Abstract

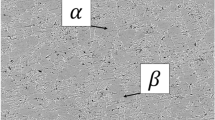

Efficient cooling and lubrication techniques are required to obtain sustainable machining of difficult-to-cut materials, which are the pillars of aerospace, automotive, medical and nuclear industries. Excessive cutting fluid is required and consumed in machining difficult-to-machine materials with high-pressure coolant supplies. Nanofluid-assisted minimum quantity lubrication (NFMQL) is adorned with improved machining performance and environmental sustainability. The present work addresses the surface integrity and chip morphology in finish hard turning of AISI D3 steel under NFMQL condition. The surface integrity aspects include microhardness, residual stress, white layer formation, machined surface morphology, and surface roughness. This experimental investigation aims to explore the feasibility of low-cost multilayer (TiCN/Al2O3/TiN) coated carbide tool in hard machining applications and to assess the propitious role of minimum quantity lubrication using graphene nanoparticles with enriched radiator coolant-based nano-cutting fluid for machinability improvement in hardened steel. Combined approach of central composite design—analysis of variance, desirability function analysis, and response surface methodology, has been subsequently employed for experimental investigation, predictive modelling, and optimization of surface roughness. With a motivational philosophy of “Go Green-Think Green-Act Green”, the work also deals with economic analysis and sustainability assessment under environmental-friendly NFMQL condition. It is expected that the found optimized parameters can contribute to machining end-outcomes such as an improved surface finish and reduced machining cost. The results showed that machining with NFMQL provided an effective cooling–lubrication strategy, safer and cleaner production, environmental friendliness and assisted in improving sustainability. In conclusion, the proposed NFMQL turning strategy is a robust method validated by statistical analysis for large industrial applications, especially in mould and die making sectors.

Similar content being viewed by others

References

Suresh R, Basavarajappa S, Gaitonde VN, Samuel G, Davim JP (2013) State-of-the-art research in machinability of hardened steels. Proc Inst Mech Eng Part B J Eng Manuf 227(2):191–209

Chinchanikar S, Choudhury SK (2014) Hard turning using HiPIMS-coated carbide tools: wear behavior under dry and minimum quantity lubrication (MQL). Measurement 55:536–548

Elmunafi MHS, Mohd Yusof N, Kurniawan D (2015) Effect of cutting speed and feed in turning hardened stainless steel using coated carbide cutting tool under minimum quantity lubrication using castor oil. Adv Mech Eng 7(8):1–7

Sharma P, Sidhu BS, Sharma J (2015) Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. J Clean Prod 108:72–79

Nouioua M, Yallese MA, Khettabi R, Belhadi S, Bouhalais ML, Girardin F (2017) Investigation of the performance of the MQL, dry, and wet turning by response surface methodology (RSM) and artificial neural network (ANN). Int J Adv Manuf Technol 93(5–8):2485–2504

Mia M, Gupta MK, Singh G, Królczyk G, Pimenov DY (2018) An approach to cleaner production for machining hardened steel using different cooling–lubrication conditions. J Clean Prod 187:1069–1081

Panday G, Ashraf MZI, Ibn Muneer K, Hossain KS, Ashik MFK, Kamruzzaman M (2018) Assessing near-dry lubrication (35 ml/h) performance in hard turning process of hardened (48 HRC) AISI 1060 carbon steel. Int J Adv Manuf Technol 99:2045–2057

Das A, Tirkey N, Patel SK, Das SR, Biswal BB (2018) A comparison of machinability in hard turning of EN-24 alloy steel under mist cooled and dry cutting environments with a coated cermet tool. J Fail Anal Prev 19:115–130

Thakur A, Manna A, Samir S (2019) Performance evaluation of different environmental conditions on output characteristics during turning of EN-24 steel. Int J Precis Eng Manuf 20:1839–1849

Kumar R, Sahoo AK, Mishra PC, Das RK (2018) Measurement and machinability study under environmentally conscious spray impingement cooling assisted machining. Measurement 135:913–927

Elbah M, Laouici H, Benlahmidi S, Nouioua M, Yallese M (2019) Comparative assessment of machining environments (dry, wet and MQL) in hard turning of AISI 4140 steel with CC6050 tools. Int J Adv Manuf Technol 105:2581–2597

Kumar R, Sahoo AK, Mishra PC, Das RK (2019) Influence of Al2O3 and TiO2 nanofluid on hard turning performance. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-04754-3

Panda A, Das SR, Dhupal D (2020) Machinability investigation and sustainability assessment in FDHT with coated ceramic tool. Steel Compos Struct 34(5):681–698

Kıvak T, Sarıkaya M, Yıldırım CV, Şirin S (2020) Study on turning performance of PVD TiN coated Al2O3 + TiCN ceramic tool under cutting fluid reinforced by nano-sized solid particles. J Manuf Process 56:522–539

Öndin O, Kıvak T, Sarıkaya M, Yıldırım ÇV (2020) Investigation of the influence of MWCNTs mixed nanofluid on the machinability characteristics of PH 13-8 Mo stainless steel. Tribol Int 148:106323

Sahoo AK, Sahoo B (2012) Experimental investigations on machinability aspects in finish hard turning of AISI 4340 steel using uncoated and multilayer coated carbide inserts. Measurement 45(8):2153–2165

Fnides B, Aouici H, Elbah M, Boutabba S, Boulanouar L (2015) Comparison between mixed ceramic and reinforced ceramic tools in terms of cutting force components modelling and optimization when machining hardened steel AISI 4140 (60 HRC). Mech Ind 16(6):609

Bensouilah H, Aouici H, Meddour I, Yallese MA, Mabrouki T, Girardin F (2016) Performance of coated and uncoated mixed ceramic tools in hard turning process. Measurement 82:1–18

Keblouti O, Boulanouar L, Azizi MA, Yallese MA (2017) Effects of coating material and cutting parameters on the surface roughness and cutting forces in dry turning of AISI 52100 steel. Struct Eng Mech 61(4):519–526

Kumar R, Sahoo AK, Mishra PC, Das RK (2018) Comparative investigation towards machinability improvement in hard turning using coated and uncoated carbide inserts: part I experimental investigation. Adv Manuf 6(1):52–70

Das A, Patel SK, Hotta TK, Biswal BB (2018) Statistical analysis of different machining characteristics of EN-24 alloy steel during dry hard turning with multilayer coated cermet inserts. Measurement 134:123–141

Kumar P, Chauhan S, Pruncu C, Gupta M, Pimenov D, Mia M, Gill H (2019) Influence of different grades of CBN inserts on cutting force and surface roughness of AISI H13 die tool steel during hard turning operation. Materials 12(1):177

Mhamdi MB, Salem SB, Boujelbene M, Bayraktar E (2013) Experimental study of the chip morphology in turning hardened AISI D2 steel. J Mech Sci Technol 27(11):3451–3461

Khan ZA, Shihab SK, Siddiquee AN (2015) Analysis of chip morphology in dry hard turning of AISI 52100 alloy steel using RSM. Int J Mach Mach Mater 17(6):481–506

Tang L, Yin J, Sun Y, Shen H, Gao C (2017) Chip formation mechanism in dry hard high-speed orthogonal turning of hardened AISI D2 tool steel with different hardness levels. Int J Adv Manuf Technol 93(5–8):2341–2356

Shihab SK, Khan ZA, Mohammad A, Siddiquee AN (2014) Investigation of surface integrity during wet turning of hard alloy steel. Int J Mach Mach Mater 16(1):22–37

Tang L, Gao C, Huang J, Shen H, Lin X (2014) Experimental investigation of surface integrity in finish dry hard turning of hardened tool steel at different hardness levels. Int J Adv Manuf Technol 77(9–12):1655–1669

Naresh Babu M, Anandan V, Muthukrishnan N, Arivalagar AA, Dinesh Babu M (2019) Evaluation of graphene based nano fluids with minimum quantity lubrication in turning of AISI D3 steel. SN Appl Sci 1(10):1–11

Asiltürk İ (2012) Predicting surface roughness of hardened AISI 1040 based on cutting parameters using neural networks and multiple regression. Int J Adv Manuf Technol 63(1–4):249–257

Saini S, Ahuja IS, Sharma VS (2012) Modelling the effects of cutting parameters on residual stresses in hard turning of AISI H11 tool steel. Int J Adv Manuf Technol 65(5–8):667–678

Xiao Z, Liao X, Long Z, Li M (2016) Effect of cutting parameters on surface roughness using orthogonal array in hard turning of AISI 1045 steel with YT5 tool. Int J Adv Manuf Technol 93(1–4):273–282

Mia M, Dhar NR (2016) Prediction of surface roughness in hard turning under high pressure coolant using artificial neural network. Measurement 92:464–474

Mia M, Dhar NR (2017) Modeling of surface roughness using RSM, FL and SA in dry hard turning. Arab J Sci Eng 43(3):1125–1136

Mia M, Razi MH, Ahmad I, Mostafa R, Rahman SMS, Ahmed DH, Dey PR, Dhar NR (2017) Effect of time-controlled MQL pulsing on surface roughness in hard turning by statistical analysis and artificial neural network. Int J Adv Manuf Technol 91(9–12):3211–3223

Asiltürk İ, Akkuş H (2011) Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 44:1697–1704

Hessainia Z, Belbah A, Yallese MA, Mabrouki T, Rigal J-F (2013) On the prediction of surface roughness in the hard turning based on cutting parameters and tool vibrations. Measurement 46(5):1671–1681

Elbah M, Yallese MA, Aouici H, Mabrouki T, Rigal J-F (2013) Comparative assessment of wiper and conventional ceramic tools on surface roughness in hard turning AISI 4140 steel. Measurement 46(9):3041–3056

Shihab SK, Khan ZA, Mohammad A, Siddiquee AN (2014) Optimization of surface integrity in dry hard turning using RSM. Sadhana 39(5):1035–1053

Rashid WB, Goel S, Davim JP, Joshi SN (2015) Parametric design optimization of hard turning of AISI 4340 steel (69 HRC). Int J Adv Manuf Technol 82(1–4):451–462

Panda A, Sahoo AK, Rout AK (2016) Investigations on surface quality characteristics with multi-response parametric optimization and correlations. Alex Eng J 55(2):1625–1633

Mia M, Dhar NR (2017) Prediction and optimization by using SVR, RSM and GA in hard turning of tempered AISI 1060 steel under effective cooling condition. Neural Comput Appl. https://doi.org/10.1007/s00521-017-3192-4

Mia M, Morshed MS, Kharshiduzzaman M, Razi MH, Mostafa MR, Rahman SMS, Hafiz MT, Kamal AM (2018) Prediction and optimization of surface roughness in minimum quantity coolant lubrication applied turning of high hardness steel. Measurement 118:43–51

Aouici H, Khellaf A, Smaiah S, Elbah M, Fnides B, Yallese MA (2017) Comparative assessment of coated and uncoated ceramic tools on cutting force components and tool wear in hard turning of AISI H11 steel using Taguchi plan and RMS. Sādhanā 42(12):2157–2170

Sahoo AK, Sahoo B (2013) Performance studies of multilayer hard surface coatings (TiN/TiCN/Al2O3/TiN) of indexable carbide inserts in hard machining: part-I (an experimental approach). Measurement 46:2854–2867

Aouici H, Elbah M, Benkhelladi A, Fnides B, Boulanouar L, Yallese MA (2019) Comparison on various machinability aspects between mixed and reinforced ceramics when machining hardened steels. Mech Ind 20:109

Shaw MC (2005) Metal cutting principles, 2nd edn. Oxford University Press, New York

Das SR, Kumar A, Dhupal D (2015) Surface roughness analysis of hardened steel using TiN coated ceramic inserts. Int J Mach Mach Mater 17(1):22–38

Suresh R, Basavarajappa S, Gaitonde VN, Samuel GL (2012) Machinability investigations on hardened AISI 4340 steel using coated carbide insert. Int J Refract Met Hard Mater 33:75–86

Yousefi S, Zohoor M (2019) Effect of cutting parameters on the dimensional accuracy and surface finish in the hard turning of MDN250 steel with cubic boron nitride tool, for developing a knowledged base expert system. Int J Mech Mater Eng 14(1):1–13

Panda A, Das SR, Dhupal D (2017) Surface roughness analysis for economical feasibility study of coated ceramic tool in hard turning operation. Process Integr Optim Sustain 1(4):237–249

Leppert T, Peng RL (2012) Residual stresses in surface layer after dry and MQL turning of AISI 316L steel. Prod Eng 6(4–5):367–374

Das A, Pradhan O, Patel SK, Das SR, Biswal BB (2019) Performance appraisal of various nanofluids during hard machining of AISI 4340 steel. J Manuf Process 46:248–270

Das SR, Dhupal D, Kumar A (2015) Experimental investigation into machinability of hardened AISI 4140 steel using TiN coated ceramic tool. Measurement 62:108–126

Mia M, Dey PR, Hossain MS, Arafat MT, Asaduzzaman M, Shoriat Ullah M, Tareq Zobaer SM (2018) Taguchi S/N based optimization of machining parameters for surface roughness, tool wear and material removal rate in hard turning under MQL cutting condition. Measurement 122:380–391

Singh RK, Sharma AK, Dixit AR, Tiwari AK, Pramanik A, Mandal A (2017) Performance evaluation of alumina–graphene hybrid nano-cutting fluid in hard turning. J Clean Prod 162:830–845

Abbas AT, Benyahia F, El Rayes MM, Pruncu C, Taha MA, Hegab H (2019) Towards optimization of machining performance and sustainability aspects when turning AISI 1045 steel under different cooling and lubrication strategies. Materials 12:3023

Costa NR, Lourenço J, Pereira ZL (2011) Desirability function approach: a review and performance evaluation in adverse conditions. Chemom Intell Lab Syst 107(2):234–244

More AS, Jiang W, Brown WD, Malshe AP (2006) Tool wear and machining performance of CBN–TiN coated carbide inserts and PCBN compact inserts in turning AISI 4340 hardened steel. J Mater Process Technol 180(1–3):253–262

Acknowledgements

This work is supported by research grant under “Collaborative Research and Innovation Scheme” of TEQIP-III via. reference no. VSSUT/TEQIP/119/2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Izabel Fernanda Machado, Dr.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dash, L., Padhan, S. & Das, S.R. Experimental investigations on surface integrity and chip morphology in hard tuning of AISI D3 steel under sustainable nanofluid-based minimum quantity lubrication. J Braz. Soc. Mech. Sci. Eng. 42, 500 (2020). https://doi.org/10.1007/s40430-020-02594-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02594-x