Abstract

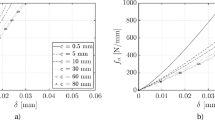

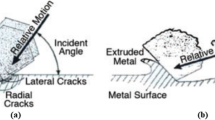

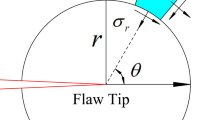

The machine tool bed and concrete foundation of heavy machine tools are typically connected by anchor bolts. The dynamic characteristics of the bolted joint's bed and foundation contact surfaces have an important influence on the machining accuracy and service life of the machine tool. This paper proposes a virtual material model based on the gradient of contact stress distribution for modeling the contact interfaces between the heterogeneous material of the machine tool bed and the foundation. An expression for the equivalent elastic modulus of the metal-concrete contact surface is derived by considering the nonlinear properties of concrete. Concrete crushing is assumed, and the evaluation basis of critical deformation parameters of asperity is established. Based on Fractal theory and Hertz contact theory, theoretical models of the elastic moduli, Poisson's ratios, densities, and thicknesses of the virtual material are established. Due to the uneven distribution of contact stress, a gradient equation with virtual material parameters is obtained according to the contact stress distribution curve. Then, the contact surface is stratified based on the virtual material parameters. The theoretical model was verified by simulations and experiments. The first-order natural frequency error was found to be 1.3%. The proposed method provides a new approach for modeling the contact between heterogeneous materials of the machine tool bed–foundation interface.

Similar content being viewed by others

Data availability

The authors declare that all data and material support their published claims and comply with field standards;

Code availability

Not applicable.

References

Greenwood J, Williamson J (1966) Contact of nominally flat surfaces [J]. Proc R Soc Lond 295(1442):300–319

Guo X, Ma B, Zhu Y (2017) A magnification-based multi-asperity (MBMA) model of rough contact where the Greenwood-Williamson and Persson theories meet

Wang W, Wu J, Gao Z et al (2018) A calculation model for tangential contact damping of machine joint interfaces. Chin J Theor Appl Mech 50(003):633–642

Hu S, Huang W, Shi X et al (2019) Review on mechanical seals using a bi-Gaussian stratified surface theory. J Mech Eng 55(01):103–117

Persson B (2007) Theory of rubber friction and contact mechanics. J Chem Phys 115(8):3840–3861

Zhao Y, Xu J, Cai L et al (2016) Stiffness and damping model of bolted joint based on the modified three-dimensional fractal topography. Proc Inst Mech Eng Part C 231(2):1

Yuan Y, Chen J, Zhang L (2018) Loading-unloading contact model between three-dimensional fractal rough surfaces. AIP Adv 8(7):115–124

Liang A, Bian Y, Chen Q, et al (2019) Fractal prediction model for the contact of friction surface and simulation analysis. In: 2019 8th International Conference on Industrial Technology and Management (ICITM)

Liu Z, Jiang K, Zhang C et al (2019) A stiffness model of a joint surface with inclination based on fractal theory. Precis Eng 1:1

Wei S, Tan L, Wu N (2018) Static hysteresis behavior analysis and stiffness and damping identification of bolted joints. J Northeastern Univ (Nat Sci) 1:1

Puchaa K, Szymczyk E, Jachimowicz J (2015) About mechanical joints desing in metal-composite structure. J Kones 19(3):381–390

Han R, Li G, Gong J et al (2019) Equivalent method of joint interface based on persson contact theory: virtual material method. Materials 12(19):1

Zhao Y, Yang C, Cai L et al (2016) Surface contact stress-based nonlinear virtual material method for dynamic analysis of bolted joint of machine tool. Precis Eng 43:230–240

Yang Y, Cheng H, Liang B et al (2020) A novel virtual material layer model for predicting natural frequencies of composite bolted joints. Chin J Aeronaut 1:1

Sun Q, Huang Q, Sun Z et al (2018) Interface parameter identification of bolted connections based on gradient virtual material. J Mech Eng 054(011):102–109

Liao J, Zhang J, Yu D et al (2016) Modeling method of bolted joint interface based on gradient virtual materials. J Jilin Univ (Eng Technol Ed) 46(4):1149–1155

Zhang J, Han Y, Han J, et al. (2014) Cement hydration based model to predict the mechanical properties of precast concrete. Mag Concret Res

Ruiz M, Muttoni A, Gambarova P (2007) Relationship between nonlinear creep and cracking of concrete under uniaxial compression. J Adv Concr Technol 5(3):383–393

Salari A, Ghadami J et al (2016) Stress-strain behavior of freshly compressed concrete under axial compression with a practical equation. Constr Build Mater 1:1

Yuan Y, Chen J, Zhang L (2018) Loading-unloading contact model between three-dimensional fractal rough surfaces. AIP Adv 8(7):1

Ciulli E, Ferreira L, Pugliese G et al (2008) Rough contacts between actual engineering surfaces—Part I. Simple models for roughness description. Wear 264(11):1105–1115

Komvopoulos K, Ye N (2001) Three-dimensional contact analysis of elastic-plastic layered media with fractal surface topographies. J Tribol 123(1):632–640

Majumdar A, Bhushan B (1990) Role of fractal geometry in roughness characterization and contact mechanics of surfaces. J Tribol 112(2):205–216

Tian H, Li B, Liu H et al (2011) A new method of virtual material hypothesis-based dynamic modeling on fixed joint interface in machine tools. Int J Mach Tools Manuf 51(3):239–249

Zhao Y, Yang C, Cai L et al (2016) Stiffness and damping model of bolted joint with uneven surface contact pressure distribution. J Mech Eng 62(11):665–677

Ye H, Huang Y, Li P et al (2016) Virtual material parameter acquisition based on the basic characteristics of the bolt joint interfaces. Tribol Int 95:109–117

Cao J, Zhang Z (2019) Finite element analysis and mathematical characterization of contact pressure distribution in bolted joints. J Mech Sci Technol 33(2):1

Liao J, Zhang J, Feng P et al (2016) Interface contact pressure-based virtual gradient material model for the dynamic analysis of the bolted joint in machine tools. J Mech Sci Technol 30(10):4511–4521

Miguel F, Aurelio M, Pietro G et al (2007) Relationship between nonlinear creep and cracking of concrete under uniaxial compression. J Adv Concr Technol 5(3):383–393

Fu W, Lou L, Gao Z et al (2017) Theoretical model for the contact stiffness and damping of mechanical joint surface. J Mech Eng 53(9):73–82

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52075012);

Author information

Authors and Affiliations

Contributions

All authors on this list have contributed to this article.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no potential conflicts of interest with respect to the research, authorship, and publication of this article.

Consent to participate

The authors declare that they consent to participate in this paper.

Consent to publish

The authors declare that they consent to publish this paper.

Additional information

Technical Editor: Ehsan Noroozinejad Farsangi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Niu, N., Zhao, Y., Li, Y. et al. Contact modeling of heterogeneous materials of the machine tool bed–foundation interface based on the gradient of contact stress distribution. J Braz. Soc. Mech. Sci. Eng. 44, 594 (2022). https://doi.org/10.1007/s40430-022-03910-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03910-3