Abstract

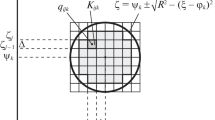

Motivated by the need to determine the transient temperature field during laser heating, the heating process is modeled as a transient three-dimensional heat conduction problem in a finite slab subjected to a moving circular heat source on the upper surface to emulate the heat generated on the irradiated surface. The boundary value problem is formulated considering all slab surfaces are subjected to heat convection. A closed form solution of transient temperature field is obtained using Green’s function which constructed using separation of variables method. Experiments are performed using a continuous wave CO2 laser machine with maximum power of 150 W to verify the obtained results. Numerical calculations are performed for two different materials to figure out the effect of the material properties on the heating process.

Similar content being viewed by others

References

Tahir, A.F.M., Rashid, A.R., Sariff, N.E., Rahim, E.A.: CO2 laser cutting performance on ultra high strength steel (UHSS). Lasers. Manuf. Mater. Process. 7, 15–37 (2020)

Muthuramalingam, T., Akash, R., Krishnan, S., Phan, N.H., Pi, V.N., Elsheikh, A.H.: Surface quality measures analysis and optimization on machining titanium alloy using CO2 based laser beam drilling process. J. Manuf. Process. 62, 1–6 (2021)

Khoshaim, A.B., Elsheikh, A.H., Moustafa, E.B., Basha, M., Showaib, E.A.: Experimental investigation on laser cutting of PMMA sheets: effects of process factors on kerf characteristics. J. Mater. Res. Technol. 11, 235–246 (2021)

Shen, H., Vollertsen, F.: Modelling of laser forming – an review. Comput. Mater. Sci. 46, 834–840 (2009)

Yocom, C.J., Zhang, X., Liao, Y.: Research and development status of laser peen forming: a review. Opt. Laser Technol. 108, 32–45 (2018)

Gisario, A., Barletta, M., Venettacci, S., Veniali, F.: Progress in tridimensional (3d) laser forming of stainless steel sheets. Lasers. Manuf. Mater. Process. 2, 148–163 (2015)

Boonpuang, R., Mongkolwongroj, M., Sakulkalavek, A., Sakdanuphab, R.: Empirical modeling and optimization of laser bending process parameters using the central composite design method for HDD slider PSA/RSA adjustment. Lasers. Manuf. Mater. Process. 7, 290–304 (2020)

Cheng, J., Lawrence Yao, Y.: Cooling effects in multiscan laser forming. J. Manuf. Process. 3, 60–72 (2001)

Paramasivan, K., Das, S., Misra, D.: A study on the effect of rectangular cut out on laser forming of AISI 304 plates. Int. J. Adv. Manuf. Technol. 72, 1513–1525 (2014)

Castillo, J.I., Celentano, D.J., Cruchaga, M.A., García-Herrera, C.M.: Characterization of strain rate effects in sheet laser forming. Comptes Rendus Mécanique. 346, 794–805 (2018)

Elsheikh, A.H., Shehabeldeen, T.A., Zhou, J., Showaib, E., Abd Elaziz, M.: Prediction of laser cutting parameters for polymethylmethacrylate sheets using random vector functional link network integrated with equilibrium optimizer. J. Intell. Manuf. (2020)

Elsheikh, A.H., Deng, W., Showaib, E.A.: Improving laser cutting quality of polymethylmethacrylate sheet: experimental investigation and optimization. J. Mater. Res. Technol. 9, 1325–1339 (2020)

Cheng, P.J., Lin, S.C.: Using neural networks to predict bending angle of sheet metal formed by laser. Int. J. Mach. Tools Manuf. 40, 1185–1197 (2000)

V. Dragos, V. Dan, R. Kovacevic, Prediction of the laser sheet bending using neural network, 2000 IEEE International Symposium on Circuits and Systems. Emerging Technologies for the 21st Century. Proceedings (IEEE Cat No.00CH36353), pp. 686–689 vol.683 (2000)

Kotobi, M., Mansouri, H., Honarpisheh, M.: Investigation of laser bending parameters on the residual stress and bending angle of St-Ti bimetal using FEM and neural network. Opt. Laser Technol. 116, 265–275 (2019)

Maji, K., Pratihar, D.K., Nath, A.K.: Laser forming of a dome shaped surface: experimental investigations, statistical analysis and neural network modeling. Opt. Lasers Eng. 53, 31–42 (2014)

Abd Elaziz, M., Shehabeldeen, T.A., Elsheikh, A.H., Zhou, J., Ewees, A.A., Al-qaness, M.A.A.: Utilization of random vector functional link integrated with marine predators algorithm for tensile behavior prediction of dissimilar friction stir welded aluminum alloy joints. J. Mater. Res. Technol. 9, 11370–11381 (2020)

Essa, F.A., Abd Elaziz, M., Elsheikh, A.H.: Prediction of power consumption and water productivity of seawater greenhouse system using random vector functional link network integrated with artificial ecosystem-based optimization. Process. Saf. Environ. Prot. 144, 322–329 (2020)

Shehabeldeen, T.A., Elaziz, M.A., Elsheikh, A.H., Hassan, O.F., Yin, Y., Ji, X., Shen, X., Zhou, J.: A novel method for predicting tensile strength of friction stir welded AA6061 Aluminium alloy joints based on hybrid random vector functional link and Henry gas solubility optimization. IEEE Access. 8, 79896–79907 (2020)

Babikir, H.A., Elaziz, M.A., Elsheikh, A.H., Showaib, E.A., Elhadary, M., Wu, D., Liu, Y.: Noise prediction of axial piston pump based on different valve materials using a modified artificial neural network model. Alexandria Eng. J. 58, 1077–1087 (2019)

Elsheikh, A.H., Abd Elaziz, M., Babikir, H.A., Wu, D., Liu, Y.: A new artificial neural network model integrated with a cat swarm optimization algorithm for predicting the emitted noise during axial piston pump operation. IOP Conference Ser: Mater. Sci. Eng. 973, (2020)

Shah, S.M., Nélias, D., Coret, M.: Numerical simulation of grinding induced phase transformation and residual stresses in AISI-52100 steel. Finite Elem. Anal. Des. 61, 1–11 (2012)

Na, X.-z., Xue, M., Zhang, X.-z., Gan, Y.: Numerical simulation of heat transfer and deformation of initial Shell in soft contact continuous casting Mold under high frequency electromagnetic field, journal of Iron and steel research. International. 14, 14–21 (2007)

Elsheikh, A.H., Guo, J., Lee, K.-M.: Thermal deflection and thermal stresses in a thin circular plate under an axisymmetric heat source. J. Therm. Stresses. 42, 361–373 (2019)

Salman, K.h., Elsheikh, A.H., Ashham, M., Ali, M.K.A., Rashad, M., Haiou, Z.: Effect of cutting parameters on surface residual stresses in dry turning of AISI 1035 alloy. J. Braz. Soc. Mech. Sci. Eng. 41, 349 (2019)

Ji, Z., Wu, S.: FEM simulation of the temperature field during the laser forming of sheet metal. J. Mater. Process. Technol. 74, 89–95 (1998)

Chen, D.J., Wu, S.C., Xiang, Y.B., Li, M.Q.: Simulation of three-dimensional transient temperature field during laser bending of sheet metal. Mater. Sci. Technol. 18, 215–218 (2002)

Che Jamil, M.S., Sheikh, M.A., Li, L.: A study of the effect of laser beam geometries on laser bending of sheet metal by buckling mechanism. Opt. Laser Technol. 43, 183–193 (2011)

Zhang, L., Reutzel, E.W., Michaleris, P.: Finite element modeling discretization requirements for the laser forming process. Int. J. Mech. Sci. 46, 623–637 (2004)

Yilbas, B.S., Akhtar, S.S.: Laser bending of metal sheet and thermal stress analysis. Opt. Laser Technol. 61, 34–44 (2014)

Forslund, R., Snis, A., Larsson, S.: Analytical solution for heat conduction due to a moving Gaussian heat flux with piecewise constant parameters. Appl. Math. Model. 66, 227–240 (2019)

Elsheikh, A.H., Guo, J., Huang, Y., Ji, J., Lee, K.-M.: Temperature field sensing of a thin-wall component during machining: numerical and experimental investigations. Int. J. Heat Mass Transf. 126, 935–945 (2018)

Ramos-Grez, J.A., Sen, M.: Analytical, quasi-stationary Wilson-Rosenthal solution for moving heat sources. Int. J. Therm. Sci. 140, 455–465 (2019)

Hibbeler, L.C., Chin See, M.M., Iwasaki, J., Swartz, K.E., O’Malley, R.J., Thomas, B.G.: A reduced-order model of mould heat transfer in the continuous casting of steel. Appl. Math. Model. 40, 8530–8551 (2016)

Mejia-Parra, D., Moreno, A., Posada, J., Ruiz-Salguero, O., Barandiaran, I., Poza, J.C., Chopitea, R.: Frequency-domain analytic method for efficient thermal simulation under curved trajectories laser heating. Math. Comput. Simul. (2019)

Sundqvist, J., Kaplan, A.F.H., Shachaf, L., Kong, C.: Analytical heat conduction modelling for shaped laser beams. J. Mater. Process. Technol. 247, 48–54 (2017)

Ma, J., Sun, Y., Yang, J.: Analytical solution of non-Fourier heat conduction in a square plate subjected to a moving laser pulse. Int. J. Heat Mass Transf. 115, 606–610 (2017)

Ma, J., Sun, Y., Yang, J.: Analytical solution of dual-phase-lag heat conduction in a finite medium subjected to a moving heat source. Int. J. Therm. Sci. 125, 34–43 (2018)

Chen, G.: Axisymmetric modeling of long pulsed laser heating with convective boundary conditions using analytical solutions. Optik. 130, 1038–1044 (2017)

Chen, G., Bi, J.: Analytical solutions for three-dimensional modeling of temperature rise inside solid material induced by laser irradiation. Optik. 132, 80–88 (2017)

Lambiase, F.: An analytical model for evaluation of bending angle in laser forming of metal sheets. J. Mater. Eng. Perform. 21, 2044–2052 (2012)

Lambiase, F., Di Ilio, A.: A closed-form solution for thermal and deformation fields in laser bending process of different materials. Int. J. Adv. Manuf. Technol. 69, 849–861 (2013)

Majumdar, P., Xia, H., Green, A.: S function model for the analysis of laser heating of materials. Appl. Math. Model. 31, 1186–1200 (2007)

D.W. Hahn, M.N. Özisik, Heat conduction, John Wiley & Sons (2012)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (E050902, E041604).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Statement

Authors testify that there is no conflict of interest.

Conflict of Interest

The authors declared that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elsheikh, A.H., Shanmugan, S., Muthuramalingam, T. et al. Modeling of the Transient Temperature Field during Laser Heating. Lasers Manuf. Mater. Process. 8, 97–112 (2021). https://doi.org/10.1007/s40516-021-00138-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-021-00138-2