Abstract

The rapid evolution in additive manufacturing (AM) technology advocates a periodic assessment of the recent progress in the process and product developments. One such area is lattice structure (LS) fabrication with controlled porosity, especially microscale triply periodic minimal surfaces. These nature-inspired and mechanically robust complex cellular structures are making significant progress in aerospace, automotive, and biomedical applications. However, limitations in the AM process, such as process-induced defects, microstructural heterogeneities, and post-processing challenges, may result in an inaccurate assessment of mechanical properties. This review paper presents a comprehensive overview of challenges in the fabrication of AM cellular structures, LS classification, simulation outline, and the effect of post-processing on their overall mechanical and microstructural development. It further provides a physical assessment and the underlying science of failure criteria and deformation mechanism of AM lattice structures. This review includes substantive discussions on LS topology, relative density, AM defects, and material type, critically analyzing the printability of various engineering alloys based on experimental and numerical studies. Finally, the knowledge gaps in the scientific understanding and the future research needs for the expansion of AM lattice materials are provided.

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacturing

- LPBF:

-

Laser powder bed fusion

- DED:

-

Direct energy deposition

- PBF:

-

Powder bed fusion

- TPMS:

-

Triply periodic minimal surfaces.

- FGs:

-

Functionally graded lattice Structures

- HIP:

-

Hot isostatic pressing.

- EBAM:

-

Electron beam additive manufacturing.

- PLB:

-

Pulse laser-based.

- CLB:

-

Continuous laser-based.

- CAD:

-

Computer aided design

- GCs:

-

Gyroid cellular

References

Abou-Ali AM, Al-Ketan O, Lee D-W, Rowshan R, Abu Al-Rub RK (2020) Mechanical behavior of polymeric selective laser sintered ligament and sheet based lattices of triply periodic minimal surface architectures. Mater Design 196:109100

Aboulkhair NT, Maskery I, Tuck C, Ashcroft I, Everitt NM (2016) Improving the fatigue behaviour of a selectively laser melted aluminium alloy: Influence of heat treatment and surface quality. Mater Des 104:174–182

Afshar M, Anaraki AP, Montazerian H (2018) Compressive characteristics of radially graded porosity scaffolds architectured with minimal surfaces. Mater Sci Eng, C 92:254–267

Ahmadi SM, Hedayati R, Li Y, Lietaert K, Tumer N, Fatemi A, Rans CD, Pouran B, Weinans H, Zadpoor AA (2018) Fatigue performance of additively manufactured meta-biomaterials: the effects of topology and material type. Acta Biomater 65:292–304

Ahmadi SM, Kumar R, Borisov EV, Petrov R, Leeflang S, Li Y, Tumer N, Huizenga R, Ayas C, Zadpoor AA, Popovich VA (2019) From microstructural design to surface engineering: a tailored approach for improving fatigue life of additively manufactured meta-biomaterials. Acta Biomater 83:153–166

Al-Ketan O, Abu Al-Rub RK, Rowshan R (2018) The effect of architecture on the mechanical properties of cellular structures based on the IWP minimal surface. J Mater Res 33(3):343–359

Al-Ketan O, Lee DW, Rowshan R, Abu Al-Rub RK (2020) Functionally graded and multi-morphology sheet TPMS lattices: design, manufacturing, and mechanical properties. J Mech Behav Biomed Mater 102:103520

Al-Ketan O, Rowshan R, Abu Al-Rub RK (2018) Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit Manuf 19:167–183

Alabort E, Barba D, Reed RC (2019) Design of metallic bone by additive manufacturing. Scripta Mater 164:110–114

Alhammadi A, Al-Ketan O, Khan KA, Ali M, Rowshan R, Abu Al-Rub RK (2020) Microstructural characterization and thermomechanical behavior of additively manufactured AlSi10Mg sheet cellular materials. Mater Sci Eng A 791

Alomarah A, Ruan D, Masood S, Sbarski I, Faisal B (2018) An investigation of in-plane tensile properties of re-entrant chiral auxetic structure. Int J Adv Manuf Technol 96(5–8):2013–2029

Amani Y, Dancette S, Delroisse P, Simar A, Maire E (2018) Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater 159:395–407

Amin Yavari S, Ahmadi SM, van der Stok J, Wauthle R, Riemslag AC, Janssen M, Schrooten J, Weinans H, Zadpoor AA (2014) Effects of bio-functionalizing surface treatments on the mechanical behavior of open porous titanium biomaterials. J Mech Behav Biomed Mater 36:109–119

Amin Yavari S, Ahmadi SM, Wauthle R, Pouran B, Schrooten J, Weinans H, Zadpoor AA (2015) Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials. J Mech Behav Biomed Mater 43:91–100

Amin Yavari S, Wauthle R, van der Stok J, Riemslag AC, Janssen M, Mulier M, Kruth JP, Schrooten J, Weinans H, Zadpoor AA (2013) Fatigue behavior of porous biomaterials manufactured using selective laser melting. Mater Sci Eng C 33(8):4849–4858

Arabnejad S, Burnett Johnston R, Pura JA, Singh B, Tanzer M, Pasini D (2016) High-strength porous biomaterials for bone replacement: a strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomater 30:345–356

Ashby MF (2006) The properties of foams and lattices. Philos Trans A Math Phys Eng Sci 364(1838):15–30

Ataee A, Li Y, Brandt M, Wen C (2018) Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater 158:354–368

Ataee A, Li Y, Wen C (2019) A comparative study on the nanoindentation behavior, wear resistance and in vitro biocompatibility of SLM manufactured CP–Ti and EBM manufactured Ti64 gyroid scaffolds. Acta Biomater 97:587–596

Averyanova M, Bertrand P, Verquin B (2011) Manufacture of Co-Cr dental crowns and bridges by selective laser Melting technology. Virtual Phys Prototyping 6(3):179–185

Aydinöz M, Brenne F, Schaper M, Schaak C, Tillmann W, Nellesen J, Niendorf T (2016) On the microstructural and mechanical properties of post-treated additively manufactured Inconel 718 superalloy under quasi-static and cyclic loading. Mater Sci Eng A 669:246–258

Bagehorn S, Wehr J, Maier HJ (2017) Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti–6Al–4V parts. Int J Fatigue 102:135–142

Bagheri ZS, Melancon D, Liu L, Johnston RB, Pasini D (2017) Compensation strategy to reduce geometry and mechanics mismatches in porous biomaterials built with Selective Laser Melting. J Mech Behav Biomed Mater 70:17–27

Bagherifard S, Beretta N, Monti S, Riccio M, Bandini M, Guagliano M (2018) On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater Des 145:28–41

Baicheng Z, Xiaohua L, Jiaming B, Junfeng G, Pan W, Chen-nan S, Muiling N, Guojun Q, Jun W (2017) Study of selective laser melting (SLM) Inconel 718 part surface improvement by electrochemical polishing. Mater Des 116:531–537

Baranowski P, Płatek P, Antolak-Dudka A, Sarzyński M, Kucewicz M, Durejko T, Małachowski J, Janiszewski J, Czujko T (2019) Deformation of honeycomb cellular structures manufactured with Laser Engineered Net Shaping (LENS) technology under quasi-static loading: Experimental testing and simulation. Addit Manuf 25:307–316

Barba D, Alabort E, Reed R (2019) Synthetic bone: design by additive manufacturing. Acta Biomater 97:637–656

Benedetti M, Torresani E, Leoni M, Fontanari V, Bandini M, Pederzolli C, Potrich C (2017) The effect of post-sintering treatments on the fatigue and biological behavior of Ti–6Al–4V ELI parts made by selective laser melting. J Mech Behav Biomed Mater 71:295–306

Bertoldi K, Boyce MC, Deschanel S, Prange S, Mullin T (2008) Mechanics of deformation-triggered pattern transformations and superelastic behavior in periodic elastomeric structures. J Mech Phys Solids 56(8):2642–2668

Bigi A, Boanini E, Bracci B, Facchini A, Panzavolta S, Segatti F, Sturba L (2005) Nanocrystalline hydroxyapatite coatings on titanium: a new fast biomimetic method. Biomaterials 26(19):4085–4089

Black J, Hastings G (2013) Handbook of biomaterial properties. Springer, New York

Boban J, Ahmed A (2021) Improving the surface integrity and mechanical properties of additive manufactured stainless steel components by wire electrical discharge polishing. J Mater Process Technol 291:117013

Bobbert FSL, Lietaert K, Eftekhari AA (2017) Additively manufactured metallic porous biomaterials based on minimalsurfaces: a unique combination of topological, mechanical, and masstransport propertie. Acta Biomater 53:572–584

Bobe K, Willbold E, Morgenthal I, Andersen O, Studnitzky T, Nellesen J, Tillmann W, Vogt C, Vano K, Witte F (2013) In vitro and in vivo evaluation of biodegradable, open-porous scaffolds made of sintered magnesium W4 short fibres. Acta Biomater 9(10):8611–8623

Boniotti L, Beretta S, Patriarca L, Rigoni L, Foletti S (2019) Experimental and numerical investigation on compressive fatigue strength of lattice structures of AlSi7Mg manufactured by SLM. Int J Fatigue 128:105181

Campoli G, Borleffs MS, Amin Yavari S, Wauthle R, Weinans H, Zadpoor AA (2013) Mechanical properties of open-cell metallic biomaterials manufactured using additive manufacturing. Mater Des 49:957–965

Carlota V (2020) A review of the most innovative 3D printing applications in automotive 2021 (25 February 2021)

Chaffaı́ S, Peyrin F, Nuzzo S, Porcher R, Berger G, Laugier P (2002) Ultrasonic characterization of human cancellous bone using transmission and backscatter measurements: relationships to density and microstructure. Bone 30(1):229–237

Chan KS (2015) Characterization and analysis of surface notches on Ti-alloy plates fabricated by additive manufacturing techniques. Surf Topogr Metrol Prop 3(4):044006

Charbonnier B, Manassero M, Bourguignon M, Decambron A, El-Hafci H, Morin C, Leon D, Bensidoum M, Corsia S, Petite H (2020) Custom-made macroporous bioceramic implants based on triply-periodic minimal surfaces for bone defects in load-bearing sites. Acta Biomater 109:254–266

Chastand V, Quaegebeur P, Maia W, Charkaluk E (2018) Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater Charact 143:76–81

Chen JK, Wu MW, Cheng TL, Chiang PH (2019) Continuous compression behaviors of selective laser melting Ti-6Al-4V alloy with cuboctahedron cellular structures. Mater Sci Eng C Mater Biol Appl 100:781–788

Choy SY, Sun C-N, Leong KF, Wei J (2017) Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density. Addit Manuf 16:213–224

Coenen V, Alderson K (2011) Mechanisms of failure in the static indentation resistance of auxetic carbon fibre laminates. Physica Status Solidi (b) 248(1):66–72

Concli F, Gilioli A (2019) Numerical and experimental assessment of the mechanical properties of 3D printed 18-Ni300 steel trabecular structures produced by Selective Laser Melting—A lean design approach. Virtual and Physical Prototyping 14(3):267–276

Cutolo A, Engelen B, Desmet W, Van Hooreweder B (2020) Mechanical properties of diamond lattice Ti–6Al–4V structures produced by laser powder bed fusion: on the effect of the load direction. J Mech Behav Biomed Mater 104:103656

Daynes S, Lifton J, Lu WF, Wei J, Feih S (2021) Fracture toughness characteristics of additively manufactured Ti–6Al–4V lattices. Eur J Mech A Solids 86:104170

DebRoy T, Wei H, Zuback J, Mukherjee T, Elmer J, Milewski J, Beese AM, Wilson-HeidDe Ad, Zhang W A (2018) Additive manufacturing of metallic components–process, structure and properties. Prog Mater Sci 92:112–224

Denti L, Sola A (2019) On the effectiveness of different surface finishing techniques on A357. 0 parts produced by laser-based powder bed fusion: surface roughness and fatigue strength. Metals 9(12):1284

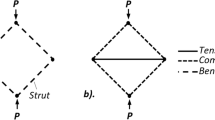

Deshpande VS, Ashby MF, Fleck NA (2001) Foam topology: bending versus stretching dominated architectures. Acta Mater 49(6):1035–1040

Deshpande VS, Fleck NA, Ashby MF (2001) Effective properties of the octet-truss lattice material. J Mech Phys Solids 49(8):1747–1769

Dong G, Marleau-Finley J, Zhao YF (2019) Investigation of electrochemical post-processing procedure for Ti–6Al–4V lattice structure manufactured by direct metal laser sintering (DMLS). Int J Adv Manuf Technol 104(9):3401–3417

Drücker S, Schulze M, Ipsen H, Bandegani L, Hoch H, Kluge M, Fiedler B (2021) Experimental and numerical mechanical characterization of additively manufactured Ti6Al4V lattice structures considering progressive damage. Int J Mech Sci 189:105986

Eliaz N (2019) Corrosion of metallic biomaterials: a review. Materials 12(3):407

Erbel R, Di Mario C, Bartunek J, Bonnier J, de Bruyne B, Eberli FR, Erne P, Haude M, Heublein B, Horrigan M, Ilsley C, Böse D, Koolen J, Lüscher TF, Weissman N, Waksman R (2007) Temporary scaffolding of coronary arteries with bioabsorbable magnesium stents: a prospective, non-randomised multicentre trial. Lancet 369(9576):1869–1875

Fahlbusch N-C, Grenestedt JL, Becker W (2016) Effective failure behavior of an analytical and a numerical model for closed-cell foams. Int J Solids Struct 97–98:417–430

Farhang B, Ravichander BB, Venturi F, Amerinatanzi A, Shayesteh Moghaddam N (2020) Study on variations of microstructure and metallurgical properties in various heat-affected zones of SLM fabricated Nickel-Titanium alloy. Mater Sci Eng A 774:138919

Feng K-Y, Liu P, Li H-X, Sun S-Y, Xu S-B, Li J-N (2017) Microstructure and phase transformation on the surface of Inconel 718 alloys fabricated by SLM under 1050 °C solid solution + double ageing. Vacuum 145:112–115

Galati M, Rizza G, Defanti S, Denti L (2021) Surface roughness prediction model for Electron Beam Melting (EBM) processing Ti6Al4V. Precis Eng 69:19–28

Galati M, Saboori A, Biamino S, Calignano F, Lombardi M, Marchiandi G, Minetola P, Fino P, Iuliano L (2020) Ti–6Al–4V lattice structures produced by EBM: heat treatment and mechanical properties. Procedia CIRP 88:411–416

Gavazzoni M, Boniotti L, Foletti S (2019) Influence of specimen size on the mechanical properties of microlattices obtained by selective laser melting. In: Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 0954406219869741

Gibson LJ (1989) Modelling the mechanical behavior of cellular materials. Mater Sci Eng, A 110:1–36

Gibson LJ (2003) Cellular solids. MRS Bull 28(4):270–274

Gong X, Anderson T, Chou K (2012) Review on powder-based electron beam additive manufacturing technology. Presented at International Symposium on Flexible Automation

Gorgin Karaji Z, Hedayati R, Pouran B, Apachitei I, Zadpoor AA (2017) Effects of plasma electrolytic oxidation process on the mechanical properties of additively manufactured porous biomaterials. Mater Sci Eng C 76:406–416

Gorgin Karaji Z, Speirs M, Dadbakhsh S, Kruth JP, Weinans H, Zadpoor AA, Amin Yavari S (2017) Additively manufactured and surface biofunctionalized porous nitinol. ACS Appl Mater Interfaces 9(2):1293–1304

Gorny B, Niendorf T, Lackmann J, Thoene M, Troester T, Maier HJ (2011) In situ characterization of the deformation and failure behavior of non-stochastic porous structures processed by selective laser melting. Mater Sci Eng, A 528(27):7962–7967

Grima JN, Gatt R, Farrugia PS (2008) On the properties of auxetic meta-tetrachiral structures. Physica Status Solidi (b) 245(3):511–520

Gümrük R, Mines RAW (2013) Compressive behaviour of stainless steel micro-lattice structures. Int J Mech Sci 68:125–139

Gümrük R, Mines RAW, Karadeniz S (2013) Static mechanical behaviours of stainless steel micro-lattice structures under different loading conditions. Mater Sci Eng, A 586:392–406

Hamidi Nasab M, Giussani A, Gastaldi D, Tirelli V, Vedani M (2019) Effect of surface and subsurface defects on fatigue behavior of alsi10mg alloy processed by Laser Powder Bed Fusion (L-PBF). Metals 9(10):1063

Han L, Che S (2018) An overview of materials with triply periodic minimal surfaces and related geometry: from biological structures to self-assembled systems. Adv Mater 30(17):1705708

Harun WSW, Kamariah MSIN, Muhamad N, Ghani SAC, Ahmad F, Mohamed Z (2018) A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol 327:128–151

Hedayati R, Ahmadi SM, Lietaert K, Pouran B, Li Y, Weinans H, Rans CD, Zadpoor AA (2018) Isolated and modulated effects of topology and material type on the mechanical properties of additively manufactured porous biomaterials. J Mech Behav Biomed Mater 79:254–263

Hedayati R, Hosseini-Toudeshky H, Sadighi M, Mohammadi-Aghdam M, Zadpoor AA (2016) Computational prediction of the fatigue behavior of additively manufactured porous metallic biomaterials. Int J Fatigue 84:67–79

Hedayati R, Sadighi M, Mohammadi-Aghdam M, Zadpoor AA (2016) Mechanics of additively manufactured porous biomaterials based on the rhombicuboctahedron unit cell. J Mech Behav Biomed Mater 53:272–294

Heinl P, Müller L, Körner C, Singer RF, Müller FA (2008) Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater 4(5):1536–1544

Helou M, Vongbunyong S, Kara S (2016) Finite element analysis and validation of cellular structures. Procedia CIRP 50:94–99

Heringa MB, Peters RJB, Bleys RLAW, van der Lee MK, Tromp PC, van Kesteren PCE, van Eijkeren JCH, Undas AK, Oomen AG, Bouwmeester H (2018) Detection of titanium particles in human liver and spleen and possible health implications. Part Fibre Toxicol 15(1):15

Hooreweder BV, Lietaert K, Neirinck B, Lippiatt N, Wevers M (2017) CoCr F75 scaffolds produced by additive manufacturing: Influence of chemical etching on powder removal and mechanical performance. J Mech Behav Biomed Mater 70:60–67

Hrabe N, Gnäupel-Herold T, Quinn T (2017) Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int J Fatigue 94:202–210

Hsieh M-T, Valdevit L (2020) Minisurf—A minimal surface generator for finite element modeling and additive manufacturing. Software Impacts 6:100026

Huang Z, Shi X, Wang G, Leukkunen P, Huttula M, Cao W (2020) Antireflective design of Si-based photovoltaics via biomimicking structures on black butterfly scales. Sol Energy 204:738–747

Hutmacher DW (2000) Scaffolds in tissue engineering bone and cartilage. Biomaterials 21(24):2529–2543

Jardini AL, Larosa MA, FilhoZavaglia CAdC, Bernardes LF, Lambert CS, Calderoni DR, Kharmandayan P RM (2014) Cranial reconstruction: 3D biomodel and custom-built implant created using additive manufacturing. J Cranio-Maxillof Surg 42(8):1877–1884

Jin N, Wang F, Wang Y, Zhang B, Cheng H, Zhang H (2019) Failure and energy absorption characteristics of four lattice structures under dynamic loading. Mater Des 169:107655

Jin N, Yan Z, Wang Y, Cheng H, Zhang H (2021) Effects of heat treatment on microstructure and mechanical properties of selective laser melted Ti-6Al-4V lattice materials. Int J Mech Sci 190:106042

Jonášová L, Müller FA, Helebrant A, Strnad J, Greil P (2002) Hydroxyapatite formation on alkali-treated titanium with different content of Na+ in the surface layer. Biomaterials 23(15):3095–3101

Kadkhodapour J, Montazerian H, Darabi A, Anaraki AP, Ahmadi SM, Zadpoor AA, Schmauder S (2015) Failure mechanisms of additively manufactured porous biomaterials: effects of porosity and type of unit cell. J Mech Behav Biomed Mater 50:180–191

Kapfer SC, Hyde ST, Mecke K, Arns CH, Schröder-Turk GE (2011) Minimal surface scaffold designs for tissue engineering. Biomaterials 32(29):6875–6882

Karami K, Blok A, Weber L, Ahmadi SM, Petrov R, Nikolic K, Borisov EV, Leeflang S, Ayas C, Zadpoor AA, Mehdipour M, Reinton E, Popovich VA (2020) Continuous and pulsed selective laser melting of Ti6Al4V lattice structures: effect of post-processing on microstructural anisotropy and fatigue behaviour. Additive Manuf 36:101433

Karamooz Ravari MR, Kadkhodaei M, Badrossamay M, Rezaei R (2014) Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int J Mech Sci 88:154–161

Karnessis N, Burriesci G (2013) Uniaxial and buckling mechanical response of auxetic cellular tubes. Smart Mater Struct 22(8):084008

Kasperovich G, Hausmann J (2015) Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J Mater Process Technol 220:202–214

Khan HM, Karabulut Y, Kitay O, Kaynak Y, Jawahir I (2020) Influence of the post-processing operations on surface integrity of metal components produced by laser powder bed fusion additive manufacturing: a review. Mach Sci Technol 25(1):118–176

Khan HM, Özer G, Yilmaz MS, Koc E (2022) Corrosion of additively manufactured metallic components: a review. Arab J Sci Eng 47:5465

Khan HM, Sirin TB, Tarakci G, Bulduk ME, Coskun M, Koc E, Kaynak Y (2021) Improving the surface quality and mechanical properties of selective laser sintered PA2200 components by the vibratory surface finishing process. SN Appl Sci 3(3):1–14

Khan HM, Waqar S, Koç E (2022b) Evolution of temperature and residual stress behavior in selective laser melting of 316L stainless steel across a cooling channel. Rapid Prototyping J (ahead-of-print)

Kim HR, Jang S-H, Kim YK, Son JS, Min BK, Kim K-H, Kwon T-Y (2016) Microstructures and mechanical properties of Co–Cr dental alloys fabricated by three CAD/CAM-based processing techniques. Materials 9(7):596

Kladovasilakis N, Tsongas K, Tzetzis D (2020) Finite element analysis of orthopedic hip implant with functionally graded bioinspired lattice structures. Biomimetics (Basel) 5(3)

Kokubo T (1996) Formation of biologically active bone-like apatite on metals and polymers by a biomimetic process. Thermochim Acta 280–281:479–490

Kumar A (2021) Researchers 3D print support-free lattices inspired by Sea Urchins 2021 (25 Feb 2021)

Kumar A, Nune KC, Murr LE, Misra RDK (2016) Biocompatibility and mechanical behaviour of three-dimensional scaffolds for biomedical devices: process–structure–property paradigm. Int Mater Rev 61(1):20–45

Kumar A, Verma S, Jeng J-Y (2020) Supportless lattice structures for energy absorption fabricated by fused deposition modeling. 3D Print Addit Manuf 7(2):85–96

Lakes RS (1993) Design considerations for materials with negative poisson’s ratios. J Mech Des 115(4):696–700

Leary M, Mazur M, Elambasseril J, McMillan M, Chirent T, Sun Y, Qian M, Easton M, Brandt M (2016) Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater Des 98:344–357

Leary M, Mazur M, Williams H, Yang E, Alghamdi A, Lozanovski B, Zhang X, Shidid D, Farahbod-Sternahl L, Witt G, Kelbassa I, Choong P, Qian M, Brandt M (2018) Inconel 625 lattice structures manufactured by selective laser melting (SLM): mechanical properties, deformation and failure modes. Mater Des 157:179–199

Lei H, Li C, Meng J, Zhou H, Liu Y, Zhang X, Wang P, Fang D (2019) Evaluation of compressive properties of SLM-fabricated multi-layer lattice structures by experimental test and μ-CT-based finite element analysis. Mater Des 169:107685

Li H, Zheng Y, Qin L (2014) Progress of biodegradable metals. Prog Natl Sci: Mater Int 24(5):414–422

Li P (2015) Constitutive and failure behaviour in selective laser melted stainless steel for microlattice structures. Mater Sci Eng A 622:114–120

Li P, Ma YE, Sun W, Qian X, Zhang W, Wang Z (2021) Fracture and failure behavior of additive manufactured Ti6Al4V lattice structures under compressive load. Eng Fract Mech 244:107537

Li P, Warner DH, Fatemi A, Phan N (2016) Critical assessment of the fatigue performance of additively manufactured Ti–6Al–4V and perspective for future research. Int J Fatigue 85:130–143

Li S, Liu Z, Shim VPW, Guo Y, Sun Z, Li X, Wang Z (2020) In-plane compression of 3D-printed self-similar hierarchical honeycombs—Static and dynamic analysis. Thin-Walled Struct 157

Lim J, You C, Dayyani I (2020) Multi-objective topology optimization and structural analysis of periodic spaceframe structures. Mater Des 190:108552

Ling C, Cernicchi A, Gilchrist MD, Cardiff P (2019) Mechanical behaviour of additively-manufactured polymeric octet-truss lattice structures under quasi-static and dynamic compressive loading. Mater Des 162:106–118

Liu L, Kamm P, García-Moreno F, Banhart J, Pasini D (2017) Elastic and failure response of imperfect three-dimensional metallic lattices: the role of geometric defects induced by Selective Laser Melting. J Mech Phys Solids 107:160–184

Löber L, Flache C, Petters R, Kühn U, Eckert J (2013) Comparison of different post processing technologies for SLM generated 316l steel parts. Rapid Prototyping J 19(3):173–179

Lozanovski B, Downing D, Tran P, Shidid D, Qian M, Choong P, Brandt M, Leary M (2020) A Monte Carlo simulation-based approach to realistic modelling of additively manufactured lattice structures. Addit Manuf 32:101092

Lozanovski B, Leary M, Tran P, Shidid D, Qian M, Choong P, Brandt M (2019) Computational modelling of strut defects in SLM manufactured lattice structures. Mater Des 171:107671

Lu Z-X, Li X, Yang Z-Y, Xie F (2016) Novel structure with negative Poisson’s ratio and enhanced Young’s modulus. Compos Struct 138:243–252

Lu Z, Wang Q, Li X, Yang Z (2017) Elastic properties of two novel auxetic 3D cellular structures. Int J Solids Struct 124:46–56

Lyczkowska-Widlak E, Lochynski P, Nawrat G, Chlebus E (2019) Comparison of electropolished 316L steel samples manufactured by SLM and traditional technology. Rapid Prototyping J 25(3):566–580

Lynch ME, Williams K, Cabrera M, Beccuti T (2021) Surface finishing of additively manufactured IN718 lattices by electrochemical machining. Int J Adv Manuf Technol

Maconachie T, Leary M, Lozanovski B, Zhang X, Qian M, Faruque O, Brandt M (2019) SLM lattice structures: properties, performance, applications and challenges. Mater Design 183

Magalhaes R, Subramani P, Lisner T, Rana S, Ghiassi B, Fangueiro R, Oliveira DV, Lourenco PB (2016) Development, characterization and analysis of auxetic structures from braided composites and study the influence of material and structural parameters. Compos A Appl Sci Manuf 87:86–97

Majeed M, Khan H, Rasheed I (2019) Finite element analysis of melt pool thermal characteristics with passing laser in SLM process. Optik 194:163068

Maleki E, Bagherifard S, Bandini M, Guagliano M (2020) Surface post-treatments for metal additive manufacturing: progress, challenges, and opportunities. Addit Manuf 37:101619

Maskery I, Aboulkhair NT, Aremu AO, Tuck CJ, Ashcroft IA (2017) Compressive failure modes and energy absorption in additively manufactured double gyroid lattices. Addit Manuf 16:24–29

Maskery I, Aboulkhair NT, Aremu AO, Tuck CJ, Ashcroft IA, Wildman RD, Hague RJM (2016) A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater Sci Eng A 670:264–274

Mazur M, Leary M, Sun S, Vcelka M, Shidid D, Brandt M (2016) Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int J Adv Manuf Technol 84(5–8):1391–1411

Melancon D, Bagheri ZS, Johnston RB, Liu L, Tanzer M, Pasini D (2017) Mechanical characterization of structurally porous biomaterials built via additive manufacturing: experiments, predictive models, and design maps for load-bearing bone replacement implants. Acta Biomater 63:350–368

Melchels FPW, Bertoldi K, Gabbrielli R, Velders AH, Feijen J, Grijpma DW (2010) Mathematically defined tissue engineering scaffold architectures prepared by stereolithography. Biomaterials 31(27):6909–6916

Mercelis P, Kruth JP (2006) Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyping J 12(5):254–265

Mousanezhad D, Haghpanah B, Ghosh R, Hamouda AM, Nayeb-Hashemi H, Vaziri A (2016) Elastic properties of chiral, anti-chiral, and hierarchical honeycombs: a simple energy-based approach. Theor Appl Mech Lett 6(2):81–96

Murr LE, Quinones SA, Gaytan SM, Lopez MI, Rodela A, Martinez EY, Hernandez DH, Martinez E, Medina F, Wicker RB (2009) Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J Mech Behav Biomed Mater 2(1):20–32

Naboni R, Mirante L (2015) Metamaterial computation and fabrication of auxetic patterns for architecture

Nagesha BK, Dhinakaran V, Varsha Shree M, Manoj Kumar KP, Chalawadi D, Sathish T (2020) Review on characterization and impacts of the lattice structure in additive manufacturing. Mater Today: Proc 21:916–919

Nazir A, Abate KM, Kumar A, Jeng J-Y (2019) A state-of-the-art review on types, design, optimization, and additive manufacturing of cellular structures. Int J Adv Manuf Technol 104(9):3489–3510

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos B Eng 143:172–196

Nguyen CHP, Kim Y, Do QT, Choi Y (2021) Implicit-based computer-aided design for additively manufactured functionally graded cellular structures. J Comput Design Eng 8(3):813–823

Ni X-Q, Kong D-C, Wen Y, Zhang L, Wu W-H, He B-B, Lu L, Zhu D-X (2019) Anisotropy in mechanical properties and corrosion resistance of 316L stainless steel fabricated by selective laser melting. Int J Miner Metall Mater 26(3):319–328

Obadimu SO, Kourousis KI (2021) Compressive behaviour of additively manufactured lattice structures: a review. Aerospace 8(8):207

Pan C, Han Y, Lu J (2020) Design and optimization of lattice structures: a review. Appl Sci 10(18):6374

Patterson AE, Messimer SL, Farrington PA (2017) Overhanging features and the SLM/DMLS residual stresses problem: review and future research need. Technologies 5(2):15

Persenot T, Burr A, Plancher E, Buffière J-Y, Dendievel R, Martin G (2019) Effect of ultrasonic shot peening on the surface defects of thin struts built by electron beam melting: consequences on fatigue resistance. Addit Manuf 28:821–830

Pinto J, Solórzano E, Rodriguez-Perez MA, de Saja JA (2013) Characterization of the cellular structure based on user-interactive image analysis procedures. J Cell Plast 49(6):555–575

Plocher J, Panesar A (2020) Effect of density and unit cell size grading on the stiffness and energy absorption of short fibre-reinforced functionally graded lattice structures. Addit Manuf 33:101171

Pyka G, Kerckhofs G, Papantoniou I, Speirs M, Schrooten J, Wevers M (2013) Surface roughness and morphology customization of additive manufactured open porous Ti6Al4V structures. Materials (Basel) 6(10):4737–4757

Qi D, Yu H, Liu M, Huang H, Xu S, Xia Y, Qian G, Wu W (2019) Mechanical behaviors of SLM additive manufactured octet-truss and truncated-octahedron lattice structures with uniform and taper beams. Int J Mech Sci 163:105091

Qiao J, Chen CQ (2015) Analyses on the in-plane impact resistance of auxetic double arrowhead honeycombs. J Appl Mech 82(5):051007

Qiu C, Yue S, Adkins NJE, Ward M, Hassanin H, Lee PD, Withers PJ, Attallah MM (2015) Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater Sci Eng A 628:188–197

Rajurkar KP, Sundaram MM, Malshe AP (2013) Review of electrochemical and electrodischarge machining. Procedia CIRP 6:13–26

Rao JH, Zhang Y, Huang A, Wu X, Zhang K (2019) Improving fatigue performances of selective laser melted Al–7Si–0.6Mg alloy via defects control. Int J Fatigue 129

Ravari MK, Kadkhodaei M (2015) A computationally efficient modeling approach for predicting mechanical behavior of cellular lattice structures. J Mater Eng Perform 24(1):245–252

Ravari MRK, Esfahani SN, Andani MT, Kadkhodaei M, Ghaei A, Karaca H, Elahinia M (2016) On the effects of geometry, defects, and material asymmetry on the mechanical response of shape memory alloy cellular lattice structures. Smart Mater Struct 25(2):025008

Rho J-Y, Kuhn-Spearing L, Zioupos P (1998) Mechanical properties and the hierarchical structure of bone. Med Eng Phys 20:92–102

Rodrigues H (2006) Topology optimization of structures: applications in the simulation and design of cellular materials. In: Computational methods in engineering & science. Springer, New York, pp 101–112

Rosenthal I, Shneck R, Stern A (2018) Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process. Mater Sci Eng, A 729:310–322

Sallica-Leva E, Caram R, Jardini AL, Fogagnolo JB (2016) Ductility improvement due to martensite alpha’ decomposition in porous Ti–6Al–4V parts produced by selective laser melting for orthopedic implants. J Mech Behav Biomed Mater 54:149–158

Saxena KK, Das R, Calius EP (2016) Three decades of auxetics research-materials with negative Poisson’s ratio: a review. Adv Eng Mater 18(11):1847–1870

Scalzo F, Totis G, Vaglio E, Sortino M (2021) Experimental study on the high-damping properties of metallic lattice structures obtained from SLM. Precision Eng

Scherillo F (2019) Chemical surface finishing of AlSi10Mg components made by additive manufacturing. Manuf Lett 19:5–9

Schneider-Maunoury C, Weiss L, Acquier P, Boisselier D, Laheurte P (2017) Functionally graded Ti6Al4V-Mo alloy manufactured with DED-CLAD® process. Addit Manuf 17:55–66

Shishkovsky I, Morozov Y, Smurov I (2007) Nanofractal surface structure under laser sintering of titanium and nitinol for bone tissue engineering. Appl Surf Sci 254(4):1145–1149

Sienkiewicz J, Płatek P, Jiang F, Sun X, Rusinek A (2020) Investigations on the mechanical response of gradient lattice structures manufactured via SLM. Metals 10(2):213

Sigmund O (2000) Topology optimization: a tool for the tailoring of structures and materials. Philos Trans R Soc Lond Ser A Math Phys Eng Sci 358(1765):211–227

Simpson J, Kazancı Z (2020) Crushing investigation of crash boxes filled with honeycomb and re-entrant (auxetic) lattices. Thin-Walled Struct 150:106676

Sing S, Yeong W, Wiria F, Tay B (2016) Characterization of titanium lattice structures fabricated by selective laser melting using an adapted compressive test method. Exp Mech 56(5):735–748

Smith M, Guan Z, Cantwell WJ (2013) Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique. Int J Mech Sci 67:28–41

Soro N, Attar H, Wu X, Dargusch MS (2019) Investigation of the structure and mechanical properties of additively manufactured Ti-6Al-4V biomedical scaffolds designed with a Schwartz primitive unit-cell. Mater Sci Eng A 745:195–202

Soro N, Saintier N, Attar H, Dargusch MS (2020) Surface and morphological modification of selectively laser melted titanium lattices using a chemical post treatment. Surface Coat Technol 393:125794

Speirs M, Van Hooreweder B, Van Humbeeck J, Kruth JP (2017) Fatigue behaviour of NiTi shape memory alloy scaffolds produced by SLM, a unit cell design comparison. J Mech Behav Biomed Mater 70:53–59

Strano G, Hao L, Everson R, Evans K (2013) A new approach to the design and optimisation of support structures in additive manufacturing. Int J Adv Manuf Technol 66(9):1247–1254

Straumit I, Lomov SV, Wevers M (2015) Quantification of the internal structure and automatic generation of voxel models of textile composites from X-ray computed tomography data. Compos A Appl Sci Manuf 69:150–158

Subramani P, Rana S, Ghiassi B, Fangueiro R, Oliveira DV, Lourenco PB, Xavier J (2016) Development and characterization of novel auxetic structures based on re-entrant hexagon design produced from braided composites. Compos B Eng 93:132–142

Tan KL, Yeo S-H, Ong CH (2016) Nontraditional finishing processes for internal surfaces and passages: a review. Proc Inst Mech Eng B: J Eng Manuf 231(13):2302–2316

Tanlak N, De Lange DF, Van Paepegem W (2017) Numerical prediction of the printable density range of lattice structures for additive manufacturing. Mater Des 133:549–558

Tascioglu E, Karabulut Y, Kaynak Y (2020) Influence of heat treatment temperature on the microstructural, mechanical, and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing. Int J Adv Manuf Technol 107(5):1947–1956

Tascioglu E, Khan HM, Kaynak Y, Coşkun M, Tarakci G, Koç E (2021) Effect of aging and finish machining on the surface integrity of selective laser melted maraging steel. Rapid Prototyping J 27(10):1900–1909

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth J-P (2010) A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58(9):3303–3312

Tillmann W, Schaak C, Nellesen J, Schaper M, Aydinöz ME, Hoyer KP (2017) Hot isostatic pressing of IN718 components manufactured by selective laser melting. Addit Manuf 13:93–102

Van Bael S, Kerckhofs G, Moesen M, Pyka G, Schrooten J, Kruth JP (2011) Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures. Mater Sci Eng A 528(24):7423–7431

Van Hooreweder B, Apers Y, Lietaert K, Kruth JP (2017) Improving the fatigue performance of porous metallic biomaterials produced by Selective Laser Melting. Acta Biomater 47:193–202

Van Hooreweder B, Kruth J-P (2017) Advanced fatigue analysis of metal lattice structures produced by Selective Laser Melting. CIRP Ann 66(1):221–224

Van Humbeeck J (2018) Additive manufacturing of shape memory alloys. Shape Memory Superelasticity 4(2):309–312

Vandenbroucke B, Kruth J-P (2007) Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyping J 13(4):196–203

Vigliotti A, Deshpande VS, Pasini D (2014) Non linear constitutive models for lattice materials. J Mech Phys Solids 64:44–60

Vilaro T, Colin C, Bartout JD (2011) As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall Mater Trans A 42(10):3190–3199

Vrancken B, Thijs L, Kruth J-P, Van Humbeeck J (2012) Heat treatment of Ti6Al4V produced by Selective Laser Melting: microstructure and mechanical properties. J Alloy Compd 541:177–185

Wang P, Lei H, Zhu X, Chen H, Fang D (2019) Influence of manufacturing geometric defects on the mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J Alloy Compd 789:852–859

Wang S, Wang J, Xu Y, Zhang W, Zhu J (2020) Compressive behavior and energy absorption of polymeric lattice structures made by additive manufacturing. Front Mech Eng 15(2):319–327

Wang Y, Duan J, Zhao Y, Yang X, Tang Q (2018) Ternary hybrid PtM@polyaniline (M = Ni, FeNi) counter electrodes for dye-sensitized solar cells. Electrochim Acta 291:114–123

Wang Z, Li P (2018) Characterisation and constitutive model of tensile properties of selective laser melted Ti-6Al-4V struts for microlattice structures. Mater Sci Eng A 725:350–358

Wehmöller M, Warnke PH, Zilian C, Eufinger H (2005) Implant design and production—a new approach by selective laser melting. Int Congr Ser 1281:690–695

Wei K, Wang Z, Zeng X (2017) Preliminary investigation on selective laser melting of Ti-5Al-2.5Sn α-Ti alloy: from single tracks to bulk 3D components. J Mater Process Technol 244:73–85

Wong M, Tsopanos S, Sutcliffe Chris J, Owen I (2007) Selective laser melting of heat transfer devices. Rapid Prototyping J 13(5):291–297

Wu M-W, Chen J-K, Lin B-H, Chiang P-H (2017) Improved fatigue endurance ratio of additive manufactured Ti–6Al–4V lattice by hot isostatic pressing. Mater Des 134:163–170

Wysocki B, Idaszek J, Zdunek J, Rożniatowski K, Pisarek M, Yamamoto A, Święszkowski W (2018) The influence of selective laser melting (SLM) process parameters on in-vitro cell response. Int J Mol Sci 19(6):1619

Xiao Z, Yang Y, Xiao R, Bai Y, Song C, Wang D (2018) Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater Des 143:27–37

Xiong Z, Liu S, Li S, Shi Y, Yang Y, Misra R (2019) Role of melt pool boundary condition in determining the mechanical properties of selective laser melting AlSi10Mg alloy. Mater Sci Eng A 740:148–156

Yadollahi A, Shamsaei N (2017) Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int J Fatigue 98:14–31

Yan C, Hao L, Hussein A, Bubb SL, Young P, Raymont D (2014) Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J Mater Process Technol 214(4):856–864

Yan C, Hao L, Hussein A, Raymont D (2012) Evaluations of cellular lattice structures manufactured using selective laser melting. Int J Mach Tools Manuf 62:32–38

Yan C, Hao L, Hussein A, Wei Q, Shi Y (2017) Microstructural and surface modifications and hydroxyapatite coating of Ti-6Al-4V triply periodic minimal surface lattices fabricated by selective laser melting. Mater Sci Eng, C 75:1515–1524

Yan C, Hao L, Hussein A, Young P (2015) Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J Mech Behav Biomed Mater 51:61–73

Yang KV, Rometsch P, Jarvis T, Rao J, Cao S, Davies C, Wu X (2018) Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater Sci Eng A 712:166–174

Yang L, Mertens R, Ferrucci M, Yan C, Shi Y, Yang S (2019) Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties. Mater Des 162:394–404

Yang L, Yan C, Cao W, Liu Z, Song B, Wen S, Zhang C, Shi Y, Yang S (2019) Compression–compression fatigue behaviour of gyroid-type triply periodic minimal surface porous structures fabricated by selective laser melting. Acta Mater 181:49–66

Yoo DJ (2011) Porous scaffold design using the distance field and triply periodic minimal surface models. Biomaterials 32(31):7741–7754

Yu H, Li F, Wang Z, Zeng X (2019) Fatigue performances of selective laser melted Ti-6Al-4V alloy: Influence of surface finishing, hot isostatic pressing and heat treatments. Int J Fatigue 120:175–183

Yuan L, Ding S, Wen C (2019) Additive manufacturing technology for porous metal implant applications and triple minimal surface structures: a review. Bioactive Materials 4:56–70

Zadpoor AA (2015) Bone tissue regeneration: the role of scaffold geometry. Biomater Sci 3(2):231–245

Zadpoor AA (2019) Mechanical performance of additively manufactured meta-biomaterials. Acta Biomater 85:41–59

Zargarian A, Esfahanian M, Kadkhodapour J, Ziaei-Rad S, Zamani D (2019) On the fatigue behavior of additive manufactured lattice structures. Theoret Appl Fract Mech 100:225–232

Zhang B, Li Y, Bai Q (2017) Defect formation mechanisms in selective laser melting: a review. Chin J Mech Eng 30(3):515–527

Zhang J, Chaudhari A, Wang H (2019) Surface quality and material removal in magnetic abrasive finishing of selective laser melted 316L stainless steel. J Manuf Process 45:710–719

Zhanga XZ, Leary M, Tangb HP, Songc T, Qianb M (2018) Selective electron beam manufactured Ti–6Al–4V lattice structures for orthopedic implant applications: current status and outstanding challenges. Current Opin Solid State Mater Sci 75–99

Zhao S, Li SJ, Hou WT, Hao YL, Yang R, Misra RDK (2016) The influence of cell morphology on the compressive fatigue behavior of Ti-6Al-4V meshes fabricated by electron beam melting. J Mech Behav Biomed Mater 59:251–264

Zhou H, Zhao M, Ma Z, Zhang DZ, Fu G (2020) Sheet and network based functionally graded lattice structures manufactured by selective laser melting: Design, mechanical properties, and simulation. Int J Mech Sci 175:105480

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Zilda de Castro Silveira.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Majeed, M., Khan, H.M., Wheatley, G. et al. Influence of post-processing on additively manufactured lattice structures. J Braz. Soc. Mech. Sci. Eng. 44, 389 (2022). https://doi.org/10.1007/s40430-022-03703-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03703-8