Abstract

Selective laser sintering (SLS) is an additive manufacturing (AM) process, which is widely used for fabrication of end used products, directly from computer aided design (CAD) data. SLS process is usually used in different areas such as biomedical, automobile and aerospace industries. The major advantage of this process is that the designer can visualize and test the specimens before the full scale production of parts. Therefore, to achieve a good dimensional accuracy in order to fulfill the demands of these fields is a key parameter. Dimensional accuracy of SLS process is mainly influenced by geometry, process parameters and materials. It can only be enhanced by controlling the shrinkage of parts. Therefore, this work is carried out to analyze the effect of crucial contributing factors (i.e, laser power, bed temperature, layer thickness, scan spacing and orientation) for the shrinkage (CAD, thermal and volumetric) of duraform polyamide specimens. Face centered central composite (CCD) design is used for the collection of data. Response surface methodology (RSM) is used to monitor the effects as well as interactions of selected parameters, and for the development of regression models. Multi-response optimization of shrinkage along with composite desirability is employed for different optimized selected SLS parameters. It has been found that the laser power 41 W, bed temperature 170 °C, layer thickness 0.09 mm, scan spacing 0.15 mm and orientation 85.68 degree is a most significant optimized range of these parameters to improve the overall shrinkage measures of parts.

Similar content being viewed by others

Abbreviations

- ANOVA:

-

Analysis of variance

- AM:

-

Additive manufacturing

- A:

-

Laser power

- B:

-

Bed temperature

- CCD:

-

Central composite design

- CAD:

-

Computer aided design

- C:

-

Layer thickness

- D:

-

Scan spacing

- ED:

-

Energy density

- E:

-

Orientation

- RSM:

-

Response surface methodology

- RP:

-

Rapid prototyping

- SLS:

-

Selective laser sintering

References

Chua, C.K., Leong, K.F., Lim, C.S.: Rapid prototyping: principles and applications. 3rd Ed., World Scientific; Singapore (2010)

Klocke, F., Arntz, K., Teli, M., Winands, K., Wegener, M., Oliari, S.: State-of-the-art laser additive manufacturing for hot work tool steels. Procedia CIRP. 63, 58–63 (2017)

Shah, K., Pinkerton, A.J., Salman, A., Li, L.: Effects of melt pool variables and process parameters in laser direct metal deposition of aerospace alloys. Mater Manuf Process. 25(12), 1372–1380 (2010)

Singh, S., Sharma, V.S., Sachdeva, A.: Optimization & analysis of shrinkage in selective laser sintered polyamide parts. Mater Manuf Process. 27(6), 707–714 (2012)

Singh, S., Sharma, V.S., Sachdeva, A.: Progress in selective laser sintering using metallic powders: a review. Mater Sci Technol. 32(8), 760–772 (2016)

Manoraj, M., Ansari, M.N.M., Shakes, R.A.: Review on the effects of process parameters on strength, shrinkage, and warpage of injection molding plastic component. Polym Plast Technol Eng. 56, 1–12 (2017)

Avraam, I.: Injection and compression molding fundamentals. Marcel Dekker Inc, New York (1987)

Aldahdooh, M., Bunnori, N.M., Johari, M.: Evaluation of ultra-high performance fibre reinforced concrete binder content using the response surface method. Mater Des. 52, 957–965 (2013)

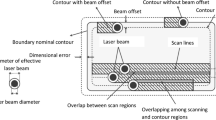

Wang, X.: Calibration of shrinkage and beam offset in SLS. Rapid Prototyp J. 5(3), 129–133 (1999)

Kumar, N., Kumar, H., Khurmi, J.S.: Experimental investigation of process parameters for rapid prototyping technique (selective laser sintering) to enhance the part quality of prototype by Taguchi method. Procedia Technol. 23, 352–360 (2016)

Wang, R.J., Wang, L., Zhao, L., Liu, Z., Influence of process parameters on part shrinkage in SLS: Int. J. Adv. Manuf. Technol. 33, 498–504 (2006)

Wu, J., Xu, X., Zhao, Z., Wang, M., Zhang, J.: Study in performance and morphology of polyamide 12 produced by selective laser sintering technology. Rapid. Prototyp. J. 1355–2546 (2017)

Raghunath, N., Pandey, P.M.: Improving accuracy through shrinkage modelling by using Taguchi method in selective laser sintering. Int J Mach Tools Manuf. 47(6), 985–995 (2007)

Dastjerdi, A.A., Movahhedy, M.R., Akbari, J.: Optimization of process parameters for reducing warpage in selected laser sintering of polymer parts. Addit Manuf. 18, 285–294 (2017)

Baturynska, I.: Statistical analysis of dimensional accuracy in additive manufacturing considering STL model properties. Int J Adv Manuf Technol. 97(5–8), 2835–2849 (2018)

Jiang, G., Jiaming, B., Kui, L., Jun, W.: Surface quality improvement of selective laser sintered polyamide 12 by precision grinding and magnetic field-assisted finishing. Mater Des. 138, 39–45 (2017)

Jain, P.K., Pandey, P.M., Rao, P.V.M.: Effect of delay time on part strength in selective laser sintering. Int J Adv Manuf Technol. 43(1-2), 117–126 (2009)

Yeganeh, A.M., Movahhedy, M.R., Khodaygan, S.: An efficient scanning algorithm for improving accuracy based on minimizing part warping in selected laser sintering process. Virtual Phys Prototyp. 14(1), 59–78 (2019)

Negi, S., Sharma, R.K.: Study on shrinkage behavior of laser sintered PA 3200GF specimens using RSM and ANN. Rapid Prototyp J. 22(4), 645–659 (2016)

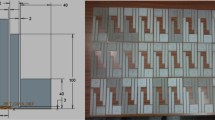

Singh, S., Sharma, V.S., Sachdeva, A.: Application of response surface methodology to analyze the effect of selective laser sintering parameters on dimensional accuracy. P. Addit. Manuf. 4(1), 3–12 (2019)

Yang, H.J., Hwang, P.J., Lee, S.H.: A study on shrinkage compensation of the SLS process by using the Taguchi method. Int J Mach Tools Manuf. 42(11), 1203–1212 (2002)

Hiren, M., Gajera, M.E., Dav, K.G., Jani, V.: Experimental investigation and analysis of dimensional accuracy of laser-based powder bed fusion made specimen by application of response surface methodology. P Addit Manuf. 4(4), 371–382 (2019)

Senthilkumaran, K., Pandey, P.M., Rao, P.V.M.: Influence of building strategies on the accuracy of parts in selective laser sintering. Mater Des. 30(8), 2946–2954 (2009)

Rong-Ji, W., Xin-hua, L., Qing-ding, W., Lingling, W.: Optimizing process parameters for selective laser sintering based on neural network and genetic algorithm. Int J Adv Manuf Technol. 42(11), 1035–1042 (2009)

Asiabanpour, B., Palmer, K., Khoshnevis, B.: An experimental study of surface quality and dimensional accuracy for selective inhibition of sintering. Rapid Prototyp J. 10(3), 181–192 (2004)

Ning, Y., Song, Y.S., Fuh, J.Y.H.: Effect and control of hatch length on material properties in the direct metal laser sintering process. J Eng Manuf. 219(1), 15–25 (2005)

Shi, Y., Li, Z., Sun, H., Huang, S., Zeng, F.: Effect of the properties of the polymer materials on the quality of selective laser sintering parts. J Mater Des A. 218(3), 247–252 (2004)

Calignano, F., Manfredi, D., Ambrosio, E.P., Iuliano, L., Fino, P.: Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int. J. Adv. Manuf. Technol. 67(9–12), 2743–2751 (2012)

Dotchev, K., Yusoff, W.: Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp J. 15(3), 192–203 (2009)

Dotchev, K., Yusoff, W.: Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp J. 15(3), 192–203 (2009)

Chunze, Y., Yusheng, S., Jingsong, Y., Jinhui, L.: Preparation and selective laser sintering of nylon-12 coated metal powders and post processing. J Mater Process Tech. 209, 5785–5792 (2009)

Cezairliyan, A., Maglic, K.D., Peletsky, V.E.: (eds.) Compendium of thermophysical property measurement methods. Springer Science Business Media New York. (1992)

Mukras, S.M.S., Omar, H.M., Al-Mufadi, F.A.: Experimental-based multi-objective optimization of injection molding process parameters. Arab J Sci Eng. 44(9), 7653–7665 (2019)

Sharma, V.S., Singh, S., Sachdeva, A., Kumar, P.: Influence of sintering parameters on dynamic mechanical properties of selective laser sintered parts. Int J Mater Form. 8, 157–166 (2015)

Montgomery, D.C.: Design and analysis of experiments. Wiley, Hoboken (2013)

Myers, R.H., Montgomery, D.C., Anderson, C.M.: Response surface methodology: process and product optimization using designed experiments, 3rd edn. John Wiley & Sons, New York (2008)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, V., Chand, R., Sharma, V.S. et al. Investigating Shrinkage: CAD, Thermal and Volumetric for Selective Laser Sintering of Polyamide Parts. Lasers Manuf. Mater. Process. 8, 73–96 (2021). https://doi.org/10.1007/s40516-020-00136-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-020-00136-w