D., Kong, L., and Li, S., “The Effect of Triangle-Shaped Surface Textures on the Performance of the Lubricated Point-Contacts,” Journal of Tribology, Vol. 135, No. 2, pp. 1–11, 2013.

Tang, H., Li, H., and Xu, J., “Growth and Development of Sapphire Crystal for LED Applications,” INTECH Open Science and Open Minds, Chap. 10, pp. 307–333, 2013.

Precision Sapphire Technologies, “Our Products-Sapphire Physical properties,” http://www.sapphire.lt/sapphire (Accessed 23 December 2016)

Neoplus, “Product-Tribology System Friction & Wear Test System-UFW200,” http://i-neoplus.co.kr/02_product/tribology-equipment.php (Accessed 23 December 2016)

Stribeck, R. and Cutaway, C., “Generating a Stribeck Curve in a Reciprocating Test (HFRR/SRV-type test),” https://www.bruker.com/fileadmin/user_upload/8-PDF-Docs/SurfaceAnalysis/TMT/Application Notes/AN1004_RevA2_Generating_a_Stribeck_Curve_in_a_Reciprocating_Test-AppNote.pdf (Accessed 23 December 2016)

Etsion, I., Halperin, G., and Becker, E., “The Effect of Various Surface Treatments on Piston Pin Scuffing Resistance,” Wear, Vol. 261, No. 7, pp. 785–791, 2006.

Elleuch, R., Elleuch, K., Abdelounis, H. B., and Zahouani, H., “Surface Roughness Effect on Friction Behaviour of Elastomeric Material,” Materials Science and Engineering A, Vol. 465, No. 1, pp. 8–12, 2007.

Nakano, M., Korenaga, A., Korenaga, A., Miyake, K., Murakami, T., et al., “Applying Micro-Texture to Cast Iron Surfaces to Reduce the Friction Coefficient Under Lubricated Conditions,” Tribology Letters, Vol. 28, No. 2, pp. 131–137, 2007.

Yu, H., Wang, X., and Zhou, F., “Geometric Shape Effects of Surface Texture on the Generation of Hydrodynamic Pressure Between Conformal Contacting Surfaces,” Tribology Letters, Vol. 37, No. 2, pp. 123–130, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, M., Lee, S.M., Lee, S.J. et al. Effect on friction reduction of micro/nano hierarchical patterns on sapphire wafers. Int. J. of Precis. Eng. and Manuf.-Green Tech. 4, 27–35 (2017). https://doi.org/10.1007/s40684-017-0004-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-017-0004-3