Abstract

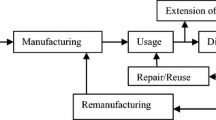

Remanufacturing is one of the critical elements moving our economy toward one that is circular. Today, remanufacturing is attracting growing attention worldwide. Meanwhile, despite its potential in terms of its effects on both environment and economy, remanufacturing has not yet been sufficiently exploited. This indicates that there exist both drivers for and barriers to an increase in remanufacturing in economies. Although there are both technological and non-technological requirements for remanufacturing, R&D is unavoidable for its promotion. This article outlines trends, drivers, and barriers for remanufacturing, and presents reviews of studies on selected topics in remanufacturing. The selected R&D topics in this article are product design for remanufacturing, additive manufacturing for remanufacturing, operations management in remanufacturing, and business models for remanufacturing.

Similar content being viewed by others

Abbreviations

- OEM:

-

original equipment manufacturer

- IR:

-

independent remanufacturer

- DfRem:

-

design for remanufacturing

- EOL:

-

end of life

- AM:

-

additive manufacturing

- CLSC:

-

closed loop supply chain

- PSS:

-

product service system

References

Giuntini, R. and Gaudette, K., “Remanufacturing: The Next Great Opportunity for Boosting US Productivity,” Business Horizons, Vol. 46, No. 6, pp. 41–48, 2003.

Nasr, N. and Thurston, M., “Remanufacturing: A Key Enabler to Sustainable Product Systems,” Proc. of 13th CIRP International Conference on Life-Cycle Engineering, pp.15–18, 2006.

Steinhilper, R., “Remanufacturing: The Ultimate Form of Recycling,” Stuttgart: Fraunhofer IRB Verlag, 1998.

Nasr, N., “Reman for Success,” Industrial Engineer, Vol. 42, No. 6, pp. 26–27, 2010.

Lund, R., “The Remanufacturing Industry: Hidden Giant,” Boston University Press, 1996.

U.S. International Trade Commission, “Remanufactured Goods: An Overview of the U.S. and Global Industries, Markets, and Trade,” USITC Publication 4356, Investigation No. 332–525, 2012.

Frost&Sullivan, “360 Degree Perspective of the North American Automotive Aftermarket,” http://wwwslidesharenet/soaringvjr/northamerican-auto-aftermarket-frost-0211# (Accessed 14 September 2015)

Hammond, R., Amezquita, T., and Bras, B., “Issues in the Automotive Parts Remanufacturing Industry: A Discussion of Results from Surveys Performed among Remanufacturers,” International Journal of Engineering Design and Automation, Vol. 4, No. 1, pp. 27–46, 1998.

Seitz, M., “A Critical Assessment of Motives for Product Recovery: the Case of Engine Remanufacturing,” Journal of Cleaner Production, Vo.15, No. 11–12, pp. 1147–1157, 2007.

Ellen MacArthur Foundation, “Towards the Circular Economy,” http://wwwellenmacarthurfoundationorg/assets/downloads/ publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1pdf (Accessed 28 December 2015)

Guide, V. D. R. and Van Wassenhove, L. N, “The Reverse Supply Chain: Smart Manufacturers are Designing Efficient Processes for Reusing Their Products,” Harvard Business Review, Vol. 80, No. 2, pp. 25–26, 2002.

Matsumoto, M. and Umeda, Y., “An Analysis of Remanufacturing Practices in Japan,” Journal of Remanufacturing, Vol. 1, No. 1, pp. 1–11, 2011.

Matsumoto, M. and Kamigaki, K., “Development and Changes in the Industrial Product Service Systems -A Case Study of the Photocopier PSS,” in: The Philosopher’s Stone for Sustainability, Shimomura, Y. and Kimita, K., (Eds.), Springer, pp. 167–172, 2013.

Duflou, J. R, Seliger, G., Kara, S., Umeda, Y., Ometto, A., et al., “Efficiency and Feasibility of Product Disassembly: A Case-Based Study,” CIRP Annals-Manufacturing Technology, Vol. 57, No. 2, pp. 583–600, 2008.

Andreu, J., “The Remanufacturing Process,” Manchester Metropolitan University, Manchester, UK, 1995.

Amezquita, T., Hammond, R., Salazar, M., and Bras, B., “Characterizing the Remanufacturability of Engineering Systems,” Proc. of ASME Advances in Design Automation Conference, pp. 271–278, 1995.

Shu, L. H. and Flowers, W. C., “Application of a Design-for-Remanufacture Framework to the Selection of Product Life-Cycle Fastening and Joining Methods,” Vol. 15, No. 3, pp. 179–190, 1999.

Rose, C., Ishii, K., and Stevels, A., “ELDA and EVCA: Tools for Building Product End-of-Life Strategy,” Journal of Sustainable Product Design, Vol. 1, No. 3, pp. 181–195, 2001.

Ijomah, W., McMahon, C., Hammond, G., and Newman, S., “Development of Robust Design-for-Remanufacturing Guidelines to Further the Aims of Sustainable Development,” International Journal of Production Research, Vol. 45, No. 18–19, pp. 4513–4536, 2007.

Charter, M. and Gray, C., “Remanufacturing and Product Design,” International Journal of Product Development, Vol. 6, No. 3–4, pp. 375–392, 2008.

Pigosso, D., Zanette, E., Filho, A., Ometto, A., and Rozenfeld, H., “Ecodesign Methods Focused on Remanufacturing,” Journal of Cleaner Production, Vol. 18, No. 1, pp. 21–31, 2010.

Resource Recovery Forum (RRF), “Remanufacturing in the UK: A Snapshot of the UK Remanufacturing Industry 2009,” http:// wwwremanufacturingorguk/pdf/story/1p342pdf (Accessed 28 December 2015)

Advanced Remanufacturing and Technology Centre, “About ARTC,” http://wwwa-staredusg/artc/About-ARTCaspx (Accessed 14 July 2015)

Malaysia Ministry of International Trade and Industry, “Exploring Re-Manufacturing Activities in Malaysia,” 2012.

Guidat, T., Barquet, A., Widera, H., Rozenfeld, H., and Seliger, G., “Guidelines for the Definition of Innovative Industrial Product-Service Systems (PSS) Business Models for Remanufacturing,” Procedia CIRP, Vol. 16, pp. 193–198, 2014.

Geyer, R. and Jackson, T., “Supply Loops and Their Constraints: the Industrial Ecology of Recycling and Reuse,” California Management Review, Vol. 46, No. 2, pp. 55–73, 2004.

Lundmark, P., Sundin, E., and Bjeorkman, M., “Industrial Challenges within the Remanufacturing System,” Proc. of Swedish Production Symposium, pp. 132–139, 2009.

Lund, R. and Skeels, F., “Guidelines for an Original Equipment Manufacturer Starting a Remanufacturing Operation,” Government Report No. DOE/CS/40192, CPA-83.8 Cambridge, Center for Policy Alternatives, 1983.

Linton, J., “Assessing the Economic Rationality of Remanufacturing Products,” Journal of Product Innovation Management, Vol. 25, No. 3, pp. 287–302, 2008.

Atasu, A., Sarvary, M., and Wassenhove, L. N. V., “Remanufacturing as a Marketing Strategy,” Management Science, Vol. 54, No. 10, pp. 1731–1746, 2008.

Chang, Y., Bae J., and Yi, H., “Ultrasonic Cleaning of Used Plastic Parts for Remanufacturing of Multifunctional Digital Copier,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 6, pp. 951–956, 2013.

Guide, V. D. R., “Production Planning and Control for Remanufacturing: Industry Practice and Research Needs,” Journal of Operations Management, Vol. 18, No. 4, pp. 467–483, 2000.

David, M. and Anderson, P. E., “Design for Manufacturability: How to Use Concurrent Engineering to Rapidly Develop Low-Cost,” High-Quality Products for Lean Production, CRC Press, 2014.

Sundin, E., “Product and Process Design for Successful Remanufacturing,” Linköping Studies in Science and Technology Dissertation, No. 906, 2004.

Ijomah, W., McMahon, C., Hammond, G., and Newman, S., “Development of Design for Remanufacturing Guidelines to Support Sustainable Manufacturing,” Robotics and Computer-Integrated Manufacturing, Vol. 23, No. 6, pp. 712–719, 2007.

Mabee, D., Bommer, M., and Keat, W., “Design Charts for Remanufacturing Assessment,” Journal of Manufacturing Systems, Vol. 18, No. 5, pp. 358–366, 1999.

McGlothlin, S. and Kroll, E., “Systematic Estimation of Disassembly Difficulties: Application to Computer Monitors,” Proc. of the IEEE International Symposium on Electronics and the Environment, pp. 83–88, 1995.

Zwolinski, P., Lopez-Ontiveros, M., and Brissaud, D., “Integrated Design of Remanufacturable Products Based on Product Profiles,” Journal of Cleaner Production, Vol. 14, No. 15, pp. 1333–1345, 2006.

Bras, B. and Hammond, R., “Towards Remanufacturing: Metrics for Assessing Remanufacturability,” Proc. of 1st International Workshop on Reuse, pp. 35–52, 1996.

Du, Y., Cao, H., Liu, F., Li, C., and Chen, X., “An Integrated Method for Evaluating the Remanufacturability of Used Machine Tool,” Journal of Cleaner Production, Vol. 20, No. 1, pp. 82–91, 2012.

Sherwood, A. and Shu, L., “FMEA-Based Design for Remanufacture Using Automotive-Remanufacturer Data,” Society of Automotive Engineers, Paper No. 2001–01-0308, 2000.

King, A. and Burgess, S., “The Development of a Remanufacturing Platform Design: A Strategic Response to the Directive on Waste Electrical and Electronic Equipment,” Journal of Engineering Manufacture, Vol. 219, No. 8, pp. 623–631, 2005.

Yang, S. S., Ong, S. K., and Nee, A. Y. C., “Design for Remanufacturing: A Fuzzy-QFD Approach,” Proc. of 20th CIRP International Conference on Life Cycle Engineering, pp. 633–638, 2013.

Hatcher, G., Ijomah, W., and Windmill, J., “Design for Remanufacture: A Literature Review and Future Research Needs,” Journal of Cleaner Production, Vol. 19, No. 17, pp. 2004–2014, 2011.

Fava, J. A., “Life Cycle Thinking: Application to Product Design,” Proc. of the IEEE International Symposium on Electronics and the Environment, pp. 69–73,1993.

Yang, S., Ngiam, H., Ong, S., and Nee, A., “The Impact of Automotive Product Remanufacturing on Environmental Performance,” Procedia CIRP, Vol. 29, pp. 774–779, 2015.

Bras, B. and McIntosh, M. W., “Product, Process, and Organizational Design for Remanufacture: An Overview of Research,” Robotics and Computer-Integrated Manufacturing, Vol. 15, No. 3, pp. 167–178, 1999.

Matsumoto, M., Nakamura, N., and Takenaka, T., “Business Constraints in Reuse Practices,” IEEE Technology and Society Magazine, pp. 55–63, 2010.

ASTM No. F2792–12a, (Withdrawn 2015), “Standard Terminology for Additive Manufacturing Technologies,” 2012.

Wholers Associates, “Wohlers Report 2015,” http://wwwwohlersa ssociatescom/2015reporthtm (Accessed 28 December 2015)

Wilson, M., Piya, P., Shin, Y., Zhao, F., and Ramani, K., “Remanufacturing of Turbine Blades by Laser Direct Deposition with Its Energy and Environmental Impact Analysis,” Journal of Cleaner Production, Vol. 80, pp. 170–178, 2014.

Zhang, Y., Yang, Z., He, G., Qin, Y., and Zhang, H., “Remanufacturing-Oriented Geometric Modelling for the Damaged Region of Components,” Procedia CIRP, Vol. 29, pp. 798–803, 2015.

Paulic, M., Irgolic, T., Balic, J., Cus, F., Cupar, A., et al., “Reverse Engineering of Parts with Optical Scanning and Additive Manufacturing,” Procedia Engineering, Vol. 69, pp. 795–803, 2014.

Chen, C., Wang, Y., Ou, H., He, Y., and Tan, Z., “A Review on Remanufacture of Dies and Moulds,” Journal of Cleaner Production, Vol. 64, pp. 13–23, 2014.

Jhavar, S., Jain, N., and Paul, C., “Development of Micro-Plasma Transferred arc (μ-PTA) Wire Deposition Process for Additive Layer Manufacturing Application,” Journal of Materials Processing Technology, Vol. 214, No. 5, pp. 1102–1110, 2014.

Navrotsky, V., “3D Printing at Siemens Power Service,” Siemens, 2014.

Gaoa, W., Zhang, Y., Ramanujan, D., Ramani, K., Chen, Y., et al., “The Status, Challenges, and Future of Additive Manufacturing in Engineering,” Computer-Aided Design, Vol. 69, pp. 65–89, 2015.

Deolitte University Press, “3D Opportunity for the Department of Defense,” http://dupresscom/articles/additive-manufacturing-defense-3d-printing/ (Accessed November 22 2015)

Boivie, K., Dolinsek, S., and Homar, D., “Hybrid Manufacturing; Integration of Additive Technologies for Competitive Production of Complex Tools and Products,” 15th International Research/Expert Conference, 2011.

CIRP, “CIRP STC DN -2014 Annual Report,” wwwcirpnet/ scientific-groups/stc-dn-design/828-stc-dn-2014-annual-reporthtml (Accessed November 22 2015)

VDI-Standard: VDI 3405, “Additive Manufacturing Processes, Rapid Manufacturing -Basics, Definitions, Processes,” 2014.

Guide, D. and Van Wassenhove, L., “Closed-Loop Supply Chain: An Introduction to the Feature Issue (Part 1),” Production and Operations Management, Vol. 15, No. 3, pp. 345–350, 2006.

Kelle, P. and Silver, E., “Forecasting the Returns of Reusable Containers,” Journal of Operations Management, Vol. 8, No. 1, pp. 17–35, 1989.

Goh, T. and Varaprasad, N., “A Statistical Methodology for the Analysis of the Life-Cycle of Reusable Containers,” IIE Transactions, Vol. 18, No. 1, pp. 42–47, 1986.

De Brito, M. P. and Van der Laan, E. A., “Inventory Control with Product Returns: The Impact of Imperfect Information,” European Journal of Operational Research, Vol. 194, No. 1, pp. 85–101, 2009.

Toktay, L. B., Wein, L. M., and Zenios, S. A., “Inventory Management of Remanufacturable Products,” Management Science, Vol. 46, No. 11, pp.1412–1426, 2000.

Marx-Gomez, J., Rautenstrauch, C., Nurnberger, A., and Kruse, R., “Neuro-Fuzzy Approach to Forecast Returns of Scrapped Products to Recycling and Remanufacturing,” Knowledge-Based Systems, Vol. 15, No. 1, pp. 119–128, 2002.

Matsumoto, M. and Komatsu, S., “Demand Forecasting for Production Planning in Remanufacturing,” International Journal of Advanced Manufacturing Technology, Vol. 79, No. 1–4, pp. 161–175, 2015.

Ilgin, M. and Gupta, S., “Environmentally Conscious Manufacturing and Product recovery (ECMPRO): A Review of the State of the Art,” Journal of environmental management, Vol. 91, No. 3, pp. 563–591, 2010.

Guide, V. D. R., “Scheduling Using Drum-Buffer-Rope in a Remanufacturing Environment,” International Journal of Production Research, Vol. 34, No. 4, pp. 1081–1091, 1996.

Guide, V. D. R., Srivastava, R., and Kraus, M. E., “Priority Scheduling Policies for Repair Shops,” International Journal of Production Research, Vol. 38, No. 4, pp. 929–950, 2000.

Guide, V. D. R., Souza, G., and Van der Laan, E., “Performance of Static Priority Rules for Shared Facilities in a Remanufacturing Shop with Disassembly and Reassembly,” European Journal of Operational Research, Vol. 164, No. 2, pp. 341–353, 2005.

Guide, V. D. R. and Spencer, M. S., “Rough-Cut Capacity Planning for Remanufacturing Firms,” Production Planning&Control, Vol. 8, No. 3, pp. 237–244, 1997.

Kim, K., Jeong, B., and Jeong, S., “Optimization Model for Remanufacturing System at Strategic and Operational Level,” Proc. of International Conference on Computational Science and Its Applications, pp. 566–576, 2005.

Franke, C., Basdere, B., Ciupek, M., and Seliger, S., “Remanufacturing of Mobile Phones -Capacity, Program and Facility Adaptation Planning,” Omega, Vol. 34, No. 6, pp. 562–570, 2006.

Guide, V. D. R., Jayaraman, V., and Srivastava, R., “Production Planning and Control for Remanufacturing: A State-of-the-Art Survey,” Robotics and Computer-Integrated Manufacturing, Vol. 15, No. 3, pp. 221–230, 1999.

Ferrer, G. and Whybark, D. C., “Material Planning for a Remanufacturing Facility,” Production&Operations Management, Vol. 10, No. 2, pp. 112–124, 2001.

Souza, G., Ketzenberg, M., and Guide, V. D. R., “Capacitated Remanufacturing with Service Level Constraints,” Production and Operations Management, Vol. 11, No. 2, pp. 231–248, 2002.

Gupta, S. and Veerakamolmal, P., “Aggregate Planning for End-of-Life Products,” in: Greener Manufacturing and Operations: From Design to Delivery and Back, Sarkis, J., (Ed.), Greenleaf Publishing Ltd., pp. 205–222, 2001.

Kiesmueller, G. and Minner, S., “Simple Expression for Finding Recovery System Inventory Control Parameter Values,” Journal of the Operational Research Society, Vol. 54, No. 1, pp. 83–88, 2003.

Fleischmann, M. and Minner, S., “Inventory Management in Closed-Loop Supply Chains,” in: Supply Chain Management and Reverse Logistics, Dyckhoff, H., Lacker, R., and Reese, J., (Eds.), Springer, Heidelberg, pp. 115–138, 2004.

Ferguson, M., “Strategic Issue in Closed-Loop Supply Chains with Remanufacturing,” Auerbach Publications, 2010.

Geyer, R., Van Wassenhove, L. N., and Atasu, A., “The Economics of Remanufacturing under Limited Component Durability and Finite Product Lifecycle,” Management Science, Vol. 53, No. 1, pp. 88–100, 2007.

Inderfurth, K. and Van der Laan, E., “Leadtime Effects and Policy Improvement for Stochastic Inventory Control with Remanufacturing,” International Journal of Production Economics, Vol. 71, No. 1, pp. 381–390, 2001.

Schrady, D. A., “A Deterministic Inventory Model for Repairable Items,” Naval Research Logistics Quarterly, Vol. 14, No. 3, pp. 391–398, 1967.

Dobos, I. and Richter, K., “The Integer EOQ Repair and Waste Disposal Model -Further Analysis,” Central European Journal of Operations Research, Vol. 8, No. 2, pp. 173–195, 2000.

Teunter, R. H., “Economic Ordering Quantities for Recoverable Item Inventory Systems,” Naval Research Logistics (NRL), Vol. 48, No. 6, pp. 484–495, 2001.

Tang, O. and Naim, M. M., “The Impact of Information Transparency on the Dynamic Behavior of a Hybrid Manufacturing/ Remanufacturing System,” International Journal of Production Research, Vol. 42, No. 19, pp. 4135–4152, 2004.

Teunter, R., Kaparis, K., and Tang, O., “Multi-Product Economic Lot Scheduling Problem with Separate Production Lines for Manufacturing and Remanufacturing,” European Journal of Operational Research, Vol. 191, No. 3, pp. 1241–1253, 2008.

Kenne, J. P., Dejax, P., and Gharbi, A., “Production Planning of a Hybrid Manufacturing-Remanufacturing System under Uncertainty within a Closed-Loop Supply Chain,” International Journal of Production Economics, Vol. 135, No. 1, pp. 81–93, 2012.

Kainuma, Y., “Sustainable Operations and Closed-Loop Supply Chain,” Journal of Japan Industrial Administration Association, Vol. 64, No. 2E, pp. 348–355, 2013.

Vandermerwe. S. and Rada, J., “Servitization of Business: Adding Value by Adding Services,” Eur Manage Journal, Vol. 6, No. 4, pp. 314–324, 1989.

Goedkoop, M. J., Van Halen C. J. G., Te Riele, H. R. M., and Rommens, P. J. M., “Product Service Systems, Ecological and Economic Basis,” VROM: Hague, 1999.

Stahel, W. R., “The Product Life Factor,” http://infohousep2ricorg/ ref/33/32217pdf (Accessed on September 14 2015)

Tukker, A., “Eight Types of Product-Service System: Eight Ways to Sustainability? Experiences from SusProNet,” Business Strategy and the Environment, Vol. 13, No. 4, pp. 246–260, 2004.

Mont, O., “Product-Service Systems -Panacea or Myth?” VDM Verlag, 2008.

Tukker, A., “Product Services for a Resource-Efficient and Circular Economy: A Review,” Journal of Cleaner Production, Vol. 97, pp. 76–91, 2015.

Sundin, E. and Bras, B., “Making Functional Sales Environmentally and Economically Beneficial through Product Remanufacturing,” Journal of Cleaner Production, Vol. 13 No. 9, pp. 913–25, 2005.

Stahel, W. R., “The Performance Economy,” Palgrave Macmillan, 2006.

Sakao, T. and Shimomura, Y., “Service Engineering: A Novel Engineering Discipline for Producers to Increase Value Combing Service and Product,” Journal of Cleaner Production, Vol. 15, No. 6, pp. 590–604, 2007.

Meier, H., Roy, R., and Seliger, G., “Industrial Product-Service Systems -IPS2,” CIRP Annals -Manufacturing Technology, Vol. 59, No. 2, pp. 607–627, 2010.

Londe, B. J. L., “Customer Service: Meaning and Measurement,” National Council of Physical Distribution Management, 1976.

Kotler, P., “Marketing Management: Analysis, Planning, Implementation, and Control,” Prentice Hall, 1997.

Um, J. Y. and Suh, S. H., “Design Method for Developing a Product Recovery Management System Based on Life Cycle Information,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 2, No. 2, pp. 173–187, 2015.

Oliva, R. and Kallenberg, R., “Managing the Transition from Products to Services,” International Journal of Service Industry Management, Vol. 14, No. 2, pp. 160–172, 2003.

Neely, A., “Exploring the Financial Consequences of the Servitization of Manufacturing,” Operations Management Research, Vol. 1, No. 2, pp. 103–118, 2008.

Baines, T. S., Lightfoot, H. W., Benedettini, O., and Kay, J. M., “The Servitization of Manufacturing: A Review of Literature and Reflection on Future Challenges,” Journal of Manufacturing Technology Management, Vol. 20, No. 5, pp. 547–567, 2009.

Turunen, T. and Toivonen, M., “Organizing Customer-Oriented Service Business in Manufacturing,” Operations Management Research, Vol. 4, No. 1–2, pp. 74–84, 2011.

Quinn, J. B., Doorley, T. L., and Paquette, P. C., “Beyond Products: Services-Based Strategy,” Harvard Business Review, Vol. 68, No. 2, pp. 58–67, 1990.

Brax, S., “A Manufacturer Becoming Service Provider-Challenges and a Paradox,” Managing Service Quality: An International Journal, Vol. 15, No. 2, pp. 142–155, 2005.

Wise, R. and Baumgartner, P., “Go Downstream: The New Profit Imperative in Manufacturing,” Harvard Business Review, Vol. 77, No. 5, pp. 133–141, 1999.

Kuo, T. C., “Simulation of Purchase or Rental Decision-Making Based on Product Service System,” International Journal of Advanced Manufacturing Technology, Vol. 52, No. 9–12, pp. 1239–1249, 2011.

Besch, K., “Product-Service Systems for Office Furniture: Barriers and Opportunities on the European Market,” Journal of Cleaner Production, Vol. 13, No. 10, pp. 1083–1094, 2005.

Aurich, J., Fuchs, C., and DeVries, M. F., “An Approach to Life Cycle Oriented Technical Service Design,” CIRP Annals -Manufacturing Technology, Vol. 53, No. 1, pp. 151–154. 2004.

Shimomura, Y., Hara, T., and Arai, T., “A Unified Representation Scheme for Effective PSS Development,” CIRP Annals -Manufacturing Technology, Vol. 58, No. 1, pp. 379–382, 2009.

Martinsen, K. and Gulbrandsen-Dahla, S., “Use of Post-Consumer Scrap in Aluminium Wrought Alloy Structural Components for the Transportation Sector,” Procedia CIRP, Vol. 29, pp. 686–691, 2015.

Crul, M., Diehl, J. C., and Ryan, C., “Design for Sustainability -A Step by Step Approach,” http://wwwd4s-sbsorg/ (Accessed September 14 2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matsumoto, M., Yang, S., Martinsen, K. et al. Trends and research challenges in remanufacturing. Int. J. of Precis. Eng. and Manuf.-Green Tech. 3, 129–142 (2016). https://doi.org/10.1007/s40684-016-0016-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-016-0016-4